The evolution of Computer Numerical Control (CNC) machines and machine tools has become the future of manufacturing that produces raw materials to finished products with such precision and accuracy that it seems metal is coming out of magic boxes. Direct CNC operations rely at their core on the most advanced software that regulates all features of the machining process computer numerical control software. The knowledge of software CNC machine is of great importance to manufacturers, engineers as well as anybody interested in precision manufacturing.

Understanding CNC Machine Software Architecture

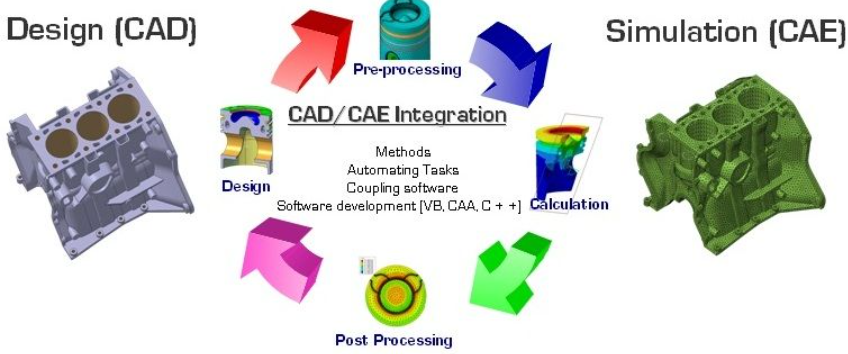

CNC software may be of several types, but the main types are computer-aided design (CAD) software, which is used to model 2D and 3D, and computer-aided manufacturing (CAM) software which turns the design into toolpath generation code that can be read by machines. This coordinated process will create smooth operations of every design through machined part.

CNC machine software is an ecosystem that functions on several levels to fulfill certain aims and objectives in the production process, including complex machining tasks . There are mainly design, programming, simulation, cam software and machine control systems software. Each type is essential in defining the best performance, accuracy and efficiency in the CNC activities.

CAD Software: The Foundation of CNC Design

Any CNC project should start with Computer-Aided Design (CAD) software, which includes exploring the top cnc software options . Such programs allow the work of engineers and designers to make detailed 2D drawings and complex 3D models that are the blueprinting of manufacturing. The commonly used CAD softwares are AutoCAD, SolidWorks, Inventor, and Fusion 360.

The key functions of the CAD software include parametric design, assembly design, and technical documentation. New CAD software provides cloud based co-working where many users are able to collaborate/work in a project and version and design integrity is maintained cam computer aided manufacturing.

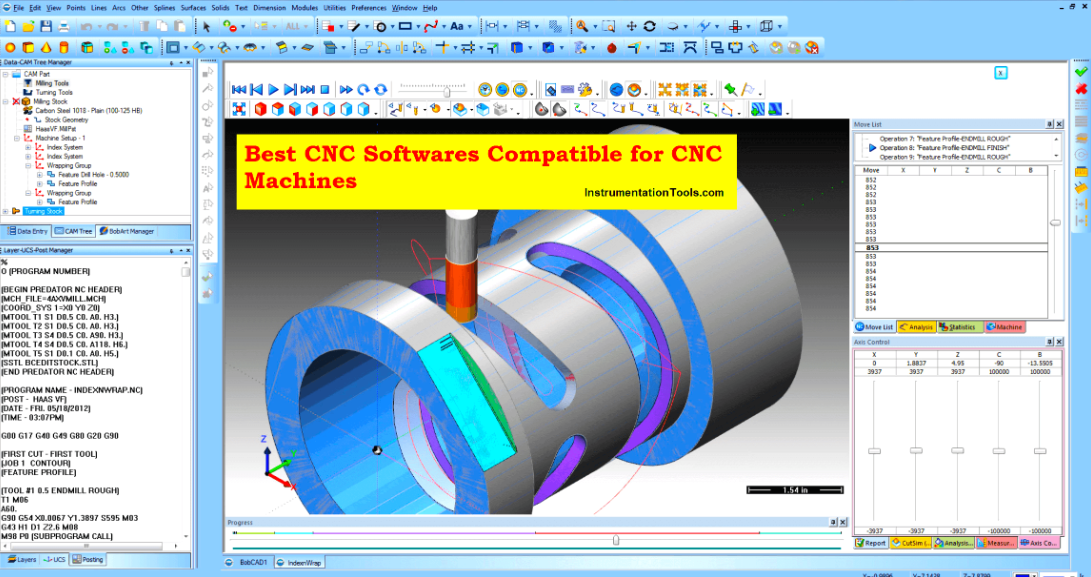

CAM Software: Bridging Design and Manufacturing

Computer-Aided Manufacturing (CAM) software converts CAD models to generate toolpaths into high speed machining machine readable instructions. This essential software produces toolpaths, estimates the cutting settings and creates G-code that is directly used to run CNC machines. The top CAM packages are Mastercam, PowerMILL and Hypermill.

Optimization in the CAM software ejection greatly influences efficiency manufacturing process and the overall surface of the finished product as well as tools life. Modern CAM systems integrate the smart algorithms that guide them to automatically optimize the cutting plans according to the material characteristics, tooling and machine features.

Integrated CAD/CAM Solutions

Fusion 360 is a full-featured CAD/CAM package that has a large share of the market of its 2D and 3D design and deep CAM capabilities and G-code editing tools. The integrated solutions also keep workflow lean in that there is no data transfer problem between individual design programs and manufacturing programs.

These integrated systems eliminate data gap and increase efficiency. Association relationships are also advantageous to the users with changes made in officials design and manufacturing programs being consistent as they move through the production process.

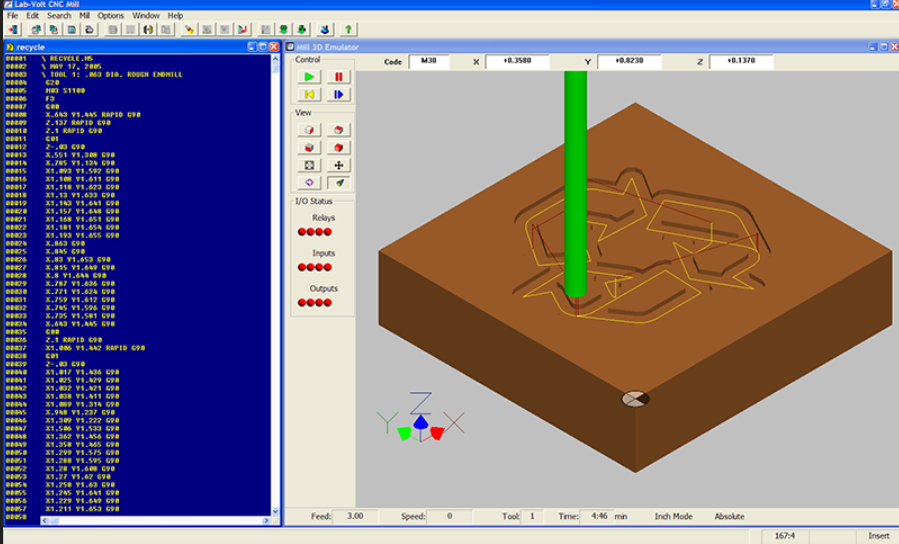

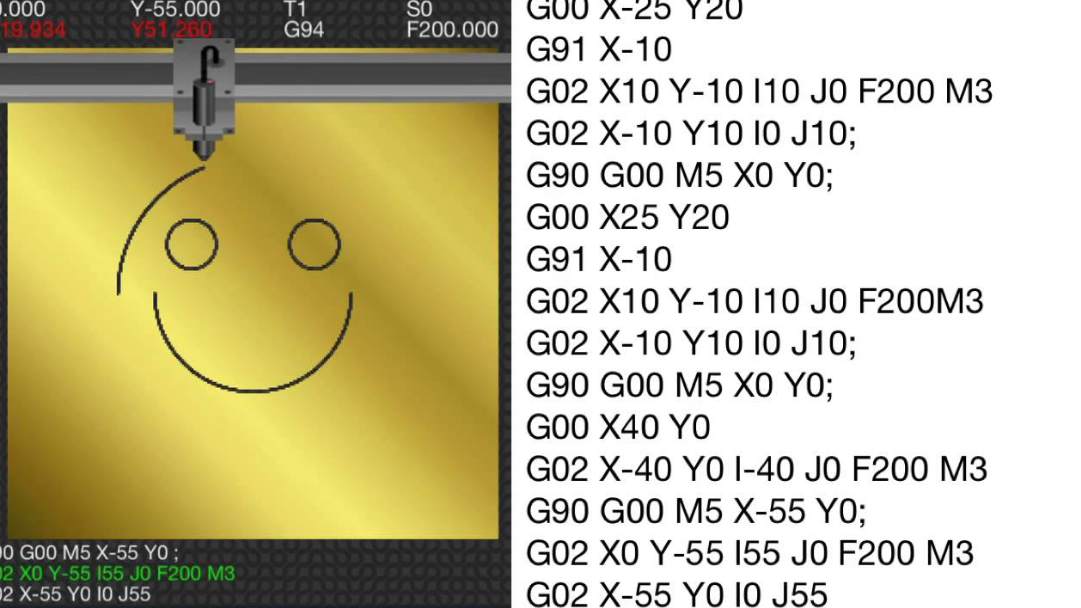

G-Code: The Universal Language of CNC

The G-code is the fundamental Linguistic code of the CNC machines, it comprises the highly defined instructions of the location of tools, speed of the spindle and the feed rate. This coding is a standard code so it makes them compatible to various brands and models of machine tools which is critical in the CNC operations.

It is possible to investigate G-code structure, which allows operators to debug a program, make some small changes, and streamline the machining process. The G-code is automatically created by the modern CAM software, however, the manual editing features are still useful in order to fine-tune the selected operation.

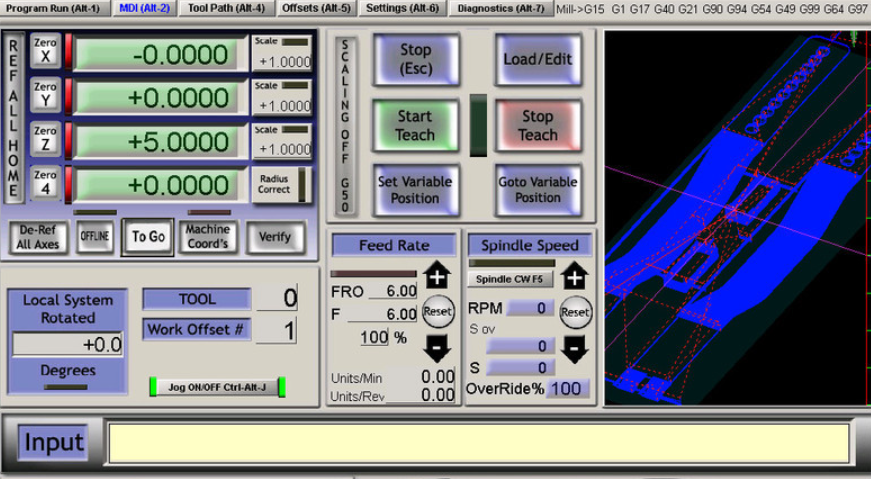

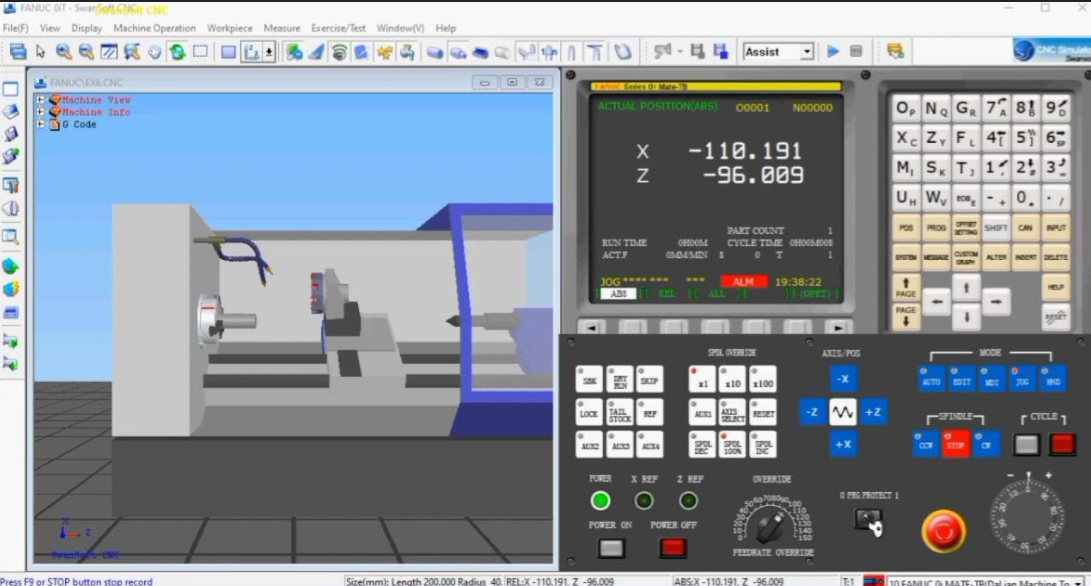

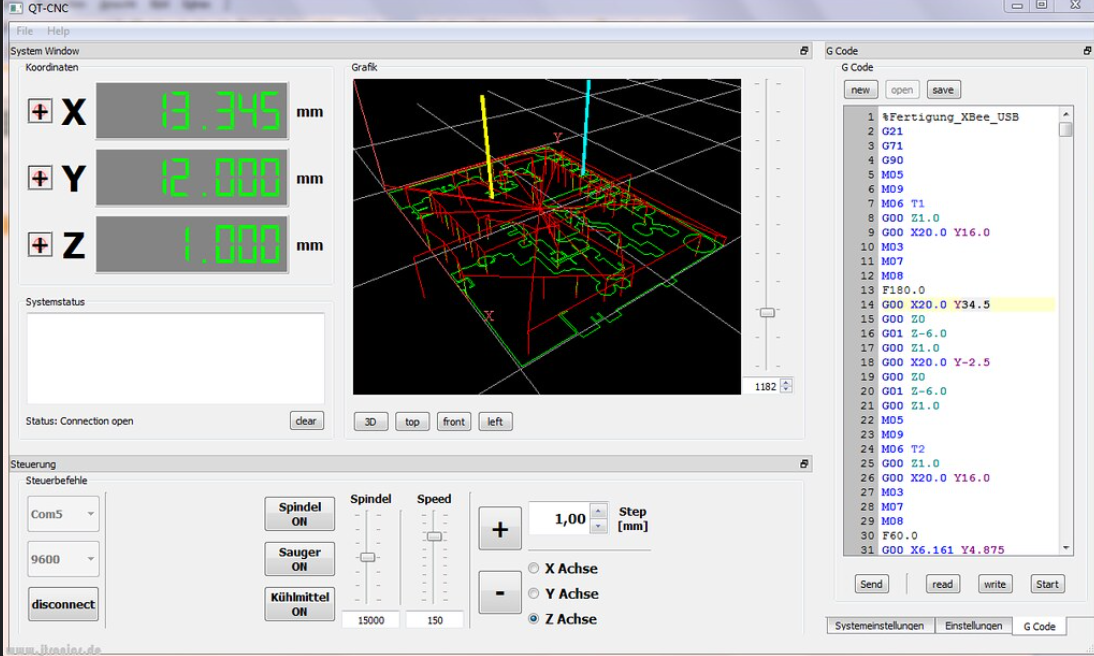

Machine Control Software

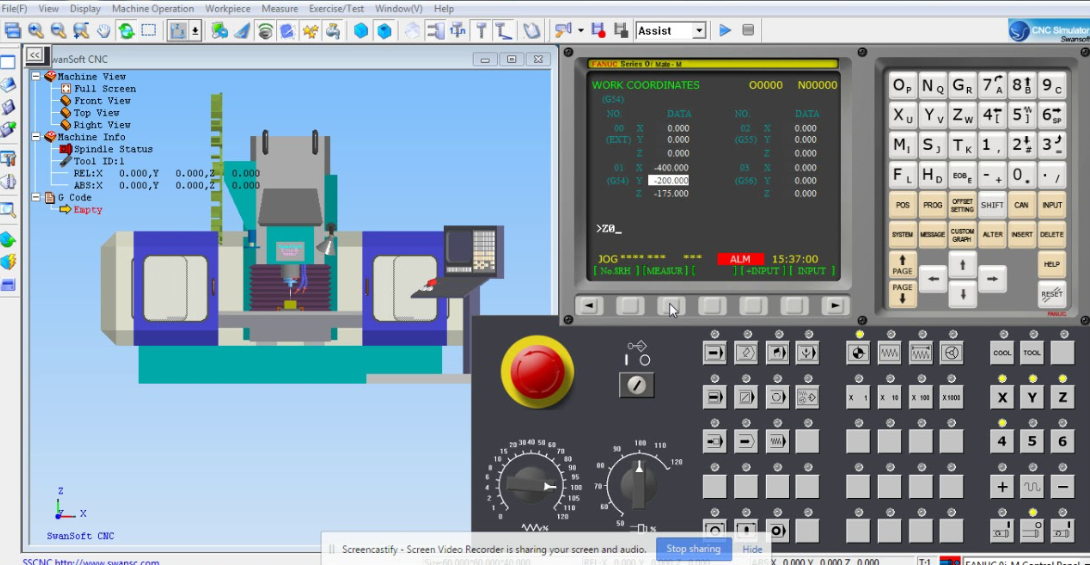

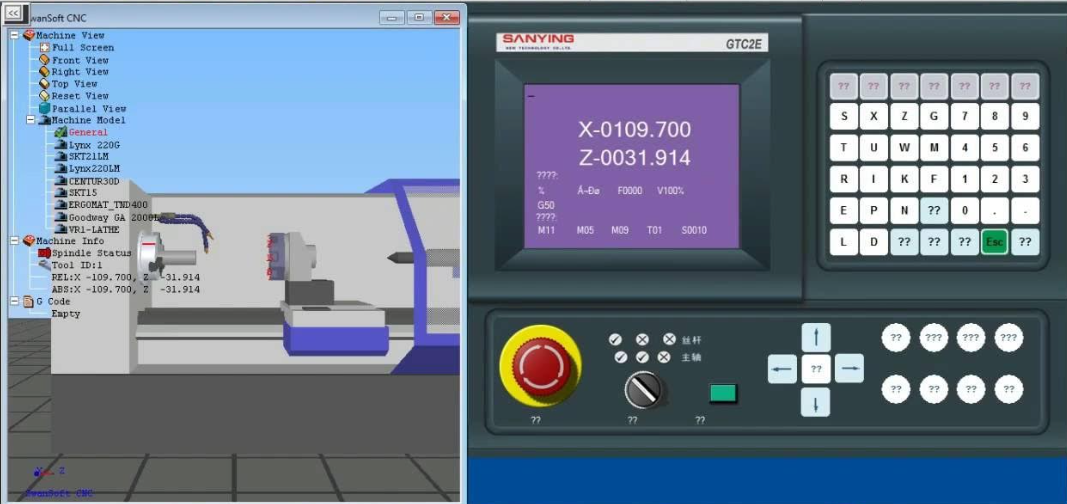

Machine control software operates CNC machinery in real time, initiating movement and interpreting G-code, as well as coordinating the motions of the machine. Desktop machines commonly use popular control software (Mach3, LinuxCNC, or GRBL) whereas industrial systems commonly use vendor proprietary systems sold by machine producers.

Control software receives and processes the CNC software and performs essential divisions with axis coordination, spindle control, coolant management, and safety monitoring. Advanced systems apply adaptive controls which changes the parameters automatically according to the cutting conditions and the tool wear.

Popular CNC Software Platforms

Common CNC computer software used in industry are Mastercam, PowerMILL, Hypermill, Cimatron, PRO-E, U.G and CATIA. Both platforms have their strong sides which can be applicable in a particular manufacturing scenario and industry demands.

Mastercam is the leader in North American market region with full 2D and 3D 21 programs. PowerMILL is good at 3D parts and Hypermill is an advanced 5-axis programmer. The choice is made depending on the requirements of the manufacturing, the budget, and the experience of operators.

Simulation and Verification Software

Computer simulation software offers virtual machine shop environments through which the users can test the programs prior to utilization of actual production. The tools recognize possible collisions, minimize cycle times and justify surface finishing without a costly waste of material and machine-time.

Powerful simulation software is featured with realistic physics engines, precise erosion of materials simulation, and forms of collision detection. The technology also saves on the number of errors during programming, helps in cutting down time that a machine is out of action, and increases the efficiency of the entire manufacturing process.

Free and Open-Source CNC Software

Freeware CAM packages similar to the basic features of CAD and may range from 2D and 3D version, the formerly having its emphasis on flat objects that lack surface curvature. Smaller operations and schools can be served by Open-source alternatives which are cost effective.

FreeCAD, OpenSCAD and Blender are popular free alternatives to design work, whereas computer control with GRBL, LinuxCNC and Universal G-Code Sender are available. These solutions offer great grounds to learn and useable alternatives to the cost-savvy users.

Cloud-Based CNC Software Solutions

The cloud-based CNC software is the new trend in manufacturing technology that is characterized by remote access, automatic upgrading, and collaboration. Using these platforms, the distributed teams are able to collaborate and work successfully, keeping its data management centralized and versioned.

The cloud solutions offer scalability, low IT overhead, and security since the required data centres professionals are involved. The advantage to users is that they have access anywhere, all their work is backed up, and software update is not in the way of production schedules.

Industry-Specific CNC Software

Industry-specific manufacturing industries have their own needs in terms of software to address them in the most specific ways, ultimately impacting manufacturing productivity . High volume programmability is required in the automotive manufacturing industry where precision and productivity are the most important aspects and intensive programmability is required in aerospace applications.

The production of medical equipment is impossible without the use of specific software programs that use a complex geometry and have a high level of quality needs. All industries have come up with their suitable tools and workflows in order to suit their specific needs and regulatory concerns.

Mobile and Tablet CNC Applications

Mobile CNC app solutions will allow operators to track and control machines, including plasma cutting, and make adjustments, as well as get notifications wherever they happen to be. The tools boost productivity since it enables one to monitor and respond to the production problems in real-time.

Applications that are built on tablets offer easy to understand user interfaces such as machines setup, tools management, and quality control. Mobile solutions are also used to merge with the current systems that help in offering end-to-end manufacturing control and oversight.

CNC Software Integration with ERP Systems

Enterprise Resource Planning (ERP) systems and CNC software are the needed features in modern manufacturing, which should be unified with each other to prevent additional costs to companies. Scheduling, tracking of materials and production of reports are fully integrated, and they are automatically scheduled, tracked and enabled, hence no manual data is required parametric modeling.

Integrated systems give real-time view of what is being produced, a clear costing data and better inventory. This inter-connectivity facilitates the lean manufacturing principles and allows data driven decision making across the organization cad computer aided design.

Artificial Intelligence in CNC Software

CNC machines powered by AI, including laser cutters, use machine learning to achieve better surface finishing, automatic cutting parameter optimization, and tools wear prediction. These smart systems are continually fed on production data in order to improve their performance as time goes by.

Predictive maintenance characteristics is the ability to use machine behaviour pattern to predict problems before it causes slack time improved productivity. The introduction of AI could be characterized as an enormous breakthrough in the field of manufacturing technologies since it allows unprecedented degrees of automation and optimization.

Quality Control and Inspection Software

Quality control software can be incorporated with CNC System to offer services of real-time monitoring as well as automated inspection. These instruments guarantee uniformity with regard to the quality of parts and minimize the number of manual inspections and the related labour cost.

High quality software includes statistical process control, trend analysis and automatic corrective action. Closed loop quality control is a function facilitated by integration with measurement equipment from which parameters can automatically be adjusted to allow machining within specifications.

CNC Software Training and Support

Correct training is the key in promoting maximum utilization of CNC software and benefit. Vendors of software on the market offer wholesome training programs, online support materials and continuous technical assistance to the user in order to be successful other software.

The trainings usually include training on basic operation, advanced features as well as troubleshooting. This support is continuous as released software is used and the software may require further updates, technical confirmations and user communities to assist the operators in problems and solutions delivery spindle speed.

Cost Considerations for CNC Software

Software packages of CNC have a wide range of prices depending on their functionality, license model and technical support tool path. The commercial CAD/CAM system would generally cost thousands of dollars per year, whereas free ones offer the bare minimum functionality and are free nc programming.

Cost of ownership is total cost of initial licensing, training, support and maintenance. Organizations have to trade off software capabilities with the budget available during the process of taking long-term productivity gain and competitive advantage edm machines.

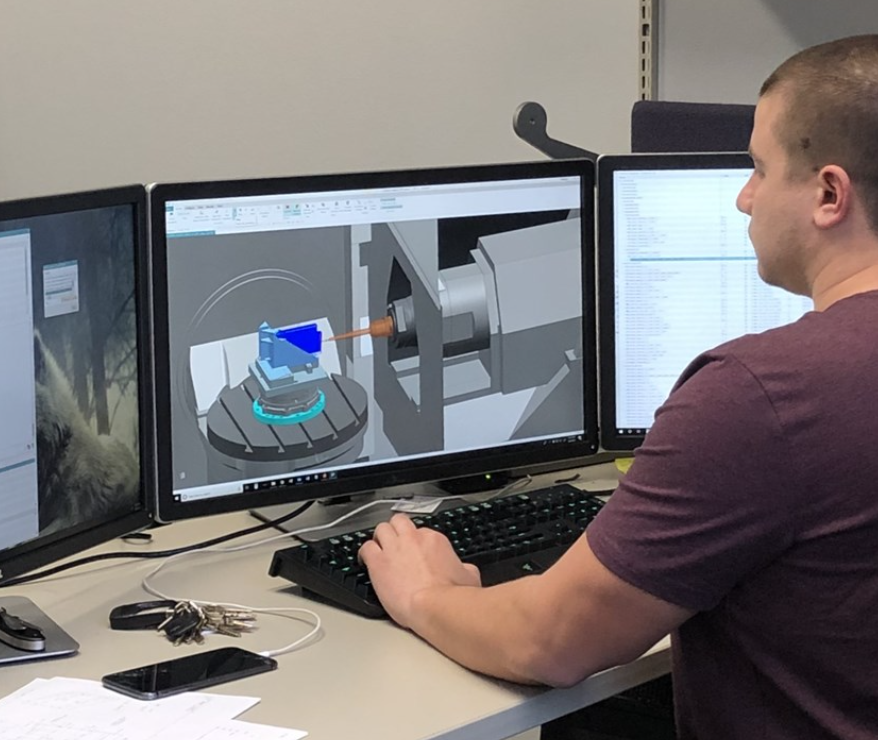

Choosing the Right CNC Software

The choice of good CNC software should be made with the consideration of manufacturing demands, cost-restrained, and operator support. Some of the important details are part complexity, production volumes, the material used and requirement of integrations with the existing systems cad package.

Practical tests, reference check and thorough examination of total cost of ownership should be part of software evaluation file formats. The optimum matching software is one that is a balance between functionality and usability and price but, offers an environment of the future.

Future Trends in CNC Software

Emerging technologies like artificial intelligence, cloud computing and Internet of Things (IoT) connectivity are continually undergoing evolution in the form of the CNC software. These trends open up the new possibilities of the transformation of manufacturing operations due to better automation and efficiency.

In the future, there is a possibility of creating more advanced AI algorithms, decently cloud collaboration tools, and more seamless linkages to digital manufacturing landscapes. manufacturing competitiveness and productivity will keep rising through such achievements.

Security Considerations for CNC Software

Cybersecurity has gained much relevance nowadays because CNC systems are connected to networks and cloud services. Strong security processes are essential to manufacturers to safeguard intellectual property, which prevents unauthorized access and promote business continuity cnc programs.

Other best practices related to security include periodical software updating, network isolation, access management and staff training cnc machine tools. Security will play an ever-increasing role and be of greater fulfilment as manufacturing becomes more interactive free software.

Integration with Industry 4.0

Among the industrial revolutions, Industry 4.0 or the fourth industrial revolution is the one based on the cyber-physical systems, IoT connection, and intelligent manufacturing multi axis milling. CNC software contributes significantly to this change by providing a possibility to gather data, make its analysis, and make decisions based on the machining process and dynamic motion technology cnc software applications.

CNC software must be able to exchange information with other systems, transfer data in real-time, and be based on predictive analytics linux operating system, which is the most important part of the smart manufacturing initiatives software for cnc. Such connectivity allows new efficiency, quality and responsiveness in manufacture operations cnc equipment.

Performance Optimization Strategies cad cam software

Machining principles, material properties and tool characteristics should be learnt in order to optimize CNC software machine controller. With advanced users they can tweak parameters to obtain the best outcome towards particular applications and necessities plasma cutters.

Performance optimization is a tradeoff of various performance parameters such as cycle time, surface finish, tool life and dimensional accuracy cnc techniques. Experienced programmers get to know tricks that will keep their productivity high and preserving the quality standards cnc mills machining operations.

Conclusion

CNC machine software forms a complicated ecosystem of interdependent tools that make up contemporary precision production. Software such as 3d modeling s is important in every step of CNC, between concept and manufacture cnc programming software. The different types of software, the capabilities and the characteristics that are used to make choices are vital in ensuring that the manufacturing process goes on successfully free cnc software.

New trends artificial intelligence, cloud computing and Industry 4.0 connection shape the future of CNC software development. The advances offer greater automation, efficiency and new capabilities that will change the way manufacturing works. The manufacturers, which invest in the proper software and training, will be in a good position to survive the competition in the global market cnc mills.