Precision CNC Machining Solutions for High-Tolerance Parts

IOS

±0.01mm accuracy

24-hour fast quote

advanced equipment

About Leading Edge Ltd: Excellence in CNC Machining

Leading Edge Ltd. stands at the forefront of precision CNC machining, combining decades of industry expertise with state-of-the-art equipment to deliver components that meet the most exacting specifications. From prototype development to high-volume production runs, our dedicated team applies rigorous quality controls and lean manufacturing principles to ensure every part achieves outstanding accuracy, surface finish, and repeatability. Whether you require tight-tolerance metal or composite components, we partner closely with you to optimize design for manufacturability, accelerate time-to-market, and uphold the highest standards of reliability and performance.

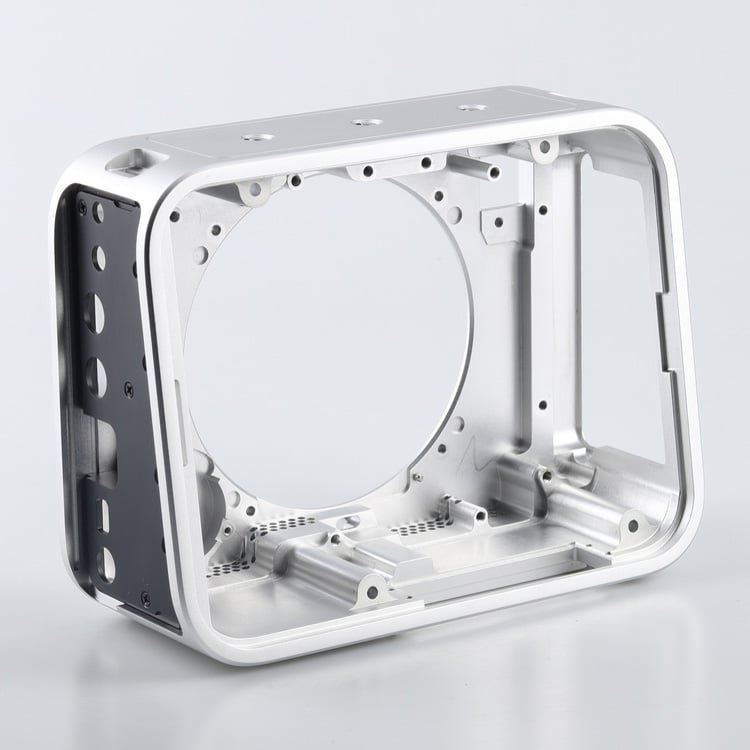

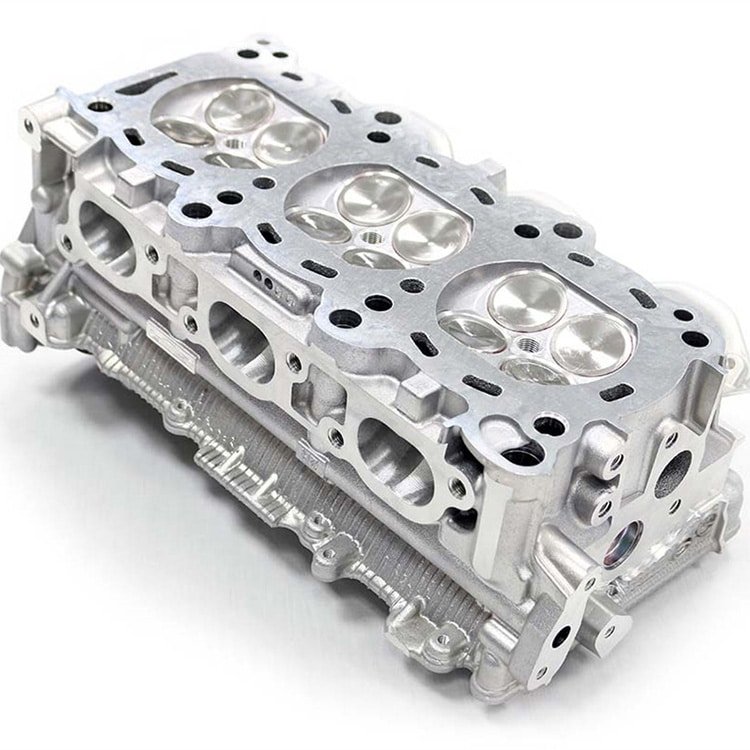

Precision-Engineered Components for Demanding Applications

At Leading Edge, we take pride in delivering a wide range of precision-engineered components tailored to meet the diverse needs of our clients. From single prototype pieces to large-scale production runs, our products are crafted with meticulous attention to detail and exceptional quality standards. We serve various industries, including aerospace, automotive, and medical, ensuring that each product performs flawlessly, withstands rigorous conditions, and meets the highest industry standards.Discover a versatile product portfolio—from aerospace-grade enclosures and medical-device prototypes to rugged industrial fittings—all machined to tolerances as tight as ±0.01 mm. Leveraging our fleet of 5-axis CNC centers and in-house finishing capabilities, we transform bar stock and billet into components with flawless surface finishes, intricate geometries, and uncompromising repeatability. Every part undergoes rigorous in-process inspection to guarantee consistent quality across single prototypes or high-volume runs. Partner with us to unlock precision solutions that elevate performance, reliability, and design integrity in your most critical projects.

What We Can Do For You

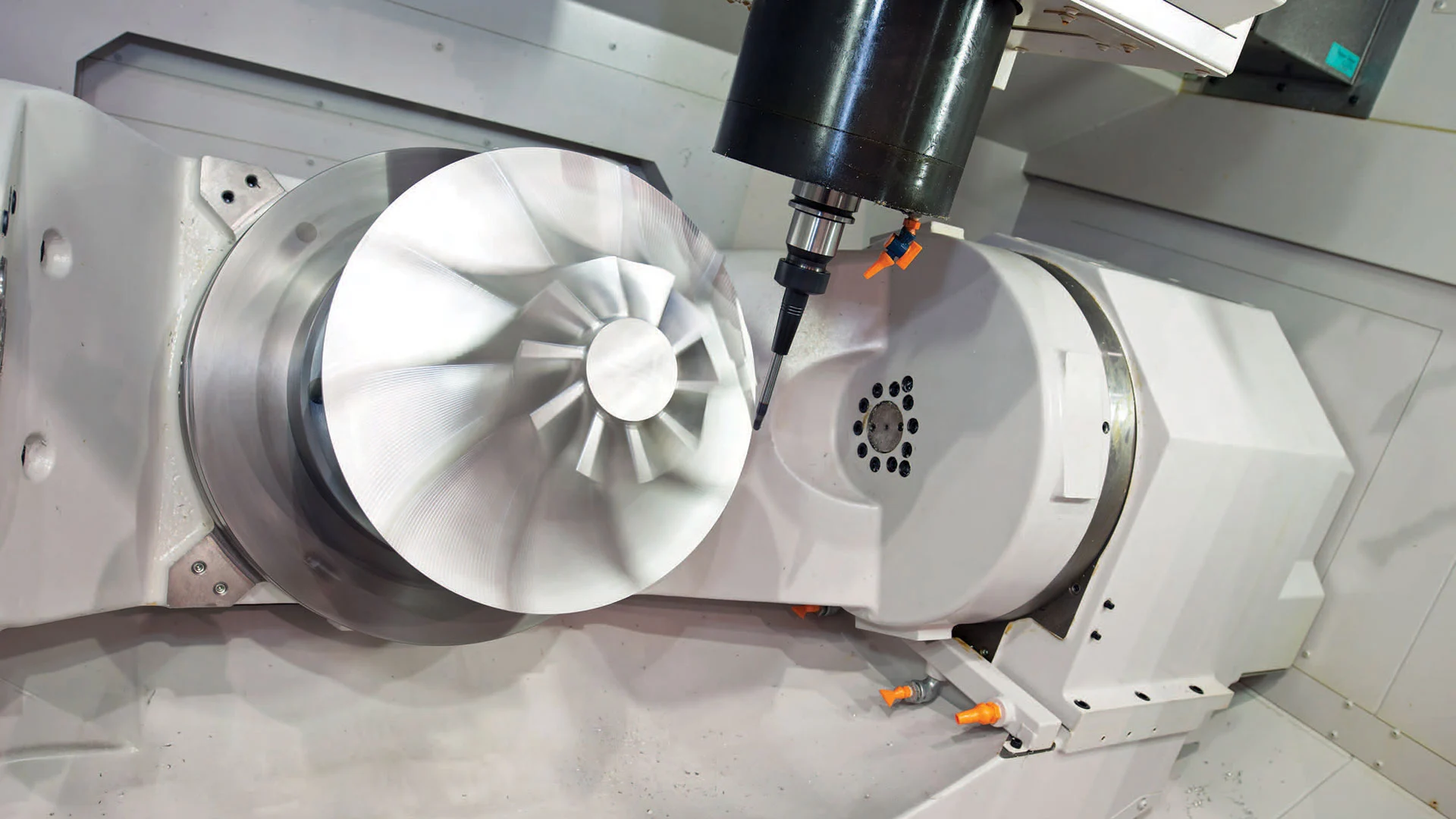

Custom CNC Machining Solutions

Tailored to your exact specifications, our CNC machining service delivers high-precision components from single prototypes to large-volume runs. With advanced multi-axis centers and flexible fixturing, we tackle complex geometries, hard-to-machine alloys, and composite materials—ensuring each part exceeds your performance and durability requirements.

Rapid Prototyping Services

Speed your innovation cycle with our turn-key prototyping. We convert your CAD designs into fully functional machined models in days—complete with tight tolerances and production-ready finishes. Test, iterate, and validate faster than ever, so you can confidently optimize your product before committing to full-scale production.

Production Optimization

Unlock lean efficiency in your manufacturing operations. We analyze your workflow, implement value-stream improvements, and integrate automation where it counts—reducing cycle times, minimizing scrap, and cutting per-part costs. The result: a streamlined production line that delivers higher quality parts at lower overall expenditure.

Industry-Specific Engineering Solutions

Meet the stringent standards of aerospace, medical, automotive, and more with our sector-focused expertise. Our engineering team partners with you to adapt materials, processes, and designs for compliance with regulatory requirements, performance targets, and environmental demands—providing robust, reliable components built for your industry’s unique challenges.

Why Choose Leading Edge: Our Competitive Advantages

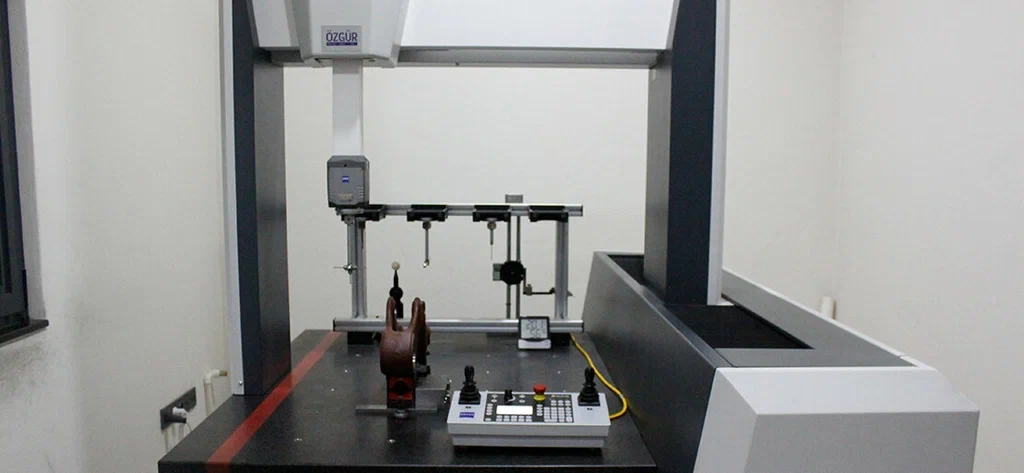

Unwavering Precision and Quality

Every part we produce is held to micron-level tolerances and 100% in-process inspected. From first prototype to full production, our commitment to quality ensures your components perform reliably under the most demanding conditions.

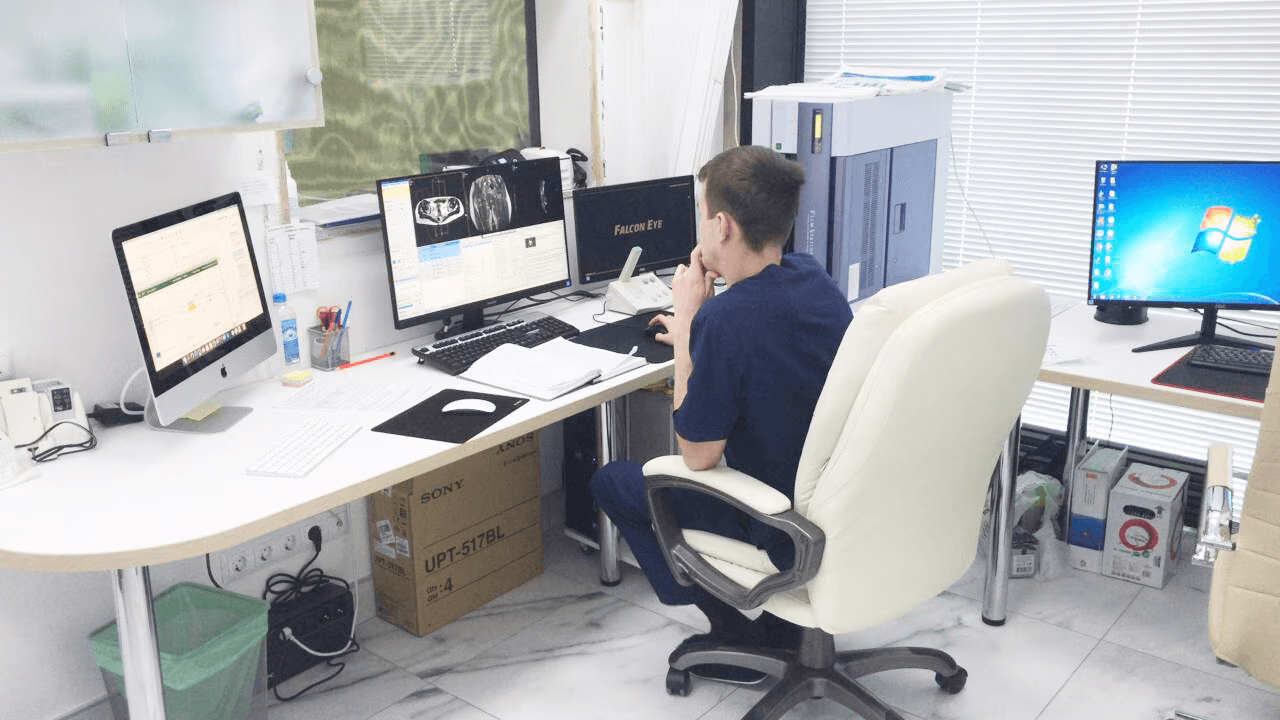

Cutting-Edge Technology

Harness the power of our multi-axis CNC centers, real-time tool monitoring, and automated inspection systems. By continually investing in the latest machines and digital workflows, we deliver faster lead times and intricate geometries that set your products apart.

Experienced Engineering Team

Our engineers average over a decade of industry experience across aerospace, medical, automotive, and industrial markets. They collaborate with you from DFM reviews to final validation, optimizing designs for manufacturability, cost, and performance.

Lean Manufacturing Processes

Through value-stream mapping and continuous improvement, we eliminate waste at every step—reducing cycle times, scrap rates, and costs. The result is a more efficient production line that consistently delivers high-quality parts on schedule and on budget.

What Our Clients Say: Real Feedback from Satisfied Customers