The thread geometry is defined with different sizes in various standards. As a classic thread system, Unified Series includes UNC, UNF, UNR, and UNS. In this article, we’ll introduce the basics of UNS threads (designation meaning, reading, full form, angle, standard, and fit classes) and list the UNS thread chart with the dimensions (diameter, pitch, TPI, and tap drill sizes) specified in ASME B1.1.

What Is a UNS Thread? – UNS Thread Meaning and Full Form

The UNS thread, with the full form being Unified Special Thread, is a designation from one of the major screw thread systems nowadays – The Unified (Inch) Screw Thread System. As the name suggests, UNS threads with diameter-pitch combinations that are not included in the standard series are used for special purposes. According to the ASME B1.1 standard, if the allowances and tolerances of special series threads are derived from a unified formulation, these threads are designated UNS or UNRS. The Unified series is mainly used in the United States and Canada. Even though both of them transfer to the ISO system, more than half of the people still use the Unified systems.

How to Read or Understand the UNS Thread Designation?

The designation consists of three parts:

- Abbreviation: UNS indicates a Unified Special thread.

- Outside Diameter: The major diameter of the thread, usually given in inches.

- Threads Per Inch (TPI): The number of threads per inch.

For example, a thread designated as 1″ – 14 UNS means the thread has an outside diameter of 1 inch and it has 14 threads per inch. The pitch (distance between threads) is not one of the standard coarse, fine, or extra fine pitches but is a special pitch within a limited range.

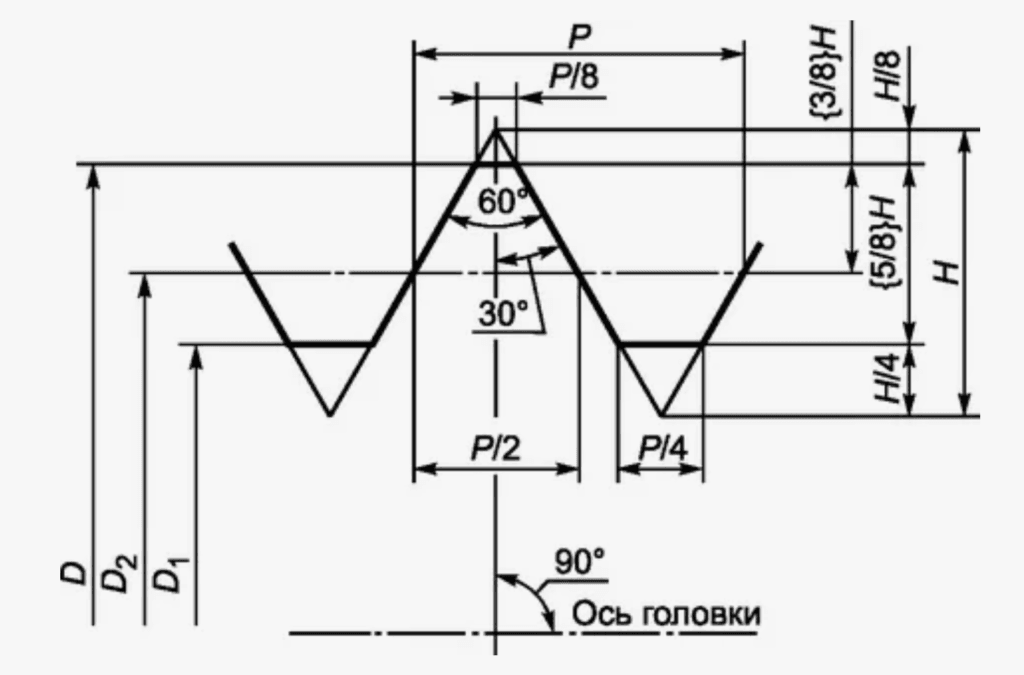

UNS Thread Angle and Profile

The flank angle of a Unified Special Thread is 60°.

UNS Thread Standard

The UNS thread dimensions and specifications follow the standard ASME B1.1-2003.

UNC vs UNS Thread

UNC (Unified National Coarse) threads are the most commonly used and preferred for general purposes. UNC thread, which is characterized by coarse pitch, results in deeper threads that are easier to assemble and less prone to cross-threading. In contrast, UNS (Unified National Special) threads require the threads per inch (TPI) to be explicitly specified, as they offer a limited and non-standard range of pitches for a given diameter. While UNC threads have fixed, standardized coarse pitches for each diameter, UNS threads provide special pitch options that fall outside the typical coarse, fine, or extra fine categories to meet unique application needs.

Additionally, other Unified thread series include UN (Unified Constant Pitch), which covers a broad range of diameter-pitch combinations with TPI values like 4, 6, 8, 12, 16, 20, 28, and 32 for use cases where standard UNC, UNF (Unified National Fine), UNEF (Unified National Extra Fine), and UNS threads are not covered.

UNS (Unified) Thread Fit Classes

When it comes to the UNS thread types, they can be classified by the thread fit, which describes how tightly or loosely the male (external) and female (internal) threads fit together. It is controlled by the class of fit, which are tolerance/allowance combinations applied to both external and internal threads. Tolerances and allowances affect the maximum thickness of coatings that can be applied without interfering with thread engagement. Proper fit ensures the right balance between strength, ease of assembly, and sealing capability.

External threads are represented with A classes, including 1A (loose fit), 2A (medium fit), and 3A (tight fit), and internal threads can be divided into 1B (loose fit), 2B (medium fit), and 3B (tight fit) variations.

UNS Thread Dimensions Chart

Note:

1. The Unified Special Threads have TPI specified. But the number of TPI for a specific diameter is limited, for example, within 1“ diameter size, the TPI allowed only includes 1“ – 10 UNS, 1“ – 14 UNS, 1“ – 18 UNS, 1“ – 24 UNS, and 1“ – 27 UNS.

2. The outside (major) diameter is often converted into millimeters for ease of use in metric systems, along with the pitch and tap drill sizes converted into millimeters.

3. If you need, Leading Edge provides a PDF file with a complete Unified Thread Dimensions Chart (1 to 3B Class) for various types of threads, including UNS, UNM, UNC, UNF, UNEF, and more.

| Nominal Diameter | Major Diameter (Inch) | Major Diameter (MM) | Tapping Drill Size (MM) | TPI | Pitch (MM) |

|---|---|---|---|---|---|

| 10 – 28 UNS | 0.1900 | 4.826 | 3.95 | 28 | 0.907 |

| 10 – 36 UNS | 0.1900 | 4.826 | 4.15 | 36 | 0.706 |

| 10 – 40 UNS | 0.1900 | 4.826 | 4.20 | 40 | 0.635 |

| 10 – 48 UNS | 0.1900 | 4.826 | 4.35 | 48 | 0.529 |

| 10 – 56 UNS | 0.1900 | 4.826 | 4.39 | 56 | 0.454 |

| 12 – 36 UNS | 0.2160 | 5.486 | 4.80 | 36 | 0.706 |

| 12 – 40 UNS | 0.2160 | 5.486 | 4.90 | 40 | 0.635 |

| 12 – 48 UNS | 0.2160 | 5.486 | 4.98 | 48 | 0.529 |

| 12 – 56 UNS | 0.2160 | 5.486 | 5.05 | 56 | 0.454 |

| 1/4″ – 24 UNS | 0.2500 | 6.350 | 5.35 | 24 | 1.058 |

| 1/4″ – 27 UNS | 0.2500 | 6.350 | 5.45 | 27 | 0.941 |

| 1/4″ – 36 UNS | 0.2500 | 6.350 | 5.70 | 36 | 0.706 |

| 1/4″ – 40 UNS | 0.2500 | 6.350 | 5.75 | 40 | 0.635 |

| 1/4″ – 48 UNS | 0.2500 | 6.350 | 5.85 | 48 | 0.529 |

| 1/4″ – 56 UNS | 0.2500 | 6.350 | 5.95 | 56 | 0.454 |

| 5/16″ – 27 UNS | 0.3125 | 7.938 | 7.10 | 27 | 0.941 |

| 5/16″ – 36 UNS | 0.3125 | 7.938 | 7.25 | 36 | 0.706 |

| 5/16″ – 40 UNS | 0.3125 | 7.938 | 7.40 | 40 | 0.635 |

| 5/16″ – 48 UNS | 0.3125 | 7.938 | 7.50 | 48 | 0.529 |

| 3/8″ – 18 UNS | 0.3750 | 9.525 | 8.20 | 18 | 1.411 |

| 3/8″ – 27 UNS | 0.3750 | 9.525 | 8.70 | 27 | 0.941 |

| 3/8″ – 36 UNS | 0.3750 | 9.525 | 8.90 | 36 | 0.706 |

| 3/8″ – 40 UNS | 0.3750 | 9.525 | 9.00 | 40 | 0.635 |

| 0.390″ – 27 UNS | 0.3900 | 9.906 | 9.00 | 27 | 0.941 |

| 7/16″ – 18 UNS | 0.4375 | 11.112 | 9.75 | 18 | 1.411 |

| 7/16″ – 24 UNS | 0.4375 | 11.112 | 10.10 | 24 | 1.058 |

| 7/16″ – 27 UNS | 0.4375 | 11.112 | 10.20 | 27 | 0.941 |

| 1/2″ – 12 UNS | 0.5000 | 12.700 | 10.75 | 12 | 2.117 |

| 1/2″ – 14 UNS | 0.5000 | 12.700 | 11.00 | 14 | 1.814 |

| 1/2″ – 18 UNS | 0.5000 | 12.700 | 11.40 | 18 | 1.411 |

| 1/2″ – 24 UNS | 0.5000 | 12.700 | 11.70 | 24 | 1.058 |

| 1/2″ – 27 UNS | 0.5000 | 12.700 | 11.85 | 27 | 0.941 |

| 9/16″ – 14 UNS | 0.5625 | 14.288 | 12.60 | 14 | 1.814 |

| 9/16″ – 27 UNS | 0.5625 | 14.288 | 13.40 | 27 | 0.941 |

| 5/8″ – 14 UNS | 0.6250 | 15.875 | 14.20 | 14 | 1.814 |

| 5/8″ – 27 UNS | 0.6250 | 15.875 | 15.00 | 27 | 0.941 |

| 3/4″ – 14 UNS | 0.7500 | 19.050 | 17.40 | 14 | 1.814 |

| 3/4″ – 18 UNS | 0.7500 | 19.050 | 17.75 | 18 | 1.411 |

| 3/4″ – 24 UNS | 0.7500 | 19.050 | 18.10 | 24 | 1.058 |

| 3/4″ – 27 UNS | 0.7500 | 19.050 | 18.20 | 27 | 0.941 |

| 7/8″ – 10 UNS | 0.8750 | 22.225 | 19.75 | 10 | 2.540 |

| 7/8″ – 18 UNS | 0.8750 | 22.225 | 21.00 | 18 | 1.411 |

| 7/8″ – 24 UNS | 0.8750 | 22.225 | 21.20 | 24 | 1.058 |

| 7/8″ – 27 UNS | 0.8750 | 22.225 | 21.40 | 27 | 0.941 |

| 1″ – 10 UNS | 1.0000 | 25.400 | 23.00 | 10 | 2.540 |

| 1″ – 14 UNS | 1.0000 | 25.400 | 23.75 | 14 | 1.814 |

| 1″ – 18 UNS | 1.0000 | 25.400 | 24.25 | 18 | 1.411 |

| 1″ – 24 UNS | 1.0000 | 25.400 | 24.50 | 24 | 1.058 |

| 1″ – 27 UNS | 1.0000 | 25.400 | 24.50 | 27 | 0.941 |

| 1 1/8″ – 10 UNS | 1.1250 | 28.575 | 26.25 | 10 | 2.540 |

| 1 1/8″ – 14 UNS | 1.1250 | 28.575 | 27.00 | 14 | 1.814 |

| 1 1/8″ – 24 UNS | 1.1250 | 28.575 | 27.75 | 24 | 1.058 |

| 1 1/4″ – 10 UNS | 1.2500 | 31.750 | 29.50 | 10 | 2.540 |

| 1 1/4″ – 14 UNS | 1.2500 | 31.750 | 30.00 | 14 | 1.814 |

| 1 1/4″ – 24 UNS | 1.2500 | 31.750 | 30.75 | 24 | 1.058 |

| 1 3/8″ – 10 UNS | 1.3750 | 34.925 | 32.60 | 10 | 2.540 |

| 1 3/8″ – 14 UNS | 1.3750 | 34.925 | 33.30 | 14 | 1.814 |

| 1 1/2″ – 10 UNS | 1.5000 | 38.100 | 35.70 | 10 | 2.540 |

| 1 1/2″ – 14 UNS | 1.5000 | 38.100 | 36.50 | 14 | 1.814 |

| 1 1/2″ – 24 UNS | 1.5000 | 38.100 | 37.30 | 24 | 1.058 |

| 1 5/8″ – 10 UNS | 1.6250 | 41.275 | 39.00 | 10 | 2.540 |

| 1 5/8″ – 14 UNS | 1.6250 | 41.275 | 39.50 | 14 | 1.814 |

| 1 5/8″ – 24 UNS | 1.6250 | 41.275 | 40.35 | 24 | 1.058 |

| 1 3/4″ – 10 UNS | 1.7500 | 44.450 | 42.00 | 10 | 2.540 |

| 1 3/4″ – 14 UNS | 1.7500 | 44.450 | 42.85 | 14 | 1.814 |

| 1 3/4″ – 18 UNS | 1.7500 | 44.450 | 43.25 | 18 | 1.411 |

| 1 7/8″ – 10 UNS | 1.8750 | 47.625 | 45.30 | 10 | 2.540 |

| 1 7/8″ – 14 UNS | 1.8750 | 47.625 | 46.00 | 14 | 1.814 |

| 1 7/8″ – 18 UNS | 1.8750 | 47.625 | 46.35 | 18 | 1.411 |

| 2″ – 10 UNS | 2.0000 | 50.800 | 48.40 | 10 | 2.540 |

| 2″ – 14 UNS | 2.0000 | 50.800 | 49.25 | 14 | 1.814 |

| 2″ – 18 UNS | 2.0000 | 50.800 | 49.50 | 18 | 1.411 |

| 2 1/16″ – 16 UNS | 2.0625 | 52.387 | 51.00 | 16 | 1.587 |

| 2 3/16″ – 16 UNS | 2.1875 | 55.563 | 54.10 | 16 | 1.587 |

| 2 1/4″ – 10 UNS | 2.2500 | 57.150 | 54.75 | 10 | 2.540 |

| 2 1/4″ – 14 UNS | 2.2500 | 57.150 | 55.50 | 14 | 1.814 |

| 2 1/4″ – 18 UNS | 2.2500 | 57.150 | 55.75 | 18 | 1.411 |

| 2 5/16″ – 16 UNS | 2.3125 | 58.737 | 57.30 | 16 | 1.587 |

| 2 7/16″ – 16 UNS | 2.4375 | 61.912 | 60.50 | 16 | 1.587 |

| 2 1/2″ – 10 UNS | 2.5000 | 63.500 | 61.20 | 10 | 2.540 |

| 2 1/2″ – 14 UNS | 2.5000 | 63.500 | 61.75 | 14 | 1.814 |

| 2 1/2″ – 18 UNS | 2.5000 | 63.500 | 62.30 | 18 | 1.411 |

| 2 3/4″ – 10 UNS | 2.7500 | 69.850 | 67.50 | 10 | 2.540 |

| 2 3/4″ – 14 UNS | 2.7500 | 69.850 | 68.25 | 14 | 1.814 |

| 2 3/4″ – 18 UNS | 2.7500 | 69.850 | 68.50 | 18 | 1.411 |

| 3″ – 10 UNS | 3.0000 | 76.200 | 73.80 | 10 | 2.540 |

| 3″ – 14 UNS | 3.0000 | 76.200 | 74.50 | 14 | 1.814 |

| 3″ – 18 UNS | 3.0000 | 76.200 | 75.00 | 18 | 1.411 |

| 3 1/4″ – 10 UNS | 3.2500 | 82.550 | 80.25 | 10 | 2.540 |

| 3 1/4″ – 14 UNS | 3.2500 | 82.550 | 81.00 | 14 | 1.814 |

| 3 1/4″ – 18 UNS | 3.2500 | 82.550 | 81.25 | 18 | 1.411 |

| 3 1/2″ – 10 UNS | 3.5000 | 88.900 | 86.55 | 10 | 2.540 |

| 3 1/2″ – 14 UNS | 3.5000 | 88.900 | 87.25 | 14 | 1.814 |

| 3 1/2″ – 18 UNS | 3.5000 | 88.900 | 87.60 | 18 | 1.411 |

| 3 3/4″ – 10 UNS | 3.7500 | 95.250 | 93.00 | 10 | 2.540 |

| 3 3/4″ – 14 UNS | 3.7500 | 95.250 | 93.60 | 14 | 1.814 |

| 3 3/4″ – 18 UNS | 3.7500 | 95.250 | 94.00 | 18 | 1.411 |

| 4″ – 10 UNS | 4.0000 | 101.600 | 99.30 | 10 | 2.540 |

| 4″ – 14 UNS | 4.0000 | 101.600 | 100.00 | 14 | 1.814 |

| 4 1/4″ – 10 UNS | 4.2500 | 107.950 | 105.60 | 10 | 2.540 |

| 4 1/4″ – 14 UNS | 4.2500 | 107.950 | 106.30 | 14 | 1.814 |

| 4 1/2″ – 10 UNS | 4.5000 | 114.300 | 112.00 | 10 | 2.540 |

| 4 1/2″ – 14 UNS | 4.5000 | 114.300 | 112.65 | 14 | 1.814 |

| 4 3/4″ – 10 UNS | 4.7500 | 120.650 | 118.35 | 10 | 2.540 |

| 4 3/4″ – 14 UNS | 4.7500 | 120.650 | 119.00 | 14 | 1.814 |

| 5″ – 10 UNS | 5.0000 | 127.000 | 124.70 | 10 | 2.540 |

| 5″ – 14 UNS | 5.0000 | 127.000 | 125.35 | 14 | 1.814 |

| 5 1/4″ – 10 UNS | 5.2500 | 133.350 | 131.00 | 10 | 2.540 |

| 5 1/4″ – 14 UNS | 5.2500 | 133.350 | 131.70 | 14 | 1.814 |

| 5 1/2″ – 10 UNS | 5.5000 | 139.700 | 137.40 | 10 | 2.540 |

| 5 1/2″ – 14 UNS | 5.5000 | 139.700 | 138.00 | 14 | 1.814 |

| 5 3/4″ – 10 UNS | 5.7500 | 146.050 | 143.75 | 10 | 2.540 |

| 5 3/4″ – 14 UNS | 5.7500 | 146.050 | 144.40 | 14 | 1.814 |

| 6″ – 10 UNS | 6.0000 | 152.400 | 150.00 | 10 | 2.540 |

| 6″ – 14 UNS | 6.0000 | 152.400 | 150.75 | 14 | 1.814 |