Introduction

Modern machining techniques called CNC, or computer numerical control, automate machine tool operation using programmed computer software. Offering exact, quick, repeatable manufacturing techniques across many sectors, CNC technology has grown to be a pillar of the whole manufacturing industry sector.

This paper offers a thorough overview of the CNC machine tools, together with its background, guiding ideas, varieties of machines, uses, benefits, difficulties, and direction of future CNC technology electric discharge machines.

The Evolution of CNC Technology

From conventional machining techniques demanding manual control, the CNC machining industry has developed cnc programming. One can follow the path of CNC technology through the following phases:

- Before automation, all machining operations were manually run and highly skilled individuals were needed to manipulate lathes, mills, and drills manual lathes.

- 1940s–1950s Numerical Control (NC) machines: Designed following World War II, NC systems automated movements using punch cards or magnetic tapes.

- The Massachusetts Institute of Technology (MIT) invented the first CNC machine in the 1950s by combining computers with NC technology.

- CNC (1970s–1990s) advancements: Microprocessors and better software transformed CNC, accelerating it and increasing accessability.

- Modern CNC (2000s–Present) — IoT connection, cloud-based controls, real-time monitoring, and artificial intelligence augmentation improves CNC machines today.

These developments have rendered CNC technology essential in manufacturing process of contemporary production.

How CNC Machines Work

Operating under programmed instructions that direct their movements and functions precision cnc machining pre programmed computer software, CNC machines are The procedure consists on three fundamental phases:

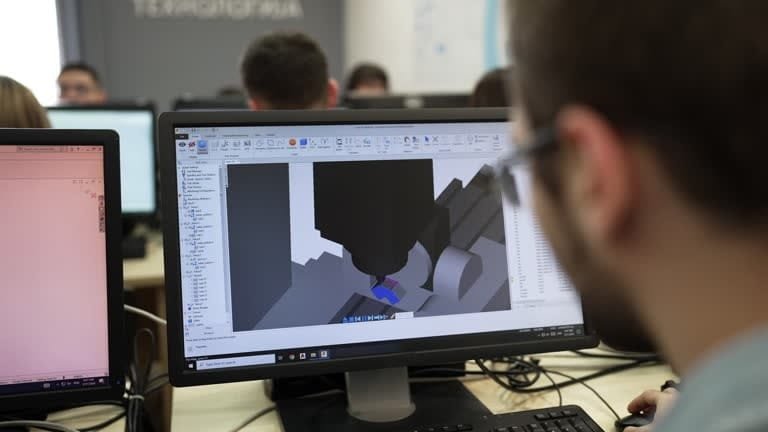

- Designing the Part with CAD Software

- Using Computer-Aided Design (CAD) tools as AutoCAD, SolidWorks, or Fusion 360, engineers produce a comprehensive 3D model of the part.

- Converting the Design into CNC Code with CAM Software

- G-code, a language CNC machines know, is derived from CAD design.

- Tool paths for the machine are produced using computer-aided manufacturing (CAM) programs.

- Setting Up the CNC Machine

- The machine is loaded with the right tools—cutting bits, drills, lasers, etc.

- On the worktable stands a raw material block—metal, plastic, wood, etc.).

- Executing the CNC Program

- Interpreting the G-code, the CNC controller guides the machine to execute exact motions.

- Minimal human involvement is involved in the totally automated process.

- Post-Processing & Quality Control

- Quality tests guarantee that a part satisfies standards once it is finished.

- Certain areas might get surface finishing, polishing, or other changes.

Types of CNC Machines

CNC technology addresses a broad spectrum of machines catered for particular purposes. Among the most often occurring categories of cnc machinery are:

1. CNC Milling Machines

- Remove material from a workpiece using turning cutting tools.

- Often used for intricate forms and finely detailed elements.

2. CNC Lathes

- Workpiece rotation while stationary cutting tools shapes it.

- Perfect for designing symmetric or cylindrical things like screws and bearings.

3. CNC Routers

- High-speed cutting blades for soft metals, plastics, and wood.

- Often used for decorative decorations, engraving, and cabinet construction.

4. CNC Plasma Cutters

- Cut very precisely through metal with a plasma torch.

- Mostly applied in automotive and metal fabrication sectors.

5. CNC Laser Cutters

- Cut or etch materials using strong laser beams.

- Common in signs, jewelry, and electronics as well as manufacturing.

6. CNC Electrical Discharge Machining (EDM)

- exact erases material using electrical discharges, sometimes known as sparks.

- Perfect for difficult components and hardy metals.

7. CNC Grinders

- Applied to high tolerances finishing and polishing metal surfaces.

Applications of CNC Technology

Because of its accuracy and efficiency, CNC finds application in complex machinery in many different fields. Among important uses are:

- Aeronautical: manufacturing precision tools, engine components, and aircraft parts.

- Manufacturing auto engine components, transmission parts, and bespoke designs.

- The medical sector produces prosthesis, surgical tools, and implants.

- Creating enclosures, connectors, and circuit boards in electronics.

- Carving, etching, and contouring of wooden furniture and decorative accents in woodworking.

- Military and Defense: creating armor, highly precise weapons, and communication tools.

Advantages of CNC Technology

Modern industry prefers the CNC machining operations since it provides various advantages over conventional machining techniques. Among its main advantages are:

- CNC machines can reach micrometer-level accuracy, hence lowering manufacturing errors.

- Once programmed, CNC machines run constantly with minimum human interaction, automaton and efficiency.

- Mass production depends on each component being exactly same, hence consistency and repeatability are absolutely vital.

- Reducing material waste, labor expenditures, and human mistakes helps to increase general profitability by means of cost-effective policies.

- Versatility: Made possible by metals, polymers, composites, and wood among other materials.

- Safety: Unlike hand machining, operators in increasing safety are less in dangerous surroundings.

Challenges & Limitations of CNC

Despite its numerous advantages, CNC technology also comes with some challenges:

- High Initial Costs – CNC machines require a significant investment in equipment, software, and training.

- Complex Programming – Requires skilled programmers to develop and optimize G-code instructions.

- Maintenance and Repairs – CNC machines need regular maintenance to prevent downtime and ensure efficiency.

- Limited by Material Constraints – Some CNC processes are not suitable for ultra-hard or brittle materials.

The Future of CNC Technology

Driven by IoT integration, artificial intelligence, and automation, CNC technology is evolving once more Several important advancements include:

- Smart Factories & Industry 4.0: Intelligent algorithms improving toolpaths and lowering mistakes; machines connecting via cloud-based networks for real-time monitoring.

- Combining CNC machining with 3D printing for advanced manufacturing is known as hybrid manufacturing; eco-friendly machining is CNC systems created for sustainable manufacture with low waste and energy use.

- CNC machining will always be crucial in precise manufacture as technology develops.

Conclusion

With unmatched accuracy, speed, and automation, CNC technology has transformed product manufacture. From custom woodworking to high-tech aeronautical parts, the CNC machining process is the backbone of contemporary industry.

Companies implementing smart machining processes, artificial intelligence-driven technologies, and automation will remain ahead in the competitive production environment as CNC develops.