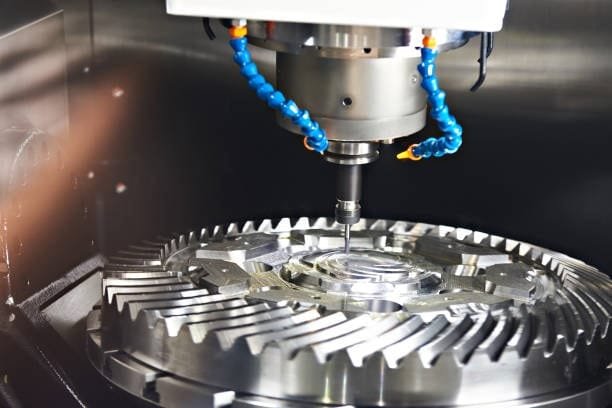

CNC (Computer Numerical Control) machines have revolutionized the manufacturing industry, enabling precise, efficient, and scalable production across various sectors. These machines are versatile and capable of crafting a wide range of items, from intricate jewelry to large-scale industrial components. Let’s explore what CNC machines can create, how they are used, and why they have become indispensable in modern manufacturing processes.

Understanding CNC Machines

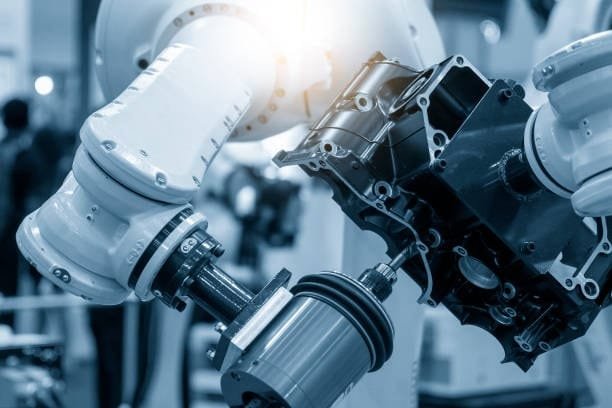

CNC machines operate by following computer-generated designs to carve, mill, cut, or shape materials. They work with diverse substances like metals, plastics, wood, and even glass. With automated control and precision, CNC machines can create complex objects with minimal human intervention diy projects. CNC (Computer Numerical Control) machines have transformed the manufacturing world by enhancing the precision, accuracy, and efficiency of part production. These versatile machines can create a wide range of products, making them indispensable in numerous industries cutting boards. To help you better understand their capabilities, we’ve compiled a detailed guide showcasing what CNC machines can produce and why they are essential for modern manufacturing cnc project ideas.

Items You Can Create Using CNC Machines

1. Precision Parts and Components

CNC machines shine in creating precisely calibrated parts and components that satisfy tight tolerances. In sectors including aerospace, automotive, and electronics, where performance and safety directly depend on accuracy, this capacity is absolutely vital cnc business.

Aerospace Industry

CNC machines produce complex parts including structural elements, engine components, and turbine blades in aerospace manufacture. These parts follow strict safety criteria and must be perfect in accuracy to guarantee best performance.

Examples:

- components of engines

- blades for a turbine

- Body elements for aircraft

Automotive Industry

In the automotive industry, CNC machining is indispensable since it enables the creation of important parts including complex chassis elements, engine components, and transmission gear storage boxes. These components support vehicle dependability, efficiency, and performance.

Examples:

- Heads of a cylinder

- Component parts of a brake system

- Elastic elements of suspension

Medical Industry

For devices and implants, the medical community expects exact, tailored solutions. CNC machines can create dental components that satisfy rigorous regulatory criteria most cnc routers, patient-specific orthopedic implants, and complex medical tools.

Examples:

- Medical instruments

- Implants for orthopedics

- Dental bridges and crowns

Electronics Industry

CNC machines produce fine-grained, precisely measured necessary components in electronics. For effective operation of mechanical systems, items including heat sinks cnc products, enclosures, and circuit boards must have exact dimensions.

Examples:

- PCBs, or printed circuits,

- Customizable connectors

- Mounting plates and enclosures

Consumer Goods Industry

CNC machining allows exact manufacturing for consumer goods including watches, phone cases, cameras, and tools, so improving their durability, appearance, and functionality custom made furniture.

Examples:

- Monitor parts.

- camera attachments

- Customisable electronic casings

2. Custom and Artistic Creations

Customized designs, artistic creations personalized accessories laser engraving, and decorative accents also find great use on CNC machines. Using CNC technology, artists, designers, and craftspeople can produce exact patterns and original works.

Examples:

- Customized designs for jewelry

- Ornamental wooden carvings

- Customized signs

- Designed custom-wise for homes

3. Industrial Machinery and Equipment

Production of strong and exact components for heavy-duty machinery depends critically on CNC machining. CNC machines precisely provide parts that can withstand stress office supplies, vibration, and extreme temperatures—that which industrial equipment requires.

Examples:

- Steel brackets

- Gears and fittings

- Custom fasteners

4. Prototypes and Product Development

CNC machines create exact models for testing and improvement projects, so simplifying the prototyping process for designers and engineers. Fast production of functional prototypes made possible by CNC machining advances product development projects.

Examples:

- Mock-ups for industrial design

- mechanical prototype

- Electronics’ concept models

5. Furniture and Woodworking

Many times used as cutting tool used in woodworking, CNC routers let designers and craftsmen create unique furniture pieces, intricate wooden carvings, and complex patterns.

Examples:

- Ornamental wall paneling

- Custom furniture for cabinets

- Precision furniture joinery

6. Signage and Advertising Materials

For commercial environments, CNC machines shine in creating bold, personalized signage create custom designs. CNC machines produce neat, aesthetically pleasing designs for branding, marketing, or decorative needs in many industries.

Examples:

- Storefront banners

- Cutouts of the logo

- Personal plaques and accolades

How CNC Machines Work

To generate digital blueprints for products, CNC machines depend on CAD (Computer-Aided Design) software. These digital designs then become G-code, a set of instructions that guides the motions of the first make with a CNC machine. This approach guarantees accuracy down to fractions of a millimeter, hence CNC machining is perfect for sectors needing accuracy.

Applications of CNC Machines

1. Automotive Industry

Manufacturing of automotive parts depends much on CNC machines. CNC machines are commonly used in the creation of parts including engine components, brake systems, and gearboxes. Their accuracy guarantees low tolerances, so improving vehicle performance and safety.

Examples:

- Heads of an engine cylinder

- Tools for gear components

- Suspension elements

- Parts related to an exhaust system

- Parts of a steering system

Custom car modifications also depend heavily on CNC machines, which let aficionados precisely engineer parts to personalize their vehicles.

2. Aerospace Industry

CNC machining’s great accuracy criteria help the aerospace industry greatly rely on it. To guarantee passenger safety and operational effectiveness, aircraft components have to satisfy exact criteria.

Examples:

- Turbine blades

- Airplane body parts

- Landing gear components

- Engine mounts

- Interior aircraft fittings

Because of the complexity of aeronautical engineering, CNC machines offer the best way to create lightweight but robust parts that satisfy high safety criteria.

3. Medical Industry

Custom prosthesis, implants, and surgical tools are created in the medical field from CNC machines. These components need exact specifications to match medical standards.

Examples:

- Titanium implants for bone

- Dental crowns and bridges

- Precision instruments for surgery

- Custom orthopedic implants

- Prosthetic limbs

Because CNC machines can produce hygienic, consistent results that satisfy high healthcare standards, they are perfect for manufacturing medical equipment.

4. Electronics Industry

Circuit boards, electronic housings, and other precision elements needed for electrical devices are produced by CNC machines.

Examples:

- printed circuit boards (PCBs)

- Aluminum frames

- Sinks of heat

- Particles of a smartphone

- Custom connections

CNC machines are indispensable in precisely creating these complex parts as electronic devices get ever smaller and more powerful.

5. Jewelry Making

When designing complex jewelry, CNC machines provide unparalleled accuracy. From intricate details on personalized rings to finely detailed pendants, CNC machining produces amazing detail.

Examples:

- Rings with engravings

- Custom jewelry

- Complex bracelet styles

- Individual pendants

- Personal wedding bands

Both mass-produced and high-end custom pieces will find CNC machines ideal since their use guarantees that every piece is exactly in quality and design.

6. Furniture and Woodworking

Custom furniture, decorative panels, and intricate carvings are among the woodworking applications for CNC routers.

Examples:

- Custom cabinets

- Ornamental wall panels

- Wooden sculptures

- detailed door carvings

- Wood furniture’s precision joinery

CNC machines enable craftspeople to achieve complex and repeatable designs in woodworking by automating difficult and intricate designs themselves.

7. Prototyping and Product Development

Product prototypes are developed by engineers and designers often using CNC machines. Perfect testing models for durability and functionality are guaranteed by CNC machining.

Examples:

- Industrial parts for products

- Technical prototypes

- Design copies

- Models for engineering research

- Consumer electronics: concept designs

Reducing development time and costs for product testing, CNC machines are indispensable in the fast prototyping process.

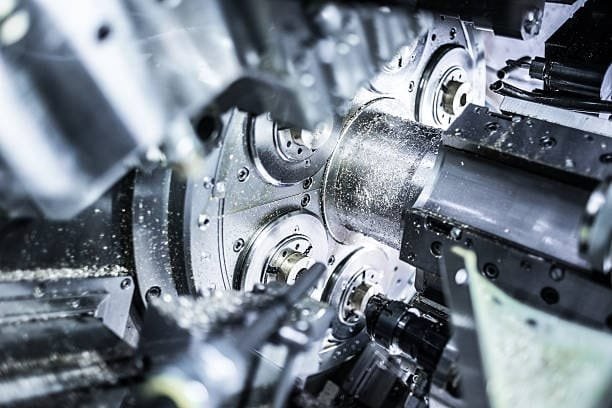

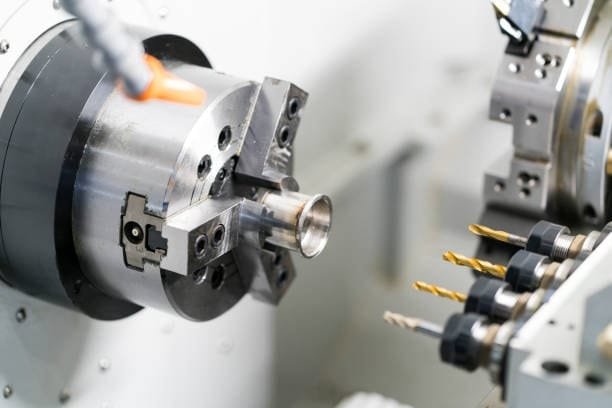

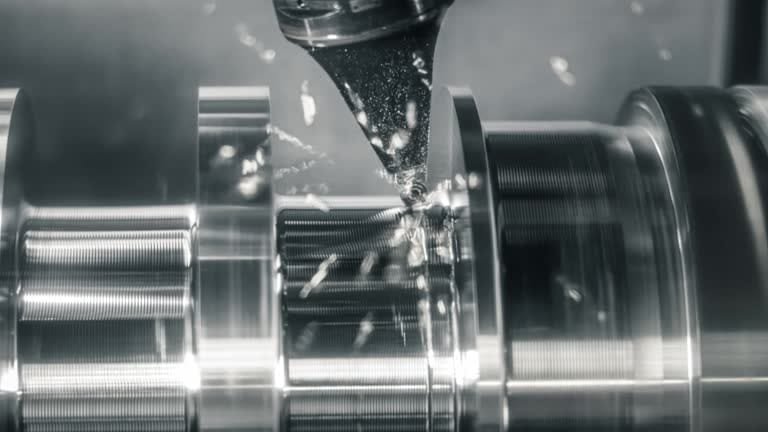

8. Metalworking and Fabrication

In metalworking, CNC milling and turning machines are absolutely indispensable. They assist in producing both small- and large-scale metal parts.

Examples:

- Steel Brackets

- Original metal fittings

- Precision tools

- Parts for industrial machinery

- Artworks and metal sculptures

CNC machines guarantee exact cuts various shapes and detailed forms by excelling in handling both strong metals and delicate alloys.

9. Signage and Advertising

Custom signage is ideal created with CNC routers. They can remarkably precisely carve out intricate patterns, letters, logos, and decorative displays.

Examples:

- Storefront markers

- Cutouts for 3D logos

- Personalized plaques

- Advertisements on billboards

- Special medals and trophies

Bold, simple construction elegant signage created by CNC machines distinguishes itself in commercial settings.

10. Arts and Crafts

Creative people and companies create unique crafts own products and artistic designs using CNC machines.

Examples:

- Wall art created by laser cutting

- Customized picture frames

- Designed specifically for coasters

- Customized present boxes

- Custom home décor

CNC machines allow artists to remarkably precisely realize their artistic ideas.

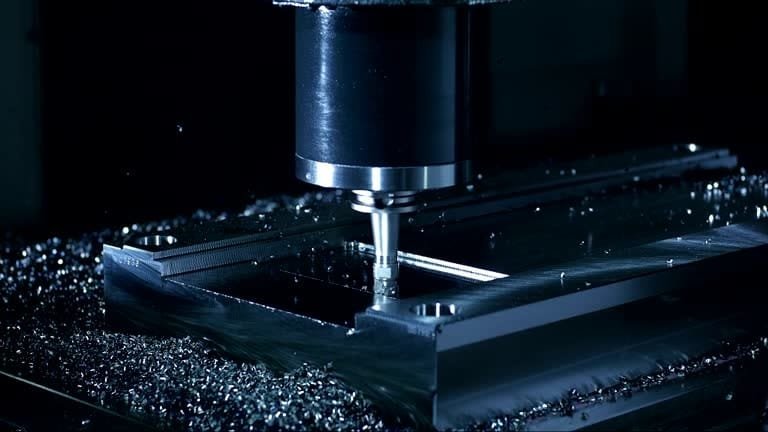

Prototyping with CNC Machines

By providing exact, quick fabrication for components created from many materials, CNC machines have greatly improved the prototyping process. This flexibility lets designers and engineers create prototypes with complicated geometries and fine details that might be difficult to reach with conventional techniques.

Key Advantages of CNC Machines in Prototyping

- Excellent precision made possible by CNC machines guarantees that prototype parts satisfy exact tolerances.

- Parts with complex designs and exacting standards are best suited for CNC machining.

- Machines can run a broad spectrum of materials, including plastics, metals, and composites.

- Every prototype component is made with the same degree of accuracy, which simplifies validation and testing.

Common CNC Prototyping Applications

- Often fabricated using CNC machines for testing fit, form, and functionality, mechanical components include gears, bearings, shafts, and housings.

- Perfect cutouts for displays, buttons, ports, and other interface elements are routinely created using CNC machining.

- Prototyping fixtures and jigs guarantees parts stay securely held during machining, assembly, or inspection operations.

- CNC machines produce mold inserts for fast prototyping of injection-molded or compression-molded parts, enabling effective mold testing prior to finalizing costly tooling.

- CNC machining makes it simple to create one-off or low-volume prototypes for consumer goods, industrial equipment, and medical devices.

CNC Machines for Artistic and Decorative Applications

CNC milling machines have opened creative opportunities by enabling designers and artists to create one-of-a-kind, extremely detailed works. Important uses abound:

- From abstract designs to kinetic structures, CNC technology allows complex detailing for artistic creations including sculptures.

- Custom furniture and home décor created from CNC milling include modular shelving systems, personalized signs, and carved wooden furniture.

- Custom jewelry created by CNC machining reflects personal tastes and features finely detailed rings, pendants, earrings, and cufflinks.

Architectural Model Fabrication

Architecture makes extensive use of CNC machines to create remarkably accurate scale models from various materials. These devices create architectural details from wood, foam, or acrylic, so shaping:

- Explicit facades

- Interior design

- Structural frameworks

Such models help architects and designers to properly visualize and present their ideas.

CNC Engraving Applications

On a range of materials, CNC machines shine in producing finely detailed and unique custom engravings. Typical uses include:

- Custom Signs and Plaques: CNC machines cut logos, text, and complex designs onto materials including wood, acrylic, and aluminum.

- CNC engraving marks serial numbers, logos, and identifiers on electronic components including laptops, tablet covers, and device enclosures.

Overview of CNC Applications

| Application | Examples | Materials Used |

| Prototyping Parts | Brackets, gears, housings | Metals, plastics |

| Art & Decor | Sculptures, furniture, jewelry | Wood, acrylic, metal |

| Architectural Models | Scale models, interior layouts | Wood, foam, acrylic |

| Engraving | Signs, plaques, industrial markings | Metal, plastic, wood |

From engineering to artistic design, CNC machining is a flexible and essential tool guaranteeing accuracy, efficiency, and exceptional results in all sectors.

Advantages of CNC Machines

- CNC machines constantly provide great accuracy, so making sure every piece exactly matches the others.

- Automated CNC systems increase production speed and help to lower hand labor requirements.

- Versatility: CNC machines are flexible enough for many different sectors and can manage several materials.

- Mass production and small-scale prototyping both are areas in which CNC systems shine.

- Every good produced on a CNC machine is exactly the same, which simplifies quality control.

- CNC machines let producers diversify their product range by switching between several designs with minimum setup changes.

Conclusion

With their capacity to produce sophisticated, exact, and high-quality goods, CNC machines have changed manufacturing. From sophisticated jewelry to complex automotive parts, their uses span several sectors, including medical devices. Whether your business is design, manufacturing, or entrepreneurship, CNC machines provide almost endless possibilities for production and creativity. CNC machines remain at the forefront as businesses change, stretching the bounds of design, accuracy, and utility. By offering exceptional accuracy, efficiency, and adaptability over many sectors, CNC machines have transformed manufacturing. From complex medical implants to handcrafted art pieces, CNC machines shine in precisely turning digital designs into physical objects. CNC machines remain a necessary instrument in obtaining creative and high-quality results as the demand for exact manufacturing keeps rising.