G-code and M-code serve as the cornerstone programming languages in CNC (Computer Numerical Control) machining. These codes provide the instructions that CNC machines rely on to execute precise operations, making them indispensable in modern manufacturing environments. For machinists, programmers, and engineers engaged in the control CNC machines’ operations, a thorough understanding of G and M codes proves vital. This in-depth guide explores the essence of G and M codes, their specific functions, key differences, practical applications, and strategies for mastering them effectively.

Understanding G-Code

G-code, short for Geometric Code, acts as the primary programming language tasked with controlling the movement and positioning of CNC machines. This language comprises a series of commands that direct the machine’s capabilities and tool along designated paths, dictating its motion and actions with pinpoint accuracy. These instructions play a critical role in cutting, drilling, and shaping materials, ensuring that the final product meets exact specifications.

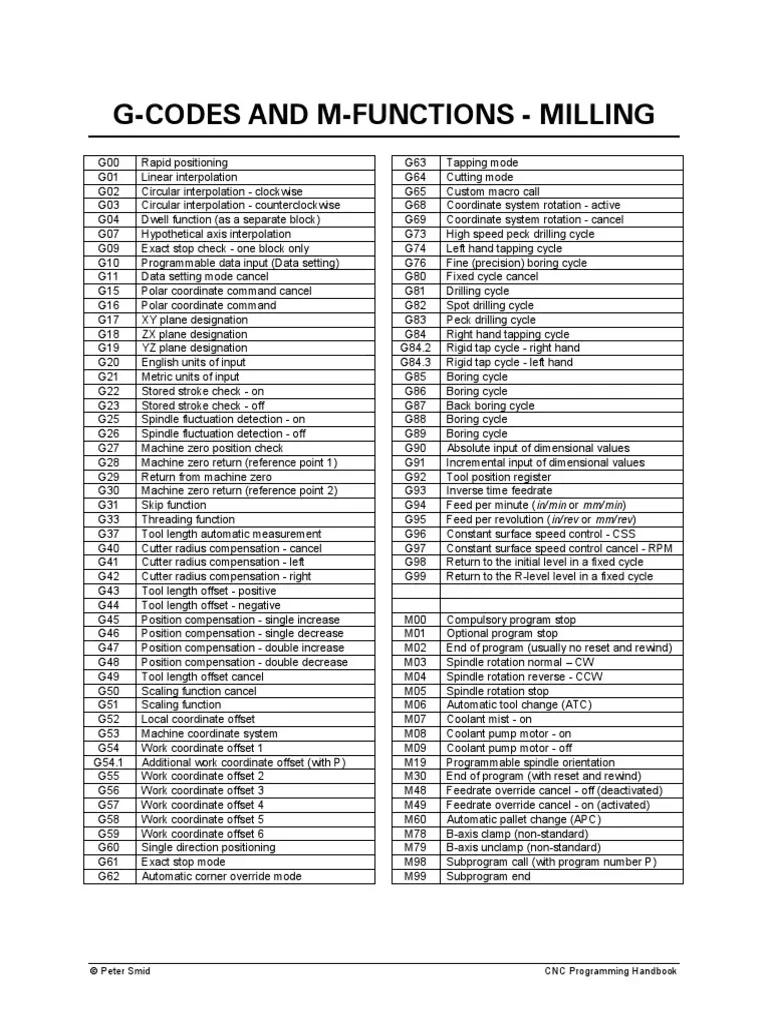

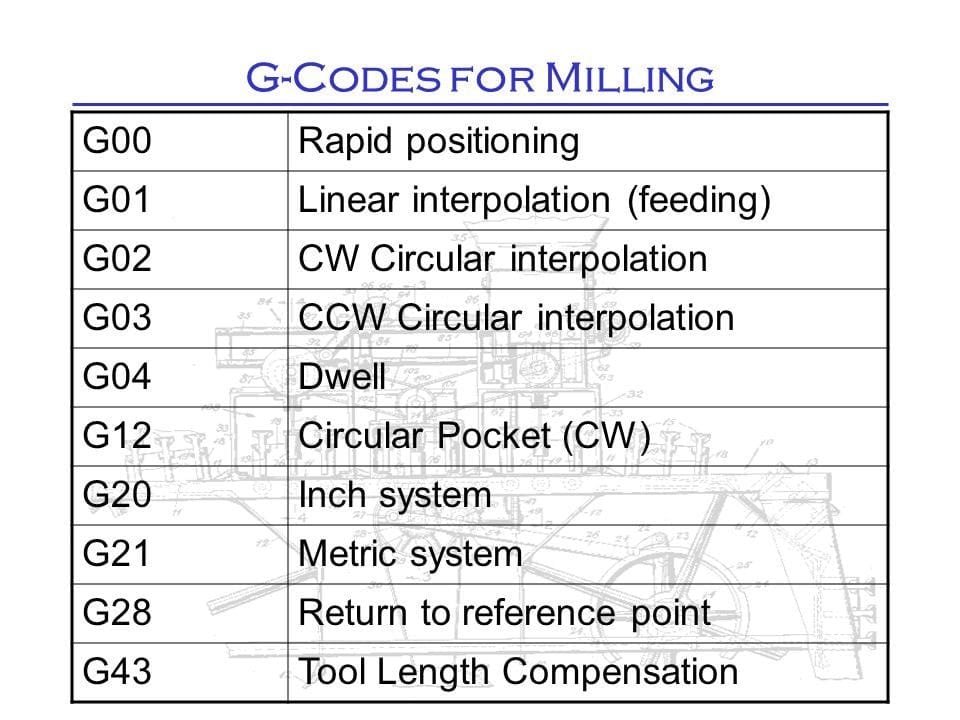

Common G-Code Functions

Several G-code commands stand out due to their frequent use and importance in CNC programming:

G00 – Rapid Positioning:

This command instructs the tool to move swiftly to a specified location without engaging in cutting, optimizing tool length of time between operations.

G01 – Linear Interpolation:

Here, the tool travels along a straight line at a controlled speed, commonly used for either cutting tools or milling straight edges.

G02 – Circular Interpolation (Clockwise):

This directs the tool to follow a circular arc in a clockwise direction, ideal for creating rounded features.

G03 – Circular Interpolation (Counterclockwise):

Similar to G02, this command guides the tool in a counterclockwise arc, offering flexibility in circular machining.

G17, G18, G19 – Plane Selection:

These codes define the working plane—G17 for x axis, for XY, G18 for XZ, and G19 for YZ—ensuring proper orientation for multi-dimensional machining.

G20/G21 – Unit Selection:

G20 sets measurements in inches, while G21 switches to millimeters, aligning the program with the desired unit system.

G28 – Return to Home Position:

This command sends the tool back to its designated home position, typically used at the start or end of a program.

G40, G41, G42 – Cutter Compensation:

These adjust for tool diameter during contour machining—G40 cancels compensation, G41 applies it to the left, and G42 to the right.

G90/G91 – Positioning Mode:

G90 establishes absolute positioning (coordinates based on a fixed reference point of origin), while G91 uses incremental positioning (relative to the current position).

These commands collectively allow modern CNC machines to navigate complex geometries with precision, forming the backbone of most machining operations.

Understanding M-Code

M-code, or Miscellaneous Code, governs a variety of machine functions that extend beyond mere movement. These codes manage critical auxiliary operations such as spindle activation, coolant flow, and tool changes, ensuring seamless integration with G-code instructions.

Common M-Code Functions

The following M-codes represent some of the most commonly utilized commands in CNC machining:

- M00 – Program Stop: This halts the program entirely, requiring manual intervention to resume, often used for inspections or adjustments.

- M01 – Optional Stop: Pauses the program only if the optional stop feature is activated, offering flexibility during operation.

- M03 – Spindle On (Clockwise): Activates the spindle in a clockwise rotation, typically initiating the cutting process.

- M04 – Spindle On (Counterclockwise): Starts the spindle in a counterclockwise direction, useful for specific tools or materials.

- M05 – Spindle Stop: Ceases spindle rotation, often employed before tool changes or at the end of a cycle.

- M06 – Tool Change: Triggers an automatic tool change, allowing the machine to switch tools mid-program.

- M08 – Coolant On: Activates the coolant system to manage heat and debris during machining.

- M09 – Coolant Off: Shuts off the coolant, typically used when cutting concludes.

- M30 – Program End and Reset: Terminates the program and resets the machine to its initial state, preparing it for the next task.

These M-codes enhance the functionality of CNC machines, ensuring that operations proceed smoothly alongside the movements dictated by G-code.

Differences Between G-Code and M-Code

While G-code and M-code work in tandem, their roles remain distinct. G-code primarily focuses on controlling the tool’s movement—its path, speed, and positioning—laying out the geometric framework of the machining process. Conversely, M-code handles the machine’s operational aspects, such non geometry machine functions such as starting or stopping the spindle, managing coolant, or executing tool changes. This division of labor ensures that both the physical motion and the supporting functions align perfectly during CNC operations.

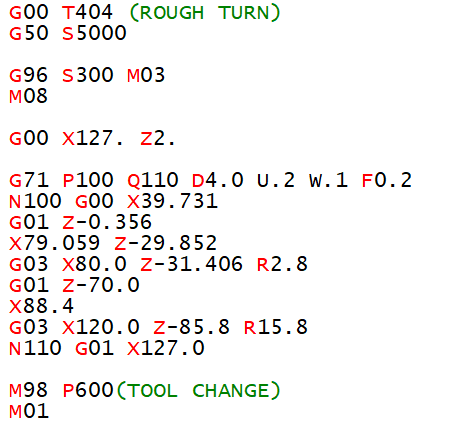

How G and M Codes Work Together

In practice, G and M codes combine within CNC programs to execute specific machining tasks efficiently. A sample program illustrates this synergy:

G21 ; Set units to millimeters

G17 ; Select XY plane

G90 ; Absolute positioning mode

G00 X50 Y30 Z10 ; Move to starting position

M03 S1500 ; Turn on spindle at 1500 RPM

G01 Z-5 F100 ; Move down into the material at 100 mm/min feed rate

G01 X100 Y30 ; Cut in a straight line

M08 ; Turn on coolant

G02 X150 Y50 I25 J0 ; Cut a clockwise arc

M09 ; Turn off coolant

M05 ; Stop spindle

M30 ; End program and reset

In this example, G-codes dictate the tool’s path—moving to a starting point, cutting a straight line, and tracing an arc—while M-codes manage the the spindle speed and coolant, ensuring the machine operates effectively throughout the process.

The Evolution of G and M Codes

The development of G and M codes reflects the broader evolution of CNC technology. In their early days, CNC machines depended on machine code made on punched tape to interpret rudimentary instructions, limiting their complexity. Over time, advancements in electronics and software transformed these codes into a sophisticated language capable of handling intricate operations. Modern CNC systems now integrate with CAM (Computer-Aided Manufacturing) software, which automatically generates G-code from digital designs, reducing the reliance on manual coding and enhancing precision.

Importance of G and M Codes in CNC Machining

The significance of G and M codes in CNC machining cannot be overstated, as they underpin several key benefits:

- Precision: These codes enable exact movements and operations, ensuring parts meet tight tolerances.

- Automation: Complex tasks unfold with minimal human intervention, streamlining production.

- Consistency: Repeatable instructions guarantee uniform results across multiple runs.

- Efficiency: Optimized tool paths and machine functions reduce production time significantly.

- Customization: The flexibility of these codes allows adaptation to diverse designs and materials.

Together, these advantages make G and M codes indispensable for industries ranging from aerospace to automotive manufacturing.

Challenges in Learning G and M Codes

Despite their power, mastering G and M codes presents notable challenges for beginners and seasoned professionals alike:

- Complex Syntax: The variety of commands and their parameters demand careful study and practice to fully grasp.

- Debugging Errors: Even minor coding mistakes—like an incorrect coordinate or forgotten M-code—can disrupt machining, requiring meticulous troubleshooting.

- Machine-Specific Variations: Different CNC machines may interpret codes uniquely, necessitating familiarity with specific equipment manuals.

- Keeping Up with Technological Advancements: As CNC systems evolve, staying current with new features and commands becomes an ongoing task.

Overcoming these hurdles requires dedication, hands-on experience, and access to reliable resources.

Best Practices for Using G and M Codes

To maximize the effectiveness of G and M codes, adhering to proven strategies proves beneficial:

- Start with Simulations: CNC simulation software allows testing of programs in a virtual environment, catching errors before they affect real materials.

- Follow Documentation: Each machine’s manual provides critical details on supported codes and variations, serving as an essential reference.

- Break Down Programs: Writing and testing small code segments minimizes the risk of widespread errors in larger programs.

- Keep a Reference Sheet: A concise list of frequently used G and M codes speeds up programming and reduces reliance on memory.

- Practice Regularly: Consistent hands-on work with CNC machines builds confidence and proficiency over time.

Implementing these practices fosters accuracy and efficiency in CNC programming.

Advanced Applications of G and M Codes

Beyond basic machining, G and M codes find use in sophisticated applications that push the boundaries of manufacturing:

Multi-Axis Machining:

These codes control 4-axis and 5-axis CNC machines, enabling the production of complex geometries like turbine blades or medical implants cad or cam software.

Robotic CNC Systems:

Integration with robotic arms enhances automation, allowing for tasks like material handling alongside machining cad software.

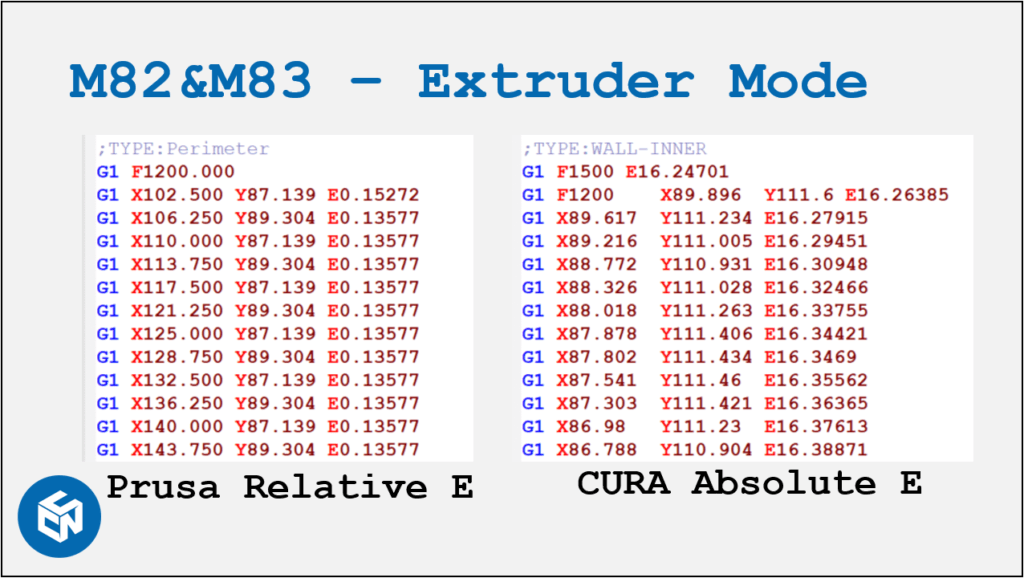

3D Printing:

Certain 3D printers interpret G-code to deposit material layer by layer, adapting CNC principles to additive manufacturing.

Laser Cutting:

CNC-controlled laser systems rely on G and M codes to achieve precise cuts in materials like metal or plastic.

These advanced uses highlight the versatility of G and M codes across diverse technologies.

The Future of G and M Codes

As technology progresses, the role of G and M codes in the CNC machining process continues to evolve. While their foundational status remains secure, emerging trends point to exciting developments:

- AI-Assisted CNC Programming: Artificial intelligence tools now analyze designs and generate optimized G-code, reducing programming time and enhancing outcomes.

- Cloud-Based CNC Control: Remote programming and real-time monitoring via cloud platforms offer greater flexibility and oversight of machining processes.

- Integration with IoT: The Internet of Things connects CNC machines to smart manufacturing systems, improving efficiency through data-driven insights cam software.

These innovations suggest that while G and M codes will persist, their application will become increasingly sophisticated and interconnected.

Conclusion

G-code and M-code form the bedrock of CNC machining, providing the instructions that drive tool movements and machine functions with unparalleled precision. G-code orchestrates the geometric aspects of machining, while M-code ensures operational harmony, together enabling efficient and accurate production. Mastery of these codes remains essential for optimizing CNC manufacturing processes, boosting productivity, and delivering high-quality results computer aided design.