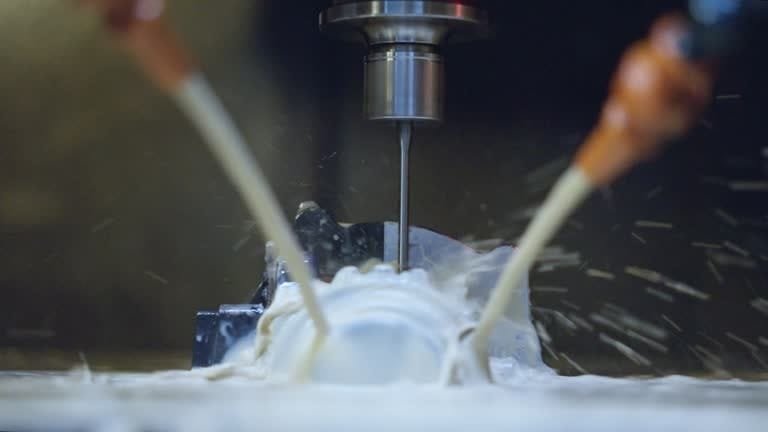

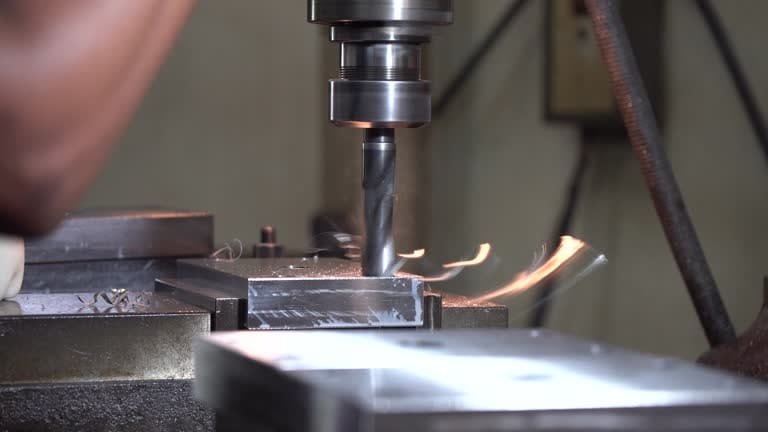

Modern manufacturing depends much on cutting fluids, particularly in machining and metalworking activities. They guarantee effective heat dissipating, raise surface finish, and extend tool life. Anyone working in metalworking must first understand their composition, varieties, and advantages. The principles of cutting metalworking fluids, their categories, uses, and best practices for usage are explored in this page.

Understanding Cutting Fluids

Specifically designed liquids or gases, cutting fluids cool and lubricate cutting tools and workpieces in machining operations. Among their several uses are those of lowering friction, chip flushing machine tool,, rust prevention, and improved general machining performance.

Cutting fluid choice depends on the material being machined, cutting speed, and kind of operation (drilling, turning, milling, or grinding). Tool lifetime, workpiece accuracy optimize machining performance, and general productivity can all be greatly impacted by the right fluid choice.

Significance of Cutting Fluids in Metalworking

Friction produced during metal cutting operations generates a lot of energy that is turned into heat. In improper control, this heat may cause the workpiece material to distort and cut tools to wear early. Four main purposes help cutting fluids to address these problems:

- Reducing friction between the tool and the workpiece helps to extend tool lifetime.

- Dissipating heat helps to keep ideal temperatures and stop thermal damage.

- Preventing corrosion of metal surfaces from oxidation and rusting.

- Helping to remove swarf, or metal chips, so guaranteeing a clean cutting environment.

While increasing machining efficiency, using cutting fluids—such cutting oils such as Aeroshell grease—helps to extend the lifetime of the tool and the machine.

Factors Influencing Cutting Fluid Selection

Choosing the suitable cutting fluid depends on several criteria, including:

- Cutting speed: More heat produced by faster speeds calls for fluids with better cooling qualities.

- Different metals and alloys react differently to cutting fluids.

- Machining Process: Choice of fluid depends on the type of cutting operation (e.g., milling, turning, drilling).

Distributors usually divide cutting fluids into three main groups depending on material type in order to simplify choice:

- Tool steels and carbon

- High-temperature alloys, stainless steel, and titanium

- Cast iron, aluminum, and other nonferrous metals

Types of Cutting Fluids

Cutting fluids come in several forms, each meant for particular use. The main divisions traditional cutting fluids are:

1. Water-Based Cutting Fluids

Often used in high-speed machining, water-based cutting fluids offer outstanding cooling qualities. These liquids comprise:

- Stable emulsions are produced by mixing oil and water with emulsifiers. Although they provide good lubrication and cooling, they must be routinely maintained to stop bacterial growth.

- Completely oil-free synthetic fluids include chemical additions for exceptional cooling and rust prevention. They find extensive application in high-speed cutting and grinding operations.

- Fluids with semi-synthetic character: Combining synthetics and soluble oils, this hybrid provides balanced lubrication and cooling qualities while reducing bacterial contamination.

2. Straight Oils (Neat Oils)

Straight oils are used un diluted form and are not emulsifiable. These comprise synthetic base oils mixed with extreme pressure (EP) additives, mineral oils, vegetable oils, or both. They are perfect for heavy-duty machining processes and metalworking operations when lubrication is absolutely crucial.

3. Mist and Aerosol Cutting Fluids

Applied as a fine mist or aerosol, these help to minimize fluid consumption and environmental impact. They offer enough lubrication, but they might not be as efficient in cooling than liquid-based fluids.

4. Gaseous and Cryogenic Cutting Fluids

In dry machining, cooling can also be accomplished with gases including nitrogen, carbon dioxide, and compressed air. Extreme cooling in high-precision machining is accomplished with cryogenic fluids—such as liquid nitrogen.

Benefits of Cutting Fluids

Cutting fluids are quite beneficial for health and safety risks hence absolutely essential in manufacturing. Their advantages include:

- Reduced heat produced during machining helps to avoid thermal damage to tools and workpieces.

- Lubricating reduces friction helps to improve surface finish and reduces tool wear.

- Good flushing of chips improves efficiency and helps to avoid re-cutting.

- Protective additives assist to stop rust on tools and workpieces.

- Reducing wear and tear helps to lower tool replacement costs.

- Guaranturing accurate and smooth cuts improves the quality of the final product.

- Faster machining made possible by proper cutting fluid helps to raise production.

- Minimized Heat Distortion: In precision work, too much heat might warp materials. Good cooling helps to avoid such problems..

Application Methods of Cutting Fluids

Effective cutting fluids need to be applied properly. There exist three main applications what are cutting fluids:

1. Flooding Method

This method uses a lot of cutting fluid applied to the cutting tool as well as the workpiece. This is quite efficient in flushing away and chilling chips.

2. Mist Application

Mist application is spraying cutting fluid mixed with gas—usually air—onto the workpiece and tool. Combining aspects of jet and flooding systems, this approach offers enough cooling with low fluid consumption.

3. Jet Application

In jet application, the cutting zone receives high pressure application of cutting fluid—either liquid or gaseous type. This approach guarantees good penetration into the very good cutting fluid in zone and enhances chip removal.

Classification of Cutting Fluids

Cutting fluid compositions and characteristics help to classify them. The four main categories are:

1. Synthetic Cutting Fluids

- Comprising polymers, organic, and inorganic compounds, these are oil-free solutions.

- Their lack of oil helps to explain their longer shelf life extreme pressure additives.

- Perfect for application with ferrous materials and high-speed machines.

- They do, however, usually stain nonferrous materials.

2. Semi-Synthetic Cutting Fluids

- a combination of synthetic and soluble oils providing cooling and lubrication qualities.

- offers resistance against contamination and corrosion.

- Fit for both ferrous and nonferrous materials rust inhibitors.

3. Soluble Oils

- Emulsifiers in these fluids help them to mix in water and create a milky emulsion.

- Commonly used in many machining operations, they offer outstanding lubrication.

- most suited for nonferrous materials.

4. Straight Oils

- non-emulsifiable oils used in their undiluted form.

- Made from base mineral oils and sometimes include polar lubricants including vegetable oils, esters, and fats.

- May also include additions of extreme pressure (EP) compounds including chlorine, phosphorous, and sulfur.

- Their cooling capacity is rather poor even if they provide better lubrication.

Primary and Secondary Functions of Cutting Fluids

Primary Functions

- Cooling tools and workspaces helps stop overheating at high cutting speeds skin irritation.

- Lubrication lowers friction between a tool and a workpiece, so reducing wear.

- Flishes metal chips from the cutting zone to stop re-cutting and tool damage..

Secondary Functions

- Protects machined surfaces from oxidation and rust development by means of corrosion prevention.

- Thermal management uses coolers on hot surfaces to facilitate part handling and increase safety.

Process Effects of Cutting Fluids in Machining

Machining uses cutting fluids for a number of advantages, including:

- Enhanced chip handling and swarf removal guarantees a flawless and quick machining operation.

- Improved surface finish generates more exact and fluid cuts.

- Longer tool life lowers wear and tear and helps to lower replacement costs.

- Prevention of thermal deformation helps the workpiece to remain dimensional accurate..

Best Practices for Using Cutting Fluids

See the following best practices to maximize cutting edge of fluid efficiency:

- Select a cutting fluid depending on the machining operation and material.

- Maintaining fluid quality, routinely look for microbial growth, pH levels, and contamination.

- Check correct application. Choose suitable delivery techniques including misting, spray nozzles, or flood cooling.

- Throw away trash correctly cutting fluids reduce friction. Follow environmental rules for the proper disposal and recycling of spent cutting fluids.

- Track levels of concentration. Steer clear of too high concentration or overdilution to impact tool lifetime or performance.

- Apply filtering systems: Maintaining cleanliness of the fluid increases its lifetime and efficiency.

- Train operators to make sure they handle and use cutting fluids correctly.

Environmental and Safety Considerations

Although cutting fluids improve machining efficiency, improper management of them raises environmental and health hazards. Some important factors are:

- Using environmentally friendly fluids can help to lower impact on the surroundings.

- Correct ventilation reduces mist and fumes exposure, so preventing respiratory problems.

- Recycling and correct disposal help to prevent pollution of water supplies.

- Wearing gloves and protective eyewear lowers direct skin contact and irritation hazards in personal protective equipment (PPE.).

- Following industry standards guarantees legal and safe practices in regulatory compliance.

- Regular treatment of fluids helps to reduce bacterial contamination by stopping microbial growth, bad smells, and worker skin conditions.

Conclusion

An indispensable part of machining processes, cutting fluids provide chip removal, lubrication, and cooling effects. Selecting the correct kind of cutting fluid, preserving its quality, and adhering to best standards will help machining efficiency and tool life be much improved. Growing attention is on eco-friendly substitutes as sectors develop to guarantee sustainability while preserving best performance. By further enhancing tool life and performance, extending machine lifetime, and guaranteeing a high-quality finish, cutting fluids are absolutely essential in metalworking. Manufacturers can maximize their machining operations, lower running costs, and get better general efficiency by choosing the correct kind of cutting fluid and applying it properly.