Vacuum casting

Leverage Leading Edge’s premium urethane vacuum casting for cost-effective, high-fidelity parts production. With our deep silicone casting expertise, we deliver precision and uncompromising quality at every manufacturing stage.

- 1 to 200+ parts

- 10+ plastic grades available

- Versatile manufacturing capabilities

- Ready within 8 days

- 10+ finishing options

What is vacuum casting?

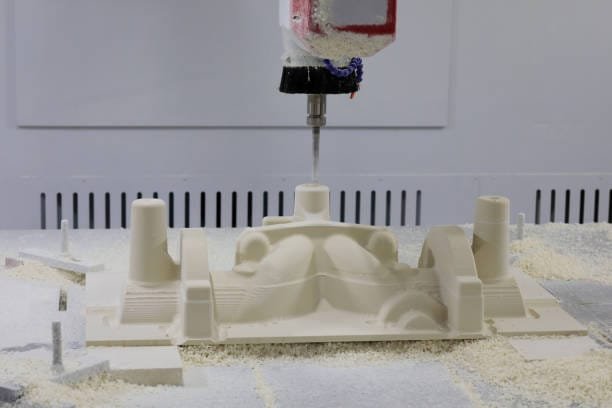

Vacuum casting—also known as urethane casting—starts by creating a 3D-printed master pattern, which is then encased in a silicone mold. Liquid resin is poured into the mold and cured under vacuum to produce a solid, high-fidelity part. From one master you can cast dozens of identical parts, unlocking significant cost savings and rapid turnaround through economies of scale.

Additional polyurethane vacuum casting services

Leading Edge goes beyond basic manufacturing processes and offers a variety of additional services.

Reaction injection molding (RIM)

RIM enables production of higher-quality parts at scale by injecting polyurethane resins into a durable mold under low pressure.

Assembling

Beyond producing individual cast parts, Leading Edge offers full assembly services—seamlessly integrating multiple components into ready-to-use, finished products.

Overmolding

Our molding processes enable overmolding of metal inserts or secondary materials, creating unified parts that combine the best properties of both.

Your project in 6 steps

Get your plastic prototypes or production parts delivered faster than ever. Our agile team offers tailor-made solutions that meet your needs with zero delays.

Step 1: Your quote

Upload files and specifications

Step 2: DFM

Design optimizations

Step 3: Tooling

Sampling and adjustments

Step 4: Production

Close follow-up

Step 5: Quality control

Dimensional report, pictures, and videos

Step 6: Delivery

Packing, door-to-door tracking

Applications

Vacuum-cast parts are ideal for rapid prototyping and short-run plastic production. These versatile components support engineering models, market testing, proof-of-concept, and small-batch runs—serving as a seamless bridge to full-scale manufacturing.

Vacuum casting materials

We offer a broad portfolio of urethane resins from top global suppliers like Sika and Heicast. Our materials can mimic everything from rigid to flexible plastics—complete with options for high-impact strength or flame retardance—so you get prototypes and production parts perfectly tailored to your performance needs. Below is a sample of our most popular vacuum casting resins.

All materials

Heicast 8263

Heicast 8400

Heicast 8150

Heicast T0387

Sika PX223 HT

Sika UP 4280

Sika PX 5690

Pelnox UR-2180

Sika PX 5210

UX50

Sika PX 527

Sika PX331

General vacuum casting characteristics

General tolerance:

Mini tolerance of +/- 0.3 mm / 0.010 in and then 0.05 mm / 0.002 in every 25 mm / 1 in

Precise tolerance:

Leading Edge will check your 2D drawing and give you our comments

Maximum part size:

1000 x 1000 x 600 mm / 39 x 39 x 24 in

Minimum part size:

0.50 mm / 0.020 in (may depend on part geometry)

Lead time:

From 5 days

Vacuum casting finishes

Explore our diverse range of finishing options that offer numerous benefits, including enhanced aesthetic appeal, and ultimately bring your prototypes to life.

Also known as mirror polishing, this premium finishing process delivers parts with a flawlessly smooth, reflective surface and striking visual appeal.

This type of finishing is a high-level polishing, also known as mirror polishing, that gives the part a smooth, reflective, and aesthetically pleasing appearance.

Achieve varying levels of transparency based on your chosen technology and material—then fine-tune opacity with polishing, sanding, or in-mass pigmentation for the perfect translucent effect.

Whether through specialized surface treatments or in-mass pigmentation, precise color matching ensures your prototypes and parts meet exact specifications and achieve the stunning visual quality your final product demands.

Enhance both function and style with our premium paint finishes—choose from satin, matte, gloss, or semi-gloss to achieve the exact look and performance you need.

Chrome plating uses galvanic or vacuum techniques to deposit a thin chromium layer onto your parts—delivering a high-gloss finish while boosting corrosion and wear resistance.

Vacuum casting capabilities

Our vacuum casting capabilities combine in-house silicone mold fabrication, precision urethane pouring under vacuum, and a full suite of post-processing options to deliver high-fidelity parts from 1 to 200+ units. With dedicated casting cells and ovens, we support over 10 resin formulations—rigid, flexible, flame-retardant, and high-impact grades—ensuring your prototypes and small-batch runs mirror final production materials. Fast turnarounds, tight dimensional control, and turnkey surface treatments make our vacuum casting service the go-to solution for bridge tooling, market testing, and low-volume production.