Meta Description: Learn the detailed structure of metal casting such as sand casting, die casting, investment casting among others. Discover processes, applications, including pouring molten metal putting processes to use, the benefits, and the option of selecting the most suitable casting procedure to diagnose your manufacturer.

Metal casting is among the most versatile and basic production industries in the modern manufacturing industry and it allows the production of intricate metal wares which would have been undoubtedly difficult or impossible to forge using other production techniques. Since the earliest bronzes cast over 3 millennia ago to the latest engine blocks in the automotive industry, casting has taken human civilization and solidified innovative advances in so many industry.

Knowledge of basic types of casting is essential to the manufacturer, engineer and procurement professional and can hardly be overemphasized. Both casting techniques have distinct advantages, constraints as well as applications that qualifies them to be versatile to a given set of needs. No matter whether you are engaged in mass production of automotive components, creating precision aerospace elements, or manufacturing custom equipment programs; the type of casting manufacturing process chosen determines both quality of the product made and its cost-effectiveness and efficiency in the manufacturing process.

In manufacturing practice Nowadays, the world is globalized to the extent that manufacturing companies have to become more logistically efficient to support the casting process. Being a professional logistics operator which provides services in global freight forwarding and supply chain service industry, we assist manufacturers all over the world in supplying raw materials, finished castings as well as respective equipments across international borders. We offer end-to-end services such as air freight, sea freight, China-Europe railway transportation, and its customs clearance, which fulfill the need of casting industry with a complicated supply chain.

Sand Casting: The Foundation of Metal Casting

Sand casting is the most common and most economical process of casting and makes up most or about 60 percent of all metal castings being cast all over the whole world. It is a classical process incorporating usage of a mold cast by finely prepared special sand and molten metal is poured into a mold, to give the desired shape. It starts by forming a pattern which also takes a shape of wood, plastic, or metal which in turn acts as a prototype to the final casting.

The casting method, which is sand casting, employs the use of green sand that is made up of silica sand, clay and water whose combination makes it an ideal molding material and permeable. The impression is stamped in the sand mixture leaving a cavity with a shape that equates with the geometry of the part on demand. As soon as the pattern is taken out, molten material is poured into the hole and cooled down and solidified, then the casting can be released by breaking the sand mold away.

Sand casting is used when high volumes of large, intricate parts are to be made with difficult inner geometries. Enormous varieties of metals and alloys, such as iron, steel, aluminum, bronze, and brass are accommodated by the process. The auto industry, the building business and heavy equipment sector are the major users of sand casting for producing various cast objects such as engine blocks, transmission cases, pump castings and structural pieces.

Die Casting: Precision and High-Volume Production

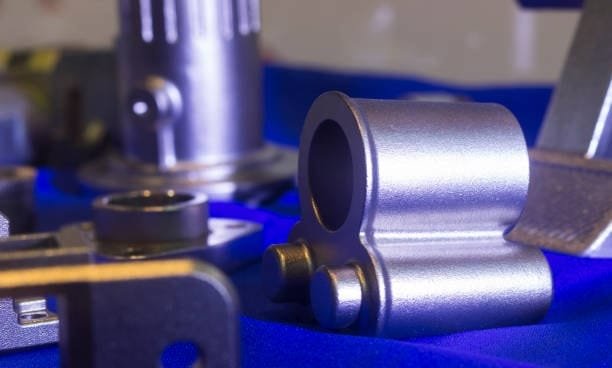

Die casting changes metal casting by enabling production of a lot of small, precision, dimensionally correct components with reusable steel molds, or dies. The process is where hot molten metal is pressed hard, with high pressure, into a die cavity, producing both good surface finish and tight tolerances so that secondary machining is frequently unnecessary.

The die casting process functions in two major categories that are hot chamber and cold chamber die casting. Hot chamber die casting is suitable to alloys with low melting point (such as zinc and tin), and cold chamber die casting to metals with high melting point (such as aluminum and magnesium). It fills the full die and due to high pressure application has better mechanical properties in the parts.

In particular Die casting is a good fit in the automotive, electronics, and consumer products markets. Automotive applications are transmission cases, engine parts and structural parts, whereas in electronics precision housings and heat sinks are being used. The process is extremely repeatable and is thus suited to high volume runs where consistency is required.

Investment Casting: The Lost Wax Process

Investment casting (or the lost wax process) is used to cast metals to provide an outstanding surface finish and dimensional consistency. The old practice enhanced using the new technology has been making complex parts with complicated geometries, which would otherwise be difficult to make using any other type of casting. In this, part of the lost wax casting proces there is a procedure that starts with the production of wax pattern that exactly replicates the desired end part.

The process of investment casting has multiple accurate stages, i.e., creation of the wax pattern, ceramic shell construction, wax elimination, and metal cooling. Several wax patterns are recombined around a core sprue system and dipped (sometimes more than once) in ceramic mixture and covered in a refractory composition; a foundation that forms a tough shell. The wax is eliminated and only a exact hole is left to pour the metal.

Due to a wide range of applications, investment casting is used almost everywhere almost in aerospace, medical, automotive, and jewelry industries. The excellent surface finishes offered by the process help in making aerospace components like turbine blades, structural brackets, and parts of the engine. Investment Casting is used to provide the accuracy and compatibility of material with biocompatible materials, including high melting point metals, in medical implants and surgical instruments.

Permanent Mold Casting: Reusable Precision

Permanent mold casting This process uses the metal molds which are normally of steel or cast iron that are re-usable to cast several pieces. This process involves a blend of sand casting and die castings, as it has higher dimensional accuracy than sand casting and more affordable than die casting in medium-run production volume.

The mold used in permanent mold casting is preheated, surface finish coating and release coating are applied on the mold and there is a pour of molten metal which is either by gravity or by low pressure and then controlled cooling. With a reusable mold, part quality can be ensured as well as little amount of material wastage seen as compared to the expendable mould processes.

Some industries that employ this method of casting are the automotive industry, aerospace and general manufacture industries. Aluminum wheels, engine components, engine pump, structures, and other fixtures are some of the common uses. This is a particularly good process with Aluminum- and Magnesium alloys, but many other metals are suitable with suitable mold materials and processes.

Shell Mold Casting: Enhanced Surface Quality

Shell mold casting is a level casting process that makes aggressive, thin, and high molds in resin-bonded sand that make castings with high grades of surface complete and dimensional control compared with customary sand-sac casting. It is done through the production of heated metal form, the application of resin-coated sand, and establishing a thin shell, which acts as the mold cavity.

The shell mold casting method starts by heating the metal pattern using about 230-250 o C temperature; The molten metal pattern is then placed upside down into a box that has resin-coated sand. The resin when heated cures and glues the sand grains together in a shell around the pattern. Once cured, the shell is removed off the pattern and is joined with a matching half, and then was used to pour metal.

The uses of shell mold casting are in automobile, aerospace and precision machining. It is especially good at making small to medium-sized components that need to be finished with a good surface and need dimensional tolerance like gear housing, valve bodies, and other mechanical-related parts. The better surface quality normally eradicates or minimizes the need on machining.

Centrifugal Casting: Utilizing Centrifugal Force

Centrifugal casting uses the centrifugal force to create hollow cylinder parts with high material properties and low porosity. The process is specialized since the molten metal is poured into a rotating mold and the centrifugal force evenly distributes the metal and pushes the impurities to the centre leading to dense and a high quality casting.

Centrifugal casting procedure works in the true centrifugal casting of hollow components and semi centrifugal casting of solid components that have radial symmetry. The pouring method, the rotation speed and the design of the mold should be carefully applied so that the outcomes can be achieved. The advantage of the centrifugal force is that it does not require cores in hollow parts and delivers better mechanical characteristics.

Major uses of centrifugal casting are in pipes, tubes, bushings and cylindrical parts of diverse industries. Centrifugal cast iron pipes are used in the water and sewer systems, with aerospace and automotive industries finding high strength cylindrical parts useful. The process especially works well with such materials as cast iron, steel and bronze.

Low-Pressure Die Casting: Controlled Metal Flow

Low-pressure die casting utilizes a carefully-controlled low pressure in order to press molten metal into die cavities, which provide much better flow of metal with little turbulence as well as higher quality of casting as compared to gravity casting processes. This technique is very tight in terms of control of the metal delivery, and this allows the manufacture of thin-walled, complex castings with the best mechanical properties.

In the low-pressure die casting method molten metal is sealed into a furnace and pressure applied by air to the molten metal which is forced upwards against a tube up to the die cavity. The consistent pressure at the fixed values allows full die filling with the minimized turbulence and entrapment of gases. The pressure is discharged after the solidification and the rest liquid metal goes back to the furnace.

Low-pressure die casting is widely found in the automotive industry, especially aluminum wheels, suspension parts, engine. Means the process offers high-quality surface finish, dimensional accuracy and mechanical properties and it remains cost-effective in terms of production needs: medium, large volume. The high-strength and lightweight property of components generated through the expendable mold casting process extends to aerospace applications as well.

Vacuum Die Casting: Eliminating Porosity

One of the major problems of the normal die casting is eliminated through vacuum die casting which is the air and gaseous trap which leaves some of the cast as porous. With this advanced process a vacuum is also formed inside the die cavity prior to and during injection of metal, this virtually eliminates the occurrence of gases that would cause defect in the casting product, and enhances the mechanical properties of the final cast.

The vacuum die casting process uses vacuum systems in the evacuation of the die cavity after which they inject metal. Once the cavity is completely full of molten metal, the vacuum still removes the gasses hence, there is no porosity and the die is filled completely. This leads to increased strength of the castings, ductility and the surface finish of the castings as compared to the traditional die casting.

Vacuum die casting finds immense use in high performance applications in automotive, aerospace and electronics industries. Improved mechanical properties and low defect rates are used to make critical safety components, lightweight structural parts, and electronics housings of the highest precision. The method is especially ideal in instances where porosity may be disastrous to the performance or safety.

Squeeze Casting: Combining Casting and Forging

In squeeze casting, the advantages of casting and forging are merged in that high pressure is exerted on molten metal that solidifies in a die. The hybrid method does away with porosity due to shrinkage, improves grain structure and castings have a mechanical property close to wrought castings.

Squeeze casting technique is a process, which entails placement of molten metal into a preheated die, followed by application of high pressure during solidification. The force or pressure, which is normally between 50 150 MPa, removes the gaps between the surfaces of the die and solidifying metal and provides high contact between the die and the metal. It leads to high quality of heat transfer, finer microstructure and superior mechanical properties.

Use Squeeze casting can be used in car manufacturing industries and even aircrafts industries to produce vital parts that need extreme strength and good performance. Applications are rods in connecting rods, suspension and structural brackets where high strength-to-weight ratios are critical. The method is especially advantageous to aluminum and magnesium alloys where parts made through it have better qualities than those done traditionally through castings.

Lost Foam Casting: Pattern-Free Innovation

Lost foam casting does not require cores or draft angles because of expandable polystyrene patterns; when it comes in contact with molten metal it vaporises. This process is innovative in that allows manufacturing of complex inner shapes as well as near net-shape castings with great dimensional accuracy and finishing.

The first step in the lost foam casting process involves making patterns by means of polystyrene which has the same shape as the required casting. These shapes are impregnated with refractory, pressed into unbonded sand and subjected to molten metal. This polystyrene is roasted and what is left is an empty cavity that will be filled with metals to form the completed casting.

Lost foam casting has significant advantages when making automotive engine blocks, cylinder heads and other complicated structural components. The method removes most of the casting constraints where coolings can be integrally made, lightweighting and complex internal features are possible. This process is used in various industries that include the automotive, art casting, and so on.

Plaster Mold Casting: Fine Detail and Smooth Surfaces

Plaster mold casting produces very smooth surface finishes and a fine details reproduction with plaster of Paris molds. Applications that involve the need of high quality of the surface and a high precision in the dimension as well as non-ferrous metal and alloys of relatively lower melting points find this process suitable.

The plaster mold casting technique is quite easy to understand due to its simplicity consisting in mixing the plaster of Paris with water and additives, pouring the mixture around a pattern, letting it dry and harden. The mold cast produces a perfect surface finish and dimensional accuracy at the cost of having low temperature resistance making it applicable on aluminum and copper and other alloys of low melting temperatures.

Plaster mold casting is used in aerospace, medical and precision manufacturing industries where components need both very high surface finish and high dimensional accuracy. They are used in applications that call for impellers, housings and decorative parts where machining after casting needs to be reduced to minimum. It is a process that is good especially in making smaller products in small production runs and prototype products.

Ceramic Mold Casting: High-Temperature Capability

Ceramic mold casting uses highly tempered ceramic casting, which is used to make casts that can accommodate superalloys and heavy metals meltings. The specialized process allows casting material to be impossible with classical mold materials, and it opens the possibility of more advanced aerospace and industry uses.

Casting manufacture using ceramic mold The ceramic mold casting procedure includes the making of ceramic slurries, the generation of shell molds by a cycle of drying and coating with the slurries and firing up the molds to accomplish the required strength and temperature resistance. Ceramic molds resulting can be heated to temperatures higher than 1500 C hence used to hold superalloys and refractory metals.

Ceramic mold casting on aerospace gas turbine parts such as blades, vanes, and structural parts are largely dependent. The process allows production of complex, thin wall parts in superalloys that offer incredible high temperature performance. Examples of industrial use include parts that go into chemical processing, electrical generation and other high-temperature applications.

Continuous Casting: Streamlined Production

Continuous casting is also seen to revolutionize metal casting because it has made it possible to continuously cast semi-finished products which include billets, blooms as well as slabs. It serves to obviate the use of separate molds, continuously hardening molten metal as it flows through a copper form water-cooled in the case of steel. It produces very economical standard shapes.

The continuous casting involves that molten metal is poured into a water cooled copper mold that moves continuously down the bottom. When the metal touches the mold walls, it starts solidifying and it immediately makes a shell inhabiting the rest of the liquid metal. Solidification is done well through controlled cooling and withdrawal rates, utilizing refractory material to minimize defects.

Continuous casting is the essential component to the production of billets, blooms, and slabs utilized as the product of steel manufacturing plants across the world, which are used as raw materials in rolling mills or the secondary manufacturing processes. The process saves a lot on energy cost and increases the yield as well as the quality of the products produced as compared to traditional ingot casting technologies.

Pressure Die Casting Applications

Due to the capability of pressure die casting technique to give extremely high quality parts with dimensional accuracy at a high production speed, pressure die casting has widespread use in many industries. Automotive is the greatest consumer of pressure die cast components applying the technology in engine blocks, transmission housings and structural components and multiple brackets and fixtures.

Pressure die casting is used to produce housings, heat sinks and electromagnetic shielding parts by the electronics, and telecommunications industries. The process’s ability to produce thin-walled parts with excellent dimensional stability makes it ideal for electronic enclosures that require precise fit and finish. Die cast components in motors, pumps and structural components are also used in consumer appliances. The aerospace sector, though on most occasions involving additional specific procedures, makes use of pressure die casting of non-sensitive components and support equipment. The process’s cost-effectiveness and production efficiency make it attractive for medium-volume aerospace applications where material properties meet specification requirements.

Gravity Die Casting Benefits

In comparison with other casting methods, gravity die casting has various advantages especially with medium size production runs when cost of permanent tooling is viable. It has more dimensional accuracy and surface finish than sand casting requires loss less initial investment than the pressure die casting systems and has an edge over sand casting.

High-pressure equipment has been removed, meaning that the complexity of the system is eliminated and that the use of gravity die casting is more affordable to smaller manufacturers when it comes to maintenance. Improved control over metal flow and solidification is also possible and the process has improved mechanical properties and lower rates of destruction than gravity sand casting.

The use of material in gravity die casting is usually higher than sand casting because of low wastage as well as yield. The investment is low, which is a strong economic incentive by virtue of the reusable nature of the dies, and the monotony of part quality in short runs of a few hundred to even a couple of thousands of parts.

Sand Casting Advantages and Limitations

Sand casting has the greatest casting depth, part size, complexity, and the capacity to cast a wide range of materials thus being the most common casting application world over. Its process handles parts as small as ounces up through tons, and practically has no geometric constraints that complex beyond a fundamental ability to be moldable. The ability to make this flexibility is what makes sand casting suitable to custom and low-volume tasks.

Another big cutting-edge of the sand casting part is cost-effectiveness especially when dealing with large parts or low volumes of production. Sand casting is affordable in that the tooling cost is low, and the equipment is not demanding of the manufacturers of any size. It is also suitable in that prototyping and design updates can be done quickly, with little commitment of permanent tooling.

But the limitations of sand casting are fair surface finish, broader dimensional tolerances, chance of inclusions and porosity. They tend to demand the recurring machining of components and quality checks by secondary processes, which are likely to influence the overall cost and lead time of production.

Investment Casting Material Compatibility

Investment casting is highly compatible with materials meaning it can cast basically every castable alloy; including superalloys, stainless steels, carbon steels, aluminum alloys, copper alloys and even some exotic materials as well. Such flexibility has made investment casting especially useful in aerospace applications in which special materials with specific properties are needed.

The process’s ability to handle superalloys such as Inconel, Hastelloy, and other high-temperature materials enables the production of gas turbine components that operate in extreme environments. These materials could not easily or could not be cast at all with the conventional methods that were used because of the reactive aspect and the high melting points of these castings.

Biocompatible materials for medical applications also benefit from investment casting’s precision and surface quality capabilities. Titanium alloys, stainless steels, cobalt-chromium alloys implants and surgical devices may be cast near net shape with little post-processing required.

Die Casting Alloy Selection

The choice of Die cast alloy greatly influences part performance, cost, and efficiency of the manufacture. Applications of aluminum alloys are the most common in die casting with such properties as excellent castability, strength-weight ratio and corrosion resistance. Aluminum common die casting alloys can be A380, A383, and A413 with different combinations of properties related to various applications.

Zinc alloys have excellent dimensional accuracy, finish and die life, which make them ideal to use in precision components and in decorative work. Zinc die castings are characterised by the minimal post-processing sometimes quite tight tolerances. However, zinc’s higher density compared to aluminum limits its use in weight-sensitive applications.

The density of magnesium alloys is lower than that of other commonly die cast materials which makes them very useful in aerospace and car applications since they have very good strength to weight ratios. However, magnesium’s reactive nature requires specialized handling procedures and environmental controls during processing.

Quality Control in Metal Casting

Metal casting Quality control includes various points covering raw material inspection to acceptance of a final part. The use of incoming material inspection means in place in order to verify that the alloy compositions conform to specifications and that the amount of contaminants achieved are not excessive. Pattern and tooling inspection checks the actual dimensions and surface finish that directly affect quality of castings.

The monitoring of the processes involved in the casting processes consists of monitoring the temperature, timing and observation of the parts being poured. Radiography, ultrasonic testing, magnetic particle inspection, represent non-destructive testing procedures to find the internal flaws that would affect the performance of parts. Destructive testing proves mechanical properties and reinforces qualities of the microstructure.

The statistical process control methods enable one to determine the trends and the variations that might cause quality problems. Frequent calibration of testing instruments and measuring equipment facilitates the achievement of accuracy and repeatable results. Documentation and traceability systems offer responsibility and permit constant enhancement.

Surface Finishing for Cast Parts

Cast parts end-quality and performance largely depend on surface finishing operations. Most of the castings must be machined to obtain final dimensions and surface finishes especially at mating surface and critical areas. Choice of the casting process directly relates to the level of machining needed and costs of production.

Shot blasting is used to remove surface oxides, scale and give a smooth surface texture to allow surface coating. Surface stress releasing and fatigue improvement are another process. The composition and parameters of different blast media allow tailoring the surface properties to certain applications.

Chemical finishing In metallurgy, chemical finishing processes like anodizing on aluminum components and different plating techniques prevent rust and improve appearance. Sometimes the treatments need certain surface preparations which need to be taken into account when deciding which type of casting process to use and part design.

Cost Analysis of Casting Methods

Casting procedures entail the evaluation of various parameters in cost analysis which require the consideration of tooling costs, material usage, labour and the after-process requirements. Sand casting usually has the lowest tooling expense and possibly greater post-processing expense whereas die casting has very initial high tooling investment although it provides near-net parts needing little finishing.

Volume aspects make a major difference when comparing cost-effectiveness. High-volume production processes prefer those that are more costly in terms of tooling but are better in costs per-part, and low-volume applications are well-suited to processes with little tooling expense. Break-even analysis assists in telling the best process to use in certain production needs.

Costs of materials differ among casting processes because of variance in yield, recyclability and process wastes. Die casting can usually use more of a material than sand casting, whereas the investment casting process can sometimes have more material expense because of alloying requirements, and the specialized processing.

Environmental Considerations

Factors to remember during environmental management related to metal casting are the energy consumed, emissions, waste products and any possibility of recycling. Modern casting plants ensure that several provision is taken to reduce effects to the environment without compromising the efficiency and quality of the production.

The amount of energy needed differs variedly across casting rates with continuous casting presumptively being the most energy efficient when maximal quantities are involved. These are the optimizations of the processes, recovery of the waste heat, and the designs of efficient furnaces, which assist in lowering the overall energy demands. In casting processes there is a growing trend towards renewable energy sources.

There is metallic and non-metallic waste stream in waste management. Molding sand reuse can be achieved through sand reclamation systems, and scrap metal reuse can be gained by metal recycling programs. The systems are used to treat cooling water and processing effluents in the interest of environmental discharge standards.

Emerging Technologies in Casting

New technologies still pour into metal casting to extend its ability and efficiency. 3D printing, in terms of casting, is applied in rapid prototyping of patterns, direct sand printing at complex molds, and so on to direct metal printing complex and small parts. The technologies allow quicker development and more freedom in designs.

Design and optimization of casting is progressively being steered by simulation software. The computer-aided modeling of computational fluid dynamics is used to forecast metal flow, solidification direction, and probable defects sites before making simulations. This ability decreases development cycles and enhances the success rate of first article, just as in other casting processes .

Robotics and automation also increase the consistency of the casting process and correct the need of labor and the safety of staff. With automated process, material handling as well as mold making and finishing takes place highly precisely and repeatably as compared to the manual procedure plaster casting.

Global Casting Industry Trends

The current trends in the global casting industry are based on the changing market requirements, technological improvement, and regulatory compulsions. The growing requirement of light weighting processes in automotive and aerospace applications is contributing towards the development of high end aluminum and magnesium casting techniques. These trends necessitate the need of constant innovations in the development of alloys and processes high pressure die casting.

The issues related to sustainability impact the technology of casting and functioning at the facilities. Investment decisions and operational practices are informed by energy efficiency, waste reduction, and circular economy principles. Compliance with regulations is also becoming significant due to the tightening standards of environment throughout the world evaporative pattern casting process.

There is opportunity and challenge of casting globally in the market. Global competition brings efficiency and cost cutting initiatives and provides opportunity to use specialized high value application sand casting process. The complexity of the supply chains rises when the manufacturers are importing material and parts around the world.

Future of Metal Casting Technology

Metal casting technology has more to offer in the future in terms of innovation of raw materials, the process, and their uses. Castings involving advanced materials such as metal matrix composites, functionally graded materials and bio-inspired structures will continue to take casting into new areas of industry and new performance demands vacuum casting.

The casting operations involving digital transformation are also going to intensify because of Industry 4.0 practices. The use of Internet of Things sensors, artificial intelligence and machine learning will perfect the process parameters in real-time and predict when maintenance is needed as well as provide superior quality control capabilities.

The incorporation of additive manufacturing will result in the development of hybrid processes which is a mixture of the benefits of casting and 3D printing. The hybrid techniques will also facilitate the manufacturing of the sections that have complicated internal shapes and functions that could not be manufactured.

Selecting the Right Casting Process

The choice of the right casting process should be made after considering various factors such as the geometry of parts, materials, estimation of the output, quality specifications, cost limitations or constraints. An orderly process of evaluation aids in determining the best method of casting when considered specific applications.

Part geometry design looks at the size, wall thickness, complexity and tolerances demands. There are processes that are best suited at doing well with simple shapes and loose tolerances and those that can handle a complex shape that require fine control in dimensions. Process selection is affected by internal features, undercuts and draft requirements.

This has a marked influence on both the economics of process selection and the volume of production. High-volume applications hold the benefit of investing in permanent tooling and automated systems, whereas low-volume production bow to the needs of a flexible process where little tooling is required. Product lifecycle volume projections should be used in analysis.

Conclusion

Metal casting is a wide use of techniques with various activities that each have distinct benefits to suit a particular application and manufacturing needs. Other than the flexibility of sand casting and the affordability, the accuracy of die casting as well as the time efficiency can be used to make informed choices in manufacturing processes.

Selection of suited casting processes has direct influence on quality of products, costs of production along with efficiency of production. Manufacturers and engineers should also think over part requirements, amounts to produce, cast type of material, and economics in order to find the best approaches to casting. New technologies keep on playing a role to increase the scope of casting and taking care of environmental and sustainability issues.

With the further development of the global manufacturing industry, casting processes will be ready to respond to the new needs related to the lighter, stronger, and more complicated components. The next step, the one to undermine potential changes in the metal casting industry, is the combination of digital technologies, novel materials, and sustainable approaches to casting that will make it relevant in contemporary manufacturing.