The Computer Numerical Control (CNC) machining is probably one of the revolutionizing technologies in the contemporary manufacturing industry that allows precise machining of even the most complex components of various productions. The CNC machining tools fall into different forms such as turning, cutting(milling), drilling and grinding tools, which are essential for various machining operations chamfering tools. The most common of them are the CNC cutting tools. Effectiveness of any CNC operation basically relies on choosing and applying appropriate cutting tools in particular applications. The continuous world of CNC tooling is a broad subject to be covered, and this book discusses it to the extreme, beginning with conventional drill bits all the way to elaborate cutting tools which allow manufacturers to be at the age of exceptional precision and efficiency.

Understanding CNC Machine Tooling Fundamentals

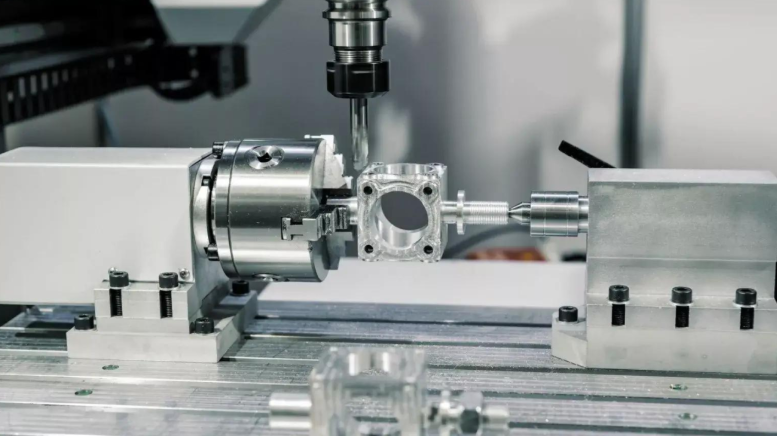

Automated manufacturing process is built on CNC tooling. A cutting tool is a tool which cuts, shapes, and removes CNC Machining material off a workpiece, including boring tools . It uses the shear deformation procedure. CNC machines have machining tools fastened on spindle. They spin at a whiplash pace and they are programmed by computer numerical programming, ensuring efficient material removal from the workpiece . Machining accuracies and quality of machined parts are directly proportional to the applied and correct selection of cutting tools.

The principle underlying CNC tooling is a semblance of guided material elimination by means of well-timed movements of rotating cutting tools. The current advanced CNC equipment can accept multiple tool geometries, including milling cutters, and are specific to the operations to be carried out: drilling, milling, turning and finishing. It is important to be versant in such fundamentals to optimize milling operations and the processes of machining and to attain expected part specifications.

Essential Drill Bits for CNC Machining

Drill bits and milling cutters re the simplest cutting tools that can be used in CNC machining. Drill bits possess a shaft with two spiraling cuts finishing with a conical cutting point. Its cutting tip angle tends to be 120 and the helical grooves serve to eject the chips to the exterior of the drilled hole. These devices make holes along cylindrical shapes with several sections of preciseness, which rely on how the gadget is designed and used.

The geometrical feature of drill bits actually influences the performance aspect of the drills. The helical flutes are better because they can act as cutting edges and carry the chips away in addition to permitting the coolant to reach the cutting area. Effective flute design grants effective material evacuation without the occurrence of chip clogging, which may create a situation by damaging the hole quality or the life of the tool, emphasizing the importance of tool geometry .

Types of CNC Drill Bits and Their Applications

CNC machining drill bits are normally available in three types-center, twist and ejector drills, which can be used for creating both internal and external threads and all these three are having different significant key roles. All the variants have certain functions during the process of machining, which makes the work in general efficient and the quality of parts good.

Center drill bits make specific start points confident on further drilling activities. These tools are characterized by short and stiff constructions which are not easily deflected to give the right placement of the hole. The conical structure offers great centering capacity, the key element in maintaining between dimensions in important applications.

The most popular type of drilling tool is twist drills in CNC. They have a helical flute which is capable of good chip evacuation and assures structural integrity under cutting. These multi-purpose tools can work on a wide range of materials and holes, which make them very useful in any general-purpose machining.

One of the best areas of ejector drills is under deep hole drilling where chips can get difficult to evacuate. Their special design has coolant delivery systems that clean chips off the zone of cut to avoid clogging tools and sustaining the cutting performance regardless of the prolonged drilling work.

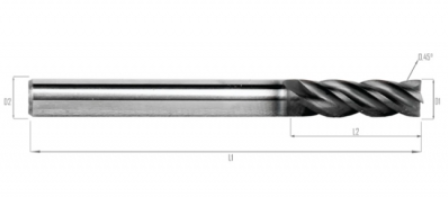

Comprehensive Guide to End Mills

End mills are versatile as compared to drills. They tend to possess anywhere between 4 and 8 sharp cutting edges and sides. Hence, they have the capacity to extract huge amounts of material in a minute. The simple cutting tool is end mill in case you would like to CNC machine parts. These tools are very versatile doing various jobs such as slotting, profiling, contouring and face milling.

End mills have multi-flute configuration and this allows them to cut more material faster than single-point tools. The cutting forces are distributed by each cutting edge, lessening tool wear and upsurging the scheme of surface finishes. The amount of flutes influences the cutting ability as well as the capability of chip evacuation in which stringent considerations need to be taken depending on the particular machining characteristics, especially when using high speed steel tool .

Standard End Mill Configurations and Features

The basis of most CNC milling activity is the standard end mill. This is because of their balanced design which produces the best performance on different materials and cutting conditions. The tools usually have straight or spiral flutes to improve evacuation of chips and rigidity resulting to structural rigidity to guarantee precision machining.

The performance qualities of standard end mills are affected by the cutting edge geometry. The cutting staff is reduced by sharp cutting edges and surface finish is better with strong edge preparation resulting in a long tool life. Newer-style end mills frequently have highly developed coatings, which increase tool life, as well as allow faster cutting.

Roughing End Mills for High-Volume Material Removal

Other than the normal end mill that is mostly used, it should be noted that there is the rouging end mill. End mills come in a variety of Rouging end mills. Their shearing blades are discontinued on the sides so as to cut up more material. They are supposed to cut materiel with a very rapid rate and then a finishing mill is used. These are super quest tools which maximize material removal rates in roughing.

Interrupted cutting edge of roughing end mills fractures chips into small fragments and minimizes cutting forces and power. The feature allows high cutting parameters without sacrificing acceptable tool life. The produced surface usually needs other finishing processes to meet final dimensional and surface quality specifications.

Ball End Mills for Complex Surface Machining

The Ball end mills are being used to create a spherical hole but it is also used to machine curved bars. Working on curved surfaces the ball end mill has as many passes as possible and they are very near each other to limit the creation of small ribs on the path of the machine. Hence the application of ball end mills is not as faster as a normal end mill, but the outcome is fantastic. These are customized to perform better in 3D contouring and generation of complex surfaces.

Ball end mills due to their spherical cutting geometry form smooth rounded surfaces. There are no acute changes that may undermine the functionality or look of the parts due to the constant radius. The point contact at the tip of the tool however must be programmed carefully to give a consistent surface finish at different angles of the surface.

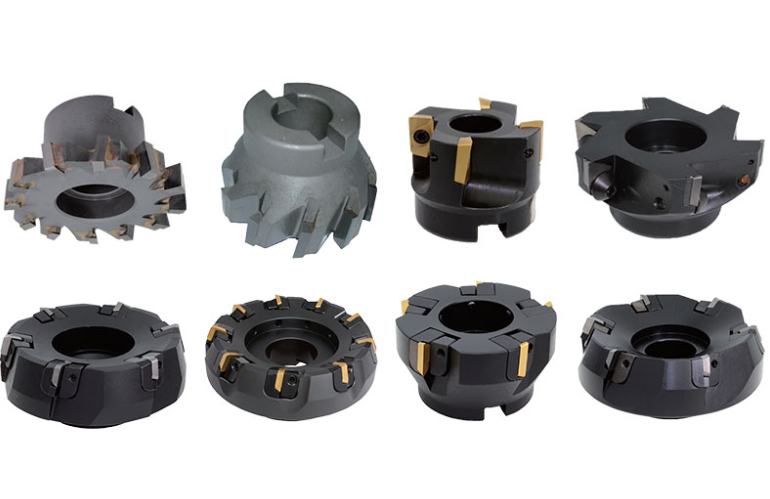

Face Mills for Efficient Surface Preparation

When machining a work piece the first stage would be to ensure that all the surfaces are flat and straight. Hence we apply Face mill since it has a large diameter and cuts the material at the bottom of the mill. They would perfectly suit to machine any flat surfaces in high speed. Typically, such mill is bigger in body, with renewable blades used in cutting. Face mills maximize production when doing surface preparation.

Face mills come in large diameters which allow high material removal rate since the cutting speed is higher. The cutting forces are shared by multiple cutting inserts causing less tool deflection and flatter surfaces. The replaceable insert is easier to machine cost wise compared to other systems as it has concurrent performance towards cutting during the lifetime of the tool.

Precision Reaming for Accurate Hole Finishing

It is in most cases impossible to drill a hole to a diameter of a particular tolerance. In order to get holes of a particular specified tolerance concerning the workpiece material, we use reamers. Tolerance tables which are used to assist in the selection of correct tolerance per hole diameter. With respect to each of those tolerances there is a reamer. Reamers bring the precision required in making close dimensional tolerances in a drilled hole.

Reaming processes are used to remove insignificant amounts of material and considerably enhance the geometry of holes and finish surface. Reamers have a multi-flute design which results in uniform material removal of the hole circumference eliminating irregularity that would possibly lead to functionality impairment of the parts. It is important to have correct speed and feed to manage reaming technique to obtain maximum results.

Specialized Edge Forming Tools

Using an external round mill we cut a radius on an outside edge. What occurs is rounded edge. Some cutting tools are used to produce designed features of the edge that make the part more functional or decoration (safety). Round shapes get rid of sharp corners that may induce injury or stress concentration in a mechanical implementation.

External round mills have curving cutting surfaces to produce regular radius geometry along edge profiles of parts. Such tools must be well programmed to ensure that they constantly stay in touch with the workpiece when tooling along intricate edge paths. The round edges that are created enhance the safety in handling parts and durability.

Hollow Mills for Specialized Applications

The hollow mills resemble the end mills. The variation here is, it has a hole on the center. By doing this it can be machined a stud of given diameter in one direction only by cutting downwards. These special work tools make it possible to create special machining plans related to special geometric needs.

These mills can mill around existing features or achieve certain geometric relations due to its hollow construction design. This is very useful especially when precise concentricity is needed or when machining parts actually formed. The core opening makes it easy to feed the coolant into the place of cutting.

Threading Tools for Mechanical Fastening

Machined parts contain a lot of threaded openings. Or we mount electronics on it or we mount other mechanical components on it. Thread in a hole is formed by the use of thread taps. That is called internal thread. Threads come in various standards as the Metric and the UNC standard. Threading functions produce needed fastening characteristics on machined parts.

Thread taps cut create threads internally by exertion of a relative cutting, creating a profile of thread geometry. Cutting process has to be closely taken care of by paying proper focus on cutting speeds, coolants applications as well as chip evictions so that the tool does not break or the thread gets spoiled too. The modern thread taps are now being provided endowed with specialized coatings that facilitate such tough materials.

Thread Cutting Mills for External Threading

This kind of mill also known as a thread cushion is used to cut external thread as this suggests. The threads on bolts among the other various purposes are external. Thread cutting mills offer flexibility in external thread manufacture, better degree of control than conventional threading and cut thread taps with integrated chip spaces.

These cutting tools allow cutting the threads without a reversing movement inherent in conventional threading operations. The cutting process happens continuously hence minimizing the cycle times and resultant in top-quality threads. Thread mills may also salvage worn or damaged threads, or thread material where tapping would be difficult.

High-Speed Fly Cutters for Surface Finishing

When a rough surface requires to be made smooth and flat in a very short time a Fly cutter is preferable. It is the kind of mill that has a long arm which does not cut except at the end. The slab mill has a greater cutting speed due to the large diameter Fly cutters are used to produce large surfaces that are of a flat nature with embarked savings in tooling.

The fly cutters have single-point cutting designs that produce highly superior generating surface finishes at high cutting speeds. The effective diameter is huge, making it remove large amounts of material easily across large surfaces. The non-balanced nature of the cutting forces however means that strong machine tools and attention during programming are necessary to keep the accuracy.

T-Shape Mills and Slitting Saws

Undercuts and grooves in the cutting direction normal to the rotation axes of the cutting tool develop in T-shape mills. Whereas slitting saws, as compared to T-shape mills, are employed in order to create a thin-cut on a vertical surface. The special instruments form special geometrical features which are needed in the mechanical assemblies.

Mill T-shaped produces undercuts accepting gasket or seal or other mechanical items. There must be the safeguarding of tool accessibility and work stock restraint to avoid an interference because of the right angle gouging. Slitting saws are effective tools that belong to the segmentation activities or the making of narrow clefts in the workpieces.

Countersink Mills for Fastener Preparation

Use of countersink mills is employed in machining chamfers on holes and edges. To achieve a well rounded countersunk hole one should lower the speed at which the cutting tool rotates. A Flush-mounted fastening can be performed by creating countersinking to do professional finishing.

Countersink mills cut conical holes that leave space to fasteners below part surface. Controlled cutting parameters are needed to control a chatter or a poor surface finish due to the angular cutting geometry. Effective countersinking increases functionality and appearance of final products.

Carbon Steel Cutting Tools

Material that is usually used in machine soft metals like brass, magnesium, aluminum, and cast iron. More precisely, other cutting tools of mills and carbon steel have the good price-quality ratio. Meanwhile they provide an excellent machinability. As an explanation of this, these tools will be fabricated using an alloy of 1 percent carbon. Carbon steel is economical when it comes to cutting the non-ferrous materials.

Carbon steel is of moderate hardness therefore sharpening and renewing it is easy and gives sufficient performance when put to the correct use. Such tools are effective at slow cutting speeds, and with adequate use of coolants. They are affordable and appealing in prototype efforts or in low volume production.

High-Speed Steel (HSS) Tool Advantages

The high-speed steel is quite similar to carbon steel. With the exception that they are alloyed all together with additives such as Chromium, vanadium, tungsten and cobalt. We refer to them as occasionally HSS cutting tools. However, one of the traits of High speed steel tools is that it good temperature resistance and lasting. We machine aluminum and also steel components with our HSS cutting tools. The HSS tools have a broader performance capability; they have better performance across a variety of materials.

The alloying additions of HSS enhances hot hardness so that the cutting speeds can be increased without affecting tool wear. This feature allows the machining tools’ life to be maintained with enhanced productivity. HSS tools are very versatile and they can comfortably absorb the machining of ferrous and non-ferrous materials in most machining tasks.

Carbide Cutting Tools for Heavy Machining

There are tungsten and carbon in carbide tools. This entails a mixture of the first two categories of materials in the production of cutting tools. Good thing about the carbide tools is that they are not affected by heat, corrosion and high temperatures. They also have a capacity to do heavy machining using multiple interchangeable cutter inserts . Carbide tools can be considered as the best option in challenging machining requirements.

The unusual rigidity and high melting temperature of carbide facilitates high feeds and speeds and long tool life. These tools have sharp cutting edges that work at high temperatures thus they can be utilized in high speed machining processes. Nevertheless, the brittleness of carbide needs special handling and the techniques in use.

Ceramic Cutting Tools for Advanced Applications

Ceramic material mills are very efficient. Moreover, they are resistance to heat and corrosion what makes them highly appropriate to CNC machining of steel and hard alloys of steel. Ceramic tools extend the envelope in the area of specialized performances of machining.

Compared to the old tool materials; the ceramic materials provide better hot hardness, which makes it possible to achieve very high cutting speeds. Their chemical resistance give them a great performance in hard to machine materials. Ceramic tools however need stiff machine tools and thoughtful programming to avoid early failure since they are brittle by nature.

Tool Holder Systems and Interface Standards

Good tool holding systems guarantee good positioning of the tool along with secure clamping of the tool during machining tasks. Different interface standards such as CAT, BT, HSK etc gives different degree of precision and strictness. Machining accuracy, tool life and productivity is influenced by the type of tool holder system that is used.

Tool holders today feature controlled features like coolant delivery, balanced clamping and precision interfaces and offer better machining performance. The connection between tool holder runout, and part quality is such that you need to have them checked and maintained frequently.

Cutting Parameter Optimization Strategies

CNC machining requires well-optimized cutting parameters such as speed, feed, and depth of cut obtained during successful machining. These parameters have the direct effect on the tool life, surface finish, dimensional accuracy and productivity. The parameter selection involves material, the shape of the tools and limits of the machines.

Better optimization of the cutting parameters means the knowledge of how the different machining variables are linked between them. Sun CAM Software includes databases and algorithms that help to make a selection of parameters, however, the skills and experience of a machinist are also needed in judging the specific requirements of an application.

Tool Path Strategies for Efficient Machining

Proper use of tool path programming will achieve high productivity without compromising part quality and the life of the tools used. Some strategies include trochoidal milling or adaptive clearing, and high-speed machining techniques, which allow intensive material removal and providing protection of cutting tools. Tool path needs to be designed properly in order to avoid as many tool changes and setups as possible.

The more advanced CAM systems have advanced tool path strategies taking into account tool deflection, machine dynamics and workpiece geometry. These plans allow lights out machining as well as uniformity in production of the part in successive runs. The knowledge of the principles of a tool path should enable machinists to streamline a program on a particular application.

Workholding Considerations for Tool Access

The work holding should be able to clamp safely and be able to offer exposure to all tool surfaces needed. The nature of interaction between the workholding and tool choice to a certain extent influences the approach to programming and cycle times. New Fixturing may allow intricate parts to be machined with fewer operations.

Recent trends in workholding systems use some elements of automation, modularity, and multisided accessibility to improve flexibility. When workholding design is integrated with tool selection, this means that finishing of the best quality will be ensured and that the work will be finished optimal.

Coolant Systems and Tool Life Extension

Appropriate use of coolants considerably influences the life time and quality of the parts produced during CNC machining procedures. Each of the flood coolant, high-pressure coolant and air blast systems has its benefits in terms of the application. The choice of coolant influences the chip removal, thermal control, as well as surface quality.

Elaborate coolant systems contain the characteristic of through spindle delivery, programmable flow rates, automatic cycling which aids in performance. Along with the tool life, there is the application of the coolant that should be carefully considered whenever planning the production in terms of cost analysis.

Quality Control and Tool Monitoring

CNC machining requires proper quality control based on the knowledge of characteristics of tool performance and wear. Monitoring of tool during machining procedures is able to verify tool wear and forecast failures, allowing tool changes before rejection of parts occur cnc milling tools. Trends and the optimization of machining processes are achieved with the help of statistical process control techniques cnc milling machines.

Personal machining technologies include sensors and monitoring systems on the machines to observe real time tool performance cnc milling cutters. Such systems facilitate a predictive maintenance solution that decreases the downtimes and leaves the quality of parts consistent. The combined data of monitoring with the production systems leads to useful knowledge aimed at being constantly improved cnc turning tools.

Cost Analysis and Tool Selection Economics

The decision on tool selection should be based on all the factors including initial price and total price of the tool ownership i.e. tool life, productivity and the quality carbon steel tools. It can pay to invest in top-quality tools and pay more initially because they can perform better and last longer. The elements to be considered in economic analysis are time rates on machines, cost of scrap and labor.

Life cycle costing is an extensive method of the tool selection so that all factors are taken into consideration cnc machine shop. It is useful in analyzing the optimum cost effective tooling solutions available to each application within specific quality standards required.

Emerging Technologies in CNC Tooling

Cutting tools get to do more and more through advanced coating technologies. Diamond like carbon (DLC) and titanium aluminium nitride (TiAlN) and other specialist coatings are used on tools to extend their usability in challenging tasks. The coatings offer better wear, low friction and good chemical stability.

Cutting tools design and manufacture are starting to be affected by the additive manufacturing technologies gear cutters. The 3D printing techniques allow intricate internal shapes and tool designs which are custom designed. Such technologies can be used in the innovation of tool optimization and customization.

Industry-Specific Tooling Applications

There are specific challenges that need to be treated differently by using special tooling solutions in the different industries. Aerospace Agencies The aerospace world also requires highly specialized equipment that can create the most fine precision from handling exotic materials. The focus of automotive manufacturing is productivity and volume consistency of high volumes. The production of medical devices needs to have tools that are precise and biocompatible.

Appreciation of the industry needs helps in selection of tools and methodologies of tool application. Industry-specific tools are much more efficient than all-purpose ones.

Troubleshooting Common Tooling Problems

The most widespread problems in the CNC machining are tool breakage, high wear, and inadequate finish. Effective troubleshooting strategies involve systematic problem diagnosis that enable proper solutions to be put in place. Knowing exactly how the cutting parameters, the geometry of the tools, and the machining results properly correlate, one will be able to solve the problem in a short period of time making cnc tools.

Preventive maintenance plans prevents manifestation of some of the common tooling issues before it hits the production line. The frequent inspection plans, correct handling of tool and coverage replacement plans reduce unexpected breakdowns and ensure the parts are of good quality.

Training and Skill Development for Tool Management

A good management of the tools needs an effective knowledge of the cutting tool technology and the application principles. Training systems are supposed to include training on tool selection, parameter optimization, troubleshooting as well as on safety procedures. Life-long learning keeps machinists at par with the changing technology and best practices.

Professional development and certification programs contribute to acquiring knowledge about cutting tool technology. Access to specialized knowledge and application support is achieved through industry partnership and vendor training program.

Safety Considerations in Tool Handling

Isolates Shoe is needed when using any cutting implements and processing CNC machineries. There are such parts on the possibilities of hazards, such as sharp edges, circular patterns, and high-pressure coolant systems which would need a proper safety consideration. Safe work practices and use of personal protective equipment reduces the chance of injury.

Machine shop safety in general as well as the hazards that are specific to cutting tool handling should be covered in safety training. First aid training and emergency measures offer an extra reinforcement in the machine operators and the maintenance workers.

Future Trends in CNC Cutting Tool Technology

The use of artificial intelligence, machine learning technologies is starting to affect the process of cutting tools selection and optimization. The embedded sensors in smart tools could give feedback in real-time of cutting conditions and the state of tool wear. These technologies had the potential of facilitating automated optimization of machining operations.

Sustainable manufacturing applications are creating an effort towards the creation of more environmentally conscious cutting tools and processes. The tool materials used can be recycled, the coolants are bio degradable, along with energy efficient strategies used to machining so that the machining can be taken care of but environmentally they can be adjusted.

Digital Integration and Industry 4.0 Applications

With manufacturing execution systems and the integration of cutting tool data, the inventory and production planning can be done better. Simulation technologies and digital twins aid in the optimization of the choice of tools and the forecast of their performance prior to the creation of the actual machining. These abilities minimize the application of trial-and-error strategies and enhance the initial-part success exertions.

Centralized databases and analytics management Corporate cloud-based tools management systems offer a multi-site solution, supporting the capabilities of centralized databases and global cloud-based analytics. These networks facilitate the exchange of the best practices and organization-wide learning in the manufacturing organizations.

Environmental Impact and Sustainability

Sustainable tooling takes account of the whole life-cycle contribution of cutting tools and includes all processes involved to obtain raw materials, manufacture of a tool and disposal of the waste. Carbide recycling programs save valuable resources and help save the environment. Use and maintenance of the tool set to achieve a longer tool life saves resources.

Green manufacturing practices favor the use of clean coolants and cut techniques that force lesser energy use. These practices have been found to give cost advantages as they also contribute towards corporate sustainability.

Global Supply Chain Considerations

The supply chains providing cutting tools exist across different markets and have diverse delivery capacity and quality standards worldwide. The trade offs in strategic sourcing have to take into consideration costs and quality, availability and lead time. The local supplier relations are responsive whereas the global suppliers can be cheaper.

The need to ensure supply chain resilience has grown more lately after the disruptions that were experienced globally. Multi-supplier sources and inventory management of strategic importance move to maintain production capacity even when the supply chain has failed.

Conclusion

CNC machine tooling has an immensely wide range of cutting tools which have the appropriate application and material to be used. Whether it is a simple drill bit or a complex ceramic cutter, the right choice of the cutting tool and the way it is utilized can make a major difference with regard to the success of the manufacturing process. Knowledge of tool capabilities, properties of materials and requirements of use will allow optimal choices of tools to balance productivity, quality and cost concerns.

The contemporary CNC machining is still developing along with the evolving tool technologies, monitoring and digital integration abilities. Lucky manufacturers invest in the entire tooling knowledge, effective training, and controlled methods of tool management. With manufacturing requirements still at an all-time high, the recognition of efficient choice and utilization of cutting tools will simply continue growing.