Introduction

Modern manufacturing depends critically on titanium CNC machining, a technique well-known for producing high-precision titanium components used in aerospace, medical, automotive, and other high-performance sectors. Although titanium is a useful material with special qualities including high strength-to—-weight ratio, excellent corrosion resistance, and biocompatibility, machining it provides great difficulty. Covering the finest methods, equipment, and applications to enable manufacturers to get optimal outcomes, this blog investigates the complexity of titanium CNC machining.

Why Titanium? Understanding Its Unique Properties

CNC machining makes titanium preferred for aircraft components for a number of reasons.

- Ideal for uses where weight reduction is crucial, titanium is as robust as steel but weights 40% less.

- Perfect for aeronautical and maritime uses, corrosion resistance allows one to withstand rust, chemicals, and severe weather conditions.

- Titanium is extensively applied in medical implants and surgical tools since it is non-toxic and compatible with human tissues.

- Perfect for jet engines and space missions, it can resist extreme temperatures without deforming.

Though alloys these benefits exist, titanium’s characteristics also make machining challenging and call for specific tools, methods, and approaches.

Challenges of Titanium CNC Machining

Machining titanium is among the most difficult operations in the field of CNC manufacturing despite its many benefits because of a mix of elements that may greatly influence tool life, machining efficiency, and surface quality. Low thermal conductivity of titanium machining is one of its main drawbacks since heat produced during the machining process is not effectively dissipated through the material, resulting in too high heat accumulation at the cutting zone, so reducing general machining accuracy and perhaps causing tool wear and possible deformation of the workpiece. Another significant obstacle is titanium’s great chemical reactivity, which causes strong adhesion between the material and the cutting tool at high temperatures, so generating built-up edge (BUE), increasing friction, and fast tool degradation, so lowering machining efficiency and raising production costs.

Moreover, titanium has a strong tendency to work harden, thus, when mechanical stress or cutting forces are applied to the material, it fast increases in hardness and becomes progressively more difficult to machine as the operation proceeds, resulting in extra tool wear and a higher risk of tool failure if improperly managed. To guarantee dimensional accuracy and prevent deviations in the final component, titanium also shows a phenomenon known as spring back effect—that is, the material’s natural elasticity and inclination to return to its original shape after being cut or deformed—which calls for exact adjustments and very rigid workholding techniques. Adopting best practices, modern machining techniques, and carefully tuned cutting conditions is essential to obtain high-quality titanium machining outcomes while minimizing tool wear, lowering heat accumulation, and preserving maximum productivity in face of these hurdles.

The special qualities of titanium also provide machining challenges:

- Low Thermal Conductivity: Titanium does not effectively dissipate heat, hence tools wear fast and overheating risk is higher.

- High Chemical Reactivity: It interacts at high temperatures with cutting tools to create material adhesion and early tool failure.

- Titanium hardens quickly when machined, hence cutting effectively becomes challenging and cautious tool choice is necessary.

- Because titanium is elastic, it has a tendency to revert to its original form and calls for exact machining corrections.

Best Practices for Titanium CNC Machining

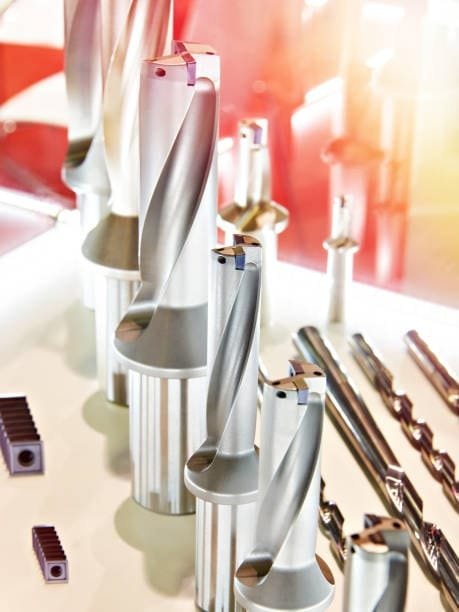

1. Tool Selection: Choosing the Right Cutting Tools

Machining titanium calls for specific tools able to resist wear and high temperatures. The finest alternatives consist in:

- High-speed carbide tools are quite durable and wear resistant.

- Coated tools assist lower friction and extend tool life by either diamond-like coatings or titanium aluminum nitride (TiAlN).

- Extreme precision and wear resistance call for CBN (Cubic Boron Nitride) and PCD (Polycrystalline Diamond) tools.

2. Optimizing Cutting Speeds and Feeds

Careful optimization of cutting speeds and feed rates is one of the most crucial features of titanium CNC machining since wrong settings can result in too high heat generation, tool failure, and poor surface finishes. Although titanium’s low thermal conductivity makes low cutting speeds (50–150 surface feet per minute, or SFM) generally advised to be used to minimize heat accumulation and prevent tool wear, high feed rates are advised to ensure effective material removal without sharp tool generating too much friction. Maintaining a shallow depth of cut (usually 0.020’-0.050′) also helps lower tool stress and stop too much heat accumulation, therefore guaranteeing steady and consistent machining performance.

Minimizing tool wear and preserving accuracy depend on correct speed and feed settings:

- Reducing cutting speeds (50–150 SFM) helps to lower heat generation.

- Greater feed rates help to avoid too much heat accumulation and tool damage.

- Shallow cuts (usually 0.020″–0.050″) help to lower tool stress.

3. Coolant and Lubrication Strategies

Reduced heat-related problems during titanium machining depend critically on effective cooling and lubricating techniques since too much heat accumulation can cause material deformation, tool wear, and diminished dimensional accuracy conclusion titanium. High-pressure coolant systems—which provide coolant straight to the cutting edge—help to effectively disperse heat, lower friction, and avoid material adhesion, thereby extending tool life and raising general machining efficiency. While flood coolant or mist systems can further maximize cooling performance, depending on the particular machining operation being performed, water-soluble coolants and synthetic titanium cutting fluids can be used to enhance lubrication, minimize heat generating, and improve surface finishes.

The low heat conductivity of pure titanium calls for a sensible cooling plan:

- Directing coolant at the cutting edge helps to dissipate heat and stop material adhesion in high-pressure coolant systems.

- These lower heat and improve surface finish using water-soluble coolants.

- Based on the operation, they can maximize cooling efficiency: flood coolant or mist systems ultimate tensile strength.

4. Chip Control and Evacuation

Long, stringy chips produced by titanium might injure titanium parts of the tool or workpiece:

- Chip breakers—inserts having chip-breaking patterns—help control chip production.

- This effectively eliminates chips and stops recutting by high-pressure air or coolant flush.

- In deep-hole drilling, these techniques—helical milling and Peck drilling—help regulate chip size.

5. Rigidity and Workholding Techniques

Machining setups have to be quite stiff to offset titanium’s springback effect:

- Good clamping systems stop movement.

- High-stiffness frame CNC machines guarantee stability by rigid machine structure.

- Using short, stiff tools helps increase accuracy by minimising tool deflection.

CNC Machining Techniques for Titanium

1. Milling Titanium

Because of heat generation, titanium milling calls for thorough preparation:

- Climb milling helps to extend tool life and lower tool pressure.

- Choose High- Efficiency Milling (HEM): Low radial depth of cut with maximum axial engagement reduces heat.

- Multiposition machining is 5-axis CNC machines cut machining times and increase surface smoothness.

2. Drilling Titanium

Drilling titanium has special difficulties because of excessive heat: and chip formation titanium grades:

- Peck drilling effectively eliminates chips and helps to minimize too much heat generation.

- Use Carbide Drills or High- Speed Steel (HSS): Slow speed, high feed coated drills help performance.

3. Turning and Boring Titanium

Specifically cutting conditions are needed for titanium turning:

- Keep a constant cutting speed; pause only to prevent work hardening.

- Sharp inserts improve chip control and help to lower tool pressure.

Applications of Titanium CNC Machining

In many different manufacturing material and sectors harder titanium alloys, titanium CNC machining is absolutely important:

1. Aerospace Industry

- Components of jet engines

- Aeroautical structural components

- Parts of spacecraft

2. Medical and Healthcare

- Hip and knee replacements—a type of surgical implant

- Dentinal implants

- Medical instruments

3. Automotive Industry

- Minimal structural components

- Performance engine components

4. Marine Industry

- Aeroplanes resistant to corrosion

- Parts for submarines.

5. Military and Defense

- Ballistic armor

- tactical gear

The Future of Titanium CNC Machining

Advanced technologies are changing titanium machining’s direction going forward:

- AI-Driven Machining: Efficiency is raised by adaptive cutting methods driven by machine learning and artificial intelligence.

- 3D printing in CNC Combining additive and subtractive techniques in hybrid manufacturing increases accuracy.

- Cryogenic machining—using liquid nitrogen as a coolant—increases tool life and lowers heat generation.

- Robotics and automation in CNC help to boost consistency and output.

Conclusion

An extremely difficult but highly rewarding process, titanium CNC machining calls for an in-depth knowledge of the particular difficulties related to machining this advanced material as well as the application of specialized tools, cutting strategies, cooling techniques, and machining parameters to obtain best results. Because of its low thermal conductivity, great chemical reactivity, work hardening tendencies, and spring back effect—all of which call for exact machining strategies and high-performance tooling solutions to ensure efficiency, accuracy, and durability— titanium is also quite difficult to machine even if it provides a remarkable mix of high strength, lightweight properties, high corrosion resistance and, and biocompatibility titanium alloys. Manufacturers can effectively overcome these obstacles and generate high-quality titanium components with extraordinary accuracy and dependability by using carbide or coated tools, optimizing cutting speeds and feeds, implementing high-pressure coolant systems, and using rigid work holding techniques. Innovations including artificial intelligence-driven machining, cryogenic cooling, and automated CNC systems will further improve the capabilities of titanium machining, so confirming its relevance across aerospace, medical, automotive, and other cutting-edge sectors as machining technology develops cnc machining titanium.