Plastic injection molding with the plastic materials and surface finish injection molding is one of the most vital elements in plastic production process that influences directly the aesthetic beauty and practical functionality in the injection molded components. Surface finish enhances the aesthetics and the aesthetics of a product because as the level of perceived value and quality of a product is augmented when an appropriate surface finish is accorded. Gathering expertise about surface finishing could be the trick to transforming a so-so product to one with high-end market positioning.

Understanding Surface Finish Injection Molding Fundamentals

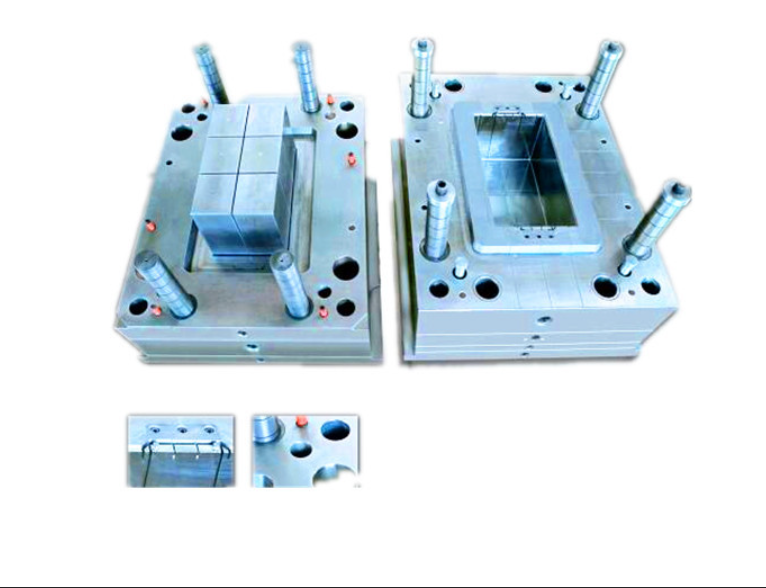

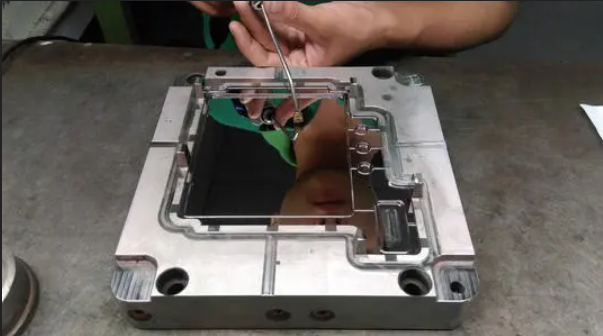

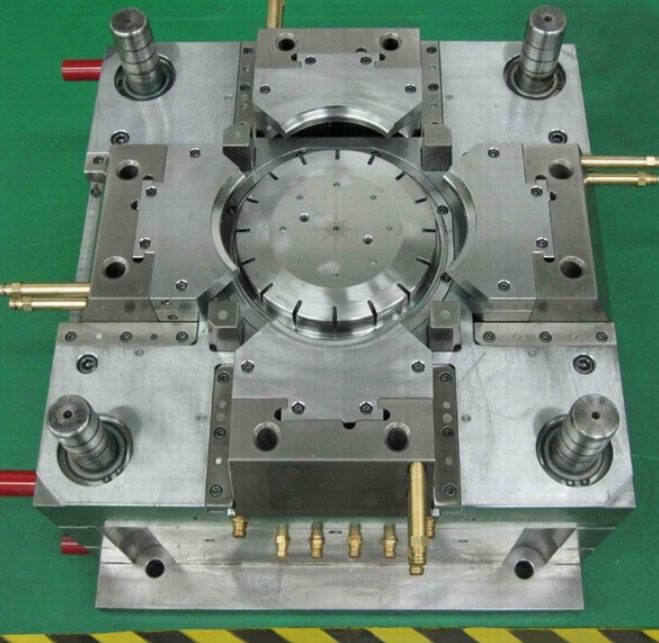

The injection molding process is known as textured surface finishes, mold finishes and surface finish injection molding when using injection molding to gain the desired texture, level of gloss and desired surface characteristics of plastic components or plastic parts. The polish and texture are all done on the mold itself and the parts undergo the injection molding process. This fact implies that mold preparation is instrumental in obtaining any desired results since the quality as well as the properties of the mold surface will correlate with the corresponding properties of the final part.

Aesthetic and functional purposes are achieved when it comes to the choice of appropriate surface finishings. Surface finishes can significantly increase the attractiveness of textured plastic finishes products (visually) but also improve the grippiness of products, conceal manufacturing flaws, support better adhesion of paint and also provide appropriate surface texture needed by certain applications.

Why Surface Finishes Are Critical in Injection Molding

Surface finishes in injection moulding and injection molding is of significant importance that goes beyond the looks. The industry of Plastic Plastic Industry association SPPI has maintained standards and guidelines that have classified the types of Surface Finish of injection molded parts into four main types (A) Glossy, (B) Semi-glossy, (C)matte and (D) textured. Every category has special uses in the designing and production of the products.

Surface finishing is used to conceal most of the typical injection molded flaws including flow lines, weld lines, sink marks and machining marks of the tooling, and dry blast 24 oxide may also be utilized . The textured surfaces may also enhance the functionality in terms of the additional grip, minimizing the slipping risk, and facilitating the following finishing process and paint adhesion by also ensuring fewer weld lines .

SPI (Plastics Industry Association) Standards Explained

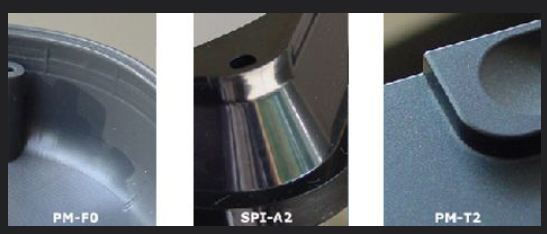

The SPI system of classification is the most popular in the world standards of injection molding surfaces. The grades of the finishes are broken down into four main grades and three subsets of each of these grades thus giving twelve varieties of surfaces finishes starting with mirror-like gloss surfaces down to heavily textural surfaces.

A grade A finishes are completed in the highest quality since they are reflected surfaces that are completed by buffing with diamonds. These finishes are the most costly ones because they need hard tool steel molds and much polishing work. Grade A-1 is at a grade with surface roughness at less than or equal to 0.012-0.025 micrometers, and Grade A-3 permits a little bit higher, 0.05-0.1 micrometers.

Grade A: Diamond Finish Applications and Specifications

Grade A finishes or commonly referred to as diamond finishes offer the best gloss and smooth textures available in injection molding. Each of these finishes applies successively finer grit diamond buffing course, A-1 uses 6000 grit diamond buff, A-2 uses 3000 grit and A-3 uses 1200 grit diamond buff.

Grade A finishes have applications in optical applications, high-end consumer electronics, automotive interior trim and medical applications requiring smooth surfaces or in any application where a superior-looking finish would be worth the increased cost. The finishes are more costly due to the high skills and time required in their manufacturing process, which also affects weld line visibility .

Grade B: Semi-Gloss Finishes for Balanced Performance

Semi gloss paints represent a very fine middle ground between affordability and quality of appearance. These finishes make use of sandpaper that has a linear movement forming a different orientation pattern that aids to conceal minor flaws and make them look good as well. The grades of Grade B finishes are in 600 grit (B-1), 320 grit (B-3) sandpaper applications.

The linear sanding texture of Grade B finish has great release properties of moulds and good sanding properties to cover machining marks and small surface defects. These finishes are suitable on consumer goods when one has to cover them but one does not need high quality gloss, especially considering the impact of mold machining .

Grade C: Matte Finishes for Cost-Effective Solutions

Matte finishes are the most cost effective surface finish available and still give a good aesthetic outcome. Grade C finishes are created through grit sanding stones and fine stone powders and contain outstanding mold releasing properties and can cover machining marks as well as imperfections on the surface perfectly.

The stone finishing is a uniform, non-directional surface which provides the foundation of better quality finishes. Grades C is widely utilized by manufacturing industries as an industrial finish, internal component, and components where something functional has higher priority over something fancy.

Grade D: Textured Finishes for Enhanced Functionality

Textured finishes offer the most practical surface qualities besides reasonable aesthetic qualities. These finishes are produced using dry blasting, using glass beads or aluminum oxide to provide maximum grip, great defect masking ability and greater paint adhesion strengths.

Dry blasting is completely random and non-directional and produces surfaces that do not smear fingerprints and those that have the tactile responses that are important to handheld products. finish Of grade D, for which both satin (D-1) and rough (D-3) finish can be achieved; the satin finish is by glass bead blasting, the rough finish by coarse aluminum oxide.

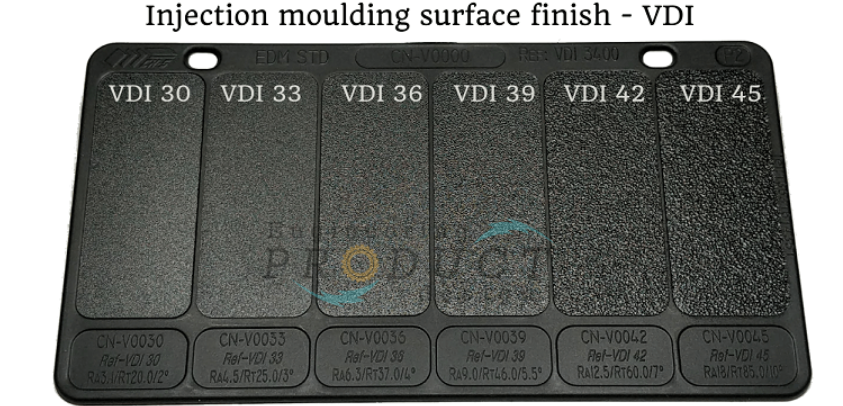

VDI 3400 Standard: European Surface Finish Classification

VDI (Verein Deutscher Ingenieure) is a Germany engineering association, which has formulated vdi surface finish an surface roughness standards in injection molding. Surface roughness ranges according to VDI 3400 standard and have VDI 0 to VDI 45 where the lower the number, the smoother the finish and the rougher the finish the higher the number.

The VDI system offers greater control of surface roughness than does SPI standards in its light, that definite numerical values are related to measured surface roughness. Typical production of VDI finishes is Electrical Discharge Machining (EDM) in the mold manufacturing process, but conventional texturing may be used.

Mold-Tech Specifications and Custom Textures

The Mold-Tech specifications provide the widest range of custom surface texture and masked chemical etching spi surface finish that can ever be done in injection molding. These are done by chemical etching or laser-induced modification of mold surfaces to reproduce natural materials, geometric patterns and proprietary designs with high precisions smooth spi surface finish.

All Mold-Tech specifications are specified by the MT -##### convention and require a definitive depth marking as well as recommended draft angles. It includes four series (A, B, C and D) each of them contains hundreds of patterns (like sand textures and strong geometrical designs) injection moulding surface finishes.

Material Compatibility with Surface Finishes\

The type of material used determines to a large extent the amount of quality surface finishes that is attainable in injection molding. Various finishing methods, including coarse matte finishes, affect different types of polymers in a different manner, and the knowledge of these correlations is critical in the basis of successful designing parts injection molding materials.

Acrylic products portray Grade A finishes with excellent to excellent rating on all specifications of the A-grade. Polycarbonate fares rather well with finishes A-2 and A-3 but could have troubles with the closest A-1 specifications. ABS serves admirably in most levels of the finishes and materials such as polyurethane (TPU) cannot be used on high-gloss.

Optimizing Molding Parameters for Surface Quality

Injection parameters are also important parameters used in attaining optimum surface finishes. Increased melt and injection velocity tend to encourage the presence of surface quality since it enhances the feeding of materials and minimizes the appearance of weld line plastic injection molded parts.

The control of temperature during the molding operation influences the fidelity surface replications. Inaking a mold at elevated temperatures enables more detail to be transferred to the part the detail of the mold and proper cooling rates avoids such problems as sink marks and non-uniform patterns of shrinkage on part surfaces.

Cost Considerations and Economic Impact

Choice of surface finish, especially at high melt temperature, has enormous cost and economic implications to tooling and production. A basic textured finish costs a tenth as much as Grade A finishes because of the intensive work to hand polish as well as hardened tool steel spi finishes.

High end surface finishing is a labour-intensive process and due to this fact, automation could not be used to a significantly larger extent in the industry. Adept artisans are still imperative to that of producing high-grade topical finishes, which also addresses the issue of tool marks, and widens the difference between the grades of finish glossy finish.

Quality Control and Surface Measurement Techniques

Robust systems of measurement and control on surface quality ought to be maintained. Profilometers and optical scanning systems qualify finish quality in terms of quantitative analysis departments in accordance with a range of specified guidelines, ensuring that visible machining marks are minimized .

Comparison to sample parts and visual inspection standards work to provide consistency between runs of production. The development of definite acceptance standards and measurement standards will ensure that surface finish demands are won and maintained in the whole manufacturing process.

Conclusion

Surface finish injection molding is that dead zone between design esthetics, functionality and manufacturing cost, particularly for injection molded plastic parts . Knowing the different standards, compatibility material problems, and optimization methods within the injection moulding process can allow the producers to make sound decisions that consider a trade off between the quality requirements and the cost limits. Depending on the particular application need, material specifications and cost, the most favorable results of choosing which should be either SPI, VDI, or Mold-Tech specification could be attained.