Learn how to master snap fit design and design snap fit joints using our detailed 2800 word guide on principles, types, materials and best practice. Improve your product designing by learning through engineering professionals.

Introduction to Snap Fit Design

Snap fit design is one of the most beautiful and cost-effective methods in modern mechanical engineering and product Developing. This clever system of fastening provides the connection of parts in a very short time without any extra hardware, adhesives and complicated assembly mechanisms. The key beauty of snap fit mechanisms is their ability to be highly simple and effective and that is why this type of mechanism is impossible to dispense with in all industries – such as in consumer electronics, automotive applications and in so many other industries.

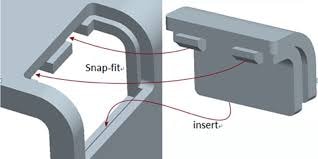

It is based upon the core concept of the snap fit design of introducing temporary deformation in two components during assembly to be followed by the elastic recovery that locks the parts together. Such mechanism offers quick connection that is bolted and adaptable to be undone. The knowledge of snap fit design peculiarities plays a key role in terms of engineers, product designers, and manufacturers that need to have the maximum of their assembly processes within a few steps, having less expenses and guaranteeing the user experience.

Understanding the Fundamentals of Snap Fit Mechanisms

Snap fit – The mechanism works by the principles of elastic deformation and recovery. When two parts are joined together one of the parts has to deflect momentarily to enable mating component to pass and through/over a retaining feature. When the parts have been correctly oriented, the deflection object forms back to its original structure and a mechanical interlock is formed and this makes it impossible to separate the parts even when subjected to normal usage conditions.

Design of any snap fit design is successful only when proper consideration is given to a range of competing requirements such as material prop, geometric restraint, force demand and desire lifetime. The engineers have to take into account maximum allowable stress and maximum strain in the deflecting member, the force of assembly and disassembly and also the long terms behavior under successive loading cycles.

Snap fit performance heavily relies upon the material choice. Their selection should be such that the selected strain resistant materials should be flexible enough to undergo the necessary deformation without causing any permanent damage, at the same time being strong enough and stiff enough so that they can provide sufficient retention force. Typical snap fit plastic parts materials are the polypropylene, polyethylene, ABS, and engineering plastics including polycarbonate and nylon, to name but a few.

Types of Snap Fit Joints and Their Applications

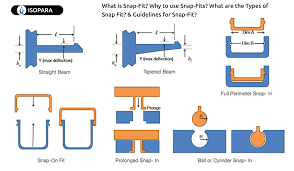

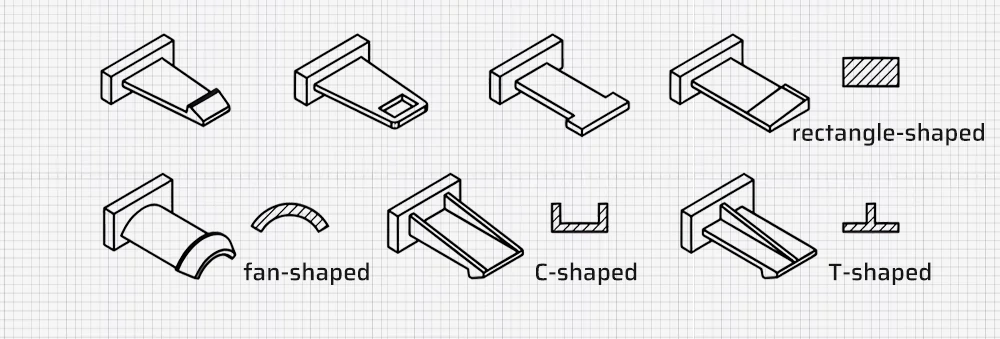

Cantilever snap fits are the most general and flexible of snap fit mechanism. These designs have a swing-beam which buckles during construction and with a hook or retain feature at the free end. The cantilever beam may be made part of either of the mating parts or be made a distinct spring element. Such an arrangement provides superior flexibility of deflection control and has a wide variety of possible retention forces.

To engage in torsion, snap fits make use of twisting action as opposed to linear deflection. These methods have been especially applied where space does not allow large amounts of traditional cantilevers to be used. The twisting movement spreads the stress more uniformly throughout the retention feature that may enhance the fatigue life over other cantilever designs with high stress concentrations.

Bayonet snap fits have rotary motions and linear motions which are used to make a solid connection. The male has one or more protruding features that interact with the female component by a quarter-turn or other rotational action by interacting with corresponding grooves on the female. The retention strength of this design is very high and it is mostly used where assembly and disassembly is repetitive.

Design Principles for Effective Snap Fits

The effective snap fit design starts by identifying the key features and functional requirements such as insertion force, retention force, disassembly force and service life. The parameters have a direct impact on the selection of materials, the proportions of geometry and the schematisation of design. The engineers also may need to take into account limitations due to manufacturing, tolerances and possible wear patterns during the product life.

The snap fit joint designs features as a geometry has to be optimized with specific consideration given to the ability to attain the desired performance characteristics and with consideration to manufacturability. Major geometrical parameters are the length of the beam, wall thickness, width of the beam, deflection angle and features of retention dimensions. All these factors influence the relationship between force and deflection and distribution of stress in the mechanism.

Stress analysis is also critical aspect of design of snap fit validation. The maximum stress in the deflecting member must remain well below the material’s yield strength, typically incorporating a safety factor of two or more. The tools like finite element analysis allow engineers to analyse the complex stress patterns and develop geometry to perform better and last longer.

Material Selection Considerations for Snap Fits

The performance of snap fit is greatly influenced by the material properties and the major aspects to be put into consideration are elastic modulus, yield strength and the elongation at break. Materials that have a low elastic modulus can be deflected using less force, but might not have the retention strength needed, and conversely, the high-modulus materials have good retention strength but might need too much force to assemble (or risk breaking under engagement retention force).

Snap fit applications are dominated by thermoplastics because of their desirable balance of flexibility, strength, and processability. Polypropylene is also used where flexibility and fatigue resistance are desirable as it is used in living hinge applications, and in snap fits where plugging and unplugging can be repeated many times. ABS is a tough material with good strength to weight ratio and excellent dimensional stability and polycarbonate is the excellent choice in cases where strength and durability are required at high temperature.

When using snap fit, environmental conditions should be borne in mind when choosing materials to be used. Extreme temperatures may also have far-reaching repercussions on material properties, whereby cold temperatures augment brittleness hazard and elevated temperatures lower strength and rigidity. The material performance can also be compromised with time under chemical exposure, UV radiation and even under humidity, thus material evaluation should be done thoroughly in regards to the operating condition required.

Manufacturing Methods and Considerations

The injection molding process is used in the production of snap fit parts with higher levels of dimensional stability and production of complex shapes in just a single step. The right material flow during the molding process has to be optimized carefully and certain defects like weld line, sink marks or short shots that reduce snap fit performance has to be prevented.

Design of tools is also important in the development of quality snap fit component. The trick lie in draft angles, gate positioning and ejection systems so as to avoid damaging the part as it is being ejected out of the mold. Grooves needed to support snap fit features may demand side actions, lifters or other complicated tooling options that add up to the cost of production but allow manufacturing of useful geometries.

Snap fit assemblies may depend on secondary operations like machining or ultrasonic welding or heat staking to finish the work. All these need to be strictly controlled to keep the dimensions correct and prevent stresses that might alter long term performance. During the quality control procedures, the snap fit mechanics should be tested to ensure that they work effectively and retain the required characteristics.

Force Analysis in Snap Fit Design

The force demands of snap fit as gathering/entry as well as keeping must be comprehended to design merchandise that is easy to use. Force of assembly should be powerful enough to give the tactile feedback of the proper engagement but it should be within comfortable ranges of the intended users. The typical assembly forces are small (a few Newton) forces on small consumer products up to hundreds of newtons in larger industrial products.

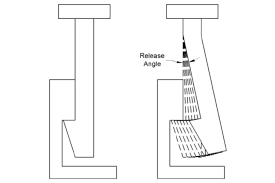

Retention force is a force that is necessary to separate mated snap fit parts and has to be bigger than the anticipated service loads with a reasonable margin of safety. The assembly force field is also dependent upon the geometric orientation of the snap fit mechanism, and the qualitative result is that asymmetrical designs can typically achieve better retention-to-assembly force ratios.

When a part with snap fit is put under dynamic loading, it can match up to a change in fit performance that may be more than it should be. This is more so in systems that get subjected to vibration, shock or even to thermocal cycling. Fatigue analysis is important in determining the anticipated service life when the material is under a repeated load condition. The S-N curves of the chosen material will present critical data regarding the determination of fatigue life judging by levels of stress amplitude and average-means stress.

Optimizing Geometry for Performance

One of the most significant parameters in geometric design of a cantilever snap fit is the beam length. The longer beams allow more flexibility and reduce the forces due to assembly and at the same are most likely buckle or need more space to deflect. Shorter beams have improved stiffness, retention force but when they are too short, they can necessitate too great assembly forces, or risk failure of the material during engagement.

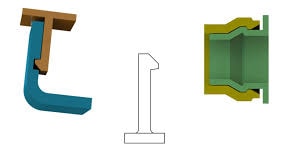

The geometry of a cross-sectional stress distribution and deflection behavior of snap fit elements is very influential. Rectangular cross-sections are simple to analyse and construct, whereas other types can have efficiency in the ratio of strength to weight and a lower weight yet same performance, e.g. an I-beam or a hollow section.

Stress concentration factors and load transfer mechanism should be paid close attention to during the building up of retention features. Sudden changes in geometry and sharp corners should be avoided and a smooth transition with wide radii should be used instead. Retention angle and depth directly affects assembly force and strength of retention and hence has to be adjusted according to the custom application needs.

Stress Concentration and Failure Prevention

The main failure mode occurring in snap fit mechanisms is stress concentrations and is usually located at the source of cantilever beams or transitions of retention features excessive force. The presence of geometric stress concentration factors can be reduced by proper design techniques such as large fillet radius, smooth transitions, and absence of steep notches and corner.

Such material aspects as molecular orientation and residual stresses left by the manufacturing process can heavily influence local stress concentrations and susceptibility to failure. They might require proper processing conditions and annealing processes in order to reduce residual stresses as well as to optimize material properties to be suitable in snap fit applications separation force.

The cracking of the fatigue initiation and propagation can be regarded as long term failure modes that need to be addressed in snap fit design. Fatigue performance is affected by the surface finish, homogeneity of the material and stress amplitude. Fatigue resistance and service life may be increased by design changes including stress relieving features or redundant load paths article covers.

Tolerancing and Dimensional Control

The dimensional tolerances themselves will have direct influence on the performance of snap fit, tight tolerances might lead to assembly challenges or high stresses, and the loose tolerances would lead to inadequate retention conditions or poor snap fit quality. The statistical tolerance analysis is used to optimise the placement of tolerances to meet required performance and remain manufacturable and cost-effective high quality parts.

Dimensions that are of main importance and must be controlled carefully are beam thickness, dimensions of retention features, and clearances between mating components. Stack-up tolerance analysis preserves, worst-case, combinations of part tolerances, to produce acceptable snap fit performance. During manufacturing processes capability studies assist in proving that manufacturing processes can repeat specified tolerances.

Geometric dimensioning and tolerancing (GD&T) principles give potentially potent tools in transporting the design purpose, and in controlling the critical snap fit functions. Position, profile and orientation tolerances can accurately specify how mating features relate to each other and provide manufacturing freedom (manufacturing latitude) in non critical features.

Testing and Validation Methods

The functional tests of the snap fit mechanisms are expected to cover not only the assembly properties but also their functioning in terms of a long time and in the service. Overall, assembly force testing will verify the ability to engage in a component with an adequate amount of force and respond tactiley. The testing of retention forces ensures sufficient holding force during possible service loads.

Durability testing fixtures test the snap fit performance in multiple assembly, disassembly operations, thermal temperature situations, and other environmental stressing situations. Rapid test procedures may be used to gain insight on long term behavior within acceptable timescales but close correlation with real service past history is necessary to be of value.

Functional non-destructive testing techniques such as visual inspection, dimensional check and stress analysis can detect the problems possibly prior to functional testing. Tensile testing to failure and tensile testing to fatigue is destructive and yield useful information to support design validation as well as to design improvements cnc machining.

Common Design Mistakes and How to Avoid Them

Lack of safety factors is a usual cause of failure of snap fits especially on systems exposed to temperature changes or creep. When conservative design principles such as proper margin of safety factors and careful stress analysis are used, pre-mature failure is normally avoided and the long term reliability of the structure is likely to be attained.

Designs that work well in theory can be poor to manufacture due to poor attention to manufacturing limits remote controls. Design and manufacturing teamwork early in the process assists in discovering problem areas and makes designs easier to manufacture as well as perform.

Failure to put environmental conditions like extreme temperature, any kind of chemical exposure, UV radiation into consideration, can result in unexpected material degradation and snap fit failure high loading frequencies. Balanced assessment of test materials under the anticipated service environment provides reasonable material choice and margins of design 3d printing.

Advanced Snap Fit Configurations

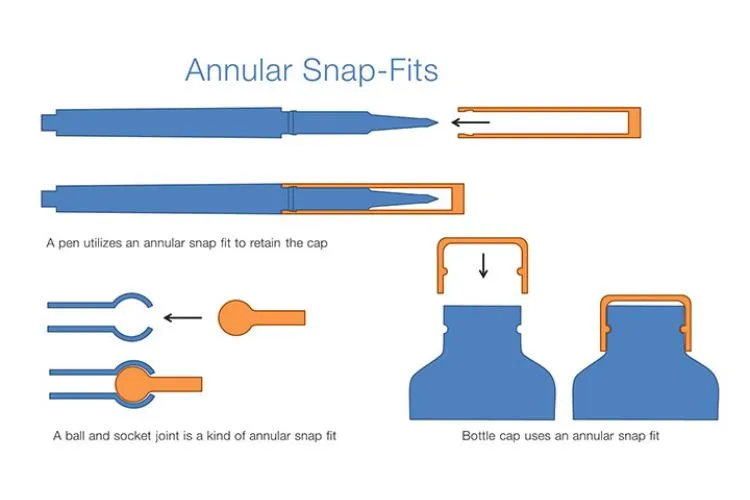

Multi-stage annular snap fit joints can include staged engagement with rising retention force, resulting in greater give-back-to-the-user and greater security mating force. The designs usually have several stages of deflection or variable geometry across the engagement path to provide a set of plateaus of various levels of force to use during assembly cantilever snap fit joints.

Combinations of other retaining mechanisms, e.g. cantilever beams with torsional sections, with some number of engagement points give compound snap fits reducing material costs. These arrangements have the potential to deliver a better retention performance and fail-safe behavior in the case of individual parts degradation or destruction torsion snap joints.

The features of adjustable snap fits enable modification of retention force after assembly to enable fine tuning of the performance characteristics or tolerating differences in tolerances. Such designs tend to use some threaded adjusters, or wedges, or other mechanical advantage systems l shaped snap fit.

Integration with Other Fastening Methods

Hybrid fastening takes advantage of snap fits with another method of retaining the components, eg screws, adhesives or mechanical fasteners, in order to optimise the overall assembly method annular snap joints. The snap fit may offer holding or location in a preliminary position and a secondary fastener offer securing or increased strength in critical cases wear resistance.

As snap fit assemblies are used to ensure easy use, complementary sealing systems become a combination of the two processes snap fit connectors. Molded in seals can be designed as, and gaskets or O-rings can be added to snap fit designs without impacting useful functions cantilever snap joint.

Snap fit can be combined with tamper evidence use to give a visual prompt of the wrongful assembly or access. Such characteristics are often made of material with frangible components or some completely permanent deformation that results when attempting preliminary disassembly flexible materials.

Quality Control and Manufacturing Standards

The use of statistical process control techniques assists to maintain standard snap fit performance during runs plastic materials. They should continuously monitor the key parameters, like the dimensional accuracy, the material properties and the functional performance so as to be able to determine trends in order to avoid the quality issues.

Technical requirements of industries like ISO, ASTM, and other applicable specifications have specifications of test procedures, material characteristics as well as requirements. Adherence to specified standards guarantees the reliability of the products, and it eases the acceptance of products by the customers.

Qualifying suppliers and inspection of incoming materials are very important to ensure quality of snap fit. Properties of material, accuracy of dimension and cleanliness should be checked to avoid quality defects in final assembly.

Cost Optimization Strategies

The manufacturing cost optimization of designs is concentrated on reducing the complexity of the tooling needs, minimizing the amount of material and restricting the secondary operations. The standardization of snap fit functions of different product lines has been able to exploit the shared tooling and manage the development of costs.

There is an optimization on the selection of materials to meet performance and cost requirements. Engineering plastics could provide a better performance at a much much exorbitant price in comparison to commodity plastics. Through proper evaluation of real service requirement, there are opportunities that can be analyzed where there is cost reduction that does not affect functionality suitable material.

The potential of assembly automation ought to be taken into account when designing a snap fit in order to achieve a high-volume production with great quantities of similar quality plastic components. Automated handling, positioning and engagement features may prove very cost effective in high volume applications.

Future Trends in Snap Fit Technology

Smart materials and nanocomposites, bio-based polymers give new potential to new snap fit applications. Such materials can offer improved performance properties, environmental or new functionality like shape memory or self healing fatigue failure.

Advances in additive manufacturing technologies are opening up design space in snap fit mechanisms allowing complex geometry and flexible functionality that would be challenging or impossible to accomplish with more established methods of manufacture. The use of additive manufacturing applications, however, needs an in-depth analysis of material properties and the necessity to resolve the surface finish of the material male and female parts.

Software design tools such as advanced simulation software, optimization algorithms and machine learning are enhancing the efficiency and effectiveness of the tendency of snap fit design. Those tools allow quick iterations and optimization of complex design and minimise physical prototyping essential design tips.

Conclusion

The snap fit design is an essential skill in current product development as the simple adjustments are providing a cost effective solution to assembly issues and could decrease the cost and enhance the interactions of the user distribute stress. The key to success is paying sufficient attention to the selection of the materials, geometric optimization, manufacturing opportunities, and the validation testing of the results u shaped snap fit. These principles and practices featured in the guide offer the basis of conceptualizing good snap fit ideas that address high-performance demands and are friendly with regards to cost, and fabrication tapered hook.

The future of snap fit technology is still seen to be growing in support of the enlargement of materials sciences, production procedures, and plan energies producing snap fit joints. Those engineers, who would have studied well these basic principles appropriately along with keeping up to date with emerging technologies will be able to design the innovative thing more gone the full potential of the snap fit mechanisms torsional snap fit.