Sheet Metal Fabrication Services

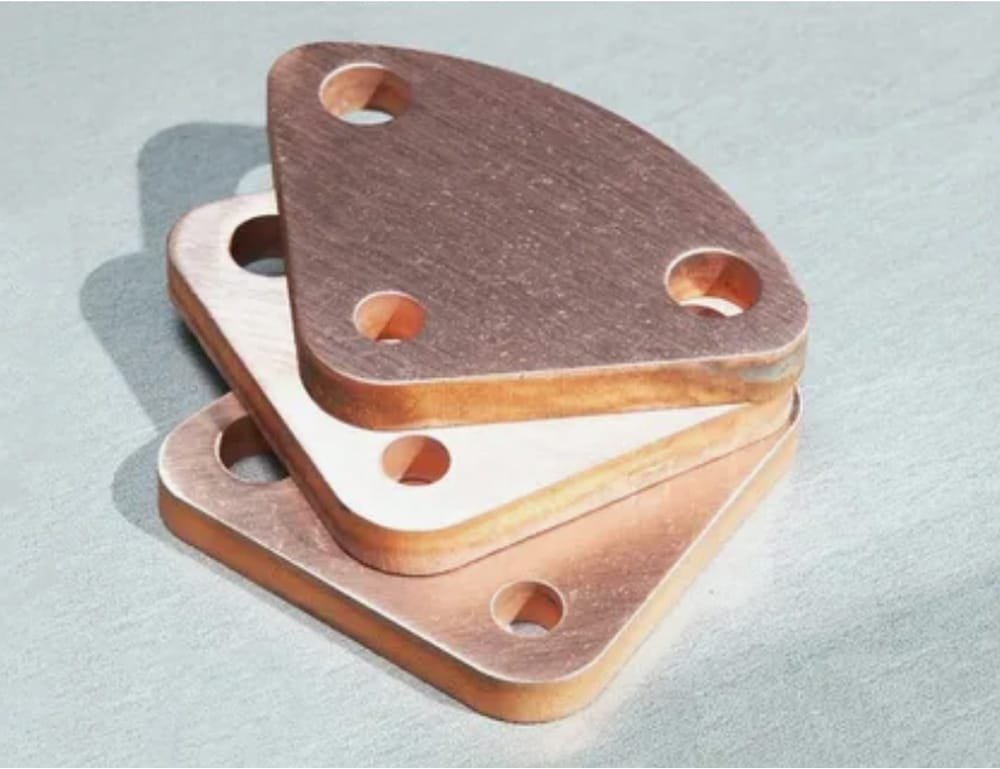

Leading Edge’s Sheet Metal Fabrication Services combine precision cutting, forming, and joining to transform flat metal sheets into complex, durable components. Using advanced laser cutting, CNC bending, and expert welding or riveting, we deliver parts that meet tight tolerances and high strength requirements—whether you need small-batch prototypes or large-volume production runs.

ISO

9001:2015 Certified

50+

CNC machines

100+

Plastic & metal materials

10K+

CNC parts made monthly

Custom Solutions for Every Need

Harness the full potential of sheet metal with Custom Solutions for Every Need—whether it’s rapid prototype brackets, precision enclosures, or high-volume production panels. Our expert team tailors cutting, bending, and joining processes to your exact specifications, delivering durable, accurately formed components that fit seamlessly into your designs and workflows.

What Is Sheet Metal

Fabrication?

Sheet metal fabrication transforms flat metal sheets into complex parts and assemblies through a series of precise processes. By combining cutting, forming, and joining techniques, we can produce everything from prototype brackets to large-scale production enclosures with exceptional accuracy and durability.

Cutting

Utilize laser, waterjet, or CNC shearing to slice sheet metal into exact shapes and profiles, ensuring clean edges and minimal kerf for tight-tolerance parts.Forming

Employ press brakes, roll bending, or stamping to bend, curve, and shape metal into the desired geometry—whether simple flanges or intricate contours—while maintaining material integrity.Joining

Integrate individual components using welding, riveting, or adhesive bonding to create robust assemblies that meet your structural and aesthetic requirements.

Why Leading Edge

Deep Expertise & Proven Experience

No matter how intricate your sheet metal project, Leading Edge brings unmatched know-how to every detail, ensuring your vision is executed flawlessly.Lightning-Fast Turnaround

We pair precision craftsmanship with rapid delivery—meeting your deadlines without ever compromising quality.Upfront, Transparent Pricing

Receive a clear, competitive quote with zero hidden fees, so you always know exactly what you’ll invest.Cutting-Edge Equipment

Our global network features the latest laser cutters, press brakes, and welding systems—guaranteeing superior quality on every part.

Why Choose Sheet Metal Fabrication?

Precision Sheet Metal Cutting

Leading Edge delivers exceptional sheet metal cutting using state-of-the-art technology, guaranteeing crisp, precise cuts—no matter the size of your project.

Sturdy and Reliable Sheet Metal Joining

Leading Edge’s sheet metal joining services—including welding and riveting—create robust, dependable assemblies for any project, with every joint crafted for maximum quality and durability.

Professional Sheet Metal Forming

Leading Edge specializes in sheet metal forming, expertly bending and pressing metal to your exact specifications. Our precision-driven process delivers high-quality custom parts—whether for intricate designs or robust functional components.