Meta Description: Find out the most important distinctions between die casting, investment casting, and sand casting manufacturing processes. Compare prices, accuracy, uses and casting materials to select the appropriate casting process to your production while considering lower cost .

When it comes to metal production, the production technique/ strategy that you adopt decides whether your production is a success or failure. The industry is taken over by two major casting methods; sand casting and die casting, which have their own definite benefits in various manufacturing situations. Learning about these differences is important in making informed decisions that will influence the quality of the products, production costs and efficiency of production.

Understanding Sand Casting Fundamentals

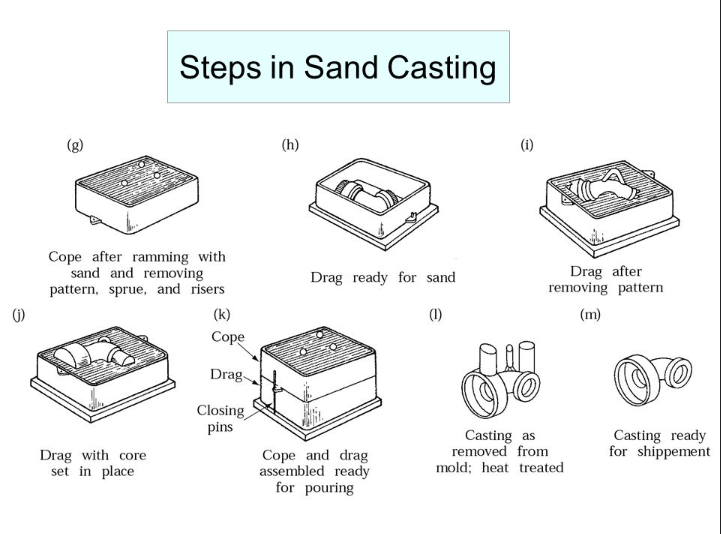

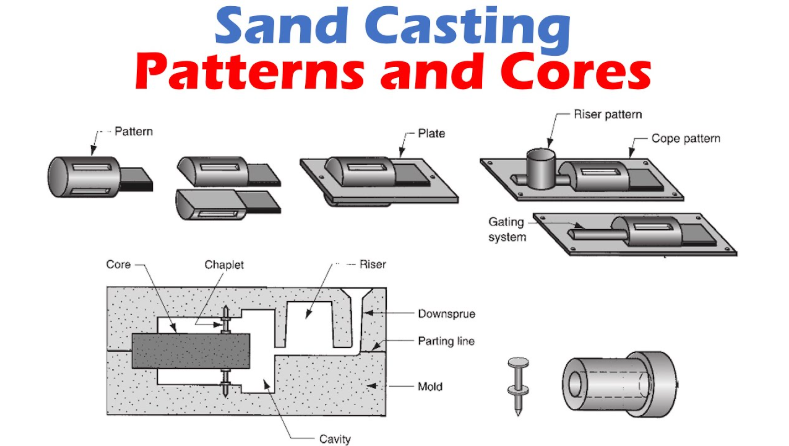

Sand casting has emerged to be one of the most dated and diverse metal forming technologies in the history of manufacturing. The Sand casting process is what is used to make metal components by pouring molten metal into a sand mold; it is a simple, but effective process of making metal components. This is done by first forming a pattern which is usually of wood, plastic or metal and this forms the shape of the sand mold cavity.

Sand mold: this is a special mold made up of special sand that is mixed with some binding agents to ensure the sand does not distort when the casting is taking place. After the molten metal has cooled and solidified in the sand mold, manufacturers remove the sand so as to expose the completed casting. The expending mold feature renders the sand casting especially accommodating to the complex shape and prototypes.

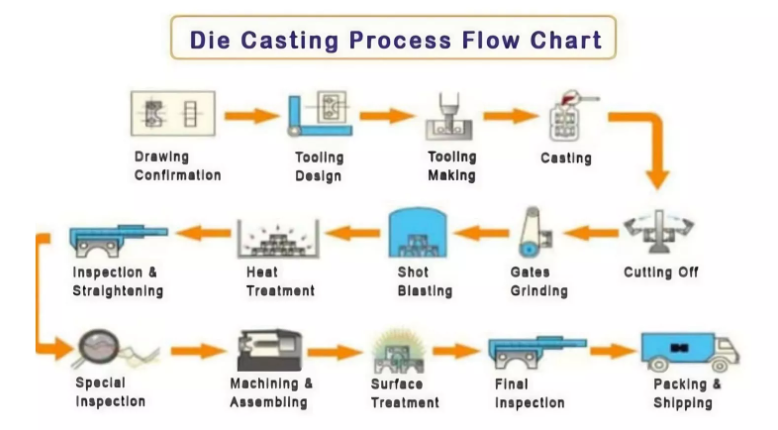

Die Casting Process Explained

Die casting, particularly high pressure die casting, is an advanced, more refined method of manufacturing process because high pressure is used to inject molten metal into a metal mold. Die casting takes pride because of the fact that, the resulting parts have smooth surface finish and are accurately measured which makes them ideal when dealing with high volume production demands.

Die casting makes use of permanent mold casting steel dies which can be used thousands of times in the casting process. Due to permanent mould, an increase in the production rate of die cast parts and Die casting with respect to sand casting is experienced, which ensures manufacturers meet quicker cycle times and manufacture high production with excellent repeatability during the manufacturing process.

Material Compatibility and Options

Sand casting proves to be highly versatile in relation to compatibility of materials. It is alloy compatible because Sand casting can be applied to most alloys typically without difficulties, including ferrous metals and non ferrous such as steel, iron, aluminum, bronze, zinc alloys non standard alloys, and can achieve certain levels of dimensional accuracy. Such flexibility renders sand casting especially useful in producing prototypes and on special applications that demand non-routine material requirements.

However, die casting is more restrictive with regard to choice of materials but is more effective with certain non-ferrous metals. 380: An all-purpose aluminum alloy with reasonable castability and good mechanical properties is one of the most popular die casting alloys. Zinc, magnesium and copper alloy materials are also viable and beneficial in different forms of applications.

Precision and Surface Quality Comparison

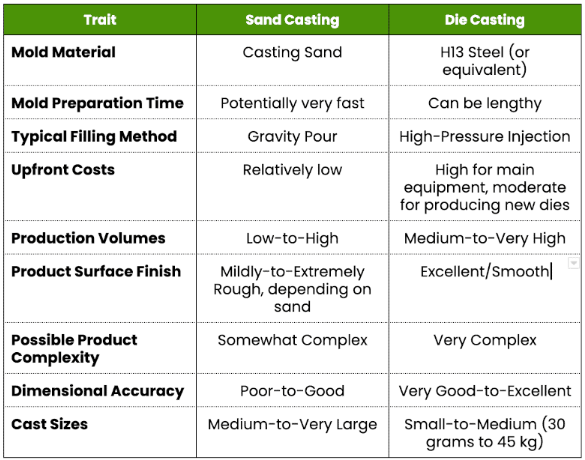

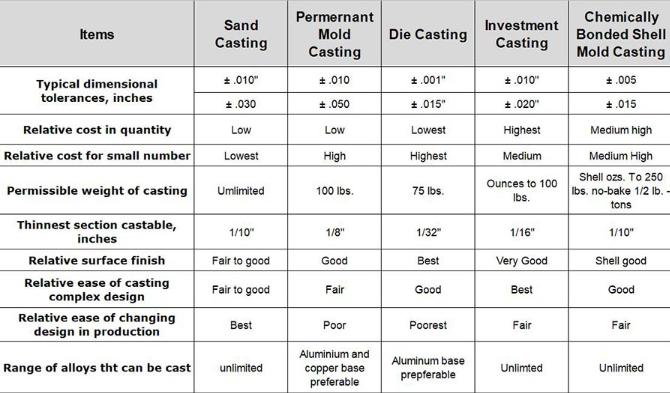

The precision capacity of these two processes varies greatly, and this aspect affects the usefulness of these two processes. The accuracy that a casting may produce using sand casting is normally lower than what can be found in other methods and the tolerance may be ± 0.8mm to ± 1.5mm based on the complexity and size of the part produced, particularly those with tight tolerances and higher melting points. while die casting often achieves high dimensional accuracy .

Sand casting produces rough surfaces on the parts due to the compact nature of the sand casting its texture on the part which necessitates further machining or finishing to smoothen such surfaces. The surface finish of Die cast products, on the other hand, is extremely high in quality and in many cases, there is no need of conducting a lot of post-processing operations.

Production Volume Considerations die casting molds and sand casting molds

The volume requirements are the other important factors that determine which type of casting (that is, sand casting or die casting) to use. Sand casting is most recommended to you when you have to work on a limited budget and your production parts should not be more than 1000 parts, contrasting with investment casting which requires more initial investment . Sand casting is cost effective and economical to use in low production runs and prototyping because initial tooling costs are cheap.

Die casting production will charge you more tooling in advance but it becomes a less costly option once you past the 1,000 quantities mark. The payoff of investment into permanent mold is lower unit cost per unit and the quicker production cycle in high-volume cases.

Size and Complexity Limitations

The size of parts made is another important distinction point among these types of casting. The metal casting process of sand casting I is much more flexible in scale and it is ideal when it comes to large parts, as it can accommodate several tons of the component required, with no major technical difficulties being incurred. Molds are expendable in nature, and the size is practically limitless.

Die casting provides greater precision when needing really intricate shapes and sand casting when creating larger part. Die cast machines are also limited in size as they are constrained by the capability of the clamping force and injection pressure requirements that are inherent in die cast machines and generally limit parts to smaller more complex parts.

Cost Analysis and Economic Factors cold chamber die casting

Knowledge of the cost implications will aide the manufacturers in coming up with economical decisions. Sand casting uses less initial investment and its initial cost is in the form of pattern cost. Money matters a lot in the selection of die casting or sand casting because initial tooling has a primary influence on the economics of projects.

Significant initial costs are needed in the establishment of permanent molds and special equipment in die casting. This is however a fairly quick and affordable process and thus it becomes an appealing solution to many applications whose production quantities make the investment worthwhile. Cost per unit goes down drastically with increase in volume, resulting into economies of scale.

Automotive Industry Applications

The automobile industry heavily relies on casting technologies to meet various parts demands. The casting can be used in the automobile sector in the manufacturing of structural parts such as engine block, cylinder head, pump housing and gear box casing, Casting methods The method used in the automobile sector in large-scale structural casting is usually sand casting.

Die casting dominates the automobile markets that need fine-tolerances and accurate finishes such as transmission cases, engine brackets as also houses used in electronics. The nature of the automotive business, where small batches are not the norm, fits just right into the capabilities of die casting production and cost efficient at scale.

Aerospace and Defense Considerations die casting involves

Aerospace requires very high quality and industrial substances which determine the form of casting used. The flexibility of the materials used in sand casting enables it to use in aerospace production specialized alloys that are becoming mandatory as such, high temperature resistant materials and the use of composites that are lightweight, in contrast to hot chamber die casting which is more restrictive . Sand casting is also appropriate on structural aerospace parts because of the capability of making large, complex parts.

Aerospace In some cases die casting is used in aerospace where high precision and consistency of quality are needed, especially in electronic enclosures, brackets and smaller structure parts. The high surface finish and close dimensional tolerance are able to meet high aerospace quality.

Electronics and Consumer Goods Manufacturing

Die casting is very instrumental in the production of components in the electronics industry. The power management and telecommunications use aluminum castings in heat sinks, LED housings, chassis and battery enclosures owing to their exemplary thermal, and electrical conductivity properties. The accurate measurement and finished surfaces from the injection process negate the need of extra machining.

Die casting is used to make consumer goods because of its aesthetic and efficiency. The most popular die cast objects are designed to be used in automobile and ornamental hardware manufacturing such as door handles, ornamental trim and appliance parts where looks count.

Environmental Impact and Sustainability

Environmental concerns are playing an important role in the manufacturing decision which actually both the processes have environmental advantages. By means of the unused molds, sand casting produces more discarded products, but requires less energy spent per piece of production, as the processing temperatures are not high, in addition to less pressure being applied. The sand can be recycled and reused quite regularly through processing.

The benefits of the process lay in a lower energy consumption and waste generation, the entrapment of air in the process of die casting, which makes it even more eco-efficient in high-volumes production. The permanent molds allow waste of pattern to be removed and they save on material usage per part.

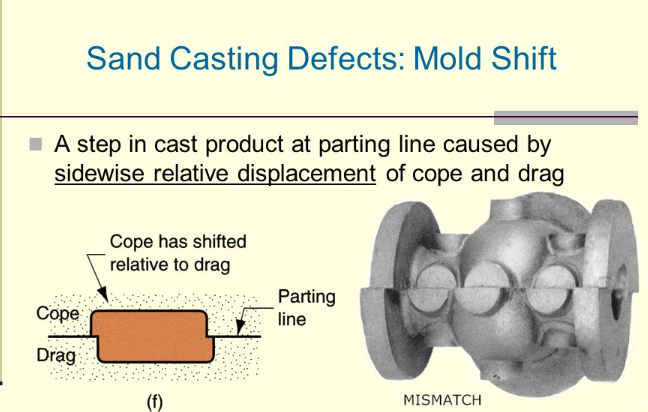

Quality Control and Inspection Methods die casting produces

The method of castings in quality control varies because of the unique nature and usage of different casting format. Sand casting needs a further check up because of variation in mold preparation and pouring. Non destructive testing like X-deep and ultrasonic testing will assist in detecting internal defects which are common in sand castings.

Die casting has an advantage of consistency and repeatability of processes allowing statistical process control process. The quality control of the injection pressure and permanent mold conditions make the results more in line, which makes the quality assurance process easier and lowers the rates of inspections.

Tooling and Equipment Requirements

Tooling costs are very important decision variables in casting decision making. Compared to other method of casting, sand casting has relatively uncomplicated tooling mainly composed of patterns and core boxes. The patterns may be produced of many different materials, wood is particularly economical in low volumes, and metal patterns are used in high volume numbers

Die casting requires highly advanced tooling such as precision machined steel dies, injection and special casting machines. The equipment used to pressurize the metal into the die is very complex and expensive, and this needs thorough economies to be invested in according to the company production and its need of parts.

Lead Times and Production Scheduling

Based on the time of production, some projects require that the correct casting method be chosen and in this case; time can dictate the casting choices. The shorter lead time associated with tooling preparation is one of the features of sand casting which results in quick prototyping and the commencement of production. The creation of a pattern may take a number of days or weeks when it is not complex.

Die casting has longer lead times of die and machine set up but a higher production rate once production is begun. Rapid production of large quantities can be achieved since fast cycle times allow die casting to fit well in situations where production needs to be done within short deadly schedules that have adequate preparations made.

Post-Processing and Finishing Requirements

Applications of post-processing differ greatly across the various casting practices, and this aspect influences the costs of production and schedules. The products produced in the process such as aluminum with sand casting process also result in a relatively rougher surface finish and may need extra machining, grinding, or surface processing processes, to effectively produce parts that meet quality standard .

Die casting Die casting reduces post-processing methods due to high quality surface coverage and dimensional precision when using liquid metal. A large volume of the die cast components need little finishing after the die casting process with a little trimming of the flash and final inspection which shortens the total production time and expense.

Material Properties and Performance Characteristics

Casting process determines the end properties of material and performance of components. The sand casting can have regulated cooling rate to allow optimisation of materials properties by heat treat process. The lower cooling rates have the ability to enhance the mechanical properties and material grain structure in specific applications.

The speed of cooling which die casting provides leads to different properties of the material, more often causing finer grains and surface hardness. The high rate of cooling may however result in internal stresses that may need stress relieving treatment in critical applications.

Future Trends and Technology Developments

Technology in manufacturing is advancing and this affects the performance capability and application of the casting techniques. High technology sand formulations and fully-automated molding technologies enhance the accuracy and repeatability of sand castings, achieving a cost benefit. 3D printing technology offering high speed in pattern production provides lead time savings and allows more complex patterns to be produced.

Advances of die casting technology are better die materials, better process control systems, and automated finishing. Such advances, including low pressure die casting, explore the power of die casting better but at the same time enhances unit consistency and efficiency in production.

Decision-Making Framework

In choosing between sand casting and die casting models, several factors have to be carefully screened out. Economy of scale and expenses is fast at work in all three methods of spending the stipulation of the significance of volume study at the time of decision making. The choices are driven by the part size, the precision required of the part, the materials needed, and the budget.

When low-volume production is desired, large parts are required and a variety of materials and components are needed or where it is necessary to minimize the tooling costs initially, sand casting may be considered. When large-scale production volumes are involved, when tolerances are high precision, when the application requires a high surface finish and when cost reduction per unit is paramount, then die casting is the best choice.

Conclusion

Now your final decision will be if you use Sand casting or die casting vs investment casting should be according to your own specifications of manufacturing as far as the volume of production, and complexity of the parts, material requirement and budget factors etc. Whereas the sand casting technique is more flexible and costs less initially, the die casting technique is far more precise and efficient in high production situations. The most profitable manufacturers do not overlook any variable in the process of evaluation and have taken into account immediate production requirements and long-term production objectives to determine the best casting before utilizing it in their respective applications.