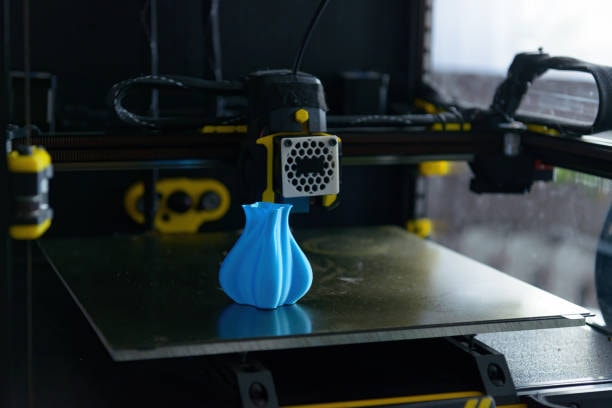

In-depth review between PLA vs PETG 3D printing filament, particularly focusing on renewable resources . Discover information about strength, durability, printing needs, and applications and what material to use when working on your projects.

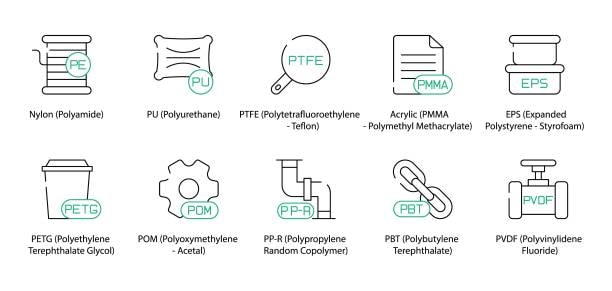

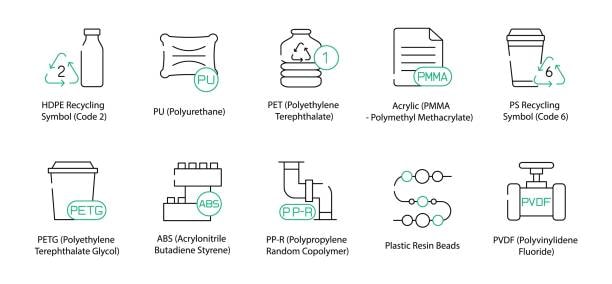

Since this could make or break a project it is important to make the choice of filament. These two thermoplastics, PLA (Polylactic Acid) and PETG (Polyethylene Terephthalate Glycol) are among the most frequently used ones because they are the most versatile and suitable materials that makers, professionals, as well as hobbyists, can use polyethylene terephthalate glycol modified. It is important to learn the basic differences, applications, and nature of the two in the context of petg vs pla to ensure optimum printing output withstand higher temperatures.

The current detailed analysis will enable you to make better choices about the advantages and disadvantages of PLA and PETG when deciding to use them in relation to special 3D printing requirements, ranging all the way to specialized requirements moderate heat resistance.

What is PLA Filament?

Polylactic Acid – or PLA as it is commonly referred to, is one of the most learner-friendly biodegradable thermoplastic derived materials used in 3D printing today. And indeed, PLA is based on renewable sources corn starch, sugarcane and other plant sources, which makes it a very eco-friendly method of 3D printing highest heat resistance. This thermoplastic that is environmentally friendly has become very popular owing to the ease of processing, little or no warping effect, and high quality finish of the surface.

PLA can be easily printed, is biodegradable and does not have a rough finish which makes it good as a first print out or a decorative printing. PETG, in its turn, is stronger, more flexible and temperature-intolerant, so it may be used both as a functional part, involving conditions of prolonged durability, especially when compared with heat resistance abs .

The material’s low printing temperature requirements and minimal odor during printing make it ideal for home environments and educational settings. PLA’s crystalline structure provides good dimensional stability, making it suitable for detailed prints and intricate geometries uv light.

What is PETG Filament?

PETG ( Polyethylene Terephthalate Glycol ) is a derivative of PET plastic, it has been boosted with glycol to enhance its 3D printing properties. It is an amorphous thermoplastic with the clearness and chemical resistance of PET and greater flexibility and impact resistance. PETG is stronger and more durable and the most important fact about PETG it is less rigid than PET and this makes 3D printing easier so that there is no chance of the print to be brittle acrylonitrile butadiene styrene.

As opposed to PLA, PETG is petroleum-based and is 100-percent recyclable. Its superior mechanical characteristics lends itself to good functional application as well as mechanical component and the need of greater durability than can be achieved with PLA key differences.

Chemical Composition and Structure

The key distinction caught up between PLA and PETG is their molecular construction and starting point, which are both crucial material properties . The PLA is a linear aliphatic polyester whose repeat unit is a lactic acid. It is semi-crystalline rendering it rigid and brittle at room temperature. The material’s glass transition temperature of approximately 60°C makes it suitable for low-temperature applications but limits its use in heated environments both petg.

PETG has an amorphous structure and its properties: irregular chain of polymers do not allow it to crystallize. This structure has very good optical transparency and greater flexibility than its crystalline equivalents petg prints. The addition of glycol disrupts the polymer’s ability to crystallize, resulting in improved impact resistance and elongation properties.

Mechanical Properties Comparison

As long as mechanical properties are compared, the two materials have different applications in the 3D printing ecosystem. Certain conditions are seen in PLA where they have higher tensile strength but portray characteristics of brittle failure. Its Young’s modulus is typically higher, indicating greater stiffness but reduced flexibility excellent layer adhesion.

PETG is more impact resistant and able to stretch further before breaking, a property that is to be preferred over applications needing toughness. PLA material may be suitable in applications with low stresses whereas ABS or PETG could be better to use in parts with high requirements of durability or heat resistance to maintain structural integrity plant based materials. The material’s ability to absorb energy before failure makes it ideal for functional parts subjected to stress.

Strength and Durability Analysis

The ability of PLA and PETG to withstand strength differs widely basing on testing conditions and the requirements one intends to use it in. PLA has an outstanding compressive strength and can handle operations that require high rigidity. But it is so brittle that it is prone to sudden failure either due to impact or stress concentration pla production.

PETG’s strength profile emphasizes toughness over pure tensile strength. The material’s ability to deform plastically before failure provides a safety margin in many applications. Such attribute is especially useful in applications requiring protective enclosures, mechanical components, and devices that are likely to be accidentally hit when in use low heat resistance.

Temperature Resistance Properties

Temperature resistance is also a serious distinguisher between these materials. PLA also starts becoming soft at a temperature of about 60 C thereby rendering it useless where there is extended high temperatures applications. The PLA parts can deform or fail in car interiors, outdoor summer temperatures or heated enclosures different materials.

PETG retains its structure over more elevated temperatures, having a glass transition temperature of approximately 80 o C. This increase in its resistance to temperature helps it to be used in places such as automobiles, electronic closures and other cases where moderate heat is likely to be experienced. It is able to contain minor exposure to heat of temperatures up to 100 C print settings.

Printing Temperature Requirements

The requirements of PLA printing temperature and that of PETG are very different, which influences the compatibility of printers and the consumption of energy. PLA has printing temperature range between 190-220, and that is why it is compatible with just about any desktop 3D printer out there. Such low temperatures need low energy consumption and heating rates could be quicker uv resistance.

PETG needs more printing temperature usually between the 220-260 0 C range. Although the majority of the modern 3D printers are able to reach such temperatures, the overall rise in the amount of heat leads to both warm-up and energy costs raw materials. The elevated temperatures also require effective cooling solutions that ensure that other printer parts are not overheated.

Bed Adhesion and Warping Characteristics

The bed adhesion behavior has an important influence in printing success and quality of parts. PLA shows great adhesion to bed on different surfaces such as glass, PEI, and fashioned build surfaces. It has a relatively low warping tendency that enables printing without heated beds, although, with slight heating (40-60 C), it can help with adhesion and surface quality very high temperatures.

PETG’s adhesion characteristics require more careful consideration. The material is very sticky in sticking onto build surfaces and this may be too sticky at times, damaging to other flexible build surfaces low stress applications. Optimal results are usually however recommended with the use of a heated bed at 70-80 o C. The high bond can be both in its favor to prevent warping and a difficulty in getting the parts out.

Surface Finish and Aesthetics

The quality of surface finishes is much different in PLA and PETG which will influence the final surface look and the need to apply some kinds of post-process applications. The PLA finish is smooth with gloss, which is good at prototyping, whereas the PETG has better strengths and flexibility, hence good at functional parts. PLA’s ability to achieve fine layer adhesion results in superior layer adhesion and smooth surfaces with minimal visible layer lines.

PETG has a different look which is commonly more transparent or even translucent, depending upon the colour variant. The material’s surface tends to be slightly rougher than PLA but offers better impact resistance. Clear PETG has optical clarity and is therefore used where the visibility of objects or light conduction is needed outdoor use.

Ease of Printing and Beginner Friendliness

Printing ease represents one of PLA’s greatest advantages for beginners and educational environments. The printing done in PLA is easy to operate since temperatures are low and PETG requires temperatures and heated bed. The material’s forgiving nature tolerates suboptimal settings while still producing acceptable results lower melting point.

PETG has a more specific requirement in parameter settings and printer calibration. PETG is more on the side of issues like stringing, bridging and adhesion to bed. Nevertheless, when adequate settings are utilized, PETG has the capacity to achieve stable and high quality results at low-maintenance levels outdoor environments..

Post-Processing Options

There is a large variation in post processing capabilities of these materials which influences the end application opportunities. Post-processing techniques applicable to PLA can be sanding, painting, acetone vapor smoothing (limited effect), mechanical. The material’s relatively soft nature makes it easy to machine or modify after printing infill density.

PETG’s chemical resistance limits some post-processing options but enables others. It may also be sanded, drilled, and machined. Because of its chemical resistance, it is apt in applications that include cleaning agents or modest chemical contact thermal stability. Nonetheless, there are fewer options of chemical smoothness as compared to other materials such as ABS.

Chemical Resistance Properties

Chemical resistance is very important when it comes to material selection of most applications. PA is not very chemically resistant, and it may be influenced by different solvents, acids and bases. This makes it improper to use under conditions or applications implying chemical exposure or routine cleaning with harsh cleaning agents many chemicals.

PETG has added benefits of excelled chemical resistance which is especially of acids, alkaline and variety of common solvents. This is what renders PETG reusable in laboratories, chemical holding units and medicine practise where a chemical exposure or sterilization is likely to occur. The material’s resistance to stress cracking in chemical environments provides additional reliability.

Flexibility and Impact Resistance

Another major dissimilarity between these materials is their flexibility attributes. PLA’s rigid nature provides excellent dimensional stability but limited ability to absorb impact energy. The parts under bending or impact loads can break suddenly.

PETG’s enhanced flexibility allows for energy absorption during impact, reducing the likelihood of sudden failure. Such a nature qualifies PETG to be used in protective equipment, enclosures, and those situations where they can be hit accidentally. The material’s ability to flex without permanent deformation extends part life in dynamic applications.

Environmental Impact and Biodegradability

The concept of environmental concern is also becoming a factor when selecting materials. PLA’s plant-based origin and biodegradability under industrial composting conditions make it an ideal environmentally conscious choice in the realm of additive manufacturing. Under special conditions the material decomposes into harmless byproducts with long-term less impact on the environment.

Although petroleum-derived, PETG is 100 percent recyclable in suitable waste rates. The material’s durability means parts last longer, potentially reducing replacement frequency. PETG, however, is not biodegradable and as such, should be managed as end of life through the appropriate recycling resources.

Cost Comparison and Value Analysis

Material decisions are influenced by cost factor especially in big applications. The prices of PLA are usually cheaper because of their availability and set production procedure. The material’s ease of printing also reduces failure rates, improving overall cost-effectiveness for many applications.

PETG has better performance and durable properties at an increased price per pound. The increased cost of materials can be countered by the fact that they will last longer and the replacement rates will be lower and the performance will also be better under stressful conditions. There is also an extra cost of printing PETG that comes with the cost of using more energy to achieve higher temperatures.

Applications and Use Cases for PLA

PLA is also composed in many operations in which its distinctive features are utilized to advantage. Prototyping represents a major use case, as PLA’s ease of printing and good surface finish make it ideal for concept validation and design iteration. Educational applications benefit from PLA’s safety profile and minimal printing requirements.

Decorative items, architectural models, and artistic projects showcase PLA’s surface quality and color availability. The material’s biodegradability makes it suitable for temporary applications or single-use items where environmental impact is a concern. Some pieces of food-safe PLA variants allow certain food contacts with appropriate certification.

Applications and Use Cases for PETG

PETG’s superior mechanical properties make it valuable for functional applications requiring durability. Mechanical parts, gears, brackets, and structural components benefit from PETG’s toughness and temperature resistance. The material’s chemical resistance suits it for laboratory equipment and chemical handling components.

Protective enclosures, electronic housings, and automotive components leverage PETG’s impact resistance and temperature stability. Medical and food contact applications (with appropriate certification) utilize PETG’s chemical resistance and sterilization compatibility. Transparent applications benefit from PETG’s optical clarity and impact resistance.

Printer Compatibility Requirements

Different printers can be used to print either PLA or PETG and this is based on the requirement. PLA is compatible with nearly any desktop 3D printer, simple ones that do not include heated beds or enclosures. This is universal compatibility which implies that PLA can be used by users with diverse printer set ups.

PETG uses printers that should be more competent and have stable temperature settings with heated beds. Only hotend made of metals will be suggested and provide a stable high-temperature operation. Closed rooms are optional but are better to achieve the quality and consistency of print size, especially those that are very large.

Troubleshooting Common Issues

Printing problems are typical of each kind of material, and their rectification depends on a special type of troubleshooting measure. The issues entailed by PLA are bed adhesion at cold environments, stringing at hot temperatures, and clogging effect concerning contaminated filament. All these can easily be solved by simple parameter settings.

The potential issue in PETG resolves around control of stringing, bed adhesion, and avoiding overheating. The material’s tendency to stick to nozzles requires attention to retraction settings and print speed optimization. Beneficial cooling methods avoid building of heat creep with layer adhesion being well preserved.

Storage and Handling Requirements

Storage will not only increase the life of the filament but will also preserve the print quality. Although it is not very hygroscopic as other materials are, it is useful to keep PLA in dry storage in sealed containers, with desiccant. Absorption of moisture might lead to print quality problems such as bubbling and a lack of adhesion to layers.

PETG is more hygroscopic and therefore moisture management takes much attention than in PET. Dry boxes or storage in a vacuum represents an aid that preserves filament quality. Both materials will enjoy safety in terms of ultraviolet light and temperature variations when under storage. Their filament spools should be properly handled to avoid mechanical damage and contamination.

Quality Control and Testing Methods

The methods of quality assessment assist in assuring uniform results on both materials. Most applications use visual inspection as the first quality control and inspect adhesion of layers, surface quality as well as dimensional accuracy. Part specification is criterion where dimensional verification with calipers or other advanced measuring devices is made.

Mechanical testing could be suitable on application of critical applications such as tensile testing, impacted testing, and fatigue studies. Generable print parameters can be used to replicate a productive outcome. Routine maintenance of printers will make them perform optimally with materials.

Future Trends and Developments

The plot of 3D printing materials is also changing with new advancements taking place in both PLA and PETG consistencies. Better PLA forms provide better temperature tolerance and mechanics safety along with being easy to print. Specific applications Specialty PLA formulations are conductive, magnetic, and composite.

The PETG development is oriented to enhanced features of processing and specific versions of the material towards certain industries. Improved optical properties, medical-grade formulations, and improved chemical resistance variants are development efforts. Filament performance characteristics are met by recycled content filaments at the same time concerns of sustainability are addressed.

Expert Recommendations and Best Practices

Selection of the materials must be based on the needs of a particular application instead of general preferences. There is no better material to be used in beginning and esthetic projects than PLA, whereas the material to choose when one needs tough and durable functional prototypes is PETG. In the choice of materials, considerations should be made towards the force requirements, environmental requirements, aesthetic and processing demands.

Successful printing requires understanding each material’s characteristics and optimizing printer settings accordingly. Begin with a recommended setting by the manufacturer and modify according to the printer specific configurations and specifications. Keep your own records of the parameters to duplicate the outcomes in various projects and periods.

Conclusion

Whether you use PLA or PETG will hinge on what your needs and wants are, what your printer can handle and how experienced you are. PLA is very easy to use and is therefore suitable when a novice is involved, education and other applications where visual quality is more important than the mechanical one. The fact that it is biodegradable and the processing temperatures that it is required to operate at are rather low also offer further environmental benefits and low cost to lesser-feature users and minimalist printer installations.

PETG provides excellent mechanical and durability properties, temperature resistant, and chemical compatibility, so it is the material of choice when considering top-level performance, functional parts or mechanical parts, or even challenging applications. Although PETG is more demanding in terms of parameter setup and the capabilities of a printer, it pays off by making some sturdy, dependable components that one can use in real-life situations.