The phrase “milling finish” reverberates across the world of engineering labs, machine shops, and factory floors. It encompasses the surface quality that remains after milling, a machining process and technique that shapes a workpiece by carving away material with rotary cutters. From the rough utility of industrial molds to the shining accuracy of aerospace components, milling finish is a crucial element influencing both the performance and impression of a product. Every aspect of milling finish—its definition, importance, varieties, tools, procedures, influencing factors, difficulties, applications, and future trends—is covered in great depth here

Ultimately, you will grasp the significance of milling finish as a combination of science, skill, and creativity that characterizes contemporary production, rather than merely a technical detail.

Understanding Milling Finish

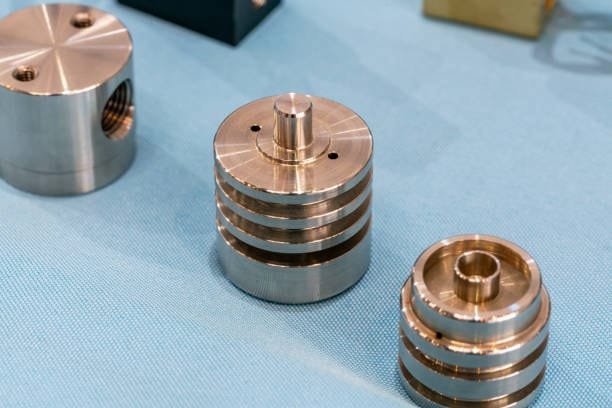

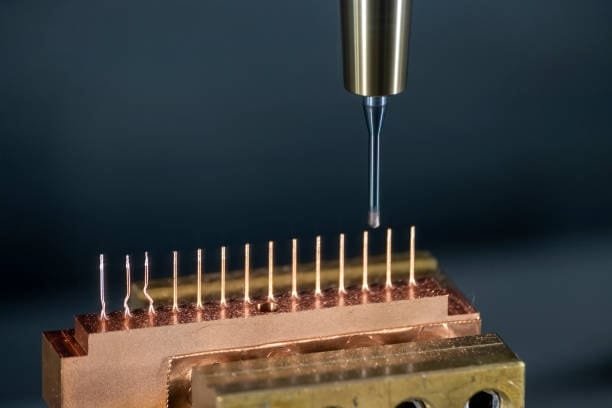

After a milling machine shapes a surface, milling finish describes its texture, smoothness, or roughness. Milling, at its core, is a subtractive process in which a cutting tool with several edges is spun around to remove material in chips. The resulting surface is a reflection of the interaction between the tool’s geometry, the cutting circumstances, and the workpiece’s qualities. As a quantitative characteristic, the finish goes beyond what meets the eye. Metrics such as Ra (average roughness) measure surface roughness as the average deviation of surface peaks and valleys in micrometers or microinches, providing a comprehensive picture of the finish.

Still, milling finish goes beyond simple numbers. It’s about intention. While a little coarser surface texture, might improve paint adhesion on an automobile part, a silky-smooth surface could be essential for a bearing race to reduce friction. A key factor in design and manufacturing since it is a customized result molded by the requirements of the end application.

The Critical Importance of Milling Finish

For what reasons is the milling finish critical? Its broad ramifications hold the solution. A poorly finished turbine blade in a high-stakes industry like aerospace could lower efficiency, interrupt airflow, or even jeopardize safety. The finish on a surgical implant in medical manufacturing has to be perfect to stop bacterial development or body irritation. Even with consumer products—consider the elegant cover of a smartphone—the surface finish measurement adds to durability, feel, and brand appeal.

Beyond just utility, milling finish affects economy. If you can get a good finish in one pass, you won’t have to grind or polish it afterwards, which will save you time and money. Conversely, over-engineering a finish over what is required might inflate costs without adding value. Understanding the part’s role and the tolerances it must satisfy makes milling finish a strategic as much as a technical decision a wise one.

Exploring the Spectrum of Milling Finishes

Milling may generate a wide range of finishes with unique properties and applications. The main forms are broken out here in great detail:

Average roughness

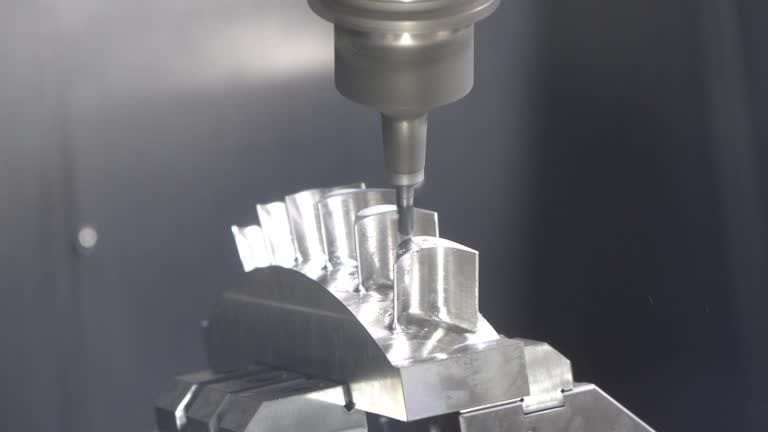

Aggressive milling, which involves using coarse tools, deep cuts, and high feed rates, results in a rough finish. The surface shows obvious tool marks, usually looking to be uneven or gritty. In roughing processes, where the objective is quick material removal rather than perfection, this finish is common. For prototypes or components that will be machined further, it’s a good option; nevertheless, machined parts for heavy-duty machinery and other similar applications may benefit from keeping a rough finish for grip and durability.

Semi-Finish: The Middle Ground

Semi-finishing closes the surface roughness-to- fine difference. By using moderate flow rates and finer tools, it is possible to smooth away the worst of the tool markings while still preserving some texture. Usually a preview of a final pass or a secondary procedure like sanding, this finish is still under construction. It’s quick and useful for portions where appearance counts but precision is not absolutely important.

Fine Finish: Precision Meets Practicality

Where milling begins to shine, a nice finish. It satisfies close tolerances and is smooth with little tool marks. Here, the secret ingredient is using high-quality cutters, slow feed rates, and shallow cuts. In precision engineering, this finish is a must-have; consider components such as shafts, gears, or decorative elements where both appearance and performance rule. It’s evidence of milling’s adaptability in juggling production reality with quality.

Mirror Finish: The Pinnacle of Perfection

Glossy, shiny, and almost faultless, the mirror finish is king of the hill. When used in conjunction with polishing or lapping, pure milling almost never accomplishes this on its own. Modern methods, however, can achieve results that are almost indistinguishable from a mirror, such as high-speed machining using diamond-tipped tools. Here, every reflection counts and this finish is the sweetheart of optics, luxury items, and high-end molds. Combining technology with artistry, it is the best way to show milling expertise.

Tools and Techniques: Crafting the Perfect Finish

The equipment and techniques applied determine the degree of a milling finish. Let us break out the basics.

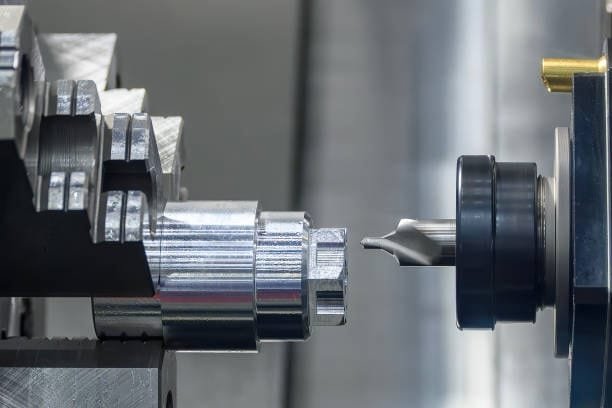

Milling Cutters: The Sculptor’s Chisel

The milling process revolves around the cutter, and the product surface finish is determined by its design. The versatile end mill, with its flat or rounded tip, is an indispensable tool for cutting slots or flat surfaces, producing patterns that are either straight or curved. Broad and multi-edged, face mills shine in smoothing out big regions. With their spherical ends, ball mills create contoured finishes for three-dimensional forms. You can get a better finish with more flutes (four or six), but they might become clogged with sticky substances, so it’s important to keep that in mind. On the other hand, fewer flutes clear chips better but leave rougher surfaces.

Tool Materials: Strength Meets Precision

Cutters come in a variety of materials, each appropriate for a given job. Affordable and strong, high-speed steel (HSS) wears fastest yet is perfect for softer metals. Modern milling is dominated by carbide tools, tougher and heat-resistant, which produce perfect finishes on alloys including titanium or stainless steel. Polycrystalline diamond (PCD) tools, which are diamond-coated, provide an unmatched level of finish and durability on plastics, non-ferrous metals, and ceramics.

Cutting Parameters: The Fine-Tune Dial

The tools of milling control include speed, feed, and depth of cut. Because of the combination of high spindle speeds (RPM) and low feed rates (the rate at which the tool advances), vibration and tool marks are reduced, which results in smoother finishes. Shallow depths of cut minimize heat and deflection, hence maintaining surface integrity. These are not general, though; brittle cast iron calls for prudence whereas soft aluminum tolerates sharp cuts. It is a dance of change calibrated to machine and content.

Coolants and Lubricants: Keeping It Smooth

Surface scorching or tool gumming caused by built-up edge can occur during milling due to the heat and friction generated. Minimum quantity lubrication (MQL), flood, or mist coolants mitigate heat, remove chips, and improve surface quality. While MQL, a thin spray, works for smaller finishing passes, flood cooling suits heavy cuts. Inspired by coated tools, dry milling bypasses fluid completely and relies on technique to preserve smoothness—a developing trend in environmentally friendly stores.

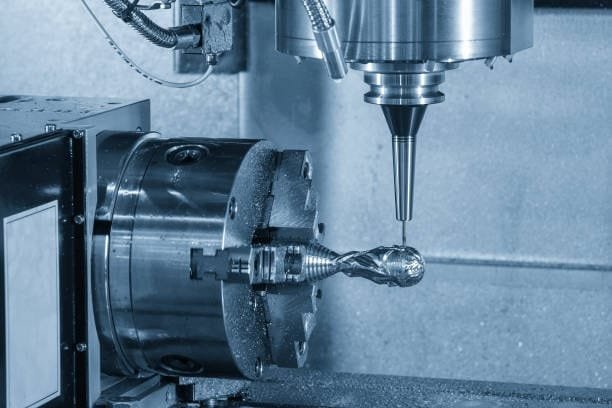

Machine Precision: The Foundation of Consistency

A quiet partner is the milling machine. Under consistent tool paths and finishes, CNC machines—guided by computer precision—outshine hand-operated mills. Rigidity is vital; an unstable machine chatters with wavy defects. For superior surface finish parameters and quality, particularly when working with fine or mirror-like materials, invest in a high-end equipment that includes linear guides, strong spindles, and vibration damping.

Factors That Shape Milling Finish

Beyond tools and methods, a multitude of factors affect the result.

Workpiece Material: The Canvas Matters

Materials react differently depending on milling. Soft and ductile, aluminium grinds easily with little effort. Exotic materials, such as Inconel, or hardened steels, resist by requiring more force and slower speeds. In the event that heat is allowed to accumulate, plastics may melt or smear, whilst composites run the risk of delamination. Every substance mandates its own finishing technique.

Tool Wear: The Silent Saboteur

An edged blade slashes with precision, while a dull one rips. Edge wear drags over the surface, rouging the finish. Tools dull faster in high volume runs, which calls for frequent checks or replacements. By keeping an eye on things like vibration or power demand, predictive maintenance can detect wear early on, which helps to keep quality high.

Vibration and Stability: The Enemy of Smoothness

Signs of chatter, which are vibrations of the tool and workpiece, can be seen as waves or ridges. It results from extended tool overhangs, high speeds, or unstable setups. Tools that are shorter or have sturdier holds or dynamic dampening devices are some of the countermeasures. A perfect surface finish chart starts with stability.

Tool Path Strategy: The Road to Perfection

The path the tool travels over the workpiece counts in CNC milling. Climb milling, the vertical distance in which the cutter and feed are aligned, frequently achieves smoother results than traditional milling, in which the cutter and feed are in opposite directions, and it effortlessly chops material. Adaptive tool paths change dynamically for complicated surfaces to provide consistency across angles and curves.

Challenges in Pursuit of Perfection

There are several challenges even with elite tools. Material defects—pores, inclusions, or hardness changes—disturb homogeneity. A run can be ruined by operator error, like as assuming too much about tool wear or speeds. Time constraints conflict with quality standards; hurrying a perfect completion invites errors. Shop temperature variations cause expansion, which skews accuracy. Mid-process, debris or dust scrapes surfaces. Overcoming these expectations calls for foresight, experience, and occasionally creativity.

Choosing the Right Tool for the Finish Pass

Sometimes the best surface finish calls for utilizing an other tool entirely for the finishing step. For instance, it may be required to use a face mill for a finishing pass after slitting sawing a component in half in order to smooth off the sawn surface. A roughing end mill is typically utilized for roughing operations, whereas a conventional end mill is typically employed for the final pass to improve the surface finish.

Improving Finish on Pocket Walls

An expert aerospace machinist on CNCZone suggested a helpful technique: when finishing off a piece of material, slightly reduce the depth of cut. This way, only the side of the end mill is coming into contact with the material surface defects. This change improves the surface polish and reduces chatter relative smoothness, therefore producing a more exact and aesthetically pleasing final result.

When machinists follow these procedures, their finishing passes will always be of the highest quality, with flat surfaces and accurate dimensions center line average surface roughness levels.

Applications: Where Milling Finish Shines

Every sector uses machining surface milling finishes. Precision finishes are required for engine blocks and pistons in the automobile industry in order to achieve efficiency and wear resistance desired surface finish. Aerospace needs landing gear and perfect airfoils. For perfect castings, mold makers hunt mirror finishes. Artists grind metal or wood for texture or polish; electronics depend on micro-milled circuits. It is a universal craft that fits every demand in every field.

The Future of Milling Finish

The horizon has promise. Driven by artificial intelligence, machining responds to material changes or tool wear on demand ra surface finish chart. Combining 3D printing with milling, hybrid systems first rough out forms then polish them predominant surface pattern. Eco-friendly coolants and dry milling pushed by sustainability help to decrease waste without compromising finish. These patterns signal a new age of accuracy and accountability in manufacturing process.

Conclusion

The hidden hero of production is milling finish, a mix of technical ability and imaginative problem-solving. Surface treatment, from surface roughness measured to cuts to mirror gleams, determines how a product feels machining surface finish chart, works, and lasts. While obstacles try the boundaries of knowledge and technology, tools, methods, and perseverance combine to meet rigorous needs achievable surface roughness. The finishes of milling will only become more amazing as milling develops, supporting the inventions of tomorrow.