A specialized manufacturing technique known as low volume machining concentrates on precisely and quickly manufacturing small quantities of parts. Low volume machining meets custom projects, prototypes complex parts, and specialized components while mass production stresses great output. Industries needing smaller quantities, quick response times and flexibility have come to favor this approach more and more.

What is Low Volume Machining?

Low volume machining is the manufacturing of small quantities of usually one to a few hundred units. It generates premium components without the need for significant further tooling and setup investments by combining high precision of engineering with effective processes. This is perfect for:

- Prototypes

- Custom parts

- Particular tools

- Limited manufacturing runs

Strategies to Optimize Budget When Designing Low-Volume CNC Parts

These useful design ideas will help you to reduce expenses produce high quality parts and save time when creating low- volume CNC machine machined parts cnc machining services:

1. Embrace Simple and Standard Designs

Reducing prices mostly depends on keeping your designs simple and consistent. More advanced than CNC milling systems, extra hand adjustments, and longer manufacturing times are common demands from complex designs cnc machining needs. When working on complex designs, think about breaking out the part into simpler pieces for easier assembly later on.

Key Considerations for Simplicity:

1.1 Use Standard Threads

Choosing standard thread sizes will save both time and money cost tooling, much as with conventional drill sizes. Selecting a common thread class instead of designing unique threads streamlines the machining process and lowers expenses prototyping projects.

1.2 Minimize Tight Tolerances

Although exact tolerances are sometimes required, too tight tolerances can greatly affect setup time, inspection procedures, and general machining costs. Set tolerances just as wide range or close as necessary to satisfy structural and functional requirements for your part.

1.3 Design Holes Using Standard Sizes

Manufacture of deeper holes is more difficult and expensive. Limit hole depth to five to six times the drill diameter if you want best results. Designing holes in common drill sizes also helps to avoid the need for specialized machine tools, so lowering machining time and expenses.

2. Select Suitable Materials for Low-Volume Production

Maintaining reasonable costs depends on selecting the correct material precision cnc machining services. Choosing rare or costly materials can cause needless inflation of expenses. When choosing supplies, think about:

- The necessary mechanical characteristics

- Material availability and cost

- Every material has machinability; some need longer processing times than others.

When at all possible, choose reasonably priced, readily available materials to cut expenses short run production without sacrificing quality.

3. Optimize Finishing Techniques and Text Application

In low-volume CNC machining, avoid complicated text designs or intricate finishes to help with lead time to control costs reduced time machine shop. While engraved text can improve the look of a product, the precision tracking needed for every character drives manufacturing time and costs.

Should labeling or branding be required, other surface finishing methods can save money and time. Using techniques like laser marking, painting, or silk screening, for instance, provides quick and reasonably priced ways to add logos or text to your machined components.

Advantages of Low Volume Machining

Low volume machining is a preferred manufacturing process of choice for many different sectors medical industries, since it provides several main advantages:

- Low volume machining reduces total costs by eliminating the need for expensive molds or dies unlike mass production.

- Faster Production Times: Setup and production times are greatly lowered since extensive tooling is not needed.

- Improved customizing allows manufacturers to quickly change designs or specs without major interruption.

- Modern methods including CNC machining guarantee exact, consistent results even for difficult designs.

- Flexibility: It fits several uses since it supports metals, plastics, and composites among other materials.

- Low volume machining is fit for just-in-time manufacturing, thus companies can cut storage costs by manufacturing just what is required.

- Companies testing new products can gain from small-scale production to find design flaws before committing to higher volumes, so lowering risk in the process of developing new products.

Common Techniques in Low Volume Machining

Low and high volume production finds several machining techniques especially successful. These comprise:

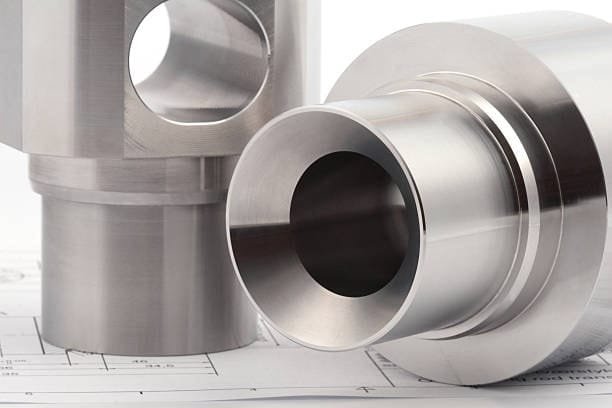

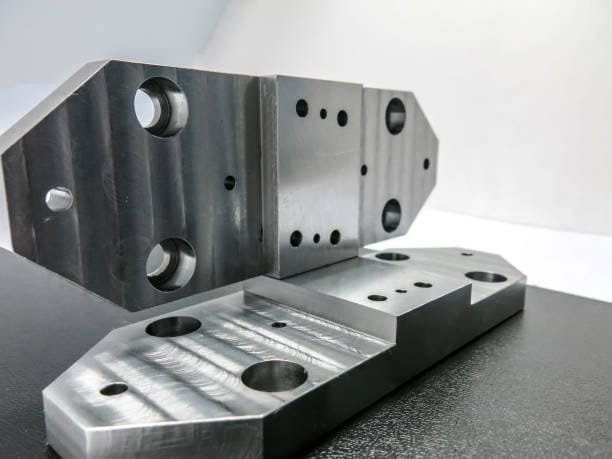

- CNC Machining: Known for accuracy and repeatability, CNC (Computer Numerical Control) machining is extensively applied for low volume production. CNC machining provides excellent finishes for plastics and metals as well as handles intricate geometries.

- 3D Printing: Perfect for fast prototyping, 3D printing lets quick design changes and effective small-batch manufacture possible. This technique shines in producing intricate forms and bespoke components.

- Laser Cutting: Perfect for precision-based designs, laser cutting—suitable for thin materials—offers clean edges and detailed intricacy.

- Water Jet Cutting: Water jet cutting is well-known for minimally heat distortion cutting through many materials to guarantee structural integrity of parts.

- EDM (Electrical Discharge Machining): Perfect for complex designs and hard materials difficult to cut conventionally, EDM—electrical discharge machining—is In the medical and aerospace sectors where accuracy is critical, EDM finds great application.

- Turning and Milling: Often combined into low volume machining systems, turning and milling are traditional machining techniques used to produce extremely precisely cylindrical or angular parts.

Applications of Low Volume Machining

Industries needing precision and accuracy, and customizing depend on low volume production runs and machining extensively. Typical uses consist in:

- Automotive Prototypes: Before going to mass production, automotive companies sometimes need specific parts for testing. Often created in small batches are components including engine parts, suspension systems, and performance enhancements.

- Aerospace Components: Custom aircraft parts have to be exact and satisfy high safety requirements. Low volume machining guarantees parts satisfy those needs without sacrificing quality.

- Medical Devices: Low volume machining is often used in surgical tools and implants to attain exact measurements. Small volumes of custom implants for each patient are often created to fulfill exact anatomical needs.

- Electronics: Accurate, small-batch manufacturing helps prototype and custom enclosure creation. Printed circuit boards, or custom PCBs, for testing new electronic equipment are often manufactured in small quantities.

- Consumer Products: Companies developing unique or premium products sometimes apply this method for consumer goods. Low volume machining is used, for instance, in luxury watches, customized cellphones, and other high-end devices.

- Robotics and Automation: Development of robotic arms, sensors, and control units sometimes requires tailored designs benefiting from low volume machining techniques.

Key Factors for Successful Low Volume Machining

In low volume machining, take these important considerations to reach best results:

- Material Selection: Selecting the correct material guarantees dependability, performance, and economy of cost. Popular materials are engineering plastics, titanium, aluminum, and stainless steel.

- Design Optimization: Simplifying designs without sacrificing functionality cuts machining time and expenses. Design can be streamlined and accuracy raised by using CAD tools.

- Precision Tools: Purchasing cutting tools and advanced CNC machines guarantees constant quality. Five-axis capable machines provide more freedom for intricate designs.

- Experienced Machinists: Skilled professionals, experienced machinists, are absolutely vital in delivering exact components with few mistakes. Skilled machinists guarantee effective production planning and reduce rework.

- Efficient Workflow: Productivity is raised by streamlining CAD/CAM design and toolpath planning among other tasks. Using digital simulations will also enable one to forecast problems before machining starts.

Challenges in Low Volume Machining

Low volume machining brings several difficulties even if it has advantages:

- Higher Cost Per Unit: Individual parts may cost more than mass production because of limited production levels.

- Material waste is a possibility from effective machining techniques.

- Frequent design changes can result in extra time and effort required for setup.

- In low volume settings, resource management—balancing production schedules—may become challenging and guaranteeing machinery availability—may prove difficult.

Key Benefits of Low-Volume CNC Machining

Low-volume CNC machining is a desirable option for companies looking for a quick turnaround and low volume production companies’ solutions because of its several benefits. Here is a closer examination at its advantages:

1. Enhanced Design Flexibility

Design flexibility in low-volume precision volume CNC machining production services is more than in conventional manufacturing techniques like die casting or injection molding. This adaptability allows producers to:

- Find design mistakes fast.

- Make little changes with low cost.

- Use customer comments effectively to enhance products before raising output levels.

2. Faster Time to Market

Low-volume CNC machining lets companies in competitive sectors where trends change quickly provide high-quality products in less time. Companies can keep ahead of rivals and fit to market needs by avoiding long and expensive tooling lead times.

3. Improved Cash Flow

Low-volume CNC machining lets companies create income faster by speeding up the production line. This effective system guarantees products reach the market rapidly in low volume, short production runs, so reducing inventory build-up and increasing cash flow by means of turnover rates enhancement.

4. Transition Support Between Prototyping and Mass Production

Between initial prototyping and full-scale manufacturing, low-volume CNC machining is absolutely vital. It helps companies test product designs, improve manufacturing techniques, and guarantee that before committing to higher volumes, the highest quality standards are satisfied.

5. Precision and High-Quality Parts

CNC machines are quite good in delivering parts with exact tolerances and excellent surface finishes. Low-volume CNC machining is perfect for automotive aerospace and companies where accuracy and durability are critical factors since this precision guarantees products satisfy exact criteria.

How to Overcome These Challenges

To properly tackle these difficulties:

- Embrace Automation: Adopting CNC programs and automated systems helps to lower labor costs and increase efficiency.

- Partner with Experts: Working with seasoned machining experts will help to maximize design efficiency and reduce mistakes.

- Leverage Prototyping Tools: Use CAD tools and digital simulations to find design defects before machining starts, so lowering expensive errors.

- Use Multi-Functional Machines: Investing in machinery that runs several machining operations helps to lower the demand for regular part transfers by so improving efficiency.

- Outsource Specialized Tasks: Outsourcing difficult operations like EDM or laser cutting to specialized companies can help to save costs and produce better results.

Future Trends in Low Volume Machining

Technological developments in low volume machining are changing its future:

- Artificial intelligence improves CNC programming, so increasing accuracy and efficiency.

- Smart machining tools let real-time monitoring for improved quality control.

- Eco-friendly materials and waste reduction techniques are starting to be standard in machining processes.

- Lightweight alloys and improved composite materials are extending the possibilities of low volume machining.

- Making digital copies of machined parts lets manufacturers virtually examine performance before building the actual component.

Conclusion

For companies looking for accuracy, adaptability, and reasonably priced manufacturing in small quantities, low volume machining offers a great answer. Combining cutting-edge machining technologies with effective processes helps companies produce excellent products free from mass production’s overhead. Low volume machining provides a sensible answer for contemporary manufacturing needs whether for prototypes, custom parts, or specialized equipment. For companies looking for accuracy, adaptability, and accelerated product development—low-volume CNC machining is a flexible and reasonably priced solution. Companies can effectively improve designs, control cash flow, and provide premium goods to the market by using this approach instead of heavily spending in big-scale production equipment.