Modern life depends on plastics, which find use in everything from electronics and cars to food packaging. Knowing how plastics are produced helps one to appreciate the science underlying this flexible substance. From raw materials to final goods, this blog looks at the plastic manufacturing process.

Introduction

Synthetic materials derived mostly from natural resources and renewable materials including crude oil, natural gas, even plants are plastics. Their adaptability, robustness, and economy have made them indispensable in many different sectors. let us dissect the complex process underlying plastic manufacture.

Types of Plastics and Their Characteristics

Thermoplastics and Thermosets are two main polymer families that divide the flexible materials known as plastics mostly. Every category shows different qualities that define its uses and behavior.

1. Thermoplastics

Thermoplastics are materials that harden once cool and soften under heat. Reversibility of this process lets thermoplastics be repeatedly reshaped. Their flexibility and simplicity of processing make these plastics rather popular.

Examples of Thermoplastics:

- Usually found in LEGO bricks and automotive parts, acrylonitrile butadiene styrene (ABS)

- Often found in electronic components and eyewear lenses, polycarbonate (PC) is well-known for impact resistance.

- Found in pipes, bottles and packaging films, polyethylene (PE)

- Common in food and beverage containers is polyethylene terephthalate, or PET.

- Commonly known as Teflon, polytetrafluoroethylene (PTFE) finds application in non-stick cookware.

- Plumbing pipes, window frames, and flooring all call for polyvinyl chloride (PVC).

- Used in display cases and signage, polymethyl methacrylate (PMMA) is a clear plastic.

- Polypropylene (PP) finds use in textiles, food containers, and automotive parts.

- Polystyrene (PS) finds application in insulation, CD cases, and throw-away cutlery.

- Ideal for packaging and building insulation, polystyrene (EPS) is lightweight.

2. Thermosets

Thermosets are plastics that, heated and molded, permanently chemically change. Unlike thermoplastics, once hardened they cannot be remelted or reshaped. Thermosets are prized for heat resistance, strength, and durability.

Examples of Thermosets:

- Applied in electrical insulators, coatings, and adhesives, epoxide (EP)

- Commonly found in kitchenware handles and electrical outlets, phenol-formaldehyde (PF) is heat-resistant.

- Furniture cushioning, mattresses, and insulation foam all contain polyurethane (PUR).

- Boat hulls, auto parts, and coatings all use unsaturated polyester resins (UP).

3. Comparison Table

See the table below to compile the traits and illustrations of every kind:

| Type of Plastic | Properties | Examples |

| Thermoplastics | Soften on heating, harden on cooling, can be reshaped multiple times | ABS, PC, PE, PET, PTFE, PVC, PMMA, PP, PS, EPS |

| Thermosets | Harden permanently after heating, cannot be reshaped | EP, PF, PUR, UP |

Knowing these plastic varieties enables businesses to select the appropriate material for particular uses, so guaranteeing durability, safety, and efficiency in product design.

Main Ingredients in Plastic

Key Components of Plastic

Usually derived from crude oil and natural gas, most plastics consist of these components. These sources are refined to produce petrochemicals needed for plastic manufacture.

Clear, opaque, flexible, rigid, and soft versions of plastics are among their several forms. Although polymer resins form the basic building block for plastic, additives are also included to improve particular qualities including color, elasticity, hardness, or toughness. For some uses, also crucial compound improving hygiene and safety are additives.

Identifying Plastic Types

The resin identification code (RIC) at the bottom of plastic containers, usually helps one identify different types of plastic. Every code relates to a particular kind of plastic having special chemical characteristics.

Common Plastic Types and Their Monomers

The following lists main forms various shapes of plastic, their corresponding monomers, and structural features:

| Resin Identification Code | Polymer Name | Monomer | Characteristics |

| ♳ PETE | Polyethylene terephthalate (PET) | Ethylene glycol + Dimethyl terephthalate | Common in beverage bottles, strong and clear |

| ♴ HDPE | High-density polyethylene (HDPE) | Ethylene (CH2=CH2) | Rigid with minimal branching, durable |

| ♵ PVC | Polyvinyl chloride (PVC) | Vinyl chloride (CH2=CH-Cl) | Strong, resistant to moisture and chemicals |

| ♶ LDPE | Low-density polyethylene (LDPE) | Ethylene (CH2=CH2) | Flexible with extensive branching, used in bags |

| ♷ PP | Polypropylene (PP) | Propylene (CH3-CH=CH2) | Heat-resistant and durable, used in containers |

| ♸ PS | Polystyrene (PS) | Styrene | Lightweight and insulating, used in packaging |

| ♹ Other | Varied | Different monomers | Includes acrylic, polycarbonates, PLA, and nylon |

Differences Between LDPE and HDPE

From the same monomer—ethylene (CH2=CH2—both LDPE and HDPE are produced). Their structural variation, though, is in the degree of branching:

- Features great branching, LDPE is flexible and fit for films or plastic bags.

- With less branching, HDPE produces denser, stronger material perfect for pipes and containers.

Knowing these differences helps businesses and consumers choose the kinds of plastic they use with knowledge.

1. Raw Materials for Plastic Production

Usually formed from hydrocarbons found in:

- One major hydrocarbon source including ethylene and propylene is crude oil.

- Often found in the manufacturing of polypropylene and polyethylene is natural gas.

- Plant-based plastics such as PLA (polylactic acid) come from corn starch or sugarcane.

2. Polymerization: The Core of Plastic Formation

Plastic manufacture is mostly based on polymerization, a chemical reaction that links monomers—small molecules—into long chains called polymers. Two main polymerizing techniques exist:

- Complementary Monomers such as ethylene and propylene bond to create polymers free of byproducts.

- Condensation: Monomers mix to release a small molecule like water in polymerization. Materials like polyester and nylon are applied to this technique.

3. Types of Plastics and Their Formation

Plastics are arranged according to various types and their structural and characteristic qualities:

- Thermoplastics—plastics—soften with heat and can be reshaped. Among these are polypropylene (PP), polyethylene (PE), and polyvinyl chloride (PVC).

- Hardening permanently after heating, thermosetting plastics cannot be reshaped. Bakelite and epoxy resins are two examples here.

4. The Manufacturing Process

The process of manufacturing plastic consists in several stages:

Step 1: Extraction and Refining

- Extracted and refined crude oil or natural gas yields naphtha, a vital component for plastic manufacture.

Step 2: Cracking

- In a process known as cracking, naphtha is heated to break big hydrocarbon molecules into smaller ones like ethylene and propylene.

Step 3: Polymerization

- Raw plastic products called resins arise from the polymer chains formed by the ethylene and propylene monomers undergoing polymerization.

Step 4: Compounding

- To get desired properties, resins are blended with additives including colorants, stabilizers, and plasticizers.

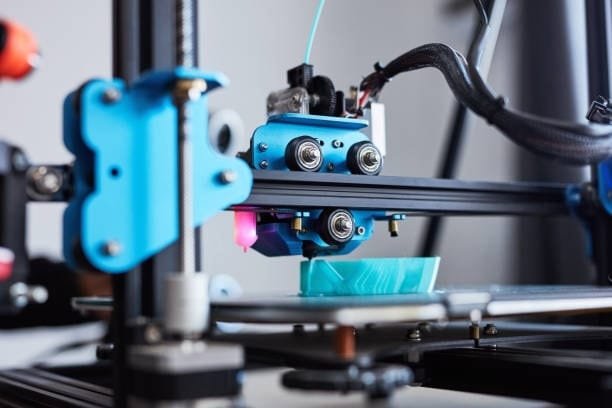

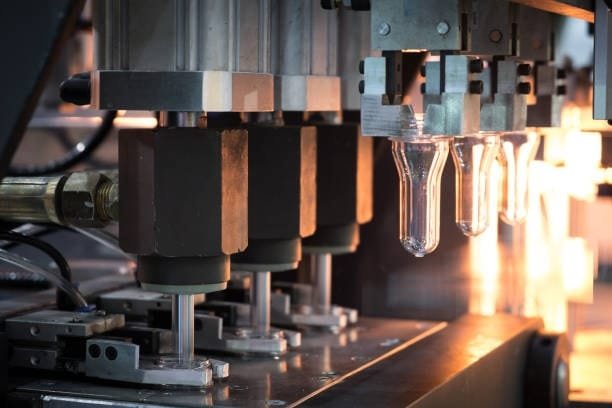

Step 5: Molding and Shaping

Different molding techniques then help shape plastics:

- Perfect for creating intricate forms like car parts and bottle caps is injection molding.

- Made for hollow objects like bottles, blow molding

- Extrusion shapes plastic into continuous profiles like window frames or pipes.

- Large hollow products like tanks are produced using rotational molding.

Step 6: Finishing

- Trimming, polishing, and assembly of plastics into their final form

5. Environmental Impact of Plastic Production

Although plastics have great benefits, their environmental effect cannot be disregarded:

- Production of plastic calls for significant energy, which fuels greenhouse gas emissions.

- Waste Management: Single-use plastics have seriously caused pollution problems.

- Efforts to advance recycling technology and create biodegradable plastics are continuous..

6. Innovations in Plastic Production

Modern developments concentrate on environmentally friendly solutions:

- derived from renewable sources such as cornstarch, bio-based plastics

- Novel materials called recyclable thermosets mix thermoset strength with recyclability.

- Closed-loop recycling systems help to increase plastic reusing efficiency.

How Plastics Are Made

Plastic production consists in several important phases that turn raw materials into adaptable and strong goods. Below are the main actions of plastic particles:

1. Extraction of Raw Materials

Most plastic manufacturing starts with raw material extraction—coal, natural gas, or heavy crude oil either. Thousands of compounds in these materials mix intricately and need processing to separate valuable components.

2. Refining Process

Crude oil is heated in a furnace first during refining before passing through a distillation unit. This divides the salt and crude oil together in smaller fractions. One distillation of crude oil of the most important byproducts, naphtha, is a fundamental component used in large amounts to make most of plastics. Furthermore derived from refining and used as substitute sources for plastic manufacturing are gases like ethylene and propylene.

3. Polymerisation

Polymerisation is a chemical process whereby light olefin gases such as ethylene, propylene, and butylene are transformed into higher molecular weight hydrocarbons and polymers result. Long chains of repeating monmers are produced by this process. Two primary polymerisation techniques exist:

Addition Polymerisation

- With this approach, monomers link one at a time under the direction of a catalyst—such as peroxide. Long polymer chains are progressively built by this chain-growth process.

- Polymer examples include polyethylene (PE), polystyrene (PS), and polyvinyl chloride (PVC).

Condensation Polymerisation

- This technique removes small molecules like water by combining two or more different monomers. Smaller polymer chains could be connected in this step-growth process into bigger structures.

- For instance: nylon and polyester.

4. Compounding and Processing

Plastic products are mixed with various chemicals and additives at this stage to produce particular formulations. An extruder melts and blends this mixture; next, it is pelletized. These pellets are then worked into either semi-finished plastic pellets or completed plastic goods. Twin-screw extruders are commonly used in the compounding process to guarantee correct final product size, shape, and color from start.

Summary Table

| Stage | Process Description | Key Examples |

| Extraction | Raw materials such as crude oil, natural gas, or coal are extracted. | Crude oil, natural gas, coal |

| Refining | Crude oil is heated and separated into lighter fractions, including naphtha. | Naphtha, ethylene, propylene |

| Polymerisation | Monomers are bonded into chains through addition or condensation methods. | PE, PS, PVC, Polyester, Nylon |

| Compounding/Processing | Blends are melted, pelletised, and shaped into products via extruders. | Plastic objects, components, and packaging |

This simplified process enables companies to create a wide range of plastic products with exact properties catered to their intended use.

The First Human-Made Plastic

With early civilizations and contemporary creators helping to shape human-made plastics, they have evolved greatly over the ages.

Early Use of Natural Materials

Natural latex and rubber were used by Mesoamerican societies including the Olmec, Maya, and Aztecs (1500 BCE) to make waterproof clothing and containers. This early awareness of polymer materials shown by this crude form of plastic

The First Bioplastic: Parkesine

Parkesine, the first man-made bioplastic patented by Alexander Parkes (UK), 1856 Parkesine derived from cellulose nitrate was well-known for being:

- Hard

- Flexible

- Transparent

Parkesine had promise but only limited commercial success. But Parkes’s creativity set the stage for next developments in plastic engineering.

Celluloid: The Improved Bioplastic

John Wesley Hyatt (US) refined Parkesine’s recipe in the 1860s by including camphor, increasing its malleability. We called this fresh material Celluloid. Making a replacement for ivory in billiard balls was Hyatt’s main aim. Celluloid started to be extensively used in many different products including:

- Film reels

- Comb handles

- Jewelry

The First Fully Synthetic Plastic: Bakelite

Leo Baekeland (Belgium) created Bakelite in 1906, so marking the breakthrough for synthetic and plastics industry. Made from phenol and formaldehyde resin, this material evolved into the first entirely synthetic plastic with amazing qualities:

- Great opposition to chemicals, heat, and electricity

- Non-conducting qualities perfect for electrical equipment

Bakelite transformed sectors and became indispensable in manufacturing products including:

- Radio casings

- Telephones

- Kitchenware

1. Polymer vs. Plastic

Though not every polymer is categorized as plastic, all plastics are a class of polymer.

Greek is the source of the words “polymer” and “moner: “poly” means “many,” “mer” means “repeating unit,” and “mono” means “one.” This suggests that several repeating monomer components make up a polymer. Like pearls strung linked together to form something, polymers are big molecules made from bonding many monomer units in a chain-like fashion.

The Latin word “plasticus” (meaning “capable of molding”), and the Greek word “plastikos” (meaning “fit for molding”) define the term “plastic”. Plastics are synthetic or naturally occurring organic polymers mixed with other materials having a high molecular weight.

Made from elements including carbon, hydrogen, oxygen, nitrogen, sulfur, and chlorine, plastics are organic polymers with significant molecular structures. Commonly found in silicone products including silicone implants or silicone hydrogels, some plastics are also made from silicon atoms. Mixing polymeric resin with other materials called chemical additives often results in plastics most of which.

A material’s plasticity—that is, its capacity to distort without breaking—determines whether a polymer can resist the heat and pressure during molding.

We can control the characteristics of polymers by changing chemical structures—that is, by changing monomers or reorganizing their configurations. This adaptability makes it possible for tailored plastics meant for particular uses.

2. Understanding Hydrocarbons

Hydrocarbons found in fossil fuels including coal, natural gas, and crude oil form most of the plastics used today.

What are Hydrocarbons?

Organic molecules with carbon and hydrogen atoms are hydrocarbons. Two varieties of these chemical compounds are distinguished:

- Aliphatic hydrocarbons lacking cyclic benzene rings

- Aromatic hydrocarbons feature benzene rings.

With four electrons in its outer shell, carbon (C) can make bonds with four hydrogen atoms, producing the simplest hydrocarbon, methane (CH4). Larger hydrocarbons including ethane (C2H6), propane (C3H8), and butane (C4H10) arise as carbon atoms bond with each other and additional hydrogen atoms. The Alkane family refers to this series.

Examples of Alkane Hydrocarbons:

- CH4, methane; C2H6, ethane

- propane (C3H8)

- Butane, C4H10, however

- Pentane (C5H12).

- Heptane, hexane, octane, and so forth.

Double or triple bonds also exist in hydrocarbons:

Alkene Family:

- C2H4 is ethylene; CH2=CH-CH3 is propylene.

- 1: butylene (CH2=CH-CH2-CH3)

- 2-butylene (CH3-Ch=CH-CH3)

Alkyne Family:

- C2H2 is ethyne; CH≡C-CH3 is propyne.

- One butyne (CH≡C-CH2-CH3)

- 2-butyne (Ch3-CH≡CH-CH3)

3. Fossil Fuels and Their Origins

Rich in carbon, hydrogen, nitrogen, sulfur, oxygen, and diverse minerals are fossil fuels including coal, natural gas, and crude oil. These fuels are thought to have originated millions of years ago from the remains of microscopic marine life called plankton. Layers of sediment buried these creatures over time, and under great heat and pressure they changed into hydrocarbons. Eventually, crude oil and gas leaked into rock formations to create reservoirs under ocean beds and below ground layers. Mostly coal comes from the remains of extinct plants.

Creating Synthetic Plastic from Crude Oil

1. Oil Extraction Process

Synthetic plastic starts with the oil being extracted from under the surface of Earth. Drilling operations are carried out to extract the oil once a feasible source has been found.

- Using pumps, which can extract between five to forty litres of oil per stroke, oil is taken from subterranean reservoirs. Platforms used in offshore drilling help to support the extraction operation.

- Extracted oil is then moved to refineries for additional processing using big tankers or pipelines occasionally spanning thousands of miles.

- Environmental Considerations: Although pipeline leaks endanger the surroundings, rigorous safety measures are followed to lower possible spills and so minimize environmental damage.

2. Refining Crude Oil

Once delivered to a refinery, the crude oil is refined in a sequence to separate its components.

- Crude oil is heated in a furnace and the resultant vapour passes via a fractional distillation column. The hydrocarbons sort in this column according to boiling points.

- While intermediate and heavier fractions settle in the middle and bottom respectively, the top of the column is cooler allowing lighter fractions like gasoline and petroleum gas to condense there.

- Key resources for many different sectors, the separated fractions include petroleum gas, gasoline, kerosene, naphtha, and heavy oils.

3. Cracking Hydrocarbons

Cracking is used to break long-chain hydrocarbons into simpler molecules fit for plastic manufacture.

- Using strong heat and pressure, this technique— Steam Cracking—breaks down intricate hydrocarbon chains free from a catalyst.

- This technique adds a catalyst so that the breakdown process may take place under less pressures and temperatures.

Obtained during oil refining, naphtha and natural gas comprise the main raw materials used to produce plastics, in this stage global plastic production. Plastic manufacturing depends on cracked hydrocarbons including ethane, propane, butane, and naphtha.

4. Types of Polymerisation

Two main forms of polymerisation, the chemical reaction used to create synthetic plastic:

- Using this technique, monomers are joined in a continuous chain whereby each one bonds to the next. The process may proceed in either the vapour or liquid phase and calls for a catalyst. Usually, addition polymerisation leaves no by-products. Among these are polystyrene, polypropylene, poly vinyl chloride (PVC), and polyethylene.

- Combining two monomers under condensation polymerization produces a dimer and generates a by-product, water. Longer chains of dimers keep combining to create tetramers and bigger molecules. Usually water, the by-products are eliminated to guarantee the success of the reaction. Sometimes these byproducts can be recycled back into the operation.

Understanding these procedures helps us to appreciate the sophisticated yet effective techniques applied to produce synthetic plastic from crude oil.

How is Plastic Created from Naphtha?

One important raw ingredient used in plastic manufacture is naphtha. Important molecules including ethylene and propylene, which form the basis for oil-based plastics, are extracted from naphtha.

Understanding Naphtha

A group of volatile liquid hydrocarbons produced from crude oil distillation is called naphtha. Usually consisting of hydrocarbons with carbon chains ranging from C5 to C10, this very complex mixture of thousands is

The Role of Naphtha in Plastic Production

Steam cracking is the process of thermal breakdown Naphtha goes through. This process heats naphtha in the presence of water vapor to very high temperatures—about 800°C. Crucially important intermediates for plastic manufacture, the naphtha breaks down into smaller hydrocarbon molecules during this heat treatment.

Key Intermediates from Naphtha Cracking

Two main sets of intermediates are produced by the thermal decomposition process:

- Ethylene (C2), propylene (C3), butane, and butadiene (C4) are among olefins.

- Benzene, toluene, and xylene comprise the group known as aromatics.

Polymer chains are built from these tiny molecules.

Polymer Formation Process

The intermediates are coupled to create long molecular chains called polymers once they are obtained. Still in their raw form at this point, the polymers typically show up as grains, powders, or liquids.

Transforming Polymers into Plastic Products

Polymers are first processed several times before they can be turned into useable plastic goods:

- To increase its flexibility and ready the raw polymer material for shaping, it is kneaded and heated.

- Melting and Cooling: The heated polymer is melted and cooled to create varied sized and designed solid forms lighter components called fractions.

- Adding stabilizers and antioxidants helps to improve the durability and performance of the plastic.

- For example, polyethylene (PE) is turned into strings by means of an extruder. These threads are ground into tiny PE pellets next-wise.

- Factories melt these pellets and shape them into completed plastic products with particular colors, forms, and properties gas salt and crude.

Following these guidelines helps naphtha-based materials to be effectively converted into the variety of plastic goods we consume on a daily basis petrochemical industry.

Materials Used Before Plastic

Before plastic was invented, many natural used materials such as cellulose were extensively used for the construction of daily goods and storage solutions climate change. Among these products were:

Common Pre-Plastic Materials

- Because of its longevity, wood is often used in utensils, tools, and furniture.

- Often used for structural, tool, and container needs is metal.

- Though often delicate and heavy, glass is used for bottles, jars, and decorative accents cellulose coal natural gas.

- Because of its heat resistance, ceramic is a common material for cookware and accent items.

- Tools, accessories, and protective gear came from animal-derived materials including leather, bone, and horn.

Early Innovations in Storage Materials

- Glass mixed with clay and pottery was formed into storage containers polymerisation or polycondensation process. Although strong, these materials were sometimes heavy and delicate coal natural gas salt.

Introduction of Natural Rubber

One of the main inventions before synthetic plastic was one made from natural materials was rubber. Originally sticky and lacking useful durability for storage and daily use lighter components, this material came from the latex resin of rubber trees.

The Discovery of Vulcanized Rubber

The 18th century saw a major discovery when Charles Goodyear unintentionally came across vulcanized rubber. Goodyear produced a material with sulfur added to heated crude rubber that was:

- Strong: Able of resisting compression and stretching plastic pollution.

- Elastic: Able to recover from deformation into its original form chemical bonds.

Comparison Table: Pre-Plastic Materials vs. Rubber

| Material | Properties | Common Uses |

| Wood | Durable, versatile, natural | Furniture, tools |

| Metal | Strong, conductive, corrosion-resistant | Tools, containers |

| Glass | Transparent, fragile, recyclable | Bottles, windows |

| Ceramic | Heat-resistant, heavy, fragile | Cookware, pottery |

| Animal Materials | Flexible, durable, organic | Accessories, tools |

| Natural Rubber | Flexible, sticky, early version lacked durability | Primitive containers, adhesives |

| Vulcanized Rubber | Resilient, elastic, durable | Tires, seals, protective gear |

Offering enhanced flexibility, durability, and lightweight characteristics, the development from these natural materials to synthetic plastics represented a significant turning point in manufacturing toxic chemicals.

Conclusion

The manufacturing of plastic is a wonderful fusion of engineering and chemistry. From basic molding techniques to crude oil refining, every step of plastic produced is vital in generating strong, flexible materials. Reduced environmental impact depends on innovations in plastic manufacture as businesses move toward sustainable practices.