CNC machining is precise, automated, and efficient, revolutionizing production. Modern production in several sectors, including aerospace, electronics, and jewelry, depends critically on computer numerical control (CNC) machining. Still, how CNC machining operations actually runs? This all-encompassing book will look at the foundations of CNC machining, covering its operational principles, types, advantages, and challenges as well as its future directions.

What is CNC? A Brief Overview

Computer Numerical Control, or CNC for short, is a method of automated machine tool operation driven by programmed software. Machines used in computer numerical control (CNC) for machining operations are more precise, repeatable, and efficient than those in manual machining, which involves human intervention cnc milling. A wide range of industries can benefit from the technique, including electronics, plastic molding, carpentry, and metalworking.

The CNC Process: Step-by-Step

CNC machining follows a structured workflow that ensures precision and consistency cnc controller. Below is a step-by-step breakdown of how the CNC manufacturing process works:

1. Designing the Model (CAD)

The first step in the procedure is creating a Computer-Aided Design (CAD) file. Using CAD tools as AutoCAD, which is SolidWorks, or Fusion 360, engineers or designers produce a thorough 2D or 3D model. The model calls for exact tolerances, dimensions, and material standards.

2. Converting the Design into Machine Code (CAM)

Following the completion of the CAD model, the CAM (computer-aided production) software begins the process of converting it into G-code and M-code. These codes inform the CNC machine of movement:

- Motion, cutting, and positioning are all controlled by G-code.

- M-code: Adjusts tools and coolants.

3. Setting Up the CNC Machine

Prior to the execution, operators are required to:

- Turn the machine on and fasten the piece of work.

- Fill drills, mills, and lathes with the right tools.

- Alignment of the axis, feed rates, and tool speeds should all be calibrated.

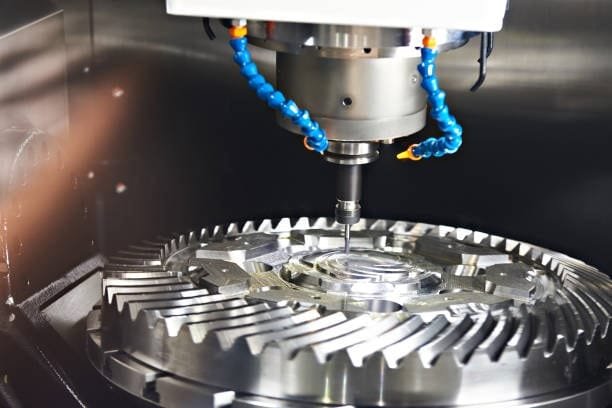

4. Executing the Machining Process

The CNC machine will then proceed to cut, drill, or shape the material in accordance with the instructions that have been programmed into it once everything has been set up. The construction of intricate components is made possible by the movement that takes place along numerous axes, sometimes even more than that.

5. Quality Control and Finishing

Calipers and laser scanners examine items after milling. The last product may be improved by means of finishing techniques including polishing, painting, and deburring.

Types of CNC Machines

There are numerous varieties of CNC machines available for use in a variety of applications. Here are some often occurring ones:

1. CNC Milling Machines

- Make use of cutting tools that rotate in order to remove material from a workpiece that is stationary.

- Hole, slot, and contour.

2. CNC Lathes

- While stationary tools are shaping the workpiece, move it about.

- This material is perfect for the production of cylindrical things like shafts and screws.

3. CNC Routers

- Principally utilized for engraving soft metal, plastic, and woodworking projects.

- quite good for carvings and fine cutting.

4. CNC Plasma Cutters

- To cut through materials that are electrically conductive, such as steel and aluminum, high-temperature plasma can be utilized.

5. CNC Laser Cutters

- When making delicate incisions, focused laser beams are the tool of choice.

- Appropriate for use with thin materials like as acrylic, wood, and metal.

6. CNC Electrical Discharge Machines (EDM)

- You can degrade materials by using electrical sparks.

- Perfect for creating finely detailed metal pieces and complex moulds.

7. CNC Water Jet Cutters

- The use of high-pressure water, which is sometimes combined with abrasives, is an effective method for cutting through difficult materials such as stone and ceramics.

Benefits of CNC Machining

CNC outperforms hand machining in many ways:

1. Precision and Accuracy

- Achieving tolerances down to the nano level is possible.

- Ensures that all of the parts are consistent with one another.

2. Efficiency and Automation

- Performs well around the clock with little oversight.

- It speeds up manufacturing while simultaneously cutting down on lead times.

3. Reduced Human Error

- Errors are reduced dramatically in computer-controlled operations.

- When huge manufacturing batches are being produced, consistency is maintained.

4. Versatility

- Metals, polymers, composites, and ceramics are just some of the materials that can be processed by this machine.

- Versatile for many sectors and uses.

5. Scalability

- Appropriate for both bulk manufacturing and prototyping in small batches.

Key Machinery Utilized in CNC Systems

These CNC machines incorporate a wide variety of specialized tools in order to reach the highest possible level of precision and adaptability. To precisely shape, cut, or engrave materials, each tool performs a distinct purpose that no other tool can. The following are some of the main CNC manufacturing machines:

1. Embroidery Machines

As a result of its ability to create detailed designs and exact stitches on materials, CNC embroidery machines are frequently utilized in the fashion and industrial textile industries.

2. Wood Routers

Perfect for creating furniture, cabinets, and ornamental objects with intricate engravings, these machines cut and shape wooden materials.

3. Turret Punch Presses

Turret punchers are utilized in a variety of industrial and automotive applications for the purpose of producing intricate perforations and forms in sheet metal.

4. Wire-Bending Machines

These devices easily manufacture custom wire shapes for wireframe constructions and bent metal components and machine parts.

5. Foam Cutters

CNC machines that cut foam enable for the precise structuring of foam materials, making them especially useful for artistic creations, packaging, and insulation.

6. Laser Cutters

Computer numerical control (CNC) laser cutters are widely used in industries such as jewelry manufacturing, metal fabrication, and signs because they are able to cut and engrave materials with pinpoint accuracy using high-powered lasers.

7. Cylindrical Grinders

Metal and other mechanical and industrial materials are smoothed by these devices on cylindrical surfaces.

8. 3D Printers

Rapid prototyping and the production of complex, individualized components may be accomplished across a variety of industries with the help of CNC-controlled 3D printers, which build items layer by layer.

9. Glass Cutters

Windows, decorative glasswork, and optics use CNC glass cutting equipment to shape and etch glass surfaces.

The Precision and Efficiency of CNC Machinery

CNC technology is distinguished by its capacity to carry out intricate cutting operations and manufacturing procedures with exceptional speed and precision. This is one of the defining qualities of the CNC machine tools technology. CNC machines cut complex multi-level or angled designs in minutes, minimizing manual effort and error.

The Role of Programming in CNC Operations

Computer numerical control (CNC) equipment are controlled by software instructions that have been properly programmed. These directions control every movement and operation of the machine, therefore guaranteeing exact performance of every stage of the process. A high level of technological refinement and attention to detail will be reflected in the end output, provided that the programming is precise.

Challenges of CNC Machining

Despite the many advantages it offers, the CNC machining process is not without its difficulties:

1. High Initial Costs

- A large financial commitment is necessary for CNC machines and software.

- Providing operators and programmers with training can be an expensive endeavor.

2. Complex Programming

- The ability to write and optimize G-code demands specialized knowledge.

- Post-processing modifications could be required for more advanced CNC machines.

3. Material Waste

- Incorrect settings or technical difficulties with the gadget can result in waste that is not essential.

- In order to keep losses to a minimum, constant monitoring is required.

4. Maintenance Requirements

- Maintenance must be performed on CNC machines on a regular basis to prevent malfunctions.

- Making sure to lubricate, readjust, and change tools often is crucial for maximizing efficiency.

Future of CNC Technology

The use of artificial intelligence, internet of things, and hybrid manufacturing techniques is rapidly being incorporated into the CNC machining industry. Notable developments include:

1. AI-Powered Optimization

- It is possible to improve tool routes and cut down on waste with the assistance of machine learning algorithms.

2. Internet of Things (IoT) Integration

- Real-time monitoring and predictive maintenance reduce downtime.

3. Hybrid Manufacturing

- Predictive maintenance and real-time monitoring reduced downtime.

4. Robotics and Automation

- In the process of material loading and handling, collaborative robots, also known as cobots, provide assistance.

Key Machinery Utilized in CNC Systems

These CNC machines incorporate a wide variety of specialized tools in order to reach the highest possible level of precision and adaptability cnc programming. When it comes to creating precise shapes, cuts, or engravings in materials, each tool has a distinct purpose. The following are some of the main CNC manufacturing tools:

1. Embroidery Machines

As a result of its ability to create detailed designs and exact stitches on materials, CNC embroidery machines are frequently utilized in the fashion and industrial textile industries.

2. Wood Routers

Perfect for creating furniture, cabinets, and ornate-engraved decorative objects, these machines can establish and shape hardwood materials.

3. Turret Punch Presses

For industrial and automotive use, turret punchers create intricate sheet metal perforations and forms.

4. Wire-Bending Machines

Applied mostly in bent metal components and wireframe construction, these machines easily manufacture custom wire forms.

5. Foam Cutters

CNC machines that cut foam enable for the precise structuring of foam materials, making them especially useful for artistic creations, packaging, and insulation.

6. Laser Cutters

Popular in sectors including signs, metal production, and jewelry manufacturing, most CNC machines and laser cutters use high-powered lasers to precisely cut and etch materials.

7. Cylindrical Grinders

Machines like these polish the cylindrical surfaces of metal and other industrial and mechanically-used materials to a mirror quality.

8. 3D Printers

Rapid prototyping and the production of complex, individualized components may be accomplished across a variety of industries with the help of CNC-controlled 3D printers, which build items layer by layer.

9. Glass Cutters

Windows, decorative glasswork, and optics use CNC glass cutting equipment to shape and etch glass surfaces.

Conclusion

Unrivaled preciseness, automation, and efficiency are just some of the benefits that CNC machining has brought to the industrial industry. From design to implementation, the full CNC machinist process guarantees excellent output with minimum human involvement. Ongoing developments in AI, IoT, and robotics offer a future whereby CNC technology becomes increasingly more accessible and efficient, notwithstanding obstacles such high costs and sophisticated programming.

In the highly competitive manufacturing industry, if you are thinking about using CNC machining equipment for your company, it is important to make sure that you invest in highly trained programmers and machines of the highest quality. CNC machines’ adaptability makes them a vital instrument in contemporary production electric discharge machines. CNC machines can make practically any product across sectors by integrating tools and components. In every manufacturing process, CNC technology guarantees great efficiency, accuracy, and dependability whether producing consumer goods, complex artistic creations, or industrial parts cnc drilling machines.