Introduction

Extremely accurate manufacturing method used for cutting hard metal and complex shapes is Electrical Discharge Machining (EDM), wire machining. Also called wire-cut EDM, this method has transformed sectors including aerospace, automotive, and medical device manufacture that call for intricate geometries and exact tolerances.

The principles of EDM wire machining, its working ideas, benefits, uses, and elements influencing its efficiency are investigated in this paper. At the end, you will know exactly why modern manufacturing depends on this machining technique.

What is EDM Wire Machining?

A non-traditional cutting method called EDM wire machining removes material from a workpiece using electrical discharges—sparks. It slices the material without direct touch using a thin, electrically charged wire passing through a dielectric fluid. This special technique allows the machining of materials including titanium, carbide, and hardened steels—that is, those difficult to cut using traditional techniques.

How EDM Wire Machining Works

The method of wire EDM machining is methodically based:

- Usually composed of brass or coated copper, a thin wire electrode setup feeds through a precision-guided system.

- The workpiece is submerged in a dielectric fluid—usually deionized water—that cools the material and flushes away trash.

- The wire is electrically charged, thus high-frequency pulses produce under control sparks between the workpiece and the wire.

- Material Erosion: Little bits of the workpiece are precisely cut by the strong heat from the electrical discharge vaporizing.

- A CNC (Computer Numerical Control) system guides the wire’s movement, so allowing the creation of complex forms with very great accuracy.

Advantages of EDM Wire Machining

1. Unmatched Precision

For parts needing great accuracy, EDM wire machining can produce tolerances as tight as ±0.0001 inches.

2. Ability to Cut Hard Materials

Wire EDM can readily cut through materials like titanium, tungsten carbide, and high-speed steels unlike conventional machining, which suffers with hardened metals.

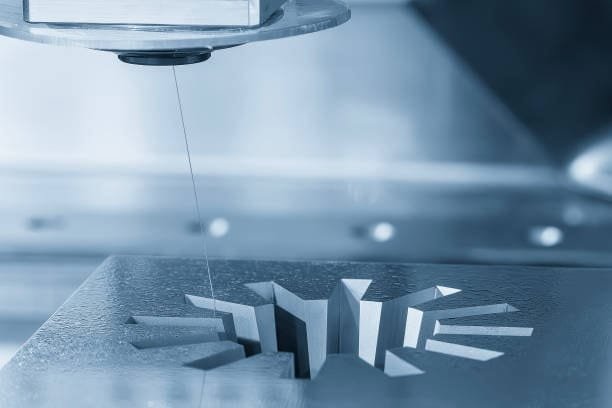

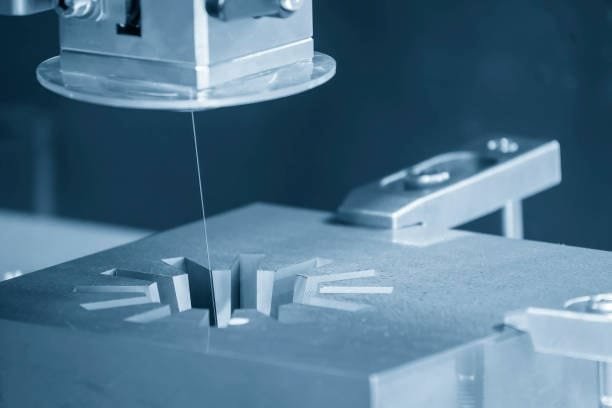

3. Complex Shape and Fine Detail Machining

Using the wire allows one to cut fine details and complex patterns impossible with conventional milling or turning techniques.

4. No Tool Wear

Tool wear is eliminated since the cutting tool (wire) does not come into direct touch with the workpiece, so guaranteeing constant results over time.

5. Smooth Surface Finish

Excellent surface finish produced by wire EDM reduces or eliminates the need for further finishing operations including grinding or polishing.

6. Minimal Material Distortion

The process is ideal for delicate parts since it does not mechanical stress the workpiece, hence there is minimal or none deformation.

Applications of EDM Wire Machining

Aerospace Industry

Turbine blades, fuel injector components, and complex structural parts needing great precision and resistance to extreme conditions are produced by EDM wire machining.

Medical Device Manufacturing

The manufacturing of surgical tools, orthopedic implants, and micro-components applied in medical equipment depends on this process.

Automotive Industry

From engine components to transmission parts, the EDM process of wire machining is absolutely vital in guaranteeing high-performance vehicle production.

Tool and Die Making

For companies needing exacting standards, wire EDM is indispensable in forming molds, dies, and precision tools.

Electronics and Micro-Machining

EDM wire machining offers the required accuracy to generate micro-sized parts with complex geometries as the market for smaller and more sophisticated electronic components increases.

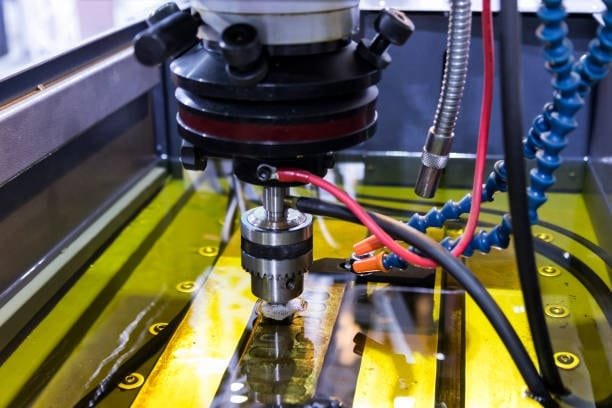

How Wire EDM Works

Operating on a simple yet highly exact technique that allows the cutting of intricate and complex forms from electrically conductive materials, wire electrical discharge machining (Wire EDM) is Usually deionized water, the workpiece is first submerged in a dielectric fluid to cool the material, eliminate waste, and regulate the electrical discharge process. To guarantee stability all through the electric discharge machining process, the workpiece is then securely fastened in place with a machinist vise.

Driven continuously with an electric current, a thin wire serving as the cutting electrode is passed over the workpiece. Strong electrical field is produced between the electrified electrode wire when approaching the conductive workpiece. The strong electrical charge overcomes the dielectric resistance to produce a spark when the wire and the workpiece come near enough. Without any physical contact between the wire and the material, this spark creates great localized heat that causes small bits of the workpiece to vaporize or melt away.

As the wire follows a preset path under control by a CNC system, the cutting operation advances. By flushing away the small particles of melted material and guaranteeing a smooth and exact cut, the dielectric fluid is absolutely vital. The technique is quite successful for manufacturing delicate or very hard materials with minimum distortion since there is no direct mechanical force applied on the workpiece.

Step-by-Step Process of Wire EDM Cutting

- Workpiece Preparation: Clamped tightly in place, the material is submerged in deionized water.

- Usually composed of brass or covered with zinc, a fine wire known as a wire electrode feeds continuously through the workpiece.

- Strong electric field between the workpiece and the wire results from opposite electrical charges carried by both of them.

- Material Removal via Sparks: Small amounts of material melt or vaporize as sparks across the gap reach a critical level of electrical field.Using dielectric fluid, the removed particles are washed away to guarantee a neat and exact cut.

- The CNC system regulates the movement of the wire, enabling very precise cuts with great complexity.

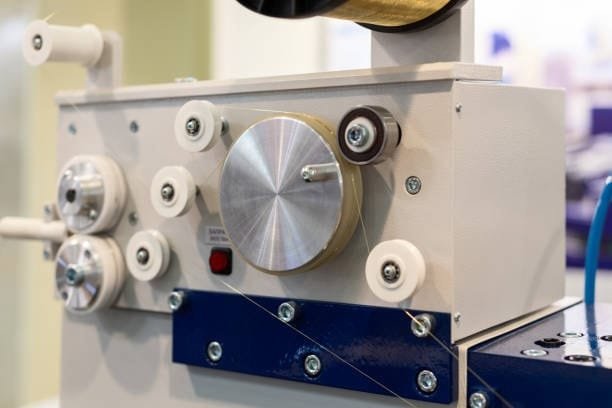

Main Components of a Wire EDM Machine

Several key parts make up a wire EDM machine, which cooperate perfectly to produce exact material removal and desired shape and development. Every element is absolutely important in guaranteeing the precision and efficiency of the cutting operation.

1. CNC Control System

The Command Center of the Wire EDM machine is the CNC (Computer Numerical Control) system, which controls all facets of the machining process and wire movement. It guarantees exact implementation of the intended design by deciding the cutting speed, wire path sequence, and other crucial parameters. The whole machining accuracy, cycle time, and error rate of the whole CNC machine and system directly depend on its sophistication.

2. Power Supply Unit

Usually ranging between 100V and 300V, the power supply unit is in charge of delivering high-frequency electrical pulses to the workpiece as well as the wire electrode. It regulates the frequency and force of the electrical discharges occurring between the material and the wire. Stable cutting conditions, effective spark generation, and premium surface finishes are guaranteed by a well-optimized power supply. Maintaining constant machining performance depends critically on the quality and dependability of the power supply.

3. Wire Electrode

The wire itself is the instrument allowing material removal by means of electrical discharges. The workpiece material and intended degree of precision determine the wire’s diameter and composition. Most often used wire diameters fall between 0.05mm and 0.25mm. Electrical conductivity, cutting speed, and durability determine the several kinds of wires used:

Brass Wire

Mostly made of copper and zinc, brass wires are the most often used wire material in EDM machining. Their great electrical conductivity makes cutting easy; the zinc content speeds machining. Nonetheless, the zinc proportion should be under close control since too high a zinc content will cause the corrosion resistance of the wire to drop.

Zinc-Coated Wire

On their surface, zinc-coated wires feature a thin layer of pure zinc or zinc oxide. This coating reduces the heat produced during cutting, so improving the machining speed and making it the perfect solution for uses needing fast machining and low wire wear.

Diffusion-Annealed Wire

High-performance machining uses call for diffusion-annealed wires. These wires undergo a specific heat treatment process whereby several layers of pure zinc are deposited on the wire surface, so enabling a greater zinc content—usually exceeding 40%. Mass production operations benefit much from this kind of wire, which can also be used to precisely and fast machine a great range of materials.

Key Differences Between EDM Wire Cutting and Conventional EDM

An advanced variation of conventional wire EDM services, wire EDM (Electrical Discharge Machining) cutting improves accuracy and efficiency in material removal. Although both techniques remove material from a workpiece by means of electrical discharge, their mode of operation, the kind of electrode used, machining speed, accuracy, and applications differ greatly. Choosing the most suitable approach depending on particular manufacturing criteria depends on knowing these differences.

1. Electrode Type and Functionality

The type of electrode used is one of the main variations between conventional and wire EDM cutting. In wire EDM machining, a thin, continuously fed thin wire serves as the electrode to create controlled electrical sparks to erode material along a designated path. Usually composed of brass, zinc-coated copper, or diffusion-annealed alloys, the wire moves across the workpiece in a precise manner enabling complex and finely detailed cuts.

Conversely, traditional EDM makes use of solid electrodes composed of highly conductive materials like copper or graphite. The particular application will determine the different forms and sizes these electrodes come in. As the electrode is pressed into the workpiece, a negative imprint or cavity reflecting its own form results. Different electrode geometries affect the surface smoothness of the final component; round electrodes generate the smoothest finish, then square, triangular, and diamond-shaped electrodes.

2. Speed and Efficiency of Machining

The speed at which machining operations can be carried out is yet another important distinction between these two EDM approaches. Before the machining operation starts, conventional EDM calls for especially shaped and designed electrodes. Particularly for intricate designs, which increases lead times and slows down manufacturing processes, the development of these electrodes calls for more time and effort.

By means of setup and operation, the wire EDM process is far more efficient as well. The machine is ready to start cutting right once the wire is set and the workpiece is fastened. This removes the need for further electrode preparation, thus wire EDM is a preferred choice for uses where time economy is a major consideration. For manufacturers especially in high-precision, time-sensitive projects, the ability to start machining almost immediately offers a major benefit.

3. Accuracy and Precision of the Cutting Process

It is well known that wire EDM machining offers more precision than standard EDM. With a thickness as little as 0.004 inches (0.1 mm), a fine wire electrode lets one create quite accurate cuts. For uses requiring intricate designs, sharp corners, and complex geometries, this degree of accuracy makes wire EDM machining services especially fit. Furthermore, wire EDM reduces mechanical distortion by not requiring direct physical contact with the workpiece, so guaranteeing great dimensional accuracy.

Conversely, traditional EDM is more suited for uses requiring more rigid cuts than highly detailed design. Less perfect for detailed work than wire EDM, the solid electrodes used in conventional EDM might not reach the same degree of fine accuracy. Conventional EDM is still useful, though, for deep cavity machining—where a molded electrode is needed to produce particular negative forms within the material.

4. Material Compatibility and Application Suitability

A very flexible machining technique, wire EDM can easily cut both ferrous and non-ferrous metals. Its great accuracy and capacity to produce precise cuts make it widely used in sectors including aerospace, medical device manufacture, electronics, and automotive engineering. Moreover, wire EDM can manage materials of different sizes—from very tiny micro-components to bigger, elongated sections—without sacrificing accuracy.

On machining thicker and harder materials, however, conventional EDM is usually chosen. The depth of cut the wire electrode in a wire EDM machine can reach is somewhat limited. Conventional EDM is more effective, on the other hand, for working with very thick workpieces since the solid electrode can produce stronger electrical discharges to reach deeper into the substance. This qualifies conventional and wire EDM capabilities more for uses including mold-making, deep-cavity machining, and heavy-duty industrial components.

Factors Affecting EDM Wire Machining Efficiency

1. Wire Material and Diameter

Cutting speed and accuracy depend on the wire chosen, including its material and diameter. Typical choices are copper with zinc-coating, brass, and tungsten.

2. Electrical Parameters

Optimizing voltage, current, and pulse frequency will help to balance surface finish quality with cutting speed.

3. Dielectric Fluid Quality

Maintaining clean and well-kept deionized water will help to guarantee efficient cooling and trash removal.

4. Workpiece Material

Different materials react differently to EDM, thus optimal performance requires changing power settings and cutting speed.

5. Machine Condition and Calibration

Regular maintenance of the EDM machine guarantees consistency and helps to avoid problems influencing accuracy.

Limitations of EDM Wire Machining

EDM wire machining has certain restrictions even with its several advantages:

- EDM is slower than conventional milling, hence it is less suited for high-volume manufacture.

- Conductive Material Requirement: Its application is limited since the process just works with electrically conductive materials.

- High Energy Consumption: EDM raises running expenses by requiring large electrical power.

Future Trends in EDM Wire Machining

EDM wire machining changes with technological development. Among the salient features are:

- AI-driven optimizations and CNC programming help to lower setup times and increase efficiency.

- New environmentally friendly dielectric fluids are under development to lower waste and energy usage.

- Combining EDM with other manufacturing techniques—such as laser cutting or milling—increases flexibility and output.

Conclusion

In precision manufacturing, EDM wire machining is a game-changing technology providing unmatched accuracy and the capacity to cut hard-to-machine materials. The process is still essential in sectors requiring complicated geometries and tight tolerances even if it has slower speed and higher energy consumption.