The use of computer-aided design (CAD) has rapidly become an essential component of contemporary engineering, architecture, and product development. It has fundamentally altered the ways in which we conceive of, create, and build. From the elegant cellphones in our pockets to skyscrapers slicing the clouds, CAD has subtly woven itself into the fabric of our daily life. Designers and engineers can create exact digital models, test concepts in virtual worlds, and rapidly bring ideas to life thanks to this potent technology. The development of CAD, its uses in several sectors, the instruments enabling its success, and what the future holds for this transforming technology will be discussed in this paper.

What is Computer-Assisted Design (CAD)?

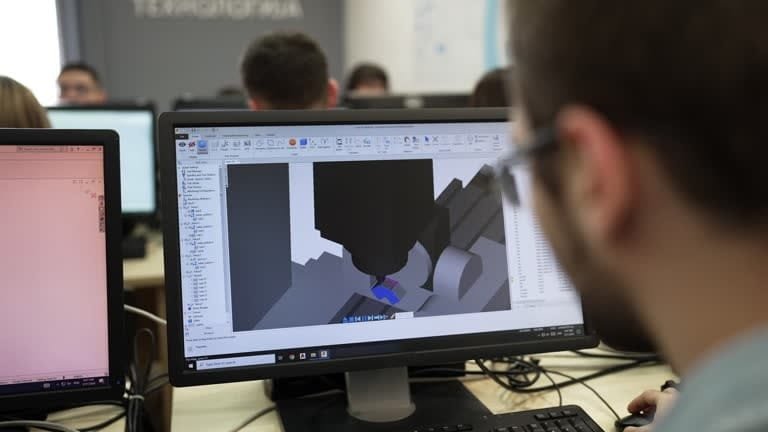

CAD, or computer software use for design creation, modification, analysis, or optimization, It helps designers to digitally see ideas before they build actual prototypes. CAD software is available for a wide range of industries, from architecture and engineering to product design and animation, and its complexity reflects this. This technology substitutes digital blueprints with better precision and efficiency for hand-drawn drawings.

A Brief History of CAD: From Drafting Tables to Digital Precision

Engineers and architects used drafting tables, rulers, and pencils to make technical drawings in the middle of the twentieth century; this is where computer-aided design (CAD) got its start. However, despite the fact that these manual procedures were excellent for their time, they required a lot of labor and were prone to human mistake. A change was started when computers first emerged in the 1950s. Early pioneers such as Patrick Hanratty, sometimes known as the “father of CAD,” unveiled in 1957 the first commercially viable full CAD computer aided design system, PRONTO. In design, this signaled the start of a fresh chapter.

Users were able to sketch directly on a screen using a light pen thanks to Ivan Sutherland’s revolutionary Sketchpad system, which was developed in the 1960s. This technology highlighted the possibilities of interactive computer graphics. Modern CAD programs owe their foundation to this creativity. The 1970s and 1980s saw the establishment of businesses such as Autodesk, Dassault Systèmes, and PTC, who were responsible for the development of renowned software applications like as AutoCAD, CATIA, and Pro/ENGINEER. These instruments gave sectors including manufacturing, aircraft, and automotive hitherto unheard-of accuracy and efficiency.

CAD is no more of a specialized tool for engineers today; it’s a worldwide standard. The shift from 2D manual drafting to 3D modeling has let designers see intricate buildings and systems in hitherto unthinkable ways, therefore facilitating their general acceptance in many different sectors.

Key Benefits of CAD software

- Improved Accuracy and Precision – CAD guarantees correct measurements and lowers mistakes unlike hand drafting. Working at a microscopic level lets designers produce incredibly precise and complex designs with little mistakes.

- Faster iterations and changes made possible by CAD’s acceleration of the design process help to increase efficiency. Faster times-to–market and faster cycles of product development follow from this efficiency.

- Digital visualization and testing design helps one to see and test ideas, therefore lowering material waste and prototype expenses. Companies can replicate real-world scenarios to forecast design performance, therefore avoiding expensive errors.

- Better workflow results from teams sharing and editing CAD files in real-time. Cloud-based CAD tools let for flawless collaboration across several geographical sites.

- 3D modeling and simulations enable designers to realistically visualize how items might operate prior to manufacturing. Additionally enabled by CAD software is photorealistic visualization, which lets stakeholders evaluate designs before they are produced.

- Customizing and Flexibility: CAD makes it simple to change designs, so it is perfect for designing unique goods depending on customer needs.

- Avoiding Legal and Safety Concerns by Ensuring Compliance with Industry Regulations — A number of CAD applications include compliance checks already implemented to make sure designs adhere to industry standards.

How CAD Works: The Nuts and Bolts of Digital Design

Fundamentally, CAD is about producing digital versions of actual items. Simple 2D blueprints to complex 3D models that replicate real-world behavior can all be found among these depictions. Interfaces for computer-aided design (CAD) software are often designed to be user-friendly. This interface allows designers to input data, such as lines, shapes, dimensions, and materials, using tools such as keyboards, mice, or even touchscreens.

In 2D CAD, the emphasis is on creating flat drawings—floor layouts or electrical schematics. Although still important, 2D design has mostly been eclipsed by the 3D CAD software, which lets users create completely realized objects with depth, texture, and utility. These 3D models provide a whole picture of a project before it is ever constructed by being spun, dissected, and examined from every angle.

Geometric modeling methods and advanced algorithms underlie CAD programs behind the scenes. For instance, surface modeling gives an object’s exterior a “skin,” while wireframe modeling produces a skeletal form of that object. The most sophisticated method, solid modeling, shows things as totally contained volumes with mass and material attributes. Long before a prototype computer or mobile device is produced, these techniques let engineers replicate how a design would behave under heat, pressure, or other conditions.

Types of CAD Software

- 2D CAD—AutoCAD LT and similar programs—focus on flat drawings and are used for basic building plans and schematics.

- SolidWorks and CATIA are examples of 3D computer-aided design software that offers the capability to model solids, surfaces, and wireframes.

- In architecture, BIM, or building information modeling, is a specialized CAD tool used for planning and building management (such as Revit).

- While direct modeling gives flexibility in shape changes, parametric modeling lets design changes under predefined limitations.

- Computer-Aided Manufacturing, or CAM – Through design conversion into machine-readable instructions, along with CAD, CAM tools aids automate production processes.

The Tools of the Trade: Popular CAD Software

There are several program choices in CAD that fit particular requirements. Designed by Autodesk, AutoCAD is still a gold standard for 2D and 3D design valued for its adaptability and large add-on library. Revit provides strong Building Information Modeling (BIM) data management tools for architects, which combine structural data with collaborative elements for big teams.

Popular in mechanical engineering, SolidWorks shines in modeling real-world dynamics and building intricate components. Providing powerful surface modeling and systems engineering capabilities, CATIA—from Dassault Systèmes—is a powerhouse for aerospace and automotive- aided design and drafting. Concurrent with this, Fusion 360—also from Autodesk—has attracted popularity among enthusiasts and small companies for its cloud-based cost-effectiveness.

Budget-conscious consumers can choose open-source solutions like FreeCAD and Blender, which offer strong capabilities without the high cost. Thanks to its accuracy in managing organic forms, software packages like Rhino excels in specific jobs including jewelry creation and industrial design.

Every tool has special advantages, hence the decision usually relies on the size of the project, the budget, and the industry expectations. Their capacity to bring abstract concepts to life is what binds them.

The Benefits of CAD: Precision, Speed, and Innovation

There are rather great benefits to manufacturing methods using CAD. Priority one is accuracy. Digital models provide perfect measurements and tolerance fulfillment, therefore removing the guesswork of hand drafting. Reduced manufacturing errors resulting from this accuracy save time and money.

Another trademark is speed. Drawing plans by hand or manufacturing physical prototypes once took weeks; today it may be done in hours. Without beginning from zero, CAD lets designers experiment with several iterations, adjusting factors including size, form, or material. Teams that possess this agility can push limits and investigate audacious ideas with low risk, therefore fostering creativity.

Cooperation is strengthened as well. Globally teams working on the same project in real time can use cloud-based CAD systems, which instantaneously share updates and comments. In the fast-paced, dispersed workplaces of today, this connection is really priceless.

Eventually, using CAD software tools advances environmental sustainability. Before even starting construction, businesses may maximize material consumption, lower waste, and evaluate environmental impact by visually modeling projects. CAD is a great friend in a time when environmental awareness of design rules supreme.

Challenges and Limitations: The Human Factor Persists

Though its advantages abound, CAD has several difficulties. Particularly with sophisticated programs like CATIA or SolidWorks, the learning curve can be sharp. To grasp complex functions, new users sometimes need months of training; even seasoned experts have to keep up with regular upgrades.

A further obstacle is cost. For small businesses or freelance artists, high-end CAD licenses—which range thousands of dollars yearly—are unaffordable. Although free alternatives abound, they might not be strong enough for projects of the professional level.

Though lessened, human mistake cannot be totally absent. A badly entered parameter or missed constraint can result in faulty designs, therefore demonstrating the fact that technology is only as good as the people using it. Furthermore, depending too much on the native CAD files can limit original thought if designers rely too much on templates.

Industries Utilizing CAD

Architecture and Construction

CAD allows architects to produce exact plans and 3D architectural models. In structural analysis, interior design, and urban planning it helps. CAD enables builders to see difficult constructions, test several materials, and guarantee zoning legislation and building code compliance.

Mechanical Engineering

CAD is the tool engineers use to precisely create industrial equipment, automobile components, and complicated machinery. Before they are produced, CAD tools offer simulations testing mechanical part efficiency and durability.

Aerospace and Automotive Design

Manufacturers of cars and aircraft use CAD for component integration, aerodynamic testing, and for assembly design and line planning. Particularly the aircraft sector gains from CAD’s capacity to replicate under harsh conditions structural integrity and aerodynamic characteristics.

Product Design and Manufacturing

In the realm of consumer electronics as well as medical devices, computer-aided design (CAD) makes it easier to create items that are both practical and ergonomic. Using most CAD software’s simulation capabilities, designers may build precise prototypes and examine assembly feasibility, material performance, and stress considerations.

Fashion and Textile Industry

In clothing design, CAD lets designers test fabrics, textures, and patterns before they are produced. Without using actual materials, fashion designers can make virtual clothes and test several designs.

Civil Engineering and Infrastructure

Civil engineers utilize computer-aided design (CAD) software to design highways, tunnels, bridges, and other types of infrastructure projects. Engineers are able to design more efficient and environmentally friendly buildings when they can combine 3D modeling with geographic information systems (GIS).

The Future of CAD: AI, VR, and Beyond

Driven by innovative technologies, CAD is already in a new era. By automating monotonous procedures, recommending improvements, and even creating first models based on user inputs, artificial intelligence (AI) is ready to transform design. Such powers are not far off: imagine an artificial intelligence that examines the stress regions of a bridge and suggests seconds-based reinforcements.

Additionally changing our interaction with CAD models are virtual reality (VR) and augmented reality (AR). Designers can “walk” through a 3D building or operate a car engine in midair with VR goggles, therefore obtaining insights not available from flat screens. AR lets builders see buildings on-site or surgeons plan operations with hitherto unheard-of clarity by overlaying digital models over the actual environment.

Along with CAD, additive manufacturing—also known as 3D printing—is always changing to optimize designs allow the production of intricate geometries impossible with conventional techniques. As materials science develops, CAD designs will find expression in anything from bioengineered tissues to lightweight aircraft components.

With cloud computing, CAD will become even more democratized and high-powered tools will be available on small hardware and mobile device. Cooperative platforms will change to interact with Internet of Things (IoT) devices to track designed item real-time performance product designers, therefore completing the loop between design and application.

Conclusion: CAD as a Catalyst for Progress

Originally a drafting tool, computer-aided design has evolved into a stimulant for human creativity. It helps us to conceive more broadly, create better, and precisely and stylishly solve challenges computer aided design models. The continued adoption of computer-aided design (CAD) by many industries will only lead to an increase in its influence, which will shape a future in which the boundary between fantasy, design intent and reality becomes increasingly blurry.