Introduction

Computer-aided engineering, or CAE, has transformed the way that engineers in many different fields design, test, and analyze products. CAE raises the entire engineering process in originality, accuracy, and efficiency by use of computational tools. It is the purpose of this study to examine the fundamentals of computer-aided engineering (CAE), as well as its benefits, challenges, and potential future directions for engineering simulation.

What is Computer-Aided Engineering?

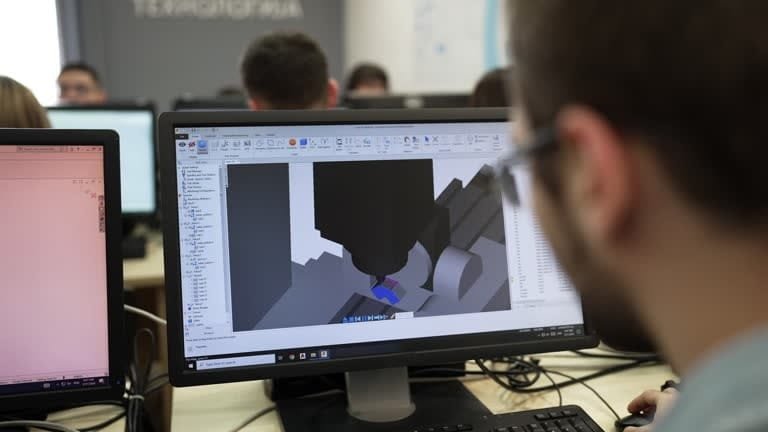

“Computer aided engineering software “-aided engineering is the employment of computer software to assist with engineering analysis tasks. CAE uses MBD, CFD, and FEA to optimize designs before prototyping. This method improves performance, reduces costs, and speeds up cycles of product development.

In current engineering, computer-aided engineering (CAE) is an indispensable tool because it enables engineers to test multiple scenarios and design choices before committing to expensive prototypes. This helps to bridge the gap between conceptual design and production, which ultimately results in more reliable and creative products.

The Key Components of CAE

1. Finite Element Analysis (FEA)

FEA, which stands for finite element analysis, is a computational process that is used to predict how a product will react to various physical effects such as vibration, heat, and forces that are present in the field. It helps designers to utilize lifetime resources and find defects. Engineering professionals find FEA especially useful for structural analysis, stress testing, and failure prediction because it allows them to model diverse load conditions and study how materials behave to varied stresses.

2. Computational Fluid Dynamics (CFD)

Within engineering, CFD investigates fluid flow, heat transport, and aerodynamics. It is widely utilized in the manufacturing, aerospace, and automotive industries due to its ability to enhance both performance and efficiency. In order to optimize designs for improved aerodynamics, cooling, and ventilation, engineers employ computational fluid dynamics (CFD) simulations before doing physical testing. This guarantees that products satisfy criteria for performance and regulation.

3. Multibody Dynamics (MBD)

MBD simulations project linked mechanical component motion. Machine learning (MBD) helps engineers optimize systems, robotic arms, engines, and suspensions. When manufacturing machinery with moving components, this method is essential since it permits exact simulations of strains, pressures, and component interactions.

4. Optimization and Simulation Tools

In order to find the best combinations of performance, weight reduction, and cost efficiency, optimization software runs several simulations. This helps in the process of developing designs. These tools offer architectural improvements enhancing product reliability and efficiency by means of artificial intelligence and machine learning.

Benefits of CAE

1. Reduced Development Costs

By letting designers test and enhance concepts online, CAE helps to lower demand for expensive physical prototypes. Because of this, the production costs associated with traditional prototyping—which include materials manufacturing tools, labor, and equipment—are significantly reduced.

2. Enhanced Product Performance

Engineers can make the best decisions about a product’s structure, aerodynamics, and thermal management before it is made by running several models. Practically, this development process produces extraordinary durability and performance.

3. Faster Time-to-Market

Using CAE, engineers may quickly repeat designs and detect possible problems early on, therefore reducing development time and accelerating production process. Faster product development process introductions by companies give them a competitive advantage.

4. Improved Accuracy and Reliability

By means of their precision, perfect data analysis provided by CAE technologies reduces human mistake and increases engineering confidence. Modern simulation methods improve dependability and safety by ensuring thorough testing of objects before production.

5. Sustainability and Environmental Benefits

Through bettering material use and waste reduction, CAE enables engineers to produce designs with energy efficiency. The use of computer-aided engineering (CAE) simulations makes it easier to apply sustainable engineering concepts such as energy-saving components and lightweight buildings.

Applications of CAE in Different Industries

1. Automotive Industry

Design of vehicles, crash analysis tools, aerodynamics modeling all rely on CAE. It helps manufacturers develop safer, highly performing, fuel-efficient vehicles. When modern cars are tested for accidents, they go through thorough CAE simulations first to make sure the best structural stability and passenger safety.

2. Aerospace and Defense

Aerospace experts use CAE to test jet engines, aircraft structures, and avionics systems under demanding environments. High-stress situations are guaranteed by finite element analysis (FEA), while aerodynamic performance is maximized by computational fluid dynamics (CFD) simulations.

3. Healthcare and Biomedical Engineering

CAE allows designers of biomedical devices to produce implants, prosthetics, and other medical equipment that is both safer and more effective than they would have been otherwise. By letting engineers imitate human body interactions with medical equipment, CAE helps to improve product design, confidence and patient outcomes.

4. Manufacturing and Industrial Machinery

CAE helps industrial applications maximize machine components, reduce material waste, and increase operational efficiency of manufacturing processes. Using CAE tools helps advanced manufacturing equipment to be designed, thereby increasing production and decreasing downtime.

5. Energy Sector

In the context of clean energy, CAE aids in the design of solar panels, wind turbines, and hydropower systems with best efficiency. In ecologically friendly energy solutions, simulations allow engineers to cut material prices and raise converted energy rates.

6. Electronics and Semiconductor Industry

Greatly in part is design of electronic components, thermal control assurance, and circuit board layout improvement based on CAE. Thermal simulations allow engineers to lower overheating and increase the energy efficiency of electronic devices.

Challenges in CAE Implementation

However, in order for engineers to fully harness the possibilities of CAE, they must first solve challenges. CAE has several advantages.

1. High Initial Costs

For the implementation of CAE software and hardware, a significant financial commitment is necessary. Small and medium-sized companies could not be able to afford the most recent simulation tools cam software and computer resources operating environment simulating complex geometries.

2. Steep Learning Curve

Complicated CAE tools need certain knowledge. In order to keep up with the ever-evolving capabilities of tools cad software and systems, engineers are required to continually improve their skills.

3. Dependence on Accurate Input Data

The quality of the data entered determines the accuracy in CAE simulations. The production of misleading conclusions, which in turn impact design decisions, may be the result of incorrect presumptions about environmental factors or poor material characteristics computer aided engineering task.

4. Computational Resource Demands

Modern CAE simulations demand high performance cloud computing and substantial computational capacity computer aided design software. Infrastructure for high-performance computing (HPC) is essential to the successful operation of large-scale simulations.

The Future of Computer-Aided Engineering

As computing power grows, advancements in machine learning, AI, and the cloud are fostering the growth of the CAE software companies. While cloud-based CAE permits for cooperative engineering, so reducing hardware restrictions, AI-driven simulations improve forecast accuracy. The intriguing possibility of more intelligent efficient CAE tools to affect engineering developments in the next years is presented.

- The incorporation of machine learning techniques into CAE systems powered by AI aims to enhance simulation accuracy and speed.

- By enabling remote cooperation and access to high-performance computing resources, cloud computing makes CAE possible for smaller businesses.

- Engineers may see CAE simulations in completely immersive settings with the help of VR and AR. This improves their comprehension of designs and allows them to make better judgments.

- By monitoring and modeling physical systems in real time, digital twin technology simplifies optimization and predictive maintenance.

Conclusion

CAE has changed engineering by arming robust tools for replication, analysis, and the design process improvement computer aided design

. As long-standing technical improvements come about, industries will depend more and more on CAE to enhance the efficiency of goods, save costs, and encourage innovation. Given CAE’s bright future and growing impact on engineering, it will play a crucial role in the creation and development of modern products.