Precision and efficiency rule highest in the modern manufacturing scene. Modern production is mostly based on computer numerical control (CNC) machining since it allows the creation of complex parts with unheard-of accuracy. CNC programming, a fundamental ability that turns design ideas into real-world products, drives this technology. Examining its basic ideas programming methods, software tools, and useful applications, this page explores the key elements of CNC programming.

What is CNC programming?

CNC programming is the process of designing commands for a CNC machine to follow, so enabling it to engage exact machining operations. Usually developed in a a CAD software (Computer-Aided Design) program, it uses specialist software to translate a design into a set of numerical codes controlling the machine’s movements conversational programming. Called G-code, these codes define the tool path, speed, feed rate, and other parameters required to generate the intended part manual programming. CNC programming is, all things considered, the link between digital design and its physical realization.

What is CAM software for CNC?

CNC programming’s importance results from its capacity to automatically optimize manufacturing processes. It minimizes human error and lowers production time by allowing the manufacturing of complicated parts with constant quality and great accuracy. From aerospace and automotive to medical and consumer electronics, where exact tolerances and complex designs are critical, this capability is absolutely vital. Moreover, various types of CNC programming lets design iterations and quick prototyping possible, so enabling faster cycles of product development cad and cam software. Crucially important for any contemporary manufacturing process, it is the basis for mass production of premium components.

What is the role of a CNC programmer?

The machining process is architectially created by the CNC machine programming programmer. Interpreting engineering drawings and CAD models, choosing suitable cutting tools, and creating the G-code to direct the CNC machine fall to them. This entails a thorough awareness of machining concepts, material qualities, and CNC machine capability. The programmer must also maximize the code to reduce cycle time and material waste, so guaranteeing effective and low-cost manufacture. They also have to troubleshoot any problems that might develop during the machining process, which calls both sharp eye for detail and problem-solving ability. To guarantee that the last product satisfies the necessary criteria, they also have to be able to interact properly with machinists and designers.

Why is CNC programming important?

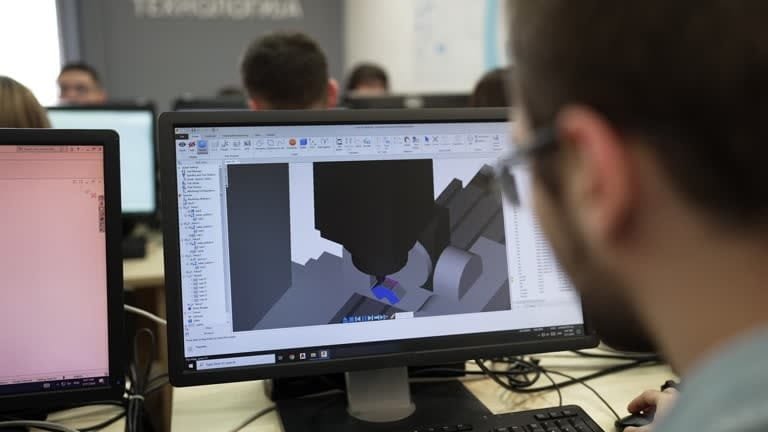

Essential tool for CNC programmers is computer-aided manufacturing (CAM) program. It offers a graphical interface for specifying tool paths and machining parameters, so simplifying the G-code generating process. By automatically creating the required machine code from the CAD model as input, CAM software greatly lowers the time and effort needed for hand programming. Advanced tools like toolpath simulation and collision detection—which help to avoid mistakes and maximize machining operations—also provide benefits. Handling sophisticated geometries and multi-axis machining depends on CAM software, which also helps to produce parts that would be difficult or impossible to produce by hand.

Benefits of using CNC programming software

Using CNC programming software has many advantages that improve manufacturing processes’ accuracy and efficiency. First of all, it greatly lowers machine programming’ time and effort, so enabling faster turnaround times and higher production. Second, it guarantees consistent quality by lowering the possibility of human mistake, so controlling scrap rates. Thirdly, it helps machining parameters and tool paths to be optimized, so reducing cycle times and manufacturing costs. Fourthly, it helps machining operations to be simulated, so enabling the identification and fixing of possible flaws before they start. Finally, it helps to support the development of intricate geometries and multi-axis machining, so increasing the range of produced parts.

Types of CAM CNC machines

Different configurations of CNC machines are meant for different machining operations various cutting tools and materials kinds. Choosing the correct machine for a given job depends on knowing these variations. Typical kinds include:

CNC Milling Machines

- The workhorses of subtractive manufacturing, these machines precisely remove material from a workpiece using rotating cutting tools. Their adaptability renders them absolutely essential in many different fields.

- Each of their several configurations—3-axis, 4-axis, 5-axis machines—offers growing degrees of complexity and flexibility.

- Basic forms are best suited for 3-axis milling; 4- and 5-axis machines allow the creation of intricate, contoured surfaces sometimes needed in aerospace and automotive applications.

CNC Lathes

- By rotating the workpiece against a stationary cutting tool, these machines are quite good in producing cylindrical parts.

- Making components including shafts, bolts, and bushings, they are extensively used for turning, facing, and threading operations.

- Live tooling is common in modern CNC lathes so that milling and drilling operations may be carried out on the same machine, so optimizing the production process.

CNC Routers

- Though designed for processing softer materials, these machines resemble milling machines.

- Usually used for cutting wood, plastic, and composites, they find use in sign building, furniture manufacture, and prototyping.

- Usually used to process big sheets of materials, CNC routers have bigger working envelopes than most milling machines.

CNC Grinders

- Often measured in microns, these machines use abrasive wheels to attain very exact surface finishes and tight tolerances.

- Applications needing great accuracy, such the manufacturing of gears, precision bearings, and cutting tools, depend on them.

- Often a finishing step used following other machining operations to attain the required surface quality is grinding.

CNC Plasma Cutters

- These devices cut electrically conductive materials, such steel and aluminum, fast and effectively using a high-temperature plasma jet.

- For cutting big sheets and thick plates, they are extensively applied in metal fabrication, building, and shipbuilding.

- Though it may not generate the same degree of accuracy as laser cutting, plasma cutting is well-known for its ability to cut through thick materials rather quickly.

CNC Laser Cutters

- These devices provide clean, accurate cuts by cutting materials with extraordinary speed and accuracy using a focused laser beam.

- They find application in sectors including electronics, medical devices, and jewelry manufacture; they are appropriate for a broad spectrum of materials including metals, plastics, and composites.

- Often used when precision is critical, laser cutting lets one cut very complex designs and fine details.

CNC Electrical Discharge Machines (EDM)

- These devices remove material using electrical discharges, so enabling the creation of complex forms and features in hard materials challenging traditional machineability

- Used in sectors including aerospace and automotive, they are especially helpful for producing complicated molds, dies, and tooling

- Two basic forms of EDM machines are Sinker EDM, which employs a shaped electrode, and Wire EDM, which uses a thin wire electrode.

Commonly used CAM software for CNC programming

There are several CAM applications available, each with special qualities and capacity. Among the most often used ones are:

- Comprising design, simulation, and manufacturing tools, Autodesk Fusion 360 is a complete CAD/CAM/CAE system. Its cloud-based cooperation tools and simple interface are well-known.

- Mastercam is a potent CAM program extensively used in the production sector. For difficult machining processes, it provides sophisticated toolpath generating and simulation features.

- Designed straight into the SolidWorks CAD environment, SolidWorks CAM offers flawless integration between design and manufacturing.

- GibbsCAM is a flexible CAM tool supporting a vast spectrum of CNC machines and machining operations.

- Designed for advanced manufacturing uses and sophisticated multi-axis machining, Siemens NX is a high-end CAM tool.

- Designed for high speed and 5-axis machining, PowerMill (Autodesk) is used by

The complexity of the parts being manufactured, the kinds of CNC machines being used, and the particular requirements of the manufacturing operation all affect the appropriate CAM program choice of machine operator.

What is g-code?

Control of CNC machines is accomplished using G-code, sometimes referred to as RS-274. It is computer numerical control programming comprises of a set of commands controlling the motions, speeds, and other characteristics of the machine. G-code commands are set out using letters and numbers; each letter denotes a particular purpose. For instance, “G00” orders fast traverse movements; “G01” orders linear interpolation; and “G02/G03” orders circular interpolation. M-codes are used for spindle start and stop, coolant on/off, and tool changes among other uses. For CNC programmers, knowledge of G-code is crucial since it enables them to design and alter programs to reach the intended machining standards.

Writing Your Own CNC Code

Although CAM tools streamline programming, any CNC programmer should be able to write G-code by hand as a useful ability. It gives one more knowledge of the entire machining process and more machine control. Here are several basic ideas:

- Coordinate systems let CNC machines define the cutting tool’s relative position to the workpiece. Two most often used coordinate systems are polar (radius, angle) and Cartesian (X, Y, Z).

- Tool offsets guarantee the intended dimensions by adjusting for the size and form of the cutting tool.

- While spindle speeds define the rotational speed of the cutting tool, feed rates define the speed at which the cutting tool passes across the material.

- Circular arcs and helical motions are generated from G02 and G03 commands.

- Pre-programmed routines designed to streamline common machining operations—drilling, tapping, and boring—are called canned cycles.

Writing G-code requires a knowledge of command syntax and structure first. As you get experience with programming language, progressively raise the complexity starting with basic projects. For learning G-code programming, online tools and tutorials can be quite beneficial.

Conclusion

CNC programming is a fundamental ability in the ever changing field of modern manufacturing since it closes the distance between digital design and actual reality. From the basic ideas of G-code to the advanced features of CAM software, knowing CNC programming helps producers to reach unmatched accuracy, efficiency, and creativity. Above all, it is critical to be able to translate complex designs into tangible goods with consistent quality; CNC programming helps to achieve this across many different sectors. Knowing the subtleties of CNC machines and their programming is crucial whether using 3-axis milling for basic forms or 5-axis machining for complex geometries. As machining process optimizer and design interpreter, the CNC programmer’s importance is still indispensible. Manufacturers can fully utilize CNC technology by embracing the power of the CAM programming tools and developing their writing and refining abilities for G-code. The need for talented CNC programmers will only grow as manufacturing develops, thus this knowledge is quite valuable in the quest of advanced manufacturing excellence.