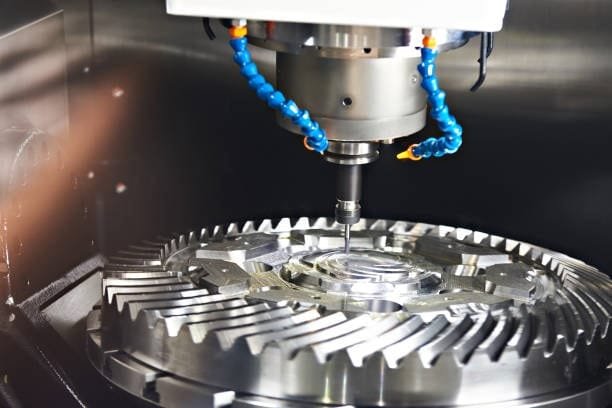

CNC (Computer Numerical Control) machining manual milling machine, is an essential manufacturing process that plays a pivotal role in producing precise components for various industries. From aerospace to automotive and even medical devices, CNC milling has revolutionized manufacturing with its efficiency and accuracy. Understanding its principles, techniques, and applications is key to mastering this versatile technology.

What is CNC Machining Milling?

CNC machining universal milling machine is a subtractive manufacturing process that uses computerized controls to operate and manipulate cutting tools. The milling machine removes material from a solid workpiece to create a desired shape. CNC milling offers high precision, repeatability, and versatility, making it a preferred method for producing complex parts.

History of CNC Machining Milling

The roots of CNC milling trace back to the early 1940s and 1950s when manufacturers sought ways to automate machine tools. Early CNC machines relied on punched tape systems to control movement. As technology advanced, these manual machines have evolved into sophisticated systems using computer software to achieve precision manufacturing. Today, CNC milling machines are highly advanced, capable of producing complex geometries with remarkable accuracy.

How CNC Milling Machines Work

CNC milling machines use specialized software to control movement and cutting operations. Here’s a step-by-step breakdown of the process:

- Design Phase: CAD (Computer-Aided Design) software is used to create a digital model of the desired part.

- Programming Phase: The CAD model is converted into a CNC-compatible code (G-code) that directs the machine’s movements.

- Machine Setup: The workpiece is secured on the milling table, and the appropriate cutting tools are installed.

- Milling Process: The CNC machine follows the programmed instructions to cut, drill, or shape the material.

- Finishing and Quality Control: The finished part is deburred, polished, and inspected for precision.

Types of CNC Milling Machines

Several types of CNC milling machines are available to meet different manufacturing needs:

- Vertical Milling Machines: The spindle is vertically oriented, making it suitable for precision cuts and detailed surface finishes.

- Horizontal Milling Machines: These machines have a horizontally oriented spindle and excel in heavy-duty milling tasks.

- 3-Axis Milling Machines: Ideal for simple designs and flat surfaces. It moves in three directions — X (left to right), Y (front to back), and Z (up and down).

- 4-Axis Milling Machines: Adds rotational capability for complex shapes, moving in the X, Y, and Z directions with an additional rotary movement.

- 5-Axis Milling Machines: The most advanced option, offering complete flexibility for intricate geometries. It provides greater precision for producing parts with complex curves and angles.

Common CNC Milling Materials

CNC milling is compatible with various materials, each chosen based on the application’s requirements:

- Metals: Aluminum, steel, brass, titanium

- Plastics: ABS, nylon, acrylic

- Composites and Wood: Used for specialized products and prototypes

- Exotic Materials: High-performance plastics, Inconel, and carbon fiber for specialized applications

CNC Milling Techniques

CNC milling machines utilize various techniques to achieve the desired outcome. Key techniques include:

- Face Milling: Used for creating flat surfaces with high accuracy.

- Profile Milling: Ideal for contouring and cutting intricate shapes.

- Slot Milling: Creates slots, grooves, and keyways in the material.

- Drilling: Often performed with specialized tools integrated into the CNC milling process for precise hole creation.

- Tapping: Creates internal threads for fasteners.

- Pocket Milling: Used for creating recessed areas within a workpiece.

CNC Milling Tools and Components

CNC milling relies on specialized tools to deliver precision results. Common tools include:

- End Mills: Ideal for cutting profiles, slots, and pockets.

- Face Mills: Suitable for surface finishing and flat cutting.

- Ball Nose Cutters: Used for 3D contouring and smooth finishing.

- Drill Bits: Designed for hole creation with accurate diameters.

Key machine components include:

- Spindle: Rotates the cutting tool.

- Table: Holds the workpiece securely during milling.

- Control Panel: The user interface for inputting and adjusting CNC programs.

Advantages of CNC Machining Milling

CNC milling offers numerous benefits, making it a superior manufacturing method:

- Precision and Accuracy: CNC machines operate with extreme accuracy, reducing errors and ensuring consistent results.

- Increased Efficiency: Automated processes improve production speed and minimize manual intervention.

- Versatility: CNC milling can produce simple to highly complex components across various industries.

- Cost-Effectiveness: CNC milling minimizes waste by optimizing material usage.

- Enhanced Safety: Automated controls reduce the need for direct operator contact with cutting tools.

Applications of CNC Machining Milling

CNC milling is used in a wide range of industries to manufacture precision parts. Common applications include:

- Automotive Industry: Engine components, transmission parts, and custom fixtures.

- Aerospace Industry: Aircraft structural components, turbine blades, and landing gear parts.

- Medical Industry: Surgical tools, prosthetics, and orthopedic implants.

- Electronics Industry: Custom enclosures, heat sinks, and circuit board housings.

- Consumer Products: Custom furniture, tools, and decorative hardware.

Challenges in CNC Machining Milling

While CNC milling offers remarkable precision, there are potential challenges to consider:

- Material Waste: Improper programming can result in excessive material removal.

- Tool Wear: Prolonged use of cutting tools can reduce performance and increase costs.

- Setup Complexity: Complex designs may require precise calibration and alignment.

- Programming Errors: Incorrect G-code instructions can lead to part defects or tool damage.

Tips for Successful CNC Milling Operations

To ensure efficient CNC milling, follow these best practices:

- Use High-Quality Tools: Investing in durable cutting tools improves precision and longevity.

- Optimize Feed Rates and Speeds: Finding the right balance minimizes tool wear and maximizes productivity.

- Regular Maintenance: Cleaning and inspecting machines prevent breakdowns and ensure consistent performance.

- Accurate Programming: Well-written G-code ensures flawless machining.

- Material Selection: Choosing materials that complement the project’s requirements reduces production issues.

What is CNC Milling?

CNC milling is an automated, subtractive manufacturing technique designed to remove material from a stationary workpiece using a rotating cutting tool. The process follows pre-programmed instructions, enabling efficient and precise machining. CNC mills are versatile and capable of handling diverse materials, making them essential for producing parts like engine blocks, gears, and brackets.

CNC Milling vs. CNC Turning

While CNC milling moves the cutting tool across a stationary workpiece, CNC turning operates differently. In how CNC milling works without turning, the workpiece rotates while a stationary cutting tool shapes the material. Each method has unique advantages depending on the desired component design.

The CNC Milling Process

The CNC milling process follows a structured workflow that includes design, programming, and machining. Here’s a detailed breakdown:

1. Design Phase

- Engineers use CAD (Computer-Aided Design) software to create a 3D model of the desired part.

- Design for Manufacturing (DFM) principles are applied to ensure the design is suitable for CNC milling.

2. CAM Programming

- Once the design is finalized, CAM (Computer-Aided Manufacturing) software converts the model into machining instructions (G-code).

- The G-code provides details such as cutting tool selection, spindle speed, feed rates, and coolant usage.

- CAM software automates much of this process, ensuring efficiency and accuracy.

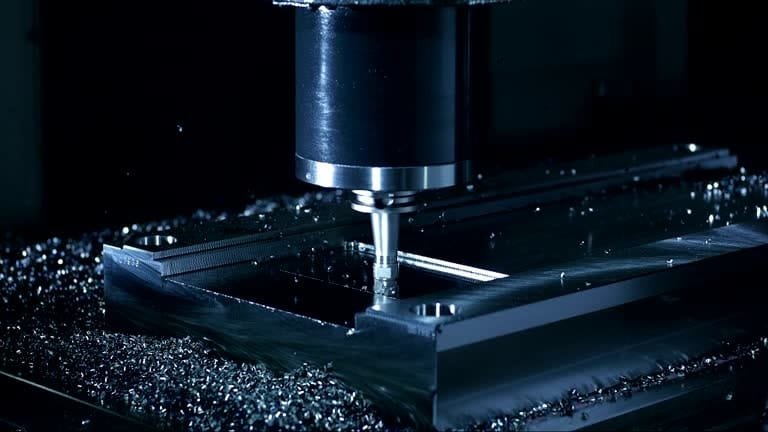

3. Machining Process

- The G-code instructions are loaded into the CNC milling machine.

- Raw materials are secured in place using clamps or fixtures on the worktable.

- The CNC mill follows programmed paths to shape the workpiece.

- Once complete, the finished part is removed for inspection, assembly, or additional processing.

CNC Mill Add-Ons for Enhanced Efficiency

To further improve performance and productivity, CNC mills can be equipped with additional features such as:

1. Automatic Tool Changers (ATC)

- ATCs automatically switch tools during machining, reducing downtime and enhancing efficiency.

2. Robotic Arms

- Robotic arms load and unload materials, change fixtures, and reposition parts.

- This automation supports continuous production with minimal human intervention.

3. Chip Conveyors

- These systems automatically remove debris (chips) from the work area.

- By preventing buildup, chip conveyors minimize downtime for cleaning and improve overall workflow.

Key Components of a CNC Milling Machine

CNC mills are equipped with various components designed to ensure precision and functionality. The following are essential parts of a CNC mill:

1. Spindle

- The spindle rotates at high speeds to power the cutting tool.

- It’s engineered to endure lateral forces and minimize deflection, ensuring precise cuts.

2. Tool Holder

- The tool holder securely clamps the cutting tool in place.

- Hydraulic systems often assist in maintaining firm tool attachment.

3. Machine Bed

- The machine bed forms the foundation of the CNC mill.

- Typically constructed from cast iron or steel, it provides stability and reduces vibration during machining.

4. Worktable

- Positioned on top of the machine bed, the worktable holds the workpiece securely.

- It often includes slots or holes to support clamps and fixtures.

- On standard CNC mills, the worktable moves along the X and Y axes, while advanced models may also rotate for complex machining.

5. Drive Components

- Servo motors are used to move the spindle and machine bed with precision.

- Ball screws and linear guides ensure accurate motion along the designated axes.

6. Coolant System

- CNC mills feature coolant tanks that store and deliver coolant to the cutting tool.

- Advanced machines may integrate coolant delivery through the spindle for optimal cooling.

7. Controller

- The controller acts as the machine’s brain, interpreting instructions from the CAM software.

- It coordinates the movement of motors, coolant flow, and other machine functions.

8. User Interface

- CNC mills often include a screen and keyboard interface for manual controls and basic programming adjustments.

Types of CNC Milling Machines

CNC milling machines are available in various designs, each suited to specific machining needs. The two primary categories are:

1. Vertical Machining Center (VMC)

- The spindle is aligned vertically along the Z-axis.

- VMCs are ideal for surface milling, drilling, and cutting flat components.

2. Horizontal Machining Center (HMC)

- The spindle is aligned horizontally along the Z-axis.

- HMCs excel at machining complex, multi-sided parts and offer efficient chip removal.

3. Multi-Axis CNC Machines

CNC mills may include additional axes for greater flexibility and precision:

- 3-Axis Machines: Moves the tool along X, Y, and Z axes.

- 4-Axis Machines: Adds a rotational axis for angled cuts.

- 5-Axis Machines: Provides maximum versatility with movement along all three axes plus two rotational axes, ideal for complex components.

CNC Milling Operations: Techniques for Precision and Efficiency

CNC milling machines utilize a spinning cutting tool that removes material from a stationary workpiece. Depending on the design requirements, various specialized milling operations, cutting strategies and tools can be used to achieve the desired outcome. Below are some of the most common CNC milling operations:

1. Plain Milling (Surface Milling)

Plain milling is the most straightforward milling process, used to create flat surfaces that are parallel to the machine’s bed. It’s ideal for producing basic, smooth finishes on flat workpieces.

2. Face Milling

Face milling is similar to plain milling but uses a larger cutting tool. This method involves shallow cutting depths and is designed to produce wide, flat surfaces efficiently. It is commonly used to finish larger surface areas.

3. Contour Milling (Profile Milling)

Contour milling is a technique used to machine curved or contoured surfaces. Typically, rough shaping is performed first, followed by a finer pass using a specialized tool like a ball-end or milling cutter to achieve smooth, precise curves.

4. Angular Milling

Angular milling is employed to create angled surfaces that are neither parallel to the machine’s bed nor perpendicular to the front spindle axis. This method is often used to cut features like chamfers or bevels.

5. Side Milling

Side milling is used traditional milling to create vertical surfaces along the sides of a workpiece. The cutting tool engages the side of the material, producing precise, flat vertical faces.

6. Slot Milling (Groove Cutting)

Slot milling involves cutting grooves or channels into the workpiece. These slots may either pass through the material entirely or stop partway through. This technique is ideal for creating keyways, slots for bolts, or internal pathways.

7. Hole Drilling

Drilling is one of the most common CNC milling processes, designed to create circular holes in the workpiece. While standard drill bits are commonly used, larger holes can be produced by spiraling an end mill into the material.

8. Reaming

Reaming is a precision process that follows drilling. It is used to enlarge and smooth a pre-drilled hole, ensuring a precise diameter for accurate fitting of pins, fasteners, or alignment tools.

9. Hole Tapping

Tapping involves cutting internal threads inside a pre-drilled hole, allowing bolts or screws to be securely fastened. CNC machines use specialized taps to form these threads with precision.

10. Gang Milling

Gang milling utilizes multiple cutting tools simultaneously to improve efficiency. This method form milling is ideal for producing multiple features on a workpiece in one pass, reducing machining time and improving consistency.

What Does a CNC Milling Machine Do?

A CNC milling machine is responsible for cutting, shaping, and refining materials into highly detailed parts. These various vertical milling machines utilize 3, 4, or 5 axes to achieve different levels of complexity in the final product.

- 3-Axis CNC Milling Machines: Used for simpler, less intricate parts, offering high accuracy with cost efficiency.

- 4-Axis CNC Milling Machines: Provide additional rotational movement along the X-axis, enabling more complex geometries.

- 5-Axis CNC Milling Machines: Offer the highest level of precision by rotating both the X and Y axes, allowing the production of intricate parts, such as medical implants and aerospace components.

The more axes a machine has, the greater its capability to produce complex designs with high precision and intricate details.

What Does a CNC Milling Machine Do?

A CNC milling machine is responsible for cutting, shaping, and refining materials into highly detailed parts. These machines utilize 3, 4, or 5 axes to achieve different levels of complexity in the final product.

- 3-Axis CNC Milling Machines: Used for simpler, less intricate parts, offering high accuracy with cost efficiency.

- 4-Axis CNC Milling Machines: Provide additional rotational movement along the X-axis, enabling more complex geometries.

- 5-Axis CNC Milling Machines: Offer the highest level of precision by rotating both the X and Y axes, allowing the production of intricate parts, such as medical implants and aerospace components.

The more axes a machine has, the greater its capability to produce complex designs with high precision and intricate details.

The CNC Milling Process

The milling process varies depending on the part’s complexity, structural importance, and industry requirements. The choice of a milling machine is influenced by these factors:

1. Machine Selection Based on Design Complexity

- Simple parts with straightforward geometries can be processed using 3-axis CNC mills, which are easy to program and cost-effective.

- More intricate designs, such as those required in medical or aerospace applications, necessitate 4- or 5-axis CNC mills for increased precision and detail.

2. Cutting and Spindle Operation

- The cutting tools are mounted on a high-speed spindle, which rotates at thousands of RPMs.

- These tools move along linear axes (X, Y, and Z) to remove material and form the desired shape.

3. Multi-Axis Machining Capabilities

- 3-Axis Machines: Move in three directions (X, Y, Z) and are ideal for basic milling operations.

- 4-Axis Machines: Introduce a rotational movement along the X-axis, allowing more complex cuts.

- 5-Axis Machines: Add further rotation along the Y-axis, making them suitable for highly detailed designs like turbine blades and medical implants.

The CNC Milling Process

The milling process varies depending on the part’s complexity, structural importance, and industry requirements. The choice of a milling machine is influenced by these factors:

1. Machine Selection Based on Design Complexity

- Simple parts with straightforward geometries can be processed using 3-axis CNC mills, which are easy to program and cost-effective.

- More intricate designs, such as those required in medical or aerospace applications, necessitate 4- or 5-axis CNC mills for increased precision and detail.

2. Cutting and Spindle Operation

- The cutting tools are mounted on a high-speed spindle, which rotates at thousands of RPMs.

- These tools move along linear axes (X, Y, and Z) to remove material and form the desired shape.

3. Multi-Axis Machining Capabilities

- 3-Axis Machines: Move in three directions (X, Y, Z) and are ideal for basic milling operations.

- 4-Axis Machines: Introduce a rotational movement along the X-axis, allowing more complex cuts.

- 5-Axis Machines: Add further rotation along the Y-axis, making them suitable for highly detailed designs like turbine blades and medical implants.

Future Trends in CNC Machining Milling

As technology advances, CNC milling is evolving to improve efficiency and precision. Emerging trends include:

- Automation and Robotics: Integrating robotic systems enhances production capabilities.

- AI Integration: Smart systems can predict tool wear, optimize machining paths, and improve accuracy.

- Sustainable Manufacturing: Reducing waste and energy consumption is becoming a priority in CNC machining.

- Enhanced Software Solutions: Advanced CAD and CAM software simplify complex designs and programming.

Limitations of CNC Milling: Challenges to Consider

While CNC milling is a powerful and versatile manufacturing method, there are certain drawbacks to be aware of. Below are some key limitations:

1. High Equipment Costs

CNC milling machines are sophisticated, high-precision tools that come with a significant price tag. The investment required for these multi axis milling machines is considerably higher than that of traditional manual mills. As a result, CNC milling is most cost-effective for businesses that handle large production volumes or require precise, repeatable machining for complex parts.

2. Specialized Skills Required

Operating a CNC milling machine demands technical expertise. Skilled operators and programmers are essential to set up, control, and maintain the equipment. Developing these skills can involve extensive training, adding both time and cost to the overall manufacturing process.

Conclusion

CNC machining advanced milling machines is a powerful manufacturing process that enables the production of intricate, high-precision parts for various industries. By understanding the different machine types, techniques, and best practices, businesses can maximize their productivity and ensure superior product quality. As technology continues to evolve, CNC milling will remain a crucial component of modern manufacturing.

CNC milling is a powerful and versatile manufacturing method that delivers precision, efficiency, and flexibility. By automating cutting processes, CNC mills reduce labor demands and enhance product consistency. From simple 3-axis setups to advanced 5-axis machines, CNC milling has become indispensable in industries requiring high-performance parts.

For businesses looking to improve production, investing in CNC milling technology offers substantial long-term benefits. Whether producing intricate prototypes or mass-producing components, CNC milling remains a cornerstone of modern manufacturing.