Find out the main distinctions between CNC 3-axis, 4-axis, and 5 axis machining. Find out the different types of machining solutions and the ones that suit your manufacturing solutions, prices, capabilities, and production demands here.

The speedy changing world of precision manufacturing has seen the emerging Computer Numerical Control (CNC) machining being the core of the production facilities. 3 axis and 4 axis CNC is the decision between them, it is a very big decision and could underpin your manufacturing capabilities, production efficiency and bottom line. This will be the ultimate guide to enable you make a well informed choice concerning your manufacturing needs through understanding the essence of the two systems in main differences, benefits, and applications.

To know the difference between these two machining techniques is vital to manufacturers, engineers as well as business owners who desire to streamline their production processes. From aerospace and all the way to auto and medical equipment, the axis layout of your CNC machine will have a direct effect on your tolerance and surface finish requirements as well as the complexity of the geometry in your part, including threaded holes .

GWT Worldwide is a professional freight forwarder and supply chain solution provider which focuses on worldwide freight forwarding logistics services and solutions based in Shenzhen, Guanwutong International freight forwarding Co., Ltd. Our logistics services are encompassing an array of services such as air freight, sea freight, China-Europe rail freight transport, international express services and solutions, custom clearance, warehouse, and Amazon FBA shipping support. Efficiency, transparency and customer satisfaction are our guiding principles and therefore we are the customer preferred logistics partner in facilitating seamless global trade.

Understanding CNC Axis Fundamentals and Machine Architecture

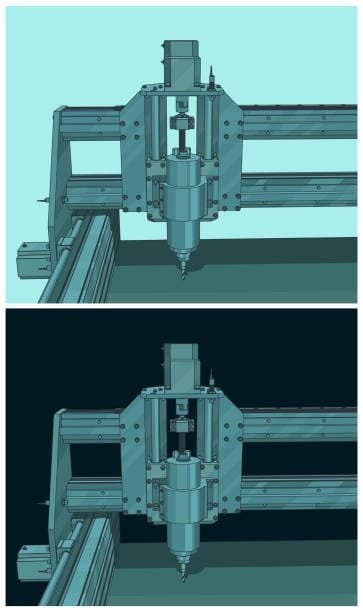

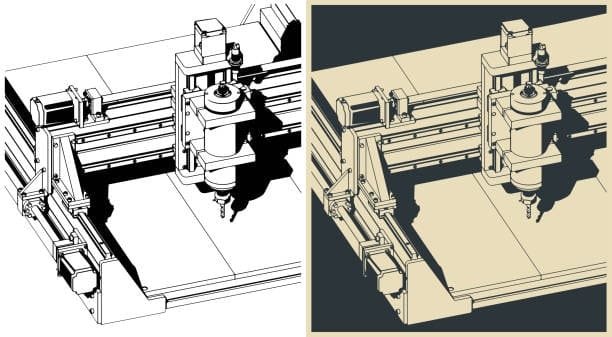

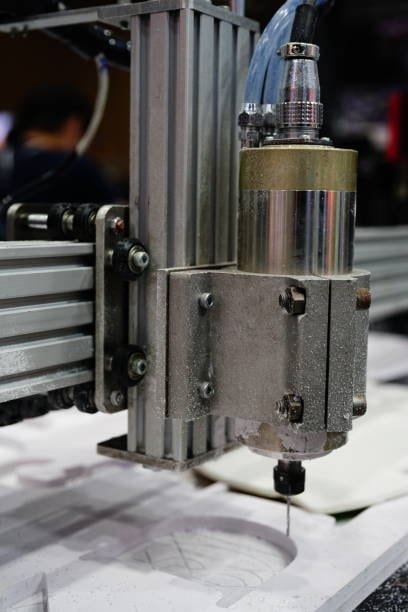

CNC machining uses coordinate system and has each axis depicting a movement direction. The whole idea lies in the fact that the machine can move the cutting tool or the piece of work at the considerably high precision on the paths chosen beforehand. In 3-axis machining the machine moves in three linear directions, X (left-right), Y (forward-backward) and Z (up-down), also known as the z axis . This assembly is suitable when making features on more than one face, and needs manual reorientation when part geometry becomes complex.

With the move to 4-axis machining, the axis of rotation is added, usually the A-axis (rotation around X-axis) or B-axis (rotation around Y-axis). This is an extra freedom to be able to run the machining continuously on the cylindrical features, angled surfaces, and also complex contours, including operations that may require the c axis, without having to have manual intervention. Rotational ability turns the machine into a more variable manufacturing platform than a completely linear cutting machine and able to manufacture complex three-dimensional geometries.

The latest CNC controllers coordinate all axes in concert, and allow an interpolated motion that forms smooth and accurate cuts. Multi-axis motion is based on sophisticated algorithms, and the program required to generate the motion is complex, although the extra effort is well worth the benefits of superior surface finishes, more cost-efficient setups, and more geometrical flexibility. These elementary concepts are vital in deciding what machine setup to apply to certain manufacturing needs.

Mechanical construction The 4-axis machines are usually mechanical and may include such extra components as indexing head, or trunnion tables, or rotary tables. Such elements should share the same standards of precision as the linear axes with regard to tolerance of rotational motions, possibility of large workpiece weight. Payload consideration and Machine rigidity, temperature stability, dynamic performance characteristics must be considered during the integration of rotational axes.

Key Differences in Machining Capabilities and Geometric Complexity

The first major difference between 3-axis and 4-axis CNC can be better described in the terms of geometrical performances and part complexity that can be manufactured in single setup. Three-axis machines are very good at producing parts to have their features accessibility in one direction, such as, flat surfaces, simple pockets, holes and simple contours. When parts need features on more than one face or on complex cornered surfaces, such as angled features, though, it is required to have multiple setups making production a longer process as well as a risk of loss of accuracy of dimensions due to the change in setups.

Four-axis machines open up the world of possibilities geometrically allowing machining of parts with rotational symmetry and parts with helical geometry, and even angular geometric surfaces which are complex. Elements like camshafts, turbines blades, impellers and elaborate brackets may be turned on a single set up with fine dimensional relationships amongst features. The ability to continuously rotate enables the forming of undercuts, holes on an angle and multi-faceted surface cuts which would be either impossibility or highly difficult with a 3-axis machine.

Quality of surface finish is usually enhanced because of optimized tool orientation with respect to the surface of the workpiece in 4-axis machining. With a steady load on the chips and no deflection of the tool due to the right axis coupling, the 4-axis machines will get good surfaces at less machining time. This fits well in industries where an extremely high level of surface quality is essential; that is, in aerospace, medical device, and precision instrumentation.

Machining 4-axes is much more complex to program and needs more powerful CAM and a more specific programmer trained on multi-axis machining. But with the advent of the modern CAM systems, it has made all search work much easier by way of automating the toolpath generation, collision avoidance, and simulation of the machine capabilities. The increased manufacturing capacities and the enhanced efficiency when it comes to production of complex parts will nullify the initial learning process.

Cost Analysis and Return on Investment Considerations

Other costs associated with online decision of 3-axis vs 4-axis CNC machine go beyond the selling price of either machine. Although 4-axis machines are usually more expensive (30-50 percent) than similar 3-axis machines, the overall cost of ownership assessment tells a more detailed story. The first cost would not only cover the cost of the machine but also tooling, fixtures, programming software, and cost of training also.

The two configurations also have a very high variance in their operating cost. When compared to complex parts, four-axis machines usually save on overall machining time by annihilation of the various set-ups, intake of less labor, and less work-in-progress inventory. Set up time can be significantly reduced, components that have to be set up four or five times on a 3-axis machine could take only one set up with a 4-axis machine. Such efficiency picks up directly in to low labor expenses and usage of machines.

The cost of tooling might be biased towards 3-axis machines since less complex fixturing is required and common cutting tools. But 4-axis machines may be able to attain a longer tool life due to superior cutting conditions and less vibration. Long-tool life is a benefit that can be realized by the capability to keep the optimum cutting angles over complex cutting operations in which the cost of the fixtures of the rotational work holders may be more than compensated.

The return on investment should factor in volume of production, complexity of parts and rates of labor. A typical high volume production of complex parts will normally make the 4-axis payback worth the investment in as short as 12-18 months; however, simpler or lower volume production may not pay up within the same time. The flexibillity benefit of 4-axis machines also covers a safeguard against the everchanging production needs and makes manufacturers take more elaborate projects at hand and this may give them access into more market.

Applications and Industry-Specific Use Cases

Depending on the needs of a particular industry and geometries of a certain part, 3-axis and 4-axis CNC are utilized in different industries. Aerospace industry is making extensive use of 4-axis machining in manufacture of turbine blade parts, intricate brackets and compound angled structural parts. 4-axis machining can close angular tolerances and obtain high quality surface finish and is critical in aerospace where understanding the requirements, both dimensional and surface finish effects the safety and performance of the aero device.

Both configurations are widely used in the automotive industry; the 3-axis machines work with large-volume production of rather narrow components: brackets, covers, elements of housing and so on. Four-axis is important in engine parts, transmission parts and parts with complex suspension that have tight tolerances and where angles are important. 4-axis machine flexibility also promotes the trends in the automotive industry of non-competitive models and customizing.

The 4-axis capabilities are especially useful in medical device manufacturing because of the intricate shapes needed in implants, surgical and diagnostic equipment. 4-axis machining can make sharp angular features, complicated curves and undercuts in biocompatible medical materials; this makes 4-axis machining of orthodontic implants and other parts of interest to dentists and surgeons. The high surface finishes that can be quite easily attained with the 4-axis machining technology also match with the high specifications of the medical industry in terms of surface quality and cleanliness.

The 3-axis machines are adequate in general machining and job shops where most of the work involves simple brackets, plates, basic parts and small work. More and more progressive shops are however investing in 4-axis capabilities of cnc milling machines to enable themselves to stand out of the crowd and accept more challenging projects. The flexibility of 4-track machines allows job stores to do a line of business with a variety of sectors and capture high-value contracts.

Production Efficiency and Setup Time Optimization

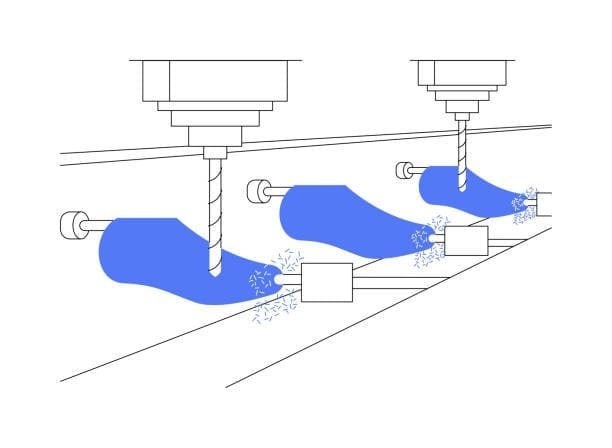

One of the most impressive benefits of 4-axis machining to be used appropriately is that it is efficient in production rotation axes. Not only does the removal of setups cut the direct time spent in the machining process, it also reduces the indirection time spend in parts handling, fixtures and their changes and the time spent in supervising the setup. Compound components, which may involve 8-12 hours of total manufacturing with a 3-axis machine, all setups considered, may be ready in 4-6 hours on a 4-axis machine.

The reduction of setup time is even more important in the low to medium volume production, when the setup time is quite significant compared to the total time spent in production. With the capability to perform complex components in single set up there is no tolerance stack up that would be registered in multiple set ups which can in most cases lead to better dimensional accuracy and, in the least, less production time due to improved cutting tool movement additional axis. This efficiency superiority is enhanced with an increase in complexity of part.

With 4-axis machining handling and setup differences are reduced which increases the consistency of quality. Any set up operation brings the opportunity of error, and these include positioning of fixtures, workpiece location, and differences in reference surface. The 4-axis machines mitigate these sources of error because they hold both the workpiece and the tool only in one set up all through the machining process thereby providing more repeatable actions in different batches of production.

The 4-axis capabilities lead to operator efficiency. Skilled operators would be able to load a work piece, start the program and leave the machine undisturbed as the machine does complex task by itself. This allows the operators to attend to more than two machines or prioritize in other value addition works whilst complex programs run automatically in 4-axis machines planar milled profiles. The overall shop productivity can be greatly enhanced by the fact that relatively less operator intervention is needed when 4-axis operations are involved.

Making the Right Choice for Your Manufacturing Needs

The choice between 3-axis CNC machining and 4-axis CNC machining should be closely studied in terms of present and future needs of production. Main attention should be given to part geometry analysis- look at your common parts and see whether they have features that need numerous setups, angular surfaces, or any multi-axis of symmetry axis cnc milling. In the case you produce a signification amount of parts with such features, a 4-axis machine will be an immense help to you rotary axis.

The level of production taken into consideration plays a role in the production choice. Simple parts with high-volume production could possibly not be worth the 4-axis investment and the complex parts with low volumes are often worth the 4-axis investment. The future-fighting capability with the flexibility advantage of 4-axis machines additionally enables manufacturers to be more flexible and pursue more various and lucrative jobs.

The necessity to train and the level of the skill set have to be judged realistically. There are more advanced skills needed in programming and machining 4-axis as compared to 3-axis machining. Make sure that there are sufficient training resources and personnel capabilities when one decides to invest in 4-axis technology. The learning curve however, should not be a barrier to making an investment provided there are technical and financial reasons.

Make an analysis of the competitive environment and the needs of the customers in your market. Just in case the competitors provide 4-axis abilities and customers progressively appreciate challenging parts, then it may be required to put money into 4-axis technology to survive competition. On the contrary, when your market is mostly full of simple parts such as those with threaded holes in line and cost cutting, 3-axis machines could be the best compromise of both price and performance 5 axis cnc machining.

Conclusion

The decision that concerns CNC 3-axis and 4- axis machining procedure is a strategic decision which affects manufacturing competence, manufacturing performance and competitiveness. As the 3-axis machines give great value on simpler parts and high-volume uses, the 4-axis abilities can be required when dealing with the complex geometry, better efficiency, and market separation. Longer start-up times, greater control on quality level consistency and increased possibility of applications often compensate the greater initial investment required in 4-axis technology.