Meta Description: Learn the ultimate comparison of Cast Iron, Steel material, and malleable iron, including their applications in construction equipment . Access information on properties, applications, advantages and costs implications to make an informed manufacturing decision of your projects.

The constant battle that many have seen between cast iron vs steel has lived to define twenty centuries, as seen in the manufacturing of vehicles, buildings and other structures. It is important to be aware of the essential distinctions between these iron-based alloys, as this is a key factor when choosing materials for specific projects. where an engineer, manufacturer, and professional in procurements have to choose the right material to use in particular projects. Each of the materials, including the alloying elements, has its own exclusive benefits and constraints which may have serious implications on project performance, affinity, and cost-efficiency.

The current production requires a strict choice of materials with the consideration of full assessment of mechanical characteristics, cost of production, and requirements of the application. This deliberated comparison takes a look at all the relevant factors of cast iron and steel, including their production process to ensure that you make accurate decisions that would offer maximum benefit in terms of performance and budget constraints of your manufacturing projects textile mills.

Understanding Cast Iron: Composition and Characteristics

Cast iron constitutes a series of alloys made of iron and carbon whereby the amount of carbon ranges between 2-4 percent by weight which is very high compared to the steel options. Such a high level of carbon content completely changes the microstructure of the material, which is a crucial aspect of its chemical composition. and results in the emergence of unusual properties of cast iron, including white cast iron, that are very suitable to its application. Instead of smelting the iron ore using coke and limestone in blast furnaces in the manufacturing process and then melting the metal and separately moving it to work the metal mechanically, they used the direct pouring of the molten metal in the molds.

The cast mix additionally consists of 1-3 per cent silicon enhancing its casting characteristics, gray iron, and tiny percentages of manganese, phosphorus and sulfur. These other factors affect the end properties, including the carbon percentage, and which cast iron is made. The large proportion of carbon forms graphite forms in the iron matrix and this aspect gives good casting properties although it influences mechanical property characteristics.

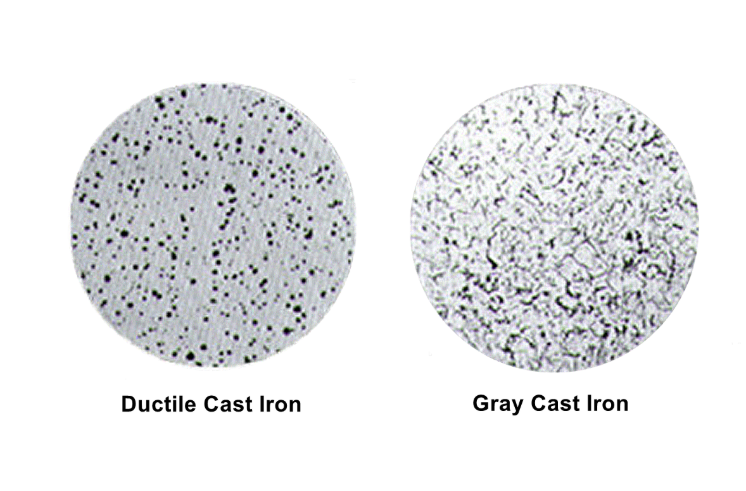

Cast iron can be white, ductile, malleable, compacted graphite, gray and white. Each of the types, including ductile cast iron, possesses particular benefits depending on the location of the carbon and heating measures based on the process used to make them. These differences help to choose the right grade of cast iron depending on the purpose the one is to be used in.

Steel Fundamentals: Composition and Properties

Steel is an alloy of iron with the addition of a small amount of carbon of 0.15 to 2 percent change. This reduced amount of carbon as compared to cast iron leads to a drastic variation in mechanical properties, including enhanced shock resistance. and processing qualities. With controlled carbon in quantity, mechanical properties, including those of tool steel, can be easily modified, such as control of strength, ductility and other mechanical properties, by alloying and heat treatment regimes.

Other materials that will in turn improve the qualities of the steel may be added and these would include silicon, manganese, phosphorus, Sulphur and oxygen. High quality steels as inbuilt chromium, nickel, molybdenum, or other alloying agents to give certain desirable properties like corrosion resistance, high temperature working, or greater mechanical property.

The production of steel can be achieved by adding or taking away unwanted carbon elements on pig iron by undergoing different steps of refinement followed by accurate control of the make-up mechanical properties. This control allows the creation of steels with specific property endowments to meet exact applications, such as structural building, fine tool and aerospace material.

Mechanical Properties: Strength Comparison Analysis

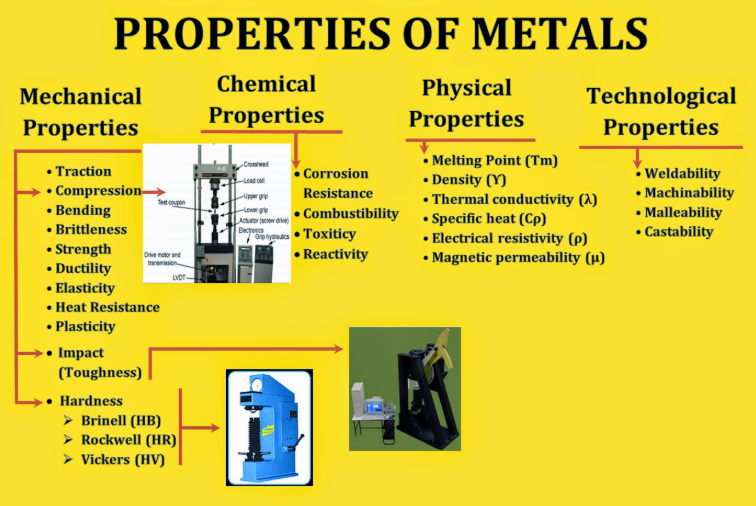

The basic variation in the quantity of carbon between cast iron and steel would result in the existence of unique lists of mechanical properties that categorizes them on the type of applications they can be used. Cast iron usually possesses high compressive strength superior to steel, hence it is ideal in places where there is no movement or the release of pressure. Cast iron has a compressive strength of between 600-1,400MPa depending on the particular type and makeup.

Tensile strength Cast steel is potentially far stronger in tensile strength than cast iron and may have tensile strength as great as 400-1200 MPa as against the standard strain of cast iron of 150-400 MPa. This high tensile strength is why steel is used in tension, bending and when high tensile loadings are subjected where failure of the manufacture may cause disastrous effect.

Exposed to high levels of stress, steel has superb toughness and ductility and may deform (temporarily or permanently) without fracture. It is this property that makes steel buildings energy absorbent and have warning conditions prior to their sudden failure mode, especially in critical wear surfaces. that is typical of brittle materials, such as cast iron.

Manufacturing and Casting Characteristics

Cast iron is easy to cast compared to steel since it flows easily and also does not continue to shrink too much. The high flowability of molten cast iron additionally enables the ability to cast complex shapes, making it a perfect material for intricate designs. consisting of minute details that could not be easily or even at all created via a steel casting procedure. The metal cast iron is less heat resistant than steel due to its low melting point . The melting point of its melting point falls at 2200 degree Fahrenheit as opposed to the melting point of steel which is 2500-2800 degree Fahrenheit.

Casting properties of cast iron are better due to composition and metallurgical properties. Shrinkage is counteracted in the solidification phase since the formation of graphite will help in the fabrication of castings that have fewer defects and are more accurate in terms of dimensions. This flowability also makes cast iron a perfect metal to construct structural or decorative ironworks structures such as street furniture or fencing.

Steel casting takes a lot of temperature, equipment and more complicated process in order to produce satisfactory products. This higher melting point and increased shrinkage on cooling from re melting pig iron would require to take care of mould design, gating systems and control of cooling, otherwise defects could result. The current steel casting methods have, however, improved to yield high quality components, with high mechanical properties and dimensions (in relevant features).

Machinability and Manufacturing Efficiency

Cast iron is very strong in compressions and this type of iron usually has a good machinability than steel. Less hard cast Irons such as grey iron are often easily machined at high speeds and with great accuracy. Gray cast iron has graphite flakes which serve as intrinsic lubricants during machining processes and this decreases the wear of tools and allows the tools to move at increased speeds.

The cast iron machinability benefits translate to a decrease in manufacturing production cost in terms of shortened manufacture cycle, prolonged tool life, and less power usage during the machine cutting processes. Cast iron components usually have perfect surface finishes with small amounts of secondary operations necessary.

The effects of composition on the character of machining steel depend to a high degree upon the heat treatment condition. Whereas certain grades of steel are easily machined, others do need special tooling, cutting fluids and machining parameters. The high strength steels and work-hardening grades are special cases where manufacturer costs and the cycle time are high.

Corrosion Resistance and Environmental Performance

Many environments cause cast iron to resist corrosion and rust more than steel, however cast iron and steel require protection against aggressive conditions. The relatively high levels of silicon content in cast iron gives it some corrosion protection naturally, along with other elements s the graphite structure can aide or impede natural corrosion resistance given the nature of the environment and the type of cast iron.

Gray cast iron also forms a protective oxide layer which may diminish the rate of corrosion in benign environments. But in aggressive situations using acids, salts, or high moisture content, cast iron will be corroded unless it is pre-treated with coatings, galvanizing, or other types of surface protection.

The corrosion resistance of steel dramatically depends on composition and on surroundings. Unalloyed or plain carbon steels are easily corroded in atmospheric conditions whereas stainless steels have good corrosion resistance. The microstructure of steel is much more homogenous which makes the behavior easier to predict thus easier to develop an effective protection system.

Cost Analysis and Economic Considerations

Cast iron is less expensive than steel due to the low cost of production and fact that it costs less to make a cast iron as compared with steel due to the material of production. The raw materials used in cast iron are usually cheaper by 20-40 percent compared to steel, partially due to its lower silicon content. mainly because of the less-complicated methods of refining and poor tolerance of the iron ore feedstock.

Manufacturing cost advantages do not only tolerate raw material, but also lead to energy utilized as well as holding time and tooling needs, contributing to materials longer service life . The processing of raw steel involves tremendous amounts of labour and energy because of heightened refining procedure to decrease the level of carbon and other elements s well as the impurities.

Cost analysis though should not be just based on the initial costs of material and manufacturing process only. The excellence of the mechanical properties of steel could entail lighter and more optimized designs, which is the main difference when compared to cast iron. that would compensate the increased material cost. In most applications the higher initial investment due to long service life and reduced need of maintenance of steel components can justify themselves.

Applications and Industry Usage Patterns

The cast iron is perfect in manufacturing of the pipe fittings, washers, farming equipment and machine parts, mining hardware, electrical fitting as well as hand tools. Cast iron and cast steel are commonly used in the automobile industry as manufacturing materials in engine blocks, brake rotors and several other areas where wear resistance and compressive strength are most important.

Cast iron is good casting properties and is beautiful in appearance, so it is used in architectural applications, covering decorative elements, structure, and infrastructure. Due to the faculties of being cast into intricate ornamental forms, the material is most commonly used in renovation of old buildings and ornamental purposes.

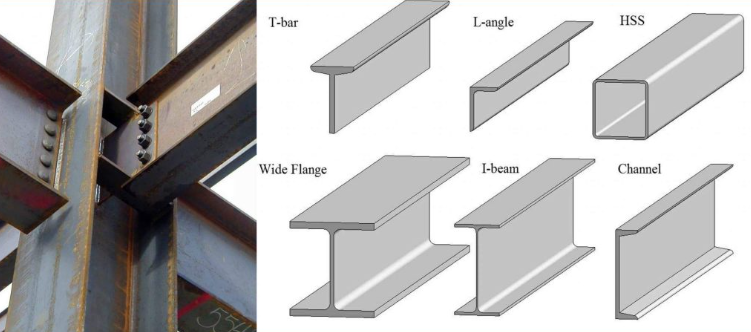

Steel can be used to develop such things as tools, weapons, electric appliances, cars, and infrastructures. Steel and alloy steel are vital in construction and infrastructure works as a structural framework, reinforcement and load-bearing component, where tensile strength and ductility are essential.

The aerospace, automotive, and machinery industries use the excellent mechanical properties of steel to manufacture perishable parts that are under dynamic loading situations and high-stress levels and operating environments. The use of tool and dies is a field where the benefits of steel influence are evident, particularly because steel is extremely strong under dynamic loads. since the steels have the property of not wearing off easily and are not dulled easily.

Impact Resistance and Safety Considerations

Cast iron also deforms much readily than wrought iron in terms of pressure or stress leading to the major impact deficiency disadvantage associated with it. The brittleness of cast iron, including nodular iron, results in potential safety issues when carrying out cast iron under impact loading, where a sudden collapse can occur.

Steel is more impact resistant as compared to cast iron. This is quite the case regarding sudden impacts. Steel maintains its material strength longer under impact loads that can cause brittle fracture in most cast irons, giving it the desired levels of safety in critical applications, while the carbon content plays a significant role . , instead of utilizing plastic deformation instead which makes it safe to use in application where shock loading or possible impact issues can be at hand.

Impact resistance is not the only aspect regarding safety as it extends to the character of failure modes. Steel usually fails in a ductile manner to the extent that they warn of impending failure by showing deformation before failure occurs giving the chance to dust off maintenance. Cast iron brittle failure mode may produce sudden and catastrophic failures without prior warning.

Heat Treatment and Property Enhancement

The low carbon content of steel and homogeneous microstructure render steel very sensitive to the application of the heat treatment. Strength and hardness may be increased significantly by quenching and tempering and by annealing may improve ductility and machinability white iron. The flexibility offered by this heat treatment will enable the manufacturers to tailor the requirements to tailor specific application property requirements.

The heat treatment of cast iron is more restricted because of intensive carbon concentration and complicated microstructure. Certain kinds of cast iron, principally malleable iron and ductile iron may be improved through particular heat treatment procedures that can reduce the size of large particles in the microstructure. , nevertheless the possibilities are less extensive than with steel malleable cast iron.

Steel has a huge advantage over other materials in many applications where property combinations are important due to its capability to change some properties by heating treatment. Heat treatment processes are developed on a toughness, strength, hardness, and other property optimization based on the needs of a challenging application.

Environmental Impact and Sustainability

Being very recyclable, both cast iron and steel have a positive effect on sustainable manufacturing. Cast-iron is well supplied and production is relatively cheap and it is infinitely recyclable and will not lose properties even when it is reused.

Recycling of steel is a project of success in a way that many areas recycle more than 85% of the steel used. Recycled steel is an environment friendly choice by the virtue of its high energy reduction in manufacturing as compared to manufacturing new primary steel white cast iron precipitates.

Materials longer service life and less maintenance are favored in consideration of life cycle assessment. Although cast iron can be used in relatively simpler processing thus having fewer initial environmental costs, a longer lifespan and durability of steel can translate into superior overall environmental performance through the lifespan of the product.

Future Trends and Material Developments

Casting and alloy technology are now used to promote cast iron qualities and steel. Compacted graphite iron is a huge innovation over cast iron technology and gives an enhancement in mechanical characteristics with retention of good castability and machinability.

Steel research is directed towards high-strength, light-weight alloys which use less material and possibly even increase performance. Lighter constructions in automotive industry and construction, through high-strength steels will result in energy efficiency, and resource saving steel stronger.

The additive manufacturing technologies are broadening the horizons regarding both materials allowing them to achieve complex geometries and tailorable properties that were unachievable using standard methods of manufacturing. New developments could change previous benefits and uses of cast iron as compared to steel in future years, particularly in how and when each material breaks .

Conclusion

The decision of either cast iron or steel will finally rely on weighing between individual application requirements on one hand and economic factors on the other. Cast iron performs best where there is a need to have an excellent castability, good compressive strength, high machinability and cost efficient-ness especially in instances where complex shapes and decorative details are required. It can be used in the complex casting and it can be good architectural materials due to its lower compacting point, superlative flow properties, and lesser shrinkages.

Heat processing and alloying of steel means that it has higher tensile strength, impact resistance, and flexibility than is otherwise possible in most materials, and it is therefore indispensable in structural use, under dynamic loading, and in safety-centric uses. The better performance, longer life, and greater safety features in hard uses can justify the additional initial cost to make the unit rather expensive.