Aluminium Extrusion

Services

Custom aluminum extrusion profiles with consistent cross-sections in any length—request your personalized quote today and bring your designs to life.

- All uploads are secure and confidential.

Certifications

ISO 9001:2015 | ISO 13485:2016 | IATF16949

Aluminum Extrusion Services

For high-volume extrusion profiles cut to your exact length, traditional extrusion houses are a perfect fit—but they seldom accept low-volume aluminum or plastic runs unless you’re a VIP customer, making prototypes hard to secure. At Leading Edge, we’ve teamed up with trusted partners who specialize in short-run custom aluminum and plastic extrusion, delivering exceptional quality and rapid lead times. We then apply our extensive in-house CNC machining and rigorous quality checks to each project before it ships—ensuring precision, consistency, and peace of mind.

Customization

We deliver custom aluminum extrusion profiles and seamlessly integrate them with CNC milling, turning, and bending to produce fully finished parts.

Low Volume

While most extrusion houses demand high minimum orders, Leading Edge welcomes low-volume runs—perfect for one-off prototype extrusions or small batches of just a few hundred units.

Fast Delivery

Skip the 30+ day wait for extrusion molds and profiles—partner with us for delivery in half the industry’s usual lead time—or even faster.

Custom Low Volume Extrusion Services

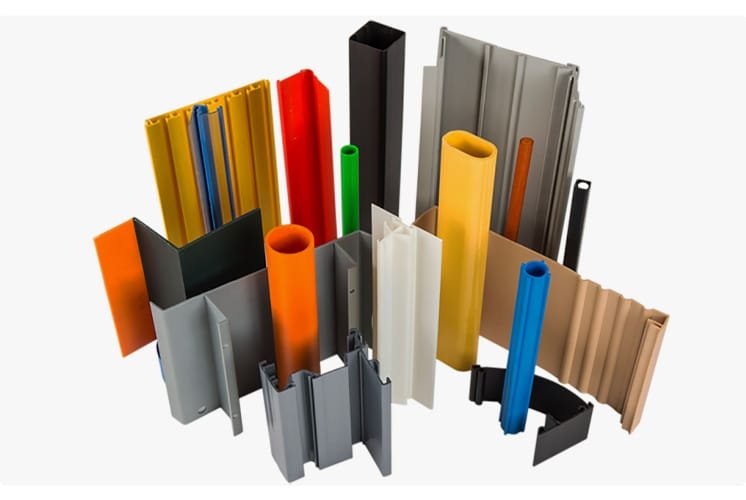

Plastic Extrusion

Aluminum Extrusion

What is Aluminum Extrusion?

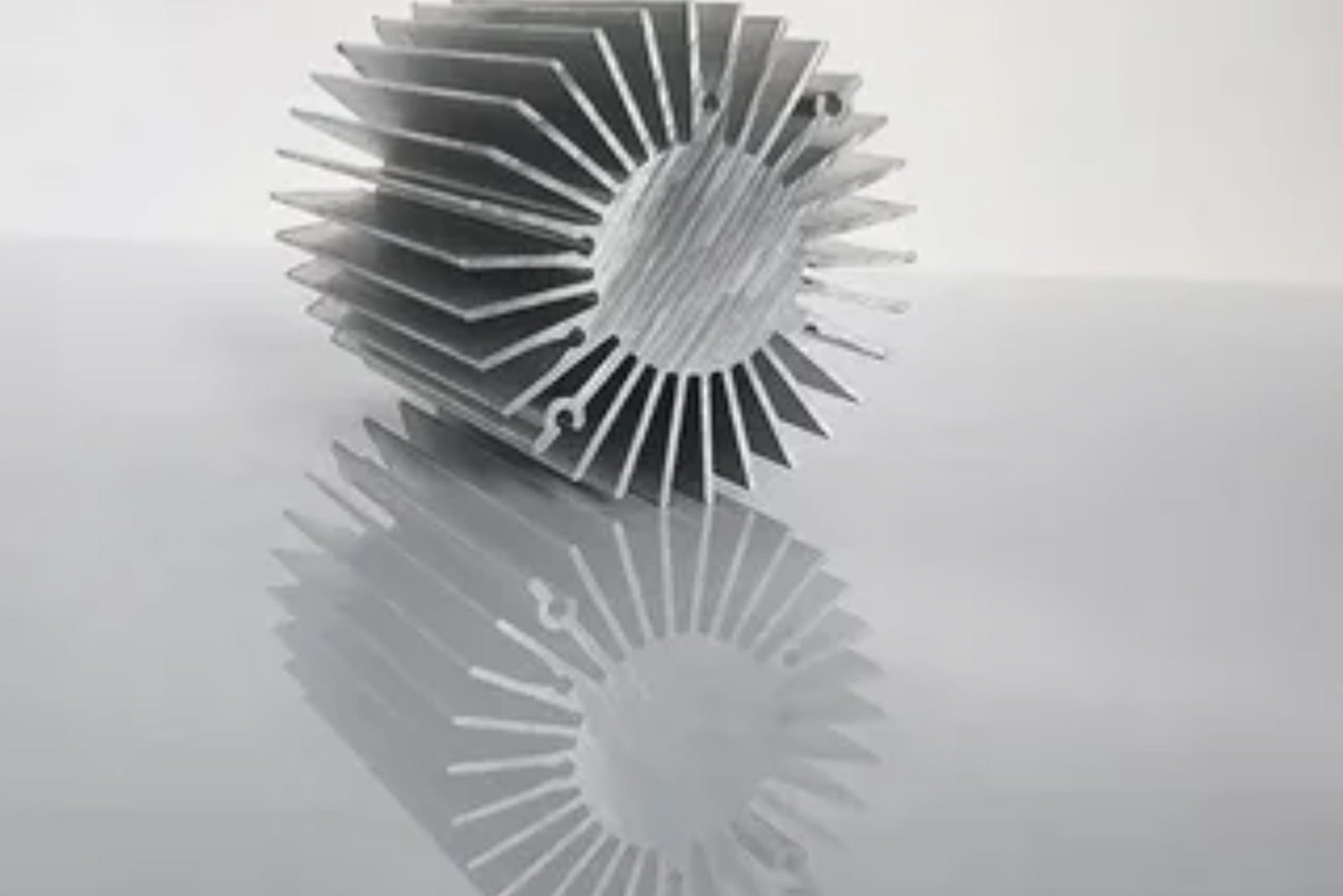

Aluminum extrusion is a versatile manufacturing process where heated aluminum billets are forced through a precision-engineered die to create continuous profiles with uniform cross-sections. This technique lets you produce complex shapes—from simple bars and tubes to intricate custom profiles—while benefiting from aluminum’s lightweight strength, corrosion resistance, and excellent thermal conductivity. Whether you need structural framing, heat sinks, or decorative trims, extrusion delivers consistent, high-quality parts that can be cut to length or further machined to your exact specifications.

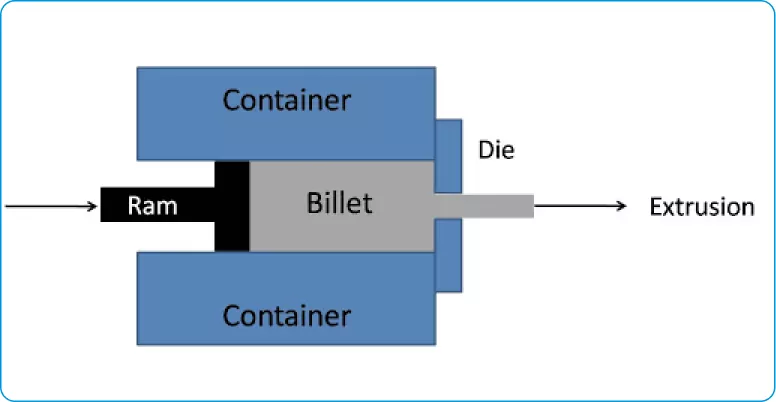

How Does Aluminum Extrusion Work?

Aluminum extrusion can be done hot or cold—each with its own advantages. Hot extrusion feeds larger volumes through the die quickly and at lower pressures, while cold extrusion delivers mechanically superior parts with smoother finishes and enhanced oxidation resistance.

To perform hot extrusion, aluminum billets are first cut to size and heated to 300–600 °C—soft enough to flow but not melt. A hydraulically powered ram then pushes the heated billet through a die—be it a simple round or square aperture or a custom profile—using pressures of up to 10 million pounds. The extruded metal cools on a quench table before being cut to your specified lengths, and can undergo heat treatment afterward to achieve the desired hardness.

Common Extrusion Applications

- Aerospace

- Construction Industry

- Electronics

- Automotive

- Medical Devices

- Automation

- Trains

- Display Industry

- Ships

- Heatsink

Standard Aluminum Extrusion Profiles

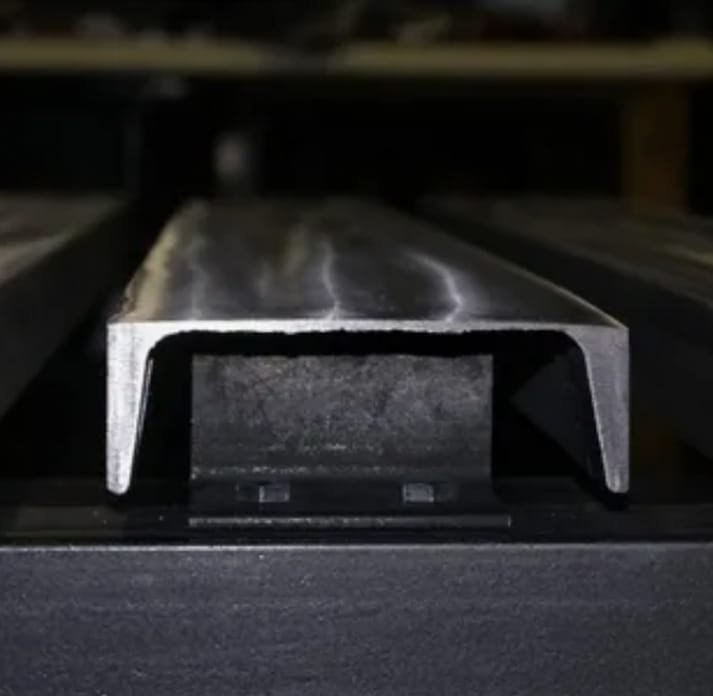

Custom aluminum extrusions can be formed into virtually any 2D profile, but a range of standard shapes—like solid bars and various channel designs—are ready-made solutions for many applications.

Standard profiles include:

- Circular bar

- F-shape

- C-shape

- J-shape

- Square tube

- Square bar

- Circular tube

- T-shape

- L-shape

- U-shape

Thermosets

- 2020 aluminum extrusion (20 mm x 20 mm)

- 80/20 aluminum extrusion (T-slot aluminum extrusion)

- 2040 aluminum extrusion (20 mm x 40 mm)

- 3030 aluminum extrusion (30 mm x 30 mm)

Custom Aluminum Extrusion Profiles

Standard aluminum profiles—like bars and channels—are best sourced in bulk from extrusion specialists. But when you need nonstandard shapes or low-volume runs, Leading Edge is your go-to partner. We welcome prototype and small-batch extrusion orders, empowering you to experiment freely with custom profiles.

Beyond bespoke dies, we also integrate extrusion with CNC machining to deliver finished parts faster and more affordably—especially when most of the component shares a uniform cross-section. Experience the flexibility of custom extrusion without the high-volume minimums.

Example operations:

Creating a custom extrusion, then using a CNC mill to add details, holes, or threads.

Creating a custom extrusion, then using a CNC mill to add details, holes, or threads.

Creating a custom extrusion, then using a CNC mill to add details, holes, or threads.