Introduction

In today’s fast-paced industrial world, the demand for high-quality, custom-machined parts is greater than ever. Whether in aerospace, automotive, medical, or manufacturing industries, precision is essential. A-1 Machining is a leader in the field, specializing in crafting custom parts tailored to the unique needs of its clients. By combining advanced machining technology, skilled craftsmanship, and high-quality materials, A-1 Machining delivers reliable and precise components for various applications.

This article explores A-1 Machining’s expertise, its commitment to quality, and the benefits of custom-machined plastic and metal parts for for industries requiring precision engineering.

The Importance of Custom Machining

Custom machining plays a crucial role in multiple industries, providing tailored solutions where standard parts simply won’t work. Off-the-shelf components may not always meet specific requirements, and that’s where custom machining comes in. Companies like A-1 Machining ensure that every piece is designed to exact specifications, offering several key advantages:

- Precision Engineering: Custom machining allows for tight tolerances, ensuring every part fits perfectly.

- High-Quality Materials: The choice of materials is crucial for durability and performance. A-1 Machining works with a variety of metals, plastics, and composites.

- Cost-Effectiveness: While custom parts may have a higher initial cost, they often result in long-term savings by reducing downtime and enhancing efficiency.

- Customization for Specific Applications: Every industry has unique requirements. A-1 Machining creates solutions that match exact needs.

A-1 Machining: Excellence in Custom Parts Manufacturing

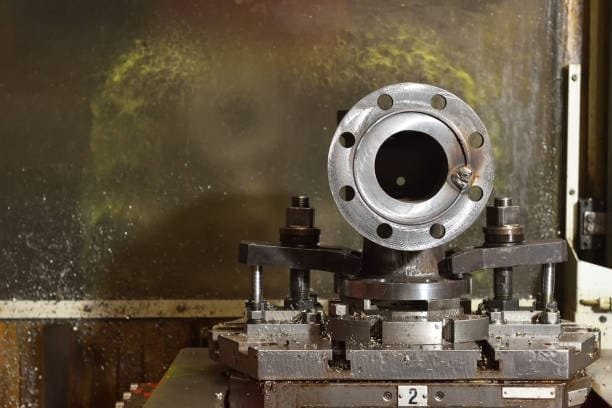

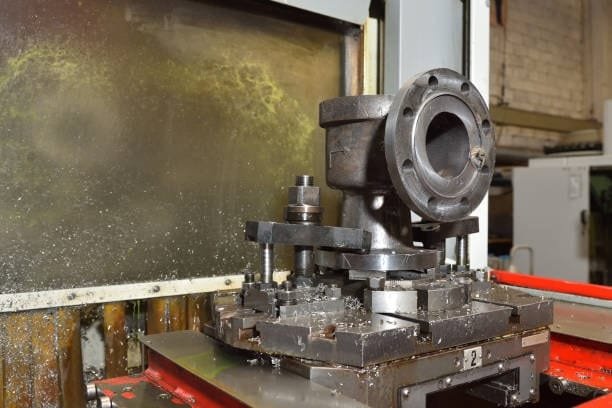

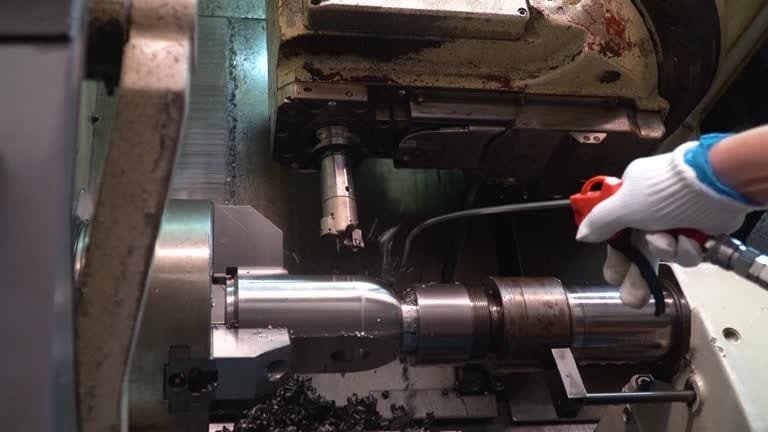

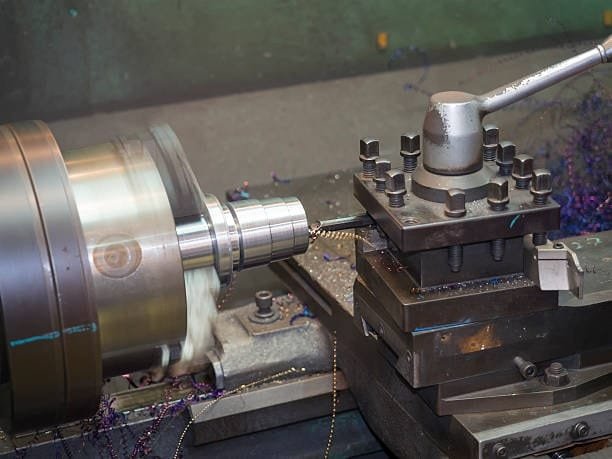

Advanced CNC Machining Capabilities

A-1 Machining uses state-of-the-art Computer Numerical Control (CNC) machines to produce highly accurate and repeatable parts. CNC machining ensures that every component meets precise tolerances, whether it’s a prototype or a large production run. Some of the many custom CNC machined parts and processes used include:

- CNC Milling: For creating complex geometries and intricate details.

- CNC Turning: Ideal for cylindrical parts with precise dimensions.

- Multi-Axis Machining: Ensuring efficiency in producing complex shapes.

These advanced capabilities allow A-1 Machining to work with tight tolerances and create parts with superior accuracy.

Materials Used in Custom Machining

A-1 Machining works with a variety of materials to meet the needs of different industries. Each material is selected based on the part’s intended function, durability, and environmental conditions. Some common materials include:

- Metals: Aluminum, stainless steel, titanium, brass, and copper.

- Plastics: ABS, acrylic, nylon, PEEK, and polycarbonate.

- Composites: Carbon fiber and fiberglass for lightweight but strong applications.

Choosing the right material is essential for the longevity and performance of the final product.

Industries Served by A-1 Machining

A-1 Machining provides custom parts for a wide range of industries, including:

- Aerospace: High-precision components for aircraft and spacecraft.

- Automotive: Custom engine parts, brackets, and performance-enhancing components.

- Medical: Surgical instruments, prosthetic components, and medical device housings.

- Manufacturing and Industrial Equipment: Gears, shafts, and machine components.

- Electronics: Heat sinks, enclosures, and precision connectors.

Each industry benefits from the reliability and precision of A-1 Machining’s custom parts.

Quality Control and Assurance

Quality is at the core of A-1 Machining’s operations. Each part undergoes rigorous testing and inspection to ensure it meets industry standards. The company follows strict quality control protocols, including:

- Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM): Ensuring accuracy from design to production.

- Coordinate Measuring Machines (CMM): Verifying dimensions and tolerances.

- ISO-Certified Processes: Meeting industry regulations for safety and reliability.

With these quality measures in place, A-1 Machining ensures that every custom part performs flawlessly.

Benefits of Choosing A-1 Machining for Custom Parts

Partnering with A-1 Machining offers numerous benefits, including:

- Expertise and Experience: Years of industry knowledge and skilled professionals.

- Advanced Technology: Cutting-edge CNC machines and software.

- Custom Solutions: Tailored designs for unique applications.

- Fast Turnaround Times: Efficient production processes to meet deadlines.

- Competitive Pricing: High-quality parts at cost-effective rates.

These advantages make A-1 Machining a trusted choice for companies requiring precision-engineered structural components.

Key Advantages of Custom Machining

1. Production of Custom Components

There are instances where the only way to obtain a particular component is to have it custom-made. This is especially true for parts that are discontinued or require an exceptional degree of customization to meet unique specifications. Custom machining ensures that these essential automotive components remain accessible and functional.

2. Flexible Production Quantities

Custom machining providers can manufacture parts in quantities that align precisely with a client’s needs. Whether a project requires a single prototype, a small batch, or large-scale production, machining services can accommodate varying volume demands without unnecessary waste or excess inventory.

3. Superior Product Quality

Partnering with a professional custom and CNC machining services provider enables close collaboration with skilled engineers and machine operators. This ensures that every component adheres to the specified design, meets tight tolerances, and upholds the highest standards of quality and durability.

4. Customizable Finishing Options

Many machining providers offer a selection of finishing options to enhance the final product’s appearance and functionality. These may include painting, powder coating, anodizing, or other surface treatments to meet specific aesthetic or performance requirements.

The Custom Machining Process

The journey from concept to final product in custom machining follows a series of well-defined steps:

1. Creating 2D and 3D Designs

The manufacturing process often begins with engineers utilizing Computer-Aided Design (CAD) software to develop detailed 2D technical drawings and 3D models. These designs serve as the blueprint for machining operations, ensuring precise dimensions and specifications.

2. Generating CNC Programs

Once the designs are finalized, engineers translate them into machine-readable code. This program dictates the tool paths, stopping points, tool changes, and other essential machining instructions that the CNC machine will execute during production.

3. Preparing the Machine for Operation

The machine operator loads the program into the CNC machine and ensures that all necessary tools are available and correctly configured. Proper setup is crucial to maintaining accuracy and preventing errors during production.

4. Conducting a Trial Run

Before proceeding with the final material, the operator runs a test to verify the program’s accuracy. This may involve a “dry run,” where the machine moves without cutting, or a trial on a softer material, such as wood, to detect potential issues and refine the process.

5. Producing the Final Component

Once the program is validated, the actual production process begins using the specified material. The CNC machine meticulously follows the coded instructions to create the custom part, ensuring high precision and consistency in every detail.

Comprehensive Custom Machining Capabilities

Custom machining providers utilize an array of advanced technologies and techniques to manufacture precise and complex parts. While the capabilities of each provider may vary based on their available machinery, most custom machining services include the following:

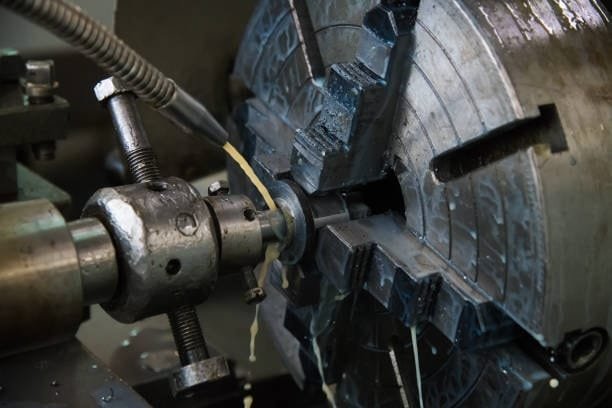

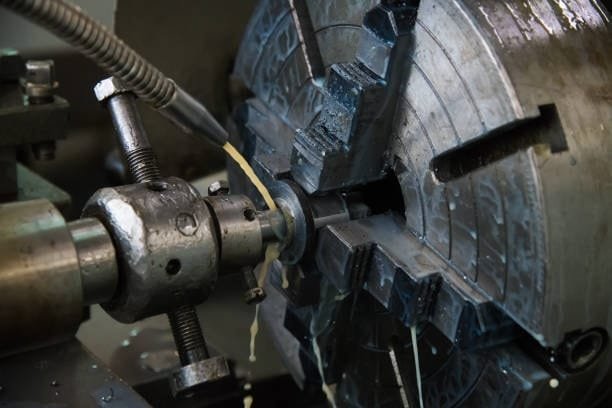

1. CNC Turning

CNC turning is a machining process in which a lathe rotates a workpiece while a cutting tool moves along various axes to shape it. This technique allows for the precise removal of material to create cylindrical and contoured parts. the standard of CNC machining machines, lathes can also perform additional operations such as drilling, reaming, knurling, and threading, further expanding their versatility.

2. CNC Milling

CNC milling involves the use of a rotating spindle that holds and maneuvers a cutting tool to remove material from a stationary workpiece. The milling machine’s table securely holds the workpiece in place, ensuring stability during both the cutting tool machining process. Modern CNC mills feature automatic tool changers, allowing for seamless transitions between different cutting tools without requiring manual intervention. This capability enables the completion of multiple machining operations within a single setup, significantly improving efficiency.

3. Electric Discharge Machining (EDM)

EDM is a non-traditional machining process that utilizes electrical discharges (sparks) to remove material from a workpiece. The component is submerged in a dielectric fluid, and the machine moves the electrode close to the surface to generate controlled sparks that shape the material. This process is particularly useful for cutting intricate shapes, hardened metals, and delicate features that would be difficult to achieve through conventional machining techniques.

4. CNC Laser Cutting

CNC laser cutting technology employs high-powered laser beams to slice through and shape raw materials with extreme precision. The intense heat from the laser vaporizes or melts the material, resulting in a clean and precise cut with minimal waste. Depending on the power settings, the laser can also be used for surface engraving, allowing for custom designs, markings, and decorative details to be applied to various materials.

When Should You Consider Custom Machining?

Custom machining is an invaluable solution for businesses that require specialized components. The following scenarios illustrate when investing in custom machining services is highly beneficial:

1. Reproducing Discontinued or Nonstandardized Components

Many industries rely on machinery that may no longer be supported by manufacturers. When a critical component of industrial machinery becomes obsolete, custom machining offers a solution by reverse-engineering and recreating the part based on existing samples or technical documentation. This ensures continued functionality widely used manufacturing process without the need for costly equipment replacements.

2. Manufacturing High-Precision Parts

CNC machining is renowned for its exceptional precision and ability to handle a variety of materials, including metals, plastics, and composites. Additionally, the advantages of CNC machining machines can perform multiple machining operations—such as reaming, boring, broaching, and slitting—in a single setup, making them highly versatile for producing intricate and high-tolerance components.

3. Prototyping New Inventions

For inventors and product developers, custom machining provides a practical way to transform conceptual ideas into tangible prototypes. By working with skilled engineers and machine operators, businesses can produce functional models for testing rapid prototyping and refinement before committing to mass production.

4. Addressing Emergency Part Needs

Unexpected equipment failures can disrupt business operations. Custom machining providers offer rapid turnaround times for critical components, reducing downtime and maintaining operational continuity. Whether a replacement part or an entirely new component is needed, these services ensure that businesses can swiftly resume production.

5. A Cost-Effective Manufacturing Alternative

Custom machining is an economical option for companies seeking limited production runs or specialized parts without investing in expensive machinery. It provides a one-stop-shop solution for developing unique products, enabling businesses to experiment with new designs and test market feasibility without significant capital expenditures.

The Efficiency and Accessibility of Custom CNC Machining

When it comes to the manufacturing of specialized production components, few methods offer the same level of speed and precision as custom CNC machining services. The rapid development of computer-aided design (CAD) software, coupled with the ease of placing orders through online platforms and the widespread availability of global shipping solutions, has revolutionized the way custom machined parts are produced and delivered. As a result, it is now possible for businesses and engineers to procure precisely tailored components within just a few days, making custom online CNC machining service an incredibly efficient and reliable solution for modern production needs. In fact, ordering custom components from an online machine shop has become as straightforward as selecting pre-made parts from a standardized catalog.

Defining Custom Machining and Its Role in Manufacturing

Custom machining refers to the process of using various online CNC machining techniques—such as CNC milling, CNC turning, electrical discharge machining (EDM), and other precision machining methods—to manufacture components that are uniquely designed and do not exist as off-the-shelf products. Unlike mass-produced standard parts that can be easily sourced from suppliers, custom machined components are typically required in situations where engineers and manufacturers need specific items that cannot be readily purchased or acquired at a reasonable cost.

The necessity for custom machining arises from various scenarios. In some instances, engineers may be working on an innovative product with distinctive design requirements, necessitating components that have never been manufactured before cnc machining cost. These production parts could range from something as simple as a gear, bolt, or button in a non-standard size or material to entirely new mechanical innovations developed from scratch cnc machining projects. Additionally, custom machining may be required for widely used components that need specialized modifications, such as a unique adapter, an additional design feature, or custom textual engravings.

The Advantages of Custom CNC Machining for Unique Components

One of the most significant advantages of custom CNC machining process is its ability to produce complex piece parts—large components that integrate multiple intricate features—ensuring that they are tailor-made for specific applications custom cnc machining. Because these components are custom-ordered for individual projects, there is no obligation to conform to universal design standards or predefined configurations. This means that designers and manufacturers of electrical components can prioritize optimal functionality, efficiency, and durability based on their exact needs, rather than being constrained by the limitations of standard parts.

Furthermore, custom machining is a highly adaptable process that accommodates both metal and plastic materials, allowing manufacturers to select from a wide range of options, including aluminum, stainless steel, brass, bronze, and various high-performance plastics custom cnc machining. Another major benefit of cnc machining orders is the speed at which quality parts can be fabricated from digital designs cnc parts. Since the online CNC machining service has minimal setup time and does not usually require a minimum order quantity cnc machining design guidelines, it is an excellent choice for businesses that need quick turnarounds, particularly in situations requiring urgent replacements or emergency production standard cnc machines.

Key Reasons to Opt for Custom CNC Machining

- Unavailability of Standard Parts: Custom CNC machining is essential when a particular component cannot be sourced from suppliers due to its non-standard dimensions, materials, or design specifications computer numerical control machining.

- Unique Design Requirements: When a part requires specialized features, such as additional engravings, modified structures, or enhanced functional attributes, custom machining provides the flexibility to incorporate these elements.

- Combination of Multiple Features: Instead of assembling multiple smaller components, custom machining allows manufacturers to consolidate multiple design features into a single, fully integrated part.

- Rapid Turnaround in Critical Situations: CNC machining enables manufacturers to produce high-quality components with exceptional speed, making it an ideal solution for emergency repairs or time-sensitive production runs.

- Cost-Effective Small Batch Production: Machine shops that offer custom machining services are typically willing to accommodate low-volume production needs without imposing excessive costs or requiring bulk orders cnc machined prototypes.

Conclusion

A-1 Machining stands out as a premier provider of custom parts, delivering high-precision solutions across multiple industries. With advanced CNC machining materials and technology, a commitment to quality, and expertise in working with various materials, the company ensures that every component meets exact specifications. Whether for aerospace, automotive, medical, or industrial applications cnc machining service cost, A-1 Machining provides reliable and durable custom parts that enhance performance and efficiency. Custom machining is an essential manufacturing solution that offers a wide range of benefits cnc machining advantages, from the ability to produce specialized components to flexible production quantities and high-quality output chemical resistance. With advanced cnc machining materials and capabilities such as CNC turning, milling, EDM, and laser cutting, custom machining providers can deliver precise, durable, and customized parts that cater to diverse industrial and commercial needs. Whether for prototyping, production, or emergency replacements, custom machining remains an invaluable resource for businesses seeking precision-engineered solutions for corrosion resistance.