Modern manufacturing depends on CNC machining, a critical operation providing accuracy, efficiency, and automation to produce premium goods and parts. Knowing CNC machining will open a lot of possibilities regardless of your level of expertise—novative or industry professional. We will thoroughly discuss all CNC operations and machining in this all-inclusive guide, including definition, uses, types, tools, and future developments.

What is CNC Machining?

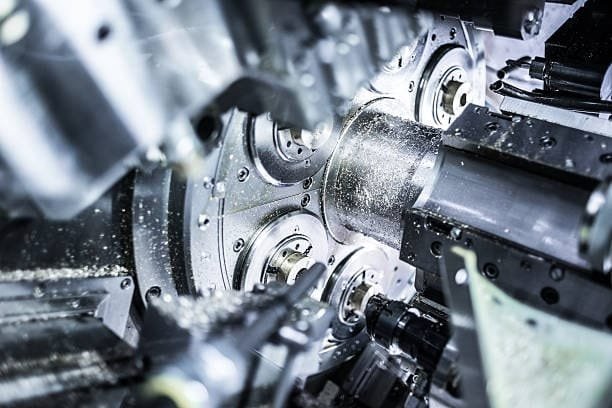

Using computerized controls, CNC (Computer Numerical Control) machining is a manufacturing process whereby tools and machinery are operated upon and manipulated to shape raw materials into completed goods. The system guarantees exact and consistent results by being rather automated.

CNC machining transformed conventional hand tool machining. CNC systems improve accuracy and production by using pre-programmed instructions to control machine motions rather than depending on human control.

History of CNC Machining

Numerical control (NC) technology developed in the 1940s and 1950s helped to start CNC machining. NC machines first ran on punched tape, but as computer technology developed these systems changed into CNC machines with digital interfaces and more complex programming capability.

Today, CNC machining is a pillar of manufacturing used extensively in sectors including aerospace, automotive, medical, and electronics.

How CNC Machining Works

CNC machining produces the intended product by several stages. Every stage guarantees efficiency and accuracy all through the production process:

1. Designing the CAD Model

The manufacturing process suitable starts with a thorough design created with CAD, or computer-aided design, software. Perfect dimensions, forms, and specs for the intended part abound in this digital model. CAD tools are used by designers and engineers to create complex designs satisfying industry standards.

2. Converting to CNC Code

CAM (Computer-Aided Manufacturing) software turns a finalized CAD model into CNC-readable instructions. Often written in G-code or M-code, the CNC code specifies cutting speed, tool path, and spindle rotation, so guiding the movements of the machine.

3. Machine Setup

After loading the material into the CNC machine, operators set cutting tools, fixtures, and reference points among other important settings. Accurate machining depends on right alignment.

4. Machining Process

The CNC machine cuts and shapes the material as directed while running the programmed instructions in this phase. Based on the design, the machine might drill, mill, turn, or grind several times.

5. Finishing and Inspection

Once machining is finished, the product gets the desired texture by means of deburring, sanding, or polishing. Before the good is delivered, final inspection guarantees that quality criteria are satisfied.

Types of CNC Machines

CNC machining covers several machine kinds, each intended for particular use. Knowing these machines facilitates manufacturers’ choice of tool for their projects:

- CNC Milling Machines: Rotating cutting tools let CNC mill machines cut, drill, and shape materials. They are rather flexible and able to generate intricate geometries.

- CNC Lathes: Perfect for creating cylindrical parts, CNC lathes spin the material against cutting tools for exact shaping.

- CNC Routers: Commonly used for cutting wood, plastic, and soft metals, CNC routers are crucial for sign-making, cabinetry, and artistic designs.

- CNC Plasma Cutters: Using plasma torches, CNC Plasma Cutters precisely cut conductive materials including steel and aluminum.

- CNC Laser Cutters: Using laser beams, CNC laser cutters are perfect for producing complex cuts with minimum material waste.

- CNC Electrical Discharge Machines (EDM): CNC Electrical Discharge Machines (EDM) use controlled electrical discharges between electrodes to produce intricate forms.

Materials Used in CNC Machining

Among the many materials CNC machines are compatible with and flexible enough for are:

- Metals: copper, titanium, brass, aluminum, steel.

- Plastics: ABS, PVC, acrylic, polycarbonate.

- Wood: MDF, softwood, plywood, hardwood.

- Composites: Comprising carbon fiber, fiberglass, and reinforced plastics, composites

Advantages of CNC Machining

Several advantages of the CNC machining process offers make it a favored method of manufacture:

- Precision and Accuracy: Tight tolerances of CNC machines guarantee exact specifications for complicated parts, so addressing accuracy and precision.

- Automation and Efficiency: CNC technology lowers hand work, so improving production consistency and speed.

- Reproducibility: CNC systems allow exactly identical manufacturing of several parts with minimum variation.

- Complex Designs: CNC machines are quite good in creating unique designs and complex forms.

- Material Versatility: CNC technology is flexible enough to allow many materials, so enabling adaptation across many sectors.

Disadvantages of CNC Machining

CNC machining has certain restrictions even if it offers many benefits:

- Initial Cost: CNC machines demand a large equipment and software investment from first.

- Programming Complexity: Perfect CNC codes need experienced operators.

- Maintenance Needs: Consistent performance and minimization of downtime depend on regular maintenance addressing maintenance needs.

- Material Waste: Inappropriate programming or setup might cause too much material waste.

Applications of CNC Machining

Because of its adaptability and accuracy, CNC machining is increasingly applied in many different sectors. Typical uses comprise:

- Aerospace: Extremely precisely produced complex engine components, turbine parts, and structural elements by CNC machines.

- Automotive: Engine blocks, gears, and custom automotive parts are made from CNC technology.

- Medical: Creation of surgical tools, implants, and prosthesis calls for CNC machining.

- Electronics: CNC machines are used often in manufacturing circuit boards, enclosures, and precision connectors.

- Consumer Goods: Custom furniture, home goods, and artistic designs are created in part by CNC machines.

CNC Machine Programming

Modern production depends much on how CNC machines operate and machine programming. This process depends on numerical control—that is, on specific software programs managing machine performance. G-code, a specialist language used in CNC programming, controls basic machine operations including speed, feed rate, and coordination.

CNC machining guarantees that jobs are completed in consistent, repeating cycles with minimum human involvement by pre-programming machine functions. Starting a 2D or 3D CAD drawing, the process turns it into computer code the CNC system uses. Operators run tests to find and fix possible code faults before starting full production.

Particularly in metal and plastic manufacture, CNC machining has transformed production in many different sectors. The following are salient features of CNC machining materials, programming systems and automation mechanisms:

Open-Loop and Closed-Loop Machining Systems

In CNC manufacturing, either an open-loop or closed-loop system controls machine position.

- Open-Loop System: Under an open-loop system, signals move one way—from the CNC controller to the motor. Processes requiring little force and speed requirements call for this approach.

- Closed-Loop System: Closed-loop systems guarantee error correction for better accuracy by means of feedback to the controller. Applications needing higher speeds, consistency, and accuracy—such as difficult metalworking jobs—this system is perfect.

Movement usually comes along the X and Y axes in CNC machining operations. Precisely guiding the tool based on G-code instructions are stepper or servo motors. For low-force jobs, open-loop systems work; for complex, high-speed applications, closed-loop systems are absolutely essential.

Automation in CNC Machining

Modern, CNC machining process is highly automated, so simplifying the part production with minimum human involvement. Starting with computer-aided design (CAD) software definition of part dimensions, the process These CAD models then translate into computer-aided manufacturing (CAM) instructions, which direct the machining operation.

To serve several purposes at once, some various CNC equipment configurations combine several tools—such as drills and cutters—into one unit. As an alternative, manufacturing systems might feature several machines moved between processes under robotic arms control. CNC automation guarantees consistent, exact part production that manual methods find difficult to match regardless of the setup.

The Different Types of CNC Machines

Originally developed in the 1940s when motors were first used to regulate the movement of current tools, CNC (Computer Numerical Control) machines are Modern CNC machining equipment that results from these mechanisms changing with the integration of analog computers and finally digital systems as technology developed.

Most CNC machines today are totally electronic and can handle a variety of challenging jobs. Common CNC-run operations include laser cutting, hole-punching, and ultrasonic welding. The following are some of the main categories of CNC machines applied in contemporary industry:

CNC Mills

Operating under programs composed of numerical and letter-based instructions guiding the component movement of the machine, or CNC programs mills These directions might follow manufacturer-designed proprietary programming languages or standard G-code.

Though advanced models may include up to six axes for maximum accuracy and flexibility, basic CNC mills usually have a three-axis system (X, Y, and Z).

CNC Lathes

Using indexable tools, CNC lathes experts in circular motion cutting of materials. CNC technology helps these machines to achieve very exact cuts at fast speeds. CNC lathes shine in creating complex designs impossible for hand lathes.

CNC lathes use either G-code or custom programming, much as CNC mills. Most CNC lathes have two main axes—X and Z—for exact machining control.

Plasma Cutters

Plasma cutters cut mostly metals using a plasma torch. Combining compressed gas and electrical arcs produces the great heat and speed needed to cut through metal. Because of its accuracy and efficiency, plasma cutting is a rather popular technique used in metal fabrication.

Electric Discharge Machines (EDM)

Using electrical discharges, a process called electric discharge machining (EDM), sometimes referred to as spark, electrical discharge machining, or die sinking, shapes materials. In EDM, electrical sparks progressively erode the material to create a desired form between two electrodes.

Types of EDM include:

- Wire EDM: Using spark erosion, Wire EDM precisely cuts across electrically conductive materials.

- Sinker EDM: Using an electrode and workpiece submerged in dielectric fluid, sink EDM shapes the material.

A dielectric liquid flushes away waste after every machining operation to guarantee a clean finish and stop extra electric charges.

Water Jet Cutters

Powerful CNC tools, water jet cutters cut through difficult materials like granite and metal using high-pressure water streams. Water jets are sometimes combined with abrasive materials like sand in order to enhance cutting strength.

For materials unable of withstand heat-intensive cutting techniques, water jet cutting is perfect. For exact, heat-free cutting operations, industries including mining and aerospace routinely rely on water jets. Water jets also shine in jobs needing fine detailing since they maintain the inherent qualities of the material without distortion from heat.

Expanded Capabilities of CNC Machines

Cutting metal for industrial hardware products is one area where CNC machines are well-known for their amazing accuracy. Still, their capacity goes much beyond that. Many different manufacturing industries use CNC technology to produce extremely complex and exact products across many materials including metal, wood, and plastic.

Common CNC-Produced Products

Many finely detailed objects, including: CNC machines, are created using:

- Steel aerospace components

- Automobile metal components

- Wooden decorations

- Parts for consumer goods made of plastics

These various outputs show how flexible CNC machinery is in both complex design-based additive manufacturing processes and heavy-duty industrial work.

Additional Tools Used in CNC Systems

CNC machines can include different specialized tools and components to increase their capability. Among the most often used augmenting machine tools, are:

- Embroidery machines

- Wood routers

- Turret punchers

- Wire-bending machines

- Foam cutters

- Laser cutters

- Cylindrical grinders

- 3D printers

- Glass cutters

Versatility and Efficiency in CNC Manufacturing

CNC machines can run intricate cuts at many angles and depths in a matter of minutes thanks to their flexible design. CNC machines effectively produce precise, detailed, high-value products with unmatched accuracy by following set instructions. The resulting product should exactly satisfy design criteria as long as the programming code is accurate, so guaranteeing both quality and functionality.

Future Trends in CNC Machining

Technological developments always help CNC machining to change. Rising trends improve automation, accuracy, and efficiency:

- AI Integration: Artificial intelligence is driving predictive maintenance and CNC programming accuracy enhancement.

- Automation Advancements: Robotic arms and automated material handling systems improve workflow and lower labor costs.

- Smart CNC Systems: Internet-connected CNC systems let real-time monitoring, diagnostics, and performance analysis possible.

- Sustainability Focus: Energy-efficient CNC machines are becoming more and more well-liked, so lowering their environmental effect.

How to Choose the Right CNC Machine

Choosing the correct CNC machine relies on a number of criteria:

- Material Type: Think about the kind of material you will be handling—metal, plastic, wood, or another.

- Project Complexity: Determine whether complex designs call for multi-axis machining.

- Production Volume: For mass production, give machines with great automated capability top priority.

- Budget: To guarantee best investment, balance first expenses with long-term advantages.

Maintenance Tips for CNC Machines

Correct maintenance guarantees maximum performance of CNC machines. Important maintenance routines consist in:

- Lubrication: To cut friction and wear, routinely lubricate moving components.

- Cleaning: To stop buildup, clear metal shavings, dust, and trash.

- Calibration: Periodically check and change machine calibration to match accuracy.

- Software Updates: Maintaining CNC software updated will help to guarantee compatibility and improved features.

Conclusion

Combining accuracy, automation, and adaptability, CNC machining is a revolutionary manufacturing method producing premium goods. Its importance is shown by its general application in sectors including medical, automotive, and aerospace. Although the CNC machining process begins calls for equipment and trained operators, the advantages greatly exceed the expenses, thus it is a necessary tool for contemporary production.