Meta Description: Learn more about in-mold labeling (IML) technology, a method including in mold graphics, manufacturing technology, cost advantages, and how spongy layer bonded labels can enhance the industries that use it. Master reference to guide manufacturers and other businesses to advance their fast and quality packaging systems.

The in-mold labeling (IML) method is a recent breakthrough in blow molding, molded plastic manufacture and packaging decoration that has revolutionized the way the companies undertake branding of their products within the mold cavity and the efficiency of packaging. It is an inclusive process of manufacturing that incorporates labels in soft products like plastics that are molded, creating a smooth product; tough, and most importantly economical alternative to the contemporary packaging requirements.

What is In-Mold Labeling Technology?

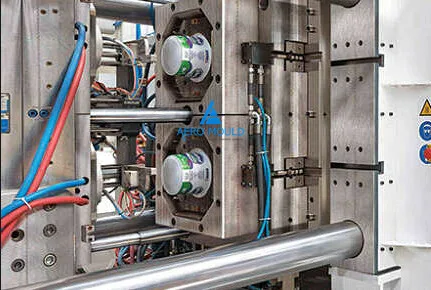

In-mold labeling applies by inserting precisely cut imprinted plastic films (so-called labels) into injection molds using special handling units with vacuum ports and attaching them by vacuum or static electricity then back-injecting material in the injection molding process. The procedure allows forming a bond between the label and the plastic container so that the label does not need to be added later.

The technology has had massive traction over the last years and since the global IML market is projected to surpass $407 million in 2023, under high pressure, and is estimated to grow by 12.0% CAGR up to 2030 and reach 914.2 million, it is evident that improvements in mold surface quality and injection molding techniques are becoming increasingly important in reducing manufacturing costs in the context of a modern manufacturing industry.

The In-Mold Labeling Manufacturing Process

The IML process, which is a single operation, commences with blank containers and pre faced body labels that are accurately cut and placed in the cavity of the mold for movement of plastic taking place. such labels are specially treated with heat-activated type of adhesive and get permanent bonds in the molding procedure. The manufacturing process is the placement of the labels, closing of the mold, injection of the hot plastic, the cooling process, and the ejection of the final product.

The latest IML systems involve use of superior robotics and automation to control perfect label material placement and uniform quality. This is a delicate operation in terms of coordination of temperature, pressure, and static charge to obtain the best fusion between label and plastic without impairing the quality of either of the two.

Key Benefits of In-Mold Labeling Systems

The use of labeling plastic in in-mold labels saves time, money, and reduces the hassle that is associated with many labels in the industry, especially the pressure sensitive labels. Its main benefits, along with considerations for wall thickness, are the increased durability, durable graphics scratch resistant quality, lower cost of production, aesthetics, and simplified manufacturing.

The combination process of IML removes the label peeling, bubbling or degradation that would otherwise occur in normal adhesive labeling. Goods retain their resemblance over their whole life time and this offers good brand illustration and customer liking. Also, no individual labeling operations using compressed air entail less time and labor costs consumed in the production process.

In-Mold Labeling vs In-Mold Decorating Comparison

In-mold decorating and decorating plastics in-mold labeling were two similar processes in the manufacturing process which were able to substitute the marking of injection-molded articles by placing the pre decorated item into the molded empties with complex shapes . Although the two processes use similar techniques, they are applicable in different ways.

In-mold labeling is applied to short life span products like the containers of cosmetics, avoiding secondary operations, but in-mold decorating to products with longer lives are taken into consideration. IML is normally directed towards the consumer packaging industry whereas IMD is oriented towards automotive, electronics and durable products.

Primary Industries Using In-Mold Labeling

IML applications include thin solid layers in bottles like shampoo bottles, deodorants and soaps, and food packaging like ice cream packs, yoghurt packs and butter containers among others, including in mold decorating . Food and beverage The hygienic nature of IML and its regulatory compliances is especially useful to the food and beverage industry.

Medicine bottles, supplement containers, and elements of medical devices in the healthcare and pharmaceutical sectors are increasingly using IML. The automotive industry uses IML in interior parts and the electronic appliance makers use IML in housing and peripherals.

Material Compatibility and Substrate Options

Two of the most common forms of labeling plastic resin used in in-mold labeling are the high density polyethylene (HDPE) as well as polypropylene (PP). The materials provide high compatibility with IML process because they are chemically resistant, fully recyclable, and have good heat properties.

Because of special application needs such as, temperature resistance, chemical compatibility, and environment of use, the selection of materials varies widely. Above all, IML is still being extended further with the more advanced formulations of polymers so that they can be applied in more challenging settings and in very specific industrial sectors.

Quality Control and Testing Standards

Effective use of IML involves strict quality control measures during the process of manufacture. The tests involve adhesion strength test, any test to assess the temperature resistant, and inspection measurements. The measures guarantee a uniform product quality and regulatory controls in various industries.

Quality controls keep an eye on the accuracy of label placement, completeness of fusion and product specification at final stage, especially when compared to other methods . The newer, more automatic methods of inspection, such as machine vision systems find the defects and keep standards up.

Environmental Sustainability and Recycling

In-mold labeling is a method of decorating cost reductions and packaging decoration that is sustainable because containers and the labels, available in multiple colors, are made of polypropylene to form a mono-material packaging that could be completely recycled. It is an environmental benefit as IML will represent an environmentally friendly option to multi-material solutions.

Recycling is easier since the use of adhesives and other added materials is eliminated and its adverse effects on the environment diminished. IML is specially used by many companies to comply with the objectives of sustainability and regulatory compliance of recyclable packaging.

Cost Analysis and Economic Advantages

IML systems have an initial cost of appropriate equipment and tooling, but offer significant long-term cost savings, due to a reduction in labor, elimination of subsequent operations, and material waste produced . The improvement of production efficiency is frequently worth the implementation cost in 12-18 months.

Economic gains do not end on direct cost savings to more elaborate inventory simpler supply lines, and better consistency of melted plastic product quality. These help in better competition and profitability.

Design Considerations for IML Applications

There are various aspects that should be considered when designing IML so as to obtain the best possible results, because graphics have to be combined with products which are able to offer finished products of durable quality. Design requirements involve speification of artwork, color management and optimizing of labels.

The critical design factors include correct label positioning, compensation of shrinkage, and being found compatible with the geometry of the molds. A good IML design takes into consideration all the aesthetic and manufacturing requirements to come up with the best outcome.

Equipment and Machinery Requirements

The production of IML involves special injection molding equipment with label handling device, recycling or electrostatic label retentions as well as precise temperature control ability. The new systems have automated label feeding, positioning and inspection automated systems.

The factors considered in investment are the capacity of machines and the level of automation and the compatibility with the existing production lines. Choice of equipment greatly influences efficiency, quality and the cost of production.

Common Applications in Consumer Products

There are many applications and types of consumer products packaging that cover food containers and personal care packaging, household products and promotional products. Each application category has specific needs when it comes to durability and appearance as well as compliance.

The effective magnification of consumer products has been successfully carried out to show that IML is flexible enough and efficient to fulfill various needs in the market and retain its competitiveness in cost and good quality.

Technical Challenges and Solutions

The IML implementation is challenged by such factors as accuracy in label positioning, yes precision of temperature, and complexity of mold design. These challenges are solved as highly automated systems and other process monitoring tools render a steady process feedback and trading capabilities.

The solution strategies include a thorough optimization of the processes, calibration of the equipment, and training program of operators. The constant development approaches guarantee five-star quality and the effectiveness of output.

Future Trends in In-Mold Labeling Technology

Among the rising tendencies, there is the integration of smart labels that can accommodate complex shapes , a higher level of sustainability, and increased material compatibility. Through digital printing technologies, short-run customization and variable-data printing are possible which provide the features of customized packaging.

The industry 4.0 integration, usage of artificial intelligence, and developments in material science form the drivers of innovation. These trends leave IML well-positioned in the future with the ability to grow and spread to new markets.

Regulatory Compliance and Standards

The IML products have to meet several regulatory guidelines with respect to the usage devices they are targeted at. Before use, food contact materials have to be approved by FDA, whereas medical devices must have ISO certifications and require biocompatibility testing.

The strategies of compliance include compliance of materials used, the documentation of a process and monitoring the quality thereof. Design decisions as well as protocols of manufacture are greatly affected by regulatory requirements.

Global Market Dynamics and Supply Chain

IML market is widely growing in key geographic locations because of the rising need of collaborative packaging solutions and the efficiency in manufacturing. These factors are used in supply chain considerations such as availability of raw materials, availability of equipments and technical support infrastructures.

Market forces indicates an increasing use in the emerging markets and expansion into new application areas. Supply chains optimization on a global scale guarantees a stable availability of materials and providing technical support.

Integration with Automated Manufacturing Systems

Incorporation of robotics, conveyor systems, and automated quality control method are the characteristics of the modern IML systems, coming together with the automated manufacturing environment consumer electronics. The advantages of integration comprise a decrease in labor demands, greater lesser consistency, and a better capability of monitoring productions.

Automation technologies include the fields of material handling, the inspection of quality, and the process of the collection of production information. The features facilitate the lean production concept and the continuous improvement undertakings.

Conclusion

In-mold labeling is an innovative technology which integrates cost effective production and blow molding product quality along with environmental friendliness, particularly in decorating . The procedure has massive advantages, as an integral part of modern manufacturing in comparison with other conventional labeling procedures in terms of incorporated design, cost, and strength. Speaking of market demand and technological progress, IML will become a more significant component in the contemporary manufacturing and packaging patterns post molding labeling.