Reaction Injection Molding (RIM)

Reaction Injection Molding (RIM) delivers large, intricately detailed plastic parts with exceptional dimensional stability, chemical resistance, toughness, and wear durability—making it the perfect solution for short-run or low-volume production of sizable components.

What is Reaction Injection Molding (RIM)?

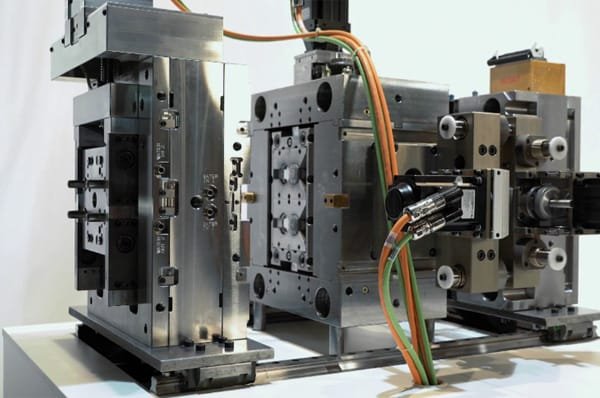

Reaction Injection Molding (RIM) is a high-performance process that blends liquid resins and catalysts at low pressure to produce large, complex plastic parts. Its fast-curing chemistry and low clamping forces let you use economical aluminum molds, slashing tooling costs and lead times. RIM parts boast tight dimensional stability, excellent chemical resistance, and superior toughness—ideal for short-run or low-volume production of sizable components with intricate details.

Innovative Solutions for High-class Prototypes and Short Runs

High-volume plastic parts typically rely on steel-injection molds—which are complex and expensive to build, making them cost-effective only for large production runs. RIM technology, on the other hand, delivers up to 1,000 units quickly and affordably. Leading Edge’s RIM portfolio includes specialized formulations with high impact resistance, elevated temperature performance, and extended pot life for large-part production—plus automotive-grade certifications to meet industry standards.

Why Reactive Injection Molding?

Reaction Injection Molding (RIM) mirrors conventional injection molding but uses thermosetting resins that polymerize during flow—often under heat, with or without high pressure. Its low viscosity lets RIM fill high aspect-ratio cavities effortlessly, and the resulting cross-linked polymers deliver exceptional mechanical strength.

Yet RIM poses challenges: thermosets are hard to recycle, and issues like flashing, scorching, and longer cycle times can arise. The complex interplay of chemistry, flow, and heat also complicates process control. That’s why Leading Edge’s RIM suite provides full 3D simulation for thermosets—unsaturated polyester, polyurethane, rubber compounds, liquid silicone, epoxy molding compounds, and more—modeling cavity fill, cure kinetics, warpage, fiber orientation, multi-component molding, and custom scenarios to optimize your RIM process.

Advantages of Choosing Reaction Injection Molding

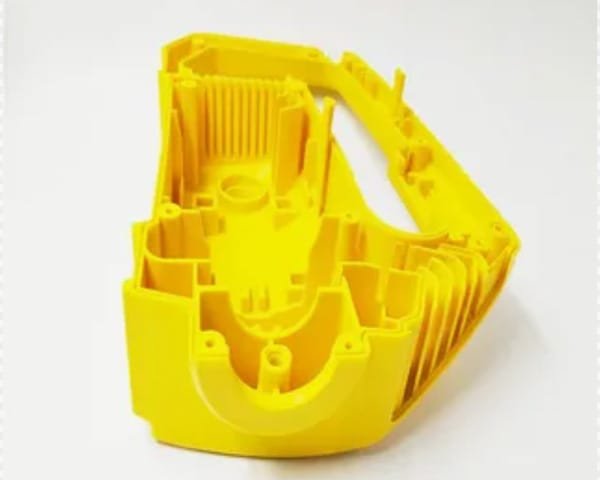

The RIM process delivers a host of benefits our customers love: thanks to its liquid injection and PUR foaming chemistry, you can easily achieve complex, deep-drawn, cylindrical, and otherwise challenging geometries in a single mold run.

Cost-Efficient

When you’re producing fewer than 5,000 parts per year, Reaction Injection Molding tooling delivers superior cost efficiency over conventional methods—leveraging affordable polymer resins to slash both tooling and per-part expenses.

Versatility

Leading Edge understands that Reaction Injection Molding is one of the most versatile manufacturing processes available. It empowers designers with unprecedented creative freedom—allowing multiple wall thicknesses within a single part, producing large or ultra-lightweight components, all without sink marks or distortion.

Materials used in RIM

Leading Edge’s RIM service supports a wide range of thermosetting resins—polyurethane, vinyl ester, ester-amide, unsaturated polyester, epoxy, and more—plus commercial formulations like HD-PU4210, DCP-RIM, and RIM AXSON-875. Our tailored material choices and precise chemistry enable fast cycle times (15–30 minutes per part) and larger castings (up to 2000 × 1200 × 1000 mm, 10 kg), with a secondary post-cure ensuring peak performance. Whether you need volume production or oversized components, our RIM expertise delivers high accuracy and efficiency in every unit.

Where can RIM moulding be used?

RIM moldings deliver rugged reliability across industries—from life-saving medical devices to demanding outdoor applications. In the medical and scientific sectors, precision polyurethane housings power cancer-treatment systems, robotic surgery tools, and laboratory equipment that must meet stringent regulatory standards, UL94 V0 flammability ratings, and even optional EMC shielding. Meanwhile, electric-vehicle chargers, personal dive units, and solar canopy components rely on UV-stable, impact-resistant RIM parts engineered to withstand harsh environments. Trust RIM moldings to provide the structural strength and confidence your critical applications demand.