Die Casting Service

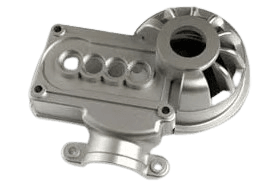

Precision die casting service for custom metal parts and prototypes with fast turnaround times. Request for an instant quote to get started today!

ISO 9001:2015 | AS9100D | ITAR Registered

Fast and easy quoting & manufacturing die casting process

Our Strict Die Casting Processes

Our strict metal die casting processes help to deliver high precision and durable end-use parts and prototypes. All of them can meet strict quality standards and tolerance requirements.

Hot Chamber Die Casting

Hot chamber die casting—also called gooseneck casting—engineers low-melting-point alloys like zinc, magnesium, and select lead types with lightning-fast cycle times, flawless surface finishes, and exceptional production throughput.

Cold Chamber Die Casting

Cold chamber die casting handles high–melting-point alloys—like aluminum, copper, and zinc-aluminum blends—enabling intricate geometries and pinpoint accuracy in part reproduction.

Our Strict Die Casting Processes

Extensive Selections

Choose from a broad range of alloys, surface finishes, tolerance levels, and casting methods to suit your die-casting project. Share your requirements, and our experts will recommend the optimal manufacturing strategy—delivering the perfect balance of performance, quality, and cost efficiency.

High Precision and Tight Tolerances

Leveraging cutting-edge die casting technology and deep industry expertise, we deliver precision-crafted metal components with tight tolerances and uncompromising quality—every time.

Rapid Prototyping and Production

We streamline product development from concept to production—our rapid prototyping and lightning-fast turnarounds accelerate iterations and slash your time to market.

Advanced Die Casting Facilities

With cutting-edge die casting facilities and advanced equipment, we harness the latest technologies to deliver precise, uniform parts. Our modern plant maximizes efficiency—ensuring shorter lead times and dependable, on-time delivery.

Die Casting Metal Materials

Die casting is a versatile manufacturing process that can use different metal materials. Choose the right material based on your intended use for the product.

- Magnesium Alloys

- Zinc Alloys

- Aluminum Alloys

Magnesium alloys boast an outstanding strength-to-weight ratio, making them perfect for weight-sensitive applications. With excellent dimensional stability and rapid heat dissipation, they’re a go-to choice in automotive and electronics industries.

Key Features:

Exceptional strength

Low viscosity for superior fluidity

Outstanding corrosion resistance

Effortless filling of intricate mold cavities

Zinc alloys are known for their high fluidity, allowing for intricate and detailed die cast parts. They offer excellent dimensional stability and good strength, and are often cost-effective. Zinc die casting is often used in automotive, telecommunications, and electrical industries.

Features:

- Tight tolerances and precise fit

- Good strength and high hardness

- Great stability

- High-quality surface finish and easily plated

- Low melting point

Aluminum alloys are widely used in aluminum die casting due to their excellent strength-to-weight ratio, corrosion resistance, and high thermal conductivity. They are commonly used in automotive, aerospace, and consumer electronics industries.

Features:

- Lightweight

- Withstand high operating temperatures

- Great resistance to corrosion

- High strength-to-weight ratio

- Excellent thermal and electrical conductivity

Die Casting Service Applications

Automotive Parts (gears, cylinder heads, gladhands, transfer cases, small engine parts, etc.)

Aerospace Industry (engine components, aircraft structural parts, brackets, housings, connectors, etc.)

Commercial & Consumer Electronics (compressor pistons and connecting rods, heat sinks, bearing housings, parts of the sink faucet, meters, locks, motor casings, etc.)

Lightning Industry (lamp housings, reflectors, fixtures, etc.)