Rapid Tooling Services

Get premium rapid tooling solutions for prototypes and low-volume runs. Leading Edge blends expert engineering with cutting-edge technology to fast-track injection mold tooling—delivering precision and performance at competitive prices.

- One-stop Tooling Solutions

- Cost-effective and Fast Turnaround

- Free DFM for Excellent Results

What is Rapid Tooling?

Rapid tooling is a fast, cost-effective approach to mold making that uses lightweight materials—like aluminum or semi-hardened steel—and quick-change insert systems to slash lead times and tooling costs. By combining expert DFM guidance with advanced modular mold bases, you can validate designs and produce low-volume parts in weeks instead of months, all while maintaining the precision and durability needed for prototype and bridge-tool applications.

Our Rapid Tooling Processes

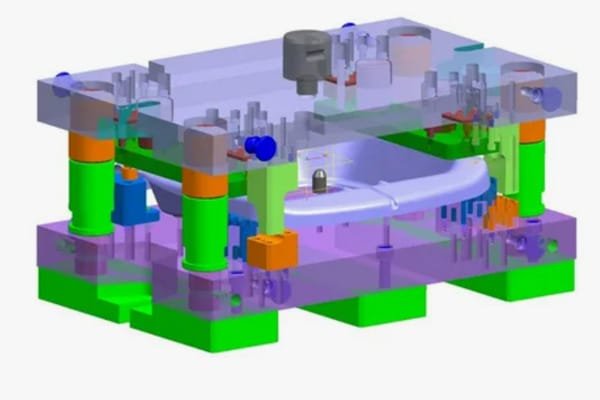

Fast Mold Tooling Making

Leverage streamlined mold design and rapid cavity fabrication with soft steel or aluminum for instant results. Tap into our stock mold components and modular bases to accelerate lead times even further.

Low Volume Injection Molding

In addition to standard production molds, we fuse rapid tooling with injection molding to deliver low-volume parts swiftly and affordably.

Why Choose Leading Edge’s Rapid Tooling Services?

High Efficiency and Quality

Our expertise guarantees prototype injection molds that match—or even rival—full-scale production quality, delivering the exact tools you need with true mass-production precision.

Competitive Prices

Our seasoned engineers leverage advanced techniques and optimal materials to deliver cost-effective rapid tooling solutions. With expert mold design and strategic material selection, we provide high-quality molds at the most competitive prices.

Design for Manufacturing Support

Integrated into our prototype injection molding process, our DFM support uncovers design issues upfront—so you can make adjustments before tooling or production starts, saving you both time and money.

Timely Delivery

By blending cutting-edge technologies with seasoned expertise, we accelerate prototype production for functional testing—cutting your development cycle and fast-tracking your time to market.

Reliable Process

Every project starts with rigorous material testing to guarantee optimal performance and integrity. We then harness industry-leading technologies to deliver rapid tooling that meets—and exceeds—your expectations every time.

One-stop Machining Capabilities

By integrating rapid prototyping—from CNC and EDM machining to 3D printing, vacuum casting, and precision finishing—Leading Edge delivers rapid production tooling and injection molds with unmatched speed and efficiency.

Common Types of Rapid Tooling

Aluminum Mold Tooling

Aluminum molds are the perfect choice for prototype injection molding, offering a cost-effective way to produce high-quality parts with exceptional dimensional stability. Their superior machinability can cut tooling costs by up to 25%, while reducing waste and part deformation. Plus, faster cycle times—30–40% shorter than steel—mean you get rapid turnarounds without sacrificing performance.

Steel Mold Tooling

Steel molds deliver unmatched durability and longevity, making them the go-to choice for large-scale runs and engineering-grade plastics. While the upfront cost and lead time are higher than aluminum, their extended lifespan and robust performance provide superior ROI for high-volume production.

Rapid Tooling & Prototype Injection Molding Services

Materials for Prototype Injection Molding

Almost all plastics is ideal for prototype injection molding. The common used plastics are listed below:

- ABS

- ABS/PC

- Acetal

- Delrin

- HDPE

- LDPE

- Nylon

- PC

- PEEK

- PET

- PETG

- PMMA (Acrylic)

- Polycarbonate

- Polypropylene

- PPA

- PPE

- PS

- PSU

- Standard silicone

- Fluorosilicone (fuel and oil resistant)

- Medical-grade silicone

- Optical-grade silicone

Our Rapid Tooling Processes

Rapid tooling’s increasing rate of adoption is due to its many benefits.

Mold Customization

Rapid prototype tooling empowers you to craft custom molds to your exact dimensions and specifications. By testing different materials through quality-control trials, you’ll gain the insights needed to select the perfect material for your project’s performance and budget goals.

Thorough Design and Functionality Testing

Rapid tooling lets you produce multiple molds—and thus several prototypes—in mere days, giving you the freedom to test fresh ideas and iterate on existing designs. The result? Enhanced functionality, accelerated innovation, and greater market impact for your products.

Faster Time to Market

Faster mold production speeds up both prototype and final product creation—shortening your prototyping phase and accelerating your time to market.

Increased ROI

Faster product development and accelerated time to market let you start earning returns sooner. Coupled with reduced prototyping and production costs, you’ll maximize ROI by minimizing expenses throughout production.

Our Rapid Tooling Processes

Need as few as 100 or more than 100,000 injection molded parts? Injection mold tooling is a cost-effective solution for your product development process.

Optimized Design for Manufacturability (DFM)

We integrate Design for Manufacturability (DFM) at every stage—from part design and mold tooling to material selection and machining—so you catch issues early, not after production starts. Our DFM-driven approach delivers cost-effective tooling and scalable injection molding, ensuring your parts are optimized for quality and efficiency from day one.

Choose the Right Material of Mold Tools

Selecting the ideal mold tool material hinges on factors like intended use, production volume, design complexity, and mold structure. Not sure which option fits your needs? Our team will help you weigh each advantage to identify the perfect rapid tooling solution for your product.

Choose from Aluminum 7075 for fast, cost-effective prototyping; P20 or NAK80 semi-hardened steels for a balance of durability and efficiency; or H13 fully hardened steel for maximum wear resistance and longevity. Plus, enhance your molds with industry-standard SPI finishes, precision EDM texturing, or specialty etched patterns from the Mold-Tech® MT and VDI® 3400 series.

Rapid Tooling Manufacturing Process

To achieve rapid production and cost savings, we leverage the Master Unit Die (MUD) Quick-Change system—only the mold insert needs updating for engineering changes, not the entire mold base. Group similar parts into a family tool for even greater economies, and choose manual or semi-automatic inserts to suit your workflow. We fabricate rapid tooling from Aluminum 7075, P20 and NAK80 semi-hardened steels, or H13 fully hardened steel—and finish with SPI polishing, precision EDM textures, or specialty etchings from Mold-Tech® MT and VDI® 3400 series.