Rapid Prototyping

with Leading Edge

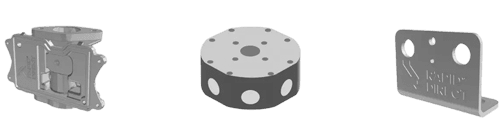

Turn your concepts into reality in days with Leading Edge’s rapid prototyping services. From precision CNC models to advanced 3D-printed parts, we deliver fully functional prototypes with tight tolerances and production-grade finishes—so you can test, iterate, and validate designs faster than ever.

Start a Leading Edge Quote

STEP STP SLDPRT IPT PRT SAT IGES IGS CATPART X_T OBJ STL

files

- All uploads are secure and confidential.

What is

Rapid Prototyping

Rapid prototyping lets you move from digital design to physical model in just days, turning concepts into tangible parts for real-world testing. By leveraging CNC machining, 3D printing, and other fast-turn methods, you can quickly validate fit, form, and function—identifying design improvements before committing to full production. This fast-feedback loop not only slashes development time and cost but also empowers you to refine your product with confidence, ensuring a smoother path from prototype to market.

Our Rapid Prototyping

Services

Rapid CNC Prototyping Service

CNC machining—milling and turning—offers the fastest route to prototypes in their final metal or plastic form, delivering fully dense, precision parts built to last. At Leading Edge, we work with a broad range of materials and can turn around high-quality CNC prototypes in as little as 24 hours. Our competitive pricing lets you order multiple parts at once, while flexible rush options ensure even your most urgent projects hit their deadlines. Partner with us for expert craftsmanship, unwavering tolerance control, and rapid product development from initial design through full production.

Maximum Part Size:

CNC Milling: 4000×1500×600 mm

CNC Turning: 200×500 mm

Standard Lead time: 1 day

Tolerance: 0.001 inches

Rapid Prototype Injection Molding Service

Accelerate your product validation with our Rapid Prototype Injection Molding Service—delivering production-grade, bridge-tooling parts in as little as 5 days. Ideal for high-performance materials and precision geometries that exceed the limits of 3D printing or CNC, our expert team ensures exceptional repeatability and surface finish. From functional testing to market pre-launch runs, trust Leading Edge to provide durable, dimensionally accurate prototypes that mirror your final production parts—so you can iterate confidently and hit every development milestone.

Maximum Part Size: 1200×1000×500 mm

Standard Lead time: 2-3 weeks

Mold Cavity Tolerance: +/- 0.05 mm

Rapid Sheet Metal Prototyping Service

Accelerate your metal design iterations with our Rapid Sheet Metal Prototyping Service—delivering precision-formed parts in as little as one week. From prototype brackets to complex enclosures, we bend, cut, and finish aluminum, steel, and copper with production-grade accuracy. Enjoy cost-effective small-batch runs, multiple material options, and turnkey surface treatments—all backed by expert engineers and lean processes. Get your sheet metal prototypes fast, test with confidence, and keep your project on schedule.

Cutting Feature: ± .00787” (0.2mm)

Bend Angle: ± 1.0°

Bend to edge: +/-0.010″(0.254mm)

Bend to hole: +/- 0.2 mm

Standard Lead time: 1-2 business days

General Tolerances: Metals : ISO 2768-c

Rapid 3D Prototyping Service

Accelerate your product development with our Rapid 3D Prototyping Service—delivering high-resolution, functional parts in as little as 24 hours. Choose from SLS, SLA, or FDM technologies and a wide array of engineering-grade plastics and resins to match your performance and aesthetic needs.

SLS offers a versatile balance of speed, mechanical performance, detail resolution, and cost-effectiveness. SLA delivers the finest surface finish and exceptional accuracy, making it ideal for clear parts with tight tolerances.With turnkey post-processing options and competitive pricing, you’ll get production-quality prototypes fast, empowering you to validate form, fit, and function before committing to tooling.

Max. Build Size: 1400x700x500mm

Standard Lead time: 4-6 days

Dimension Tolerance: ±0.2mm (For >100mm, apply 0.15%)

Rapid Vacuum Casting Prototyping Service

Accelerate your product testing with our Rapid Vacuum Casting Prototyping Service—delivering high-fidelity, production-like parts in days, not weeks. By casting polyurethane under vacuum into precision silicone molds, we replicate intricate details and textures with exceptional surface quality and mechanical performance. Ideal for small to mid-volume runs, our service offers multiple material options and turnkey post-processing, so you get durable, bridge-tooling prototypes that mirror your final injection-molded parts—helping you validate design and functionality faster than ever.

Maximum Part Size: +/- 0.025 m

Standard Lead time: Up to 20 parts in 15 days or less

Tolerance: ±0.05 mm

How to Choose

The Right Rapid Prototyping Technique

Advantages

Disadvantages

Rapid CNC Machining

High precision and suitability for a variety of materials. Ideal for functional and durable parts.

Higher cost and longer lead times compared to some additive manufacturing processes.

Rapid Injection Molding

Excellent for high-volume production. Provides end-use, functional parts with fine details.

Upfront costs for molds are high, less economical for small quantities.

Rapid Sheet Metal Fabrcation

Good for durable prototypes, allows quick modifications. Suitable for both prototyping and production.

Limited complexity, not ideal for intricate designs requiring high detail.

Rapid 3D Printing

Fast and cost-effective. Capable of complex geometries that are not possible with other methods.

Material properties might not match those of traditionally manufactured parts. Resolution varies by technology.

Rapid Vacuum Casting

Suitable for producing small quantities of highly detailed replicas quickly and affordably.

Generally used for non-functional prototypes or visual models due to material properties.

Why

Choose Us

/01

High Quality

Parts

Leading Edge guarantees superior prototype quality by employing advanced materials and precision techniques in full compliance with rigorous industry standards.

/02

Fast Lead Time

Our streamlined processes deliver prototypes rapidly, dramatically reducing development time and accelerating your time to market.

/03

Engineering Support

Leading Edge offers comprehensive engineering support, guiding you through design optimization and technical challenges to enhance prototype development.