On-demand Custom CNC Machining Services

Online, on-demand CNC machining for rapid metal and plastic prototypes or production parts—upload your CAD file, get an instant quote, and receive precision-machined components at competitive prices with fast turnaround and uncompromised tolerances.

- One-off CNC Prototypes

- 100K+ Mass Production Machining

- Tolerance as tight as ±0.01 mm

- Delivery in as little as 5 days

Start A New CNC Quote

STEP STP SLDPRT IPT PRT SAT IGES IGS CATPART X_T OBJ STL

files

- All uploads are secure and confidential.

ISO

9001:2015 Certified

50+

CNC machines

100+

Plastic & metal materials

10K+

CNC parts made monthly

Why Use Leading Edge for Custom CNC Machining Services?

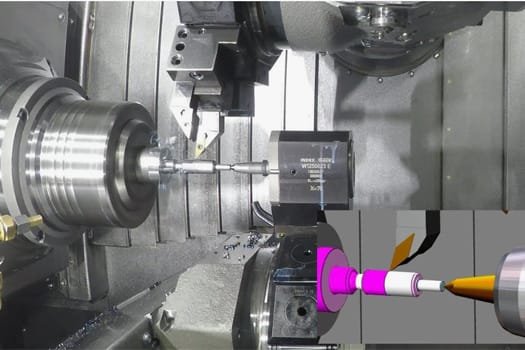

State-of-the-Art Equipment

Our multi-axis CNC centers, live-tool lathes, and automated inspection systems deliver unmatched precision—enabling complex geometries and tight tolerances in every run.

Seasoned Engineering Expertise

With an average of 10+ years’ experience, our engineers guide you from DFM reviews to final validation, optimizing designs for manufacturability, cost, and performance.

Consistent High-Quality Output

Every part undergoes in-process inspection and final QA checks to ensure repeatable accuracy, surface finish, and material integrity—batch after batch.

Lightning-Fast Turnaround

From immediate instant quotes to expedited production lanes, we compress lead times without cutting corners—so you get the parts you need, exactly when you need them.

Upload your 3D files to have a fast

DFM feedback and quote.

Our CNC Machining

Capabilities

Backed by real-time tool monitoring, in-process metrology, and expertise across metals and plastics, we deliver flawless finishes, precise tolerances, and reliable repeatability—ready for your toughest challenges. Try our precision CNC services and become our next satisfied customer.

CNC Milling Service

We operate 32 in-house 5-axis CNC milling machines, enabling effortless production of tight-tolerance plastic and metal parts with complex geometries. For budget-friendly runs, we also utilize our 3- and 4-axis mills to deliver cost-effective machined components.

CNC Turning Service

CNC turning offers an efficient way to produce round plastic and metal components—such as worm shafts—from bars or tubes, and when paired with live tooling, it can mill complex geometries in a single setup.

EDM & Wire-Cut Service

EDM and wire-cut are CNC processes that use copper or graphite electrodes, or molybdenum wire, to create sharp corners, undercuts, and remove unwanted material from workpieces. They’re also widely used for rapid tooling and production mold making.

CNC Grinding Service

Our CNC grinding service is ideal for achieving super-flat surfaces or round parts with OD/ID tolerances as tight as ±0.005 mm.

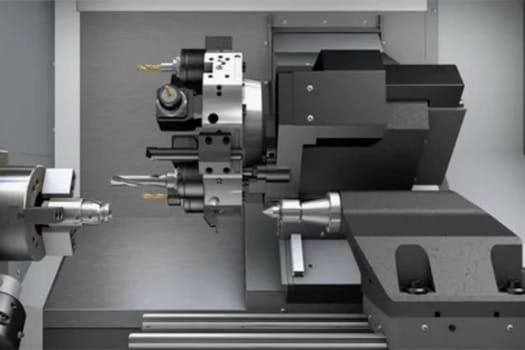

Swiss Machining Service

Swiss machining is an efficient method for producing complex or slender components. By synchronously moving both the workpiece and live tooling, material is cut very close to the guide bushing, minimizing deformation compared to a traditional CNC lathe.

CNC Routing Service

In addition to our standard milling services for engineering plastics and metals, we offer CNC routing for prototypes and parts in soft materials such as EPS foam, EVA, and wood.

One-Stop CNC Machining Parts Supplier

Whether you need just a handful of parts or over 10,000 end-use production units, CNC machining offers the perfect solution. Below are the custom CNC services available at Leading Edge.

Rapid Prototyping

At Leading Edge, you can have your CNC prototypes completed in days—our ultra-short lead times let you verify your designs quickly.

- Instant quotes

- Instant DFM feedback

- Excellent quality

- Short lead time

Low-Volume Manufacturing

CNC machining is a cost-efficient method for producing certain parts in low to medium volumes—typically ranging from 100 to 1,000 pieces.

- Lower cost

- Production-level quality

- Short lead time

- Test out the market before investment

End-use Production

Combining CNC machines with robotic automation is ideal for high-volume manufacturing, significantly lowering unit costs by eliminating manual labor.

- Experienced engineers for DFM optimization

- A professional PM working in your time zone

- First Article Inspection

- Guaranteed consistent quality

-- Ryan Growel