Introduction

Precision and efficiency are more important in the fast-paced industrial scene of today than they were years. Emerging as a game-changing technology allowing producers to create complex parts with unparalleled accuracy and consistency is CNC machining services or precision machining. In aerospace, medical, automotive, or electronics sectors, CNC machining is essential for guaranteeing excellent output with low human error.

CNC precision machining techniques has evolved with technological developments to incorporate artificial intelligence (AI), automation, and smart manufacturing, so becoming a vital instrument for the direction of industry. Examining CNC precision machining in depth, this long-form blog covers its working ideas, benefits, difficulties, future directions.

What is CNC Precision Machining?

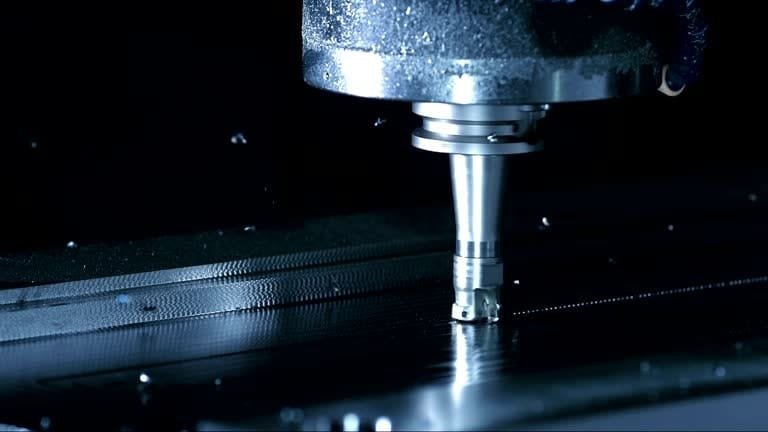

Precision machining, or precision CNC machining (Computer Numerical Control), is an advanced manufacturing technique in which tools are extremely precisely manipulated using computerised controls. This is a subtractive manufacturing process, whereby the intended form and dimensions are obtained by removing material from a workpiece.

Often within ±0.0001 inches, this process is extensively applied to produce intricate parts needing exact tolerances. CNC machining, unlike conventional manual part machining techniques, depends on automated programming to guarantee repeatability and remove human error-causing variation.

How CNC Precision Machining Works

Key stages in CNC precision machining consist in:

- Designing the Part with CAD Software

- Computer-Aided Design (CAD) tools let engineers digitally model a part.

- The design calls for exact tolerances, surface finishes needed for the finished good, and precise dimensions.

- Generating the CNC Program with CAM Software

- Computer-Aided Manufacturing (CAM) applications translate the CAD model into a machine-readable format.

- This program creates the tool paths, so guiding the cutting tools’ shaping of the workpiece.

- Setting Up the CNC Machine

- The workpiece is firmly fixed and the CNC machine has the suitable cutting tool installed.

- Operators guarantee proper configuration of machine settings including speed, feed rate, and coolant levels.

- Executing the CNC Program

- The CNC machine precisely cuts, drills, or shapes the workpiece following programmed directions.

- Real-time feedback systems and sensors help to guarantee that the machining operation stays accurate and within tolerance.

- Final Inspection and Quality Control

- Advanced metrology instruments like coordinate measuring machines (CMMs) help to measure and check the final product.

- Before the part advances to the next phase of manufacture, any deviations from the design criteria are found and fixed.

Advantages of CNC Precision Machining

Many advantages of CNC precision machining distinguish it from more traditional machining methods. Among the most clear benefits are:

1. Exceptional Accuracy and Consistency

Because CNC machines run with very great accuracy, every component satisfies exact requirements. In sectors like aerospace and medical, where even the smallest departure can cause failure, this is absolutely vital.

2. High Efficiency and Automation

CNC milling machines are automated, thus they can run continuously with little human involvement. This lowers labor costs, boosts output rates, and lessens hand-crafted machining-related mistakes.

3. Versatility in Materials and Applications

Wide spectrum of materials is compatible for CNC precision machining, including:

- Aluminium, stainless steel, titanium, brass—metals

- Plastics (polycarbonate, ABS, PEEK)

- Ceramic bowls and composites

This adaptability lets producers design components for many sectors without sacrificing durability or quality.

4. Cost-Effectiveness in Large-Scale Production

Although CNC machining’s starting setup cost could be high, over time the savings exceed the investment. An affordable manufacturing solution, automated production lowers rework, material waste, and labor costs.

5. Ability to Create Complex Geometries

Using multi-axis CNC machines—like 5-axis machining—complex and extremely detailed parts can be generated without further setups. For sectors like aerospace and medical implants that demand complicated forms, this is absolutely vital.

6. Reduced Material Waste

CNC machining precisely cuts just the required amount from the workpiece, so optimizing material use. This reduces waste and supports environmentally friendly production techniques.

7. Faster Prototyping and Customization

One very important benefit of CNC precision machining is fast prototyping. Before mass release, manufacturers can rapidly create prototypes, test them, and make changes. This lowers new product time-to-market.

Applications of CNC Precision Machining

Many sectors where great dependability and accuracy are vital rely on CNC precision machining. These are some of its most often used purposes:

1. Aerospace Industry

While upholding rigorous safety criteria, aircraft components have to resist extreme conditions. Manufactured using CNC machining are:

- Jet engine parts

- Part structures for structural airframes

- components of landing gear

- Blades for turbines

2. Medical Industry

To guarantee patient safety and efficacy, medical equipment must be absolutely precise. Created from precision CNC machining services are:

- Surgical tools

- Dentally implanted objects

- Artificial tools

- Implants for orthopaedics

3. Automotive Industry

In the automotive industry, CNC precision machining is used for:

- Parts related to engines

- Transmission components

- Parts related to the brake system

- Customised vehicle modifications

4. Electronics and Semiconductor Industry

In electronics, minaturization calls for very exact components. Machining CNC generates:

- Enclosed Circuit Boards

- Heat reservoirs

- connectors

- Micro components for wearables and cellphones

5. Defense and Military Applications

The defense sector mostly uses CNC machining to create:

- Components for a gun

- Military Vehicle Components

- Naval and aircraft equipment

- Communication tools and surveillance instruments

Challenges in CNC Precision Machining

CNC precision machining offers certain difficulties for manufacturers even with its benefits:

1. High Initial Investment

Software and CNC machines call for large upfront expenses. Long-term efficiency gains, though, justify these expenditures.

2. Skilled Workforce Requirement

Specialized knowledge in CNC programming, machine operation, and quality control is required of operators and programmers. Skilled machinists are in increasingly demand.

3. Complexity of Multi-Axis Machining

Although multi-axis CNC machines give more freedom, they need sophisticated programming knowledge and careful setup to produce best results.

4. Tool Wear and Maintenance

Regular use of CNC machines can lead to tool wear, so influencing accuracy. To guarantee constant performance, regular maintenance and premium cutting tools are absolutely vital.

Step-by-Step Guide to the CNC Precision Machining Process

A sophisticated and highly detailed process, CNC precision machining guarantees accurate fabrication of components and parts. There are several phases involved, each of which is absolutely important in reaching the intended quality, accuracy, and functionality of the final product. Every stage—from design conception to post-processing—must be painstakingly done to guarantee accuracy and effectiveness.

Emphasizing its major phases and best practices, this guide offers a thorough, step-by-step analysis of the CNC precision machining process.

1. Design and CAD Modeling

Starting in a thorough design phase, the CNC machining process produces a complete 3D model of the intended part or product by means of engineers and designers. This stage is absolutely important since a well-organized design greatly influences the accuracy and manufactureability of the part.

Key Aspects of CAD Modeling

- Using Computer-Aided Design (CAD) programs including AutoCAD, SolidWorks, or Fusion 360, engineers create a 3D model This model covers dimensions, tolerances, geometries, features, and scales defining the final part.

- Design for Manufacturability (DFM): Crucially, the design must match CNC machining capacity. Engineers maximize wall thickness, hole locations, and material choice to prevent unwarranted machining complications.

- Material Selection: Direct machining process impact of material choice (e.g., aluminum, stainless steel, titanium, plastic). Strength, durability, thermal expansion, and machining feasibility among other criteria must guide material selection.

A well defined CAD model offers the basis for exact CNC programming and machining by the end of this phase.

2. CAM Processing and CNC Programming

Computer-Aided Manufacturing (CAM) tools translate a finalized CAD model into machine-readable instructions. During this phase, G-code and M-code—which regulate the CNC machine’s movement and operations—are generated.

Key Aspects of CAM and CNC Programming

- G-Code and M-Code Generation:

- G-Code: Oversees cutting tool movement in terms of position, speed, feed rate.

- Manages auxiliary tasks (such tool changes, coolant activation) under M-Code.

- Simulating the Toolpath:

- To improve efficiency, cut material waste, and prevent collisions, CAM software models the ideal tool path.

- To further machining precision, the simulation also forecasts possible mistakes and rounding problems.

- Customization of Machining Parameters:

- To guarantee a best machining process, engineers define important parameters including spindle speed, depth of cut, and feed rate.

- Material type, complexity, and precision needs all affect each parameter.

The CNC machine is supposed to run the machining operation precisely by the end of this phase.

3. Setup of the CNC Machine

The CNC machine has to be correctly set up before the machining operation starts. To guarantee exact operation, this includes adjusting the machine tools used, workpiece holding system, and machine calibration.

Key Aspects of CNC Machine Setup

- Tool Installation and Workpiece Fixation:

- The operator sets the necessary cutting tool—end mills, face cutters, drill bits—in the tool holder or collet.

- To stop movement during machining, the workpiece is firmly fixed with clamps, vices, chucks, or specialist fittings.

- Alignment and Calibration:

- The CNC machine undergoes a calibration process to ensure proper alignment of the tool with the workpiece.

- Any slight misalignment can result in dimensional inaccuracies and machining defects.

- Automatic Tool Changing (ATC) Mechanism:

- The CNC machine is calibrated to guarantee ideal tool alignment with the workpiece.

- Any little alignment can cause machining flaws and dimensional errors.

- An Automatic Tool Changer (ATC) fitted in advanced CNC machines lets several tools be used in one setup.

4. Machining the Part

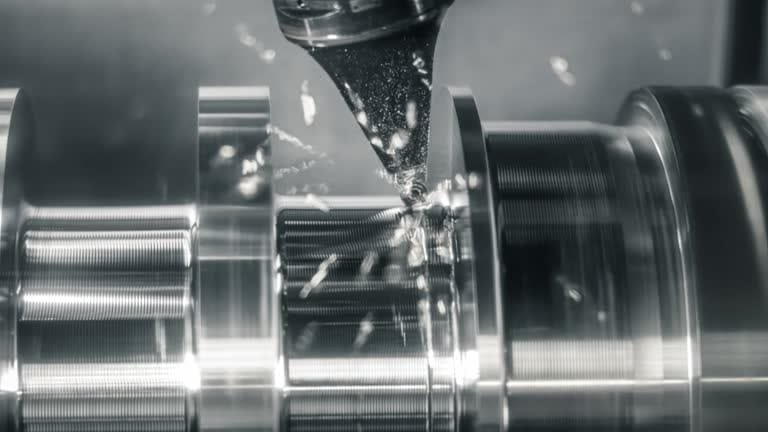

At this point the CNC machine uses pre-programmed instructions to cut, shape, and polish the workpiece into its ultimate form cnc machine shops. Maintaining accuracy and guaranteeing adherence to standards depend on this phase, which calls close attention conventional machining methods.

Key Aspects of CNC Machining Process

- Machine Initialization and Parameter Adjustment:

- Before beginning the machining process, the CNC operator verges over the spindle speed, feed rate, and depth of cut.

- Little test runs can help to verify that the settings of the parameters are accurate.

- Material Removal and Machining Operations:

- The machine runs several subtractive machining operations including:

- Milling removes materials to produce surface finishes and detailed elements.

- Turning moves the workpiece while a cutting tool removes extra material.

- Drilling leaves exact holes for components, fasteners, or fluid paths.

- Grinding smooths the surface to attain great accuracy and finishes.

- The machine runs several subtractive machining operations including:

- Real-Time Monitoring and Fine-Tuning:

- Operators track the machining process constantly in search of tool wear, vibrations, or deviations from standards.

- Changes are done as necessary to guarantee the final product satisfies the necessary quality and accuracy.

The machined part should, at the end of this stage, closely match the original CAD model with minimum variation.

5. Post-Processing and Finishing

The part is from precision machined parts then subjected to a sequence of finishing processes to increase its general look, remove flaws, and improve its accuracy.

Key Aspects of Post-Processing and Finishing

- Deburring and Surface Smoothing:

- Grinding, polishing, or sanding methods remove little flaws, burrs, or sharp edges.

- This guarantees a consistent and flawless surface free of any sharp edges.

- Surface Treatments and Coatings:

- Different finishing processes improve machined part durability, corrosion resistance, and appearance:

- Sandblasting produces either a textured or matte surface finish.

- Electroplating provides a protective metal layer meant to stop rusting.

- Anodizing enhances wear resistance and lets color be customized.

- Excellent, long-lasting paint finish offered by powder coating.

- Different finishing processes improve machined part durability, corrosion resistance, and appearance:

- Dimensional Inspection and Quality Control:

- Advanced Coordinate Measuring Machines (CMMs) confirm the final part’s geometry, tolerances, and measurements.

- Should deviations be found, secondary machining operations—such as lapping or grinding—are used to further hone the part.

- Final Cleaning and Packaging:

- Before being shipped or assembled, the completed piece is cleaned to eliminate machining fluids, dust, and trash.

This last stage guarantees that the part satisfies performance, functional, and aesthetic criteria so preparing it for use in its intended use.

Future Trends in CNC Precision Machining

Emerging technologies improving sustainability, efficiency, and automation will shape the CNC precision milling and machining going forward cnc equipment. A few important trends consist in:

1. Artificial Intelligence and Machine Learning

Real-time data analysis, tool wear prediction, and machining process optimization made possible by advanced technology and by AI-powered CNC systems help to improve accuracy and efficiency of machining operations.

2. 5-Axis and Multi-Axis Machining

Adoption of 5-axis and multi-axis machining is growing since it lets manufacturers create extremely intricate geometries with less setups and more accuracy tight tolerances rotating cutting tool.

3. Hybrid Manufacturing

Combining 3D printing (additive manufacture) with CNC machining is transforming manufacturing and providing more adaptable and reasonably priced manufacturing solutions.

4. Internet of Things (IoT) and Smart Manufacturing

Real-time monitoring, predictive maintenance, and remote diagnostics made possible by IoT-enabled CNC machines help to increase general output.

5. Sustainable and Eco-Friendly Practices

To lessen the environmental effect of machining, manufacturers are emphasizing on using recyclable raw materials only, energy-efficient CNC machines, and biodegradable coolants cnc precision machining services.

Conclusion

Offering unparalleled accuracy, efficiency, and adaptability, CNC precision machining has revolutionized contemporary production. From aerospace and medical to automotive and electronics, precision CNC machining guarantees the manufacture of premium components with least waste.

AI, IoT, and hybrid manufacturing will progressively improve CNC machining capacity as technology develops, transforming this tool even more for businesses all around. Three fields where CNC machining shines—automation, precision, and sustainability—will define manufacturing going forward.