Introduction

In computer numerical control (CNC) machining, accuracy and efficiency are main forces behind creativity and output. Among the several kinds of various axis CNC machining machines, the 4-axis milling machine is one of the most effective tools able to create highly accurate complex parts. In the aerospace, automotive, or medical sectors as well, the same CNC machining 4-axis milling machine is transforming component design and manufacture.

The principles of a CNC 4-axis milling machine are discussed in this article together with its benefits, uses, and reasons for becoming a necessary tool for contemporary machining operations.

What is a CNC 4-Axis Milling Machine?

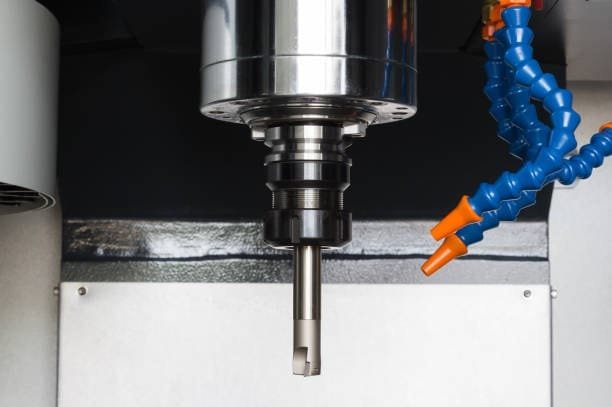

An advanced machining tool called a CNC 4-axis milling machine adds an additional axis, a rotational axis (A-axis) to the process axis machining, so improving conventional 3-axis milling. With this extra axis, one may machine complex geometries that would be difficult or impossible with a conventional 3-axis system more freely and with greater ability.

A CNC 4-axis milling machine consists in four axes:

- X-axis: Left and right tool or workpiece movement.

- Y-axis: moves the workpiece or tool both forward and backwards.

- Z-axis: Slides the workpiece or tool up and down.

- Rotating the workpiece around the X-axis generates extra machining angles from the A-axis.

How Does a CNC 4-Axis Milling Machine Work?

Operating on computer-aided design (CAD) and computer-aided manufacturing (CAM) software, a CNC 4-axis milling machine controls the movement and rotation of both the workpiece and cutting tool. Securing the workpiece to a rotary table lets it spin along the A-axis. Without hand repositioning the workpiece, this rotation allows cutting from several angles essential.

Usually, the technique consists in two main types:

- Designing the Part: Engineers digitalize a component using CAD tools.

- CAM software translates the design into machine-readable instructions.

- The workpiece is clamped tightly and the required cutting tools are chosen.

- The CNC machine moves along the X, Y, Z, and A axes to shape the material following the programmed toolpath.

Advantages of a CNC 4-Axis Milling Machine

Many sectors choose the CNC 4-axis milling machine because of its several advantages.

1. Increased Precision and Accuracy

More exact machining of complex components made possible by the extra A-axis guarantees consistency in production by so lowering errors.

2. Improved Efficiency and Productivity

4-axis milling reduces hand involvement by letting multi-sided machining in multiple setups into a single setup, so saving time and raising output.

3. Greater Design Flexibility

With a standard 3-axis machine, manufacturers cannot easily produce more complex parts, including helical forms, curved surfaces, holes and undercuts.

4. Cost Savings on Tooling and Setup

Reduced labor costs and less tool wear resulting from fewer setups help manufacturing businesses save long-term costs.

5. Better Surface Finish

Constant motion along several axes guarantees better cutting paths, so improving surface finishes three axes.

Applications of CNC 4-Axis Milling Machines

Because they can quickly create complicated components, CNC 4-axis milling machines find extensive application in many different sectors two axes.

1. Aerospace Industry

- building structural components and turbine blades.

- Aluminum and titanium, among lightweight, high-strength materials, precision machining.

2. Automotive Industry

- Manufacturing of gear housings, brake systems, and engine parts.

- High-performance automotive part customizing 4 axis cnc machining.

3. Medical Industry

- highly precisely machining surgical tools, implants, and prosthesis components.

- building intricate medical device parts multiple sides.

4. Tool and Die Making

- mass manufacture’s molds, dies, and fixture production.

- better repeatability in settings of high volume manufacturing easy setup.

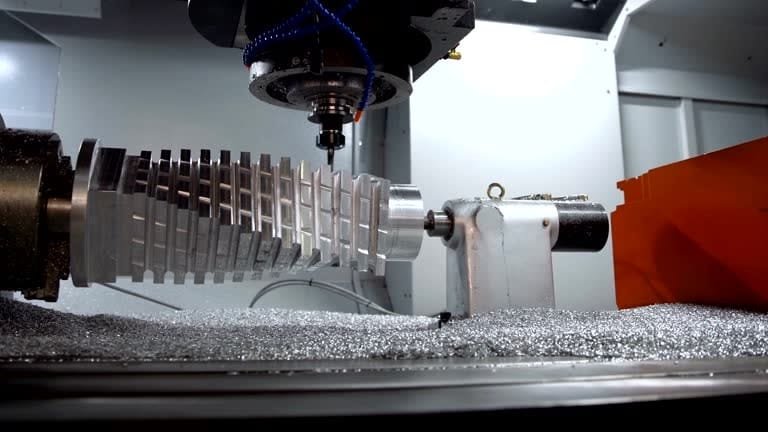

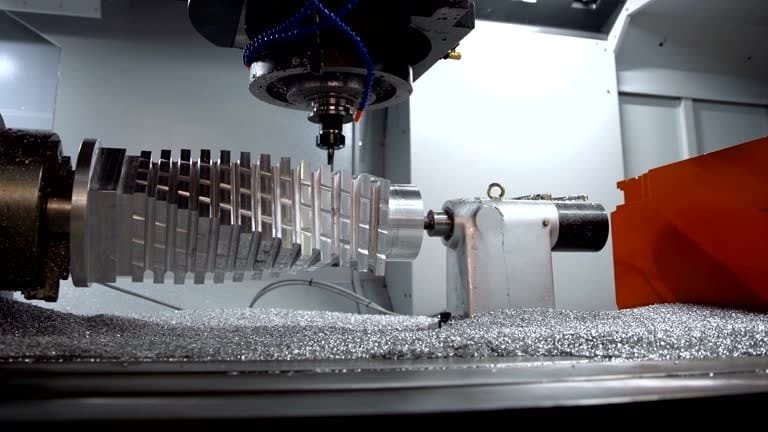

5. Electronics Industry

- manufacturing of enclosures, connectors, and heat sinks for electronic equipment additional rotary axis.

- High-precision machining for micro-mechanical parts.

Choosing the Right CNC 4-Axis Milling Machine

Several elements should be taken into account while choosing a CNC 4-axis milling machine to guarantee the best fit for your production process and requirements tight tolerances.

1. Machine Size and Work Area

Select a machine with a worktable capacity fit for the large parts you intend to produce.

2. Spindle Speed and Power

More spindle speeds and power ratings enable effective machining of harder materials.

3. Software Compatibility

Make sure the machine runs and programs seamlessly using the most recent CAD/CAM tools helical grooves.

4. Material Capability

Whether metal, plastic, or composites, different machines are optimized for particular materials; hence, choose one that fits your intended use.

5. Budget and Maintenance Costs

Consider not only the initial investment but also the long-term maintenance and operating costs angled features.

CNC 4-Axis vs. 3-Axis and 5-Axis Milling Machines

Although the CNC 4-axis milling machine has many benefits above a conventional 3-axis indexing machine c axis, its suitability for particular uses depends on comparing it with other configurations.

| Feature | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling |

| Number of Axes | X, Y, Z | X, Y, Z, A | X, Y, Z, A, B/C |

| Machining Complexity | Moderate | High | Very High |

| Setup Time | Longer | Shorter | Shortest |

| Cost | Lower | Moderate | Higher |

| Precision | Standard | High | Extreme |

A 5-axis machine could be the better choice for companies needing more complex designs and accuracy b axis. Still, a 4-axis CNC milling machine offers a great mix of cost-effectiveness and capability for most manufacturing needs linear directions.

Conclusion

By providing more accuracy, efficiency, and adaptability, CNC 4-axis milling machines have revolutionized contemporary production. Their value in sectors including aerospace, automotive, medical, and electronics comes from their capacity to execute difficult machining operations in a single setup.

Investing in the correct CNC 4-axis milling machine will help producers increase output, lower expenses, and expand their capacity to create highly accurate complex parts. In the always changing field of precision engineering, this sophisticated machining technology is a necessary instrument for both prototyping and large-scale manufacture.