Introduction

Machine carbon fiber demonstrates revolutionary capabilities in engineering, manufacturing and other industrial areas due to its extensive applicability. The unique characteristics of carbon fiber including its high strength-to-weight ratio along with its durability and corrosion resistance have transformed the design and creation of machines and mechanical components. The article investigates machine carbon fiber by examining its properties and applications along with its benefits and drawbacks and predicts its future across multiple industrial sectors.

What is Machine Carbon Fiber?

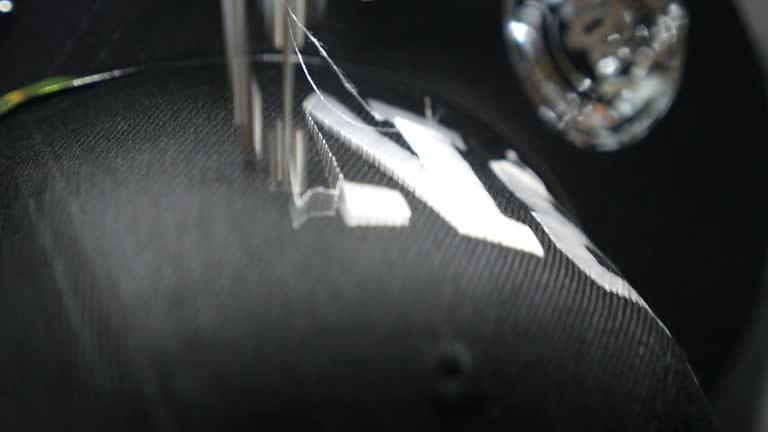

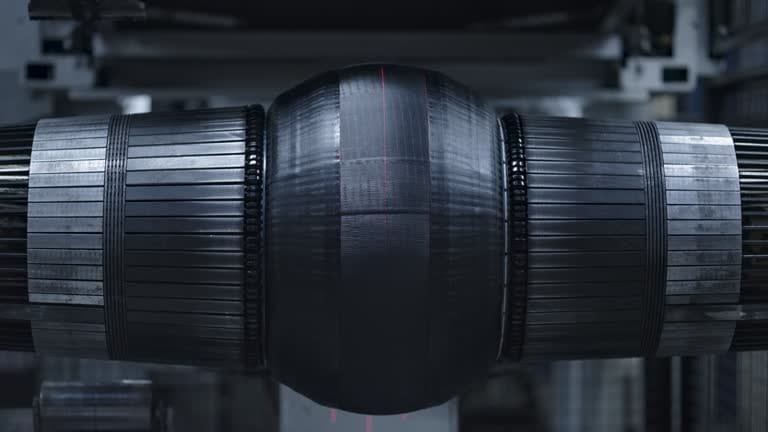

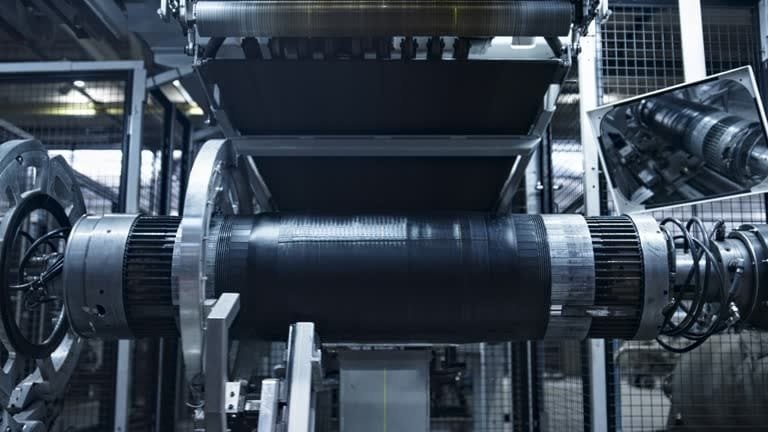

The term machine carbon fiber refers to reinforced composite materials containing carbon fibers that are utilized in machinery and industrial equipment as well as tools. The narrow carbon atom fibers arranged in a crystalline pattern form the base material cutting carbon fiber sheets which when woven into fabric and combined with resins or polymers creates components that maintain light weight while providing extreme durability.

Key Properties of Machine Carbon Fiber

- Carbon fiber boasts an exceptional strength to weight ratio with five times the strength and much lower weight than steel.

- Unlike metals, it does not rust or corrode, so even in the presence of severe environmental conditions, it remains in excellent condition.

- Thermal Stability Does Not Ruin Structures in High and Low Temperatures.

- Holds its shape and quality under repeated heavy loads.

- Electrical Conductivity – Manufacturing determines whether the material is an insulator or conductor.

- This material can be easily formed into many shapes and forms.

Applications of Machine Carbon Fiber

Aerospace and Automotive Industry

Carbon fiber has revolutionized aerospace and automotive industries through weight reduction and better fuel efficiency. Manufacturers are now producing aircraft fuselage panels, wings, and landing gear from carbon fiber composites. Sports cars and electric vehicles in the automotive sector incorporate carbon fiber to boost performance and durability.

Robotics and Automation

The optimal performance of robots depends on materials that balance lightness with strength. Carbon fiber components enhance robotic arms and structures by boosting efficiency and precision while increasing speed which makes them essential for use in manufacturing and medical technology along with space exploration.

Industrial Machinery and Equipment

CNC machines together with 3D printers and various precision metal machining devices utilize machine carbon fiber in their construction. The capacity to reduce vibrations leads to improved machining precision and operational stability.

Medical Devices and Prosthetics

Carbon fiber finds extensive use in medical implants, prosthetic limbs and surgical instruments because it combines biocompatibility with a lightweight structure. Carbon fiber-based prosthetics provide enhanced mobility and comfort for patients.

Sports and Recreation

From bicycles to tennis rackets, carbon fiber has revolutionized sports equipment by providing stronger gear that is lighter and provides better aerodynamics for athletes.

Advantages of Using Machine Carbon Fiber

- Weight Reduction – Lowering machine weight helps to increase efficiency and performance.

- Improved Durability – Increased wear and tear resistance gives components a longer life.

- The operational costs go down because lighter machines require less energy to function.

- High stiffness combined with reduced vibrations delivers superior precision and control in performance.

- Carbon fiber components maintain their integrity for extended periods which leads to decreased material waste while minimizing environmental harm.

Challenges of Machine Carbon Fiber

Machine carbon fiber fiber has many advantages, however, there are also some issues with its manufacturers and applications:

- Negative – The Downward SpiralHigh Production Costs –The manufacture of carbon fiber is expensive in comparison to conventional materials like steel or aluminum.

- Hard Recycling Process – The recycling of carbon fiber composites is difficult because of their complex structure.

- Brittleness – Carbon fiber is strong but can be brittle and crack under certain circumstances.

- Use Complex Manufacturing Techniques – Carbon fiber components need specialized knowledge and tools to mold and assemble.

Understanding Carbon Fiber and Its Characteristics

Carbon fiber is an amazing material made up of thin strands, of between 5 to 10 microns in diameter, made up of tightly entwined chains of carbon atoms arranged in a microscopic crystalline structure. This material is famous for its high-strength-to-weight ratio, meaning that it is stiffer than steel, while being much lighter. Carbon sheets or fiber sheets are known for their durability and durability, making them very desirable for sports, engineering, jet and many other industries. Carbon fiber, as a low-density composite, possesses good toughness, considerable hardness, connectivity to abrasions and Grado resistance, low thermal expansion, electromagnetic transparency, durable textured finish, and decent electrical conductivity, among other useful features.

Uses of Precision-Machined Carbon Fiber Components

Due to its exceptional mechanical properties, excellent thermal conductivity, and low coefficient of thermal expansion, carbon fiber is a great lightweight material for many different applications in many different companies.

Aerospace Sector Applications

The fact is that the aerospace industry is the most pronounced early adopter of carbon fiber, having discovered its benefits relatively early as a better solution for certain parts than traditional materials like titanium and aluminum. Having its maiden flight at MIT in Cambridge, Massachusetts in 1940, carbon fiber (usually carbon fiber reinforced polymer) has surpassed metals as the optimal material for aircraft parts due to its unique strength-to-weight ratio and increased low thermal conductivity durability compared to metals; making it one of the most popular materials for the reduced weight of aircraft components. The weight-saving properties of carbon fiber parts are also responsible for large gains in fuel consumption by gliders, jet fighters and helicopters, which increasingly depend on carbon fiber as a performance aid carbide tooling.

Sports Sector Applications

In the world of athletics, you name it, carbon fiber is probably a part of it for professional sports people, from tennis racket strings, to bike frames, wheels, helmets, archery bows, hockey sticks, golf clubs, and more. And then there’s the protective gear from this material, such as specialized leg and arm guards machining composites, helmets and durable but lightweight footwear for racing and extreme sports. High-strength and featherlight, outpacing the likes of plastic and wood, means they can handle their equipment with ease, lending to their capacity to run further and faster, jump higher and swim further tool life.

Automotive Sector Applications

In the automotive industry, carbon fiber’s impressive strength and durability make it an excellent choice for building frames and other automobile parts. Its higher strength-to-weight ratio has transformed the design of faster cars milling cutter, making it possible for manufacturers to swap out heavy metal parts in favor of carbon fiber versions — saving manufacturing and production costs, fuel wastage, and CO2 emissions.

Electronics Sector Applications

Its unique properties, especially regarding its ability to reduce weight, offers the electronics industry many advantages that tap directly into consumer preferences for lighter devices. Carbon fiber has a thermal coefficient close to invar, which helps relieve thermal issues in sensitive electronics dust particles

, sensors, mirrors, and lasers, while also exceeding both metal and plastic enclosure natural frequency and dimensional stability cutting carbon fiber parts. And apart from its mechanical advantages polycrystalline diamond, carbon fiber’s excellent electrical conductivity and non-magnetic properties make it a functional material with great utility. In conjunction with polymers, it yields a composite that is employed within electronic shielding apparatus capable of absorbing electromagnetic waves, thus improving the shielding efficiency and the mechanical properties of the case of the devices porous surface.

Top 3 Tips for Machining Carbon Fiber Composites

When machining carbon fiber composites, some best practices can be followed for a successful endeavor. Here are three important tips to remember:

1. Enhancing the Wear Resistance of the Drill Bit

The cutting temperature tends to be low at 50 to 200°C in the drilling of carbon fiber composites. The temperatore is medium, even though; but cutting tool wear continues to be a big issue, because carbon fiber materials are very abrasive.

What is inherently a very high hardness level, in the case of carbon fiber. It can achieve hardness from HS70 to HS90 or more if manufactured using petroleum coke or carbon black. On the Rockwell scale, this hardness level has the same hardness level as HRC53 to HRC65. HSS drills, in contrast, at room temperature, have a hardness rating between HRC62 and HRC65, which is extremely close to the hardness of carbon fiber composites machining carbon fiber sheets.

As a result, abrasive wear intensity on the tool surface greatly increases due to hard fiber points in composite materials during high-speed steel (HSS) milling and drill cutting of carbon-fiber composite materials. The use of higher hardness tools should resolve this complication by increasing wear resistance. Carbide, ceramics, cubic boron nitride, and diamond represent prevalent high-hardness materials that ensure tools maintain durability and longevity while machining workpieces.

Future of Machine Carbon Fiber

Machine carbon fiber remains a leading sector through the adoption of advanced technology combined with innovative solutions. Innovations such as recyclable, carbon fiber sheets, additive manufacturing techniques using carbon fiber composites and nanotechnology-enhanced fibers will make the material more sustainable and affordable carbon fiber machining. These emerging trends will expand the use of carbon fiber throughout multiple industries because companies seek to enhance efficiency while reducing environmental impact through its lightweight properties and design potential.

Conclusion

Machine carbon fiber has revolutionized modern manufacturing due to its exceptional strength and lightweight durability. The cost and recyclability issues persist but technology improvements are driving wider acceptance. The application of carbon fiber will expand as industries look for sustainable and innovative materials for engineering and manufacturing progress.