Introduction

Modern manufacturing defines industry standards by means of accuracy, efficiency, complexity, and perfection. 5- axis CNC machining is among the most developed technologies transforming the machining industry. By allowing producers to produce complex components with unmatched accuracy, this innovative approach traditional machining helps to greatly lower manufacturing time and expenses.

This article will give a thorough review of 5-axis CNC machining technology, its benefits, applications, and why it has evolved into the gold standard in the machining sector regardless of your level of expertise—engineering, machining, or just someone fascinated in modern manufacturing techniques.

What Is 5-Axis CNC Machining?

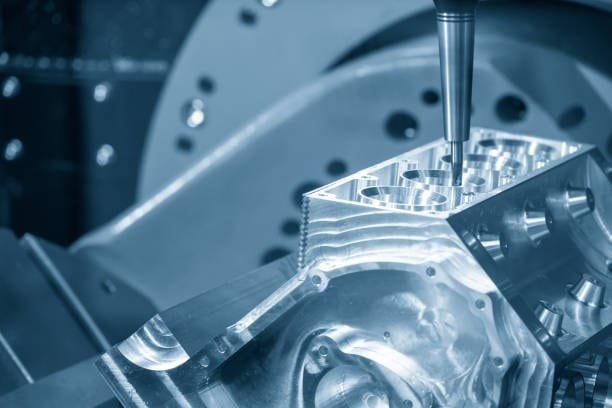

In computer-controlled process known as five-axis CNC machining, the cutting tool moves concurrently in five separate axes. Whereas conventional 3-axis machines run on the X, Y, and Z axes, a 5-axis CNC machine adds rotation around two of these three axes with additional axes each—usually denoted as A, B, or C axes.

Greater flexibility and precision made possible by this extra freedom of movement enable the manufacturing of intricate geometries that would be either impossible or extremely time-consuming with traditional CNC machining processes.

How Does 5-Axis CNC Machining Work?

Though with two extra rotary axes, a 5-axis CNC machine runs just like a conventional CNC machine. The machine precisely moves the tool in many directions to shape the material after interpreting digital instructions (G-code).

The five axes of movement consist in producing parts:

- X-axis: Left and right movement

- Y-axis: movement forward and backwards

- Z-axis: ascending and descending motion

- A-axis: rotational around the X-axis

- B-axis: Rotational around the Y-axis

This mix of motions lets the machine cut from almost any angle, so saving energy equipment and the need for multiple setups for several setups and increasing efficiency.

Types of 5-Axis CNC Machines

5-axis CNC machines come in several configurations, each fit for particular uses. The most often occurring forms consist in:

1. Simultaneous 5-Axis Machines

All five axes in this arrangement move simultaneously, enabling intricate and precise alignment and very accurate cuts. For complex parts needed in the medical, automotive, and aerospace sectors, this kind single setup is perfect.

2. 3+2 Axis Machines (Positional 5-Axis Machines)

This machine lets one position the tool using two extra rotational axes and enable three-axis cutting. Though less complicated than a simultaneous 5-axis machine, it still provides more flexibility shorter cutting tools than 3-axis machining.

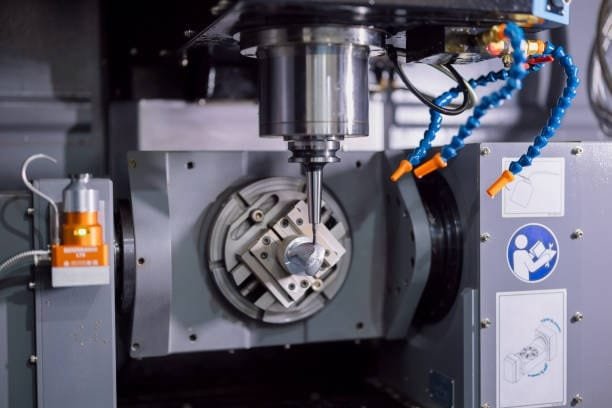

3. Table-Table Configuration

While the cutting tool stays still, this kind has a revolving table moving in the A and B axes simultaneously. Machining small to medium-sized parts usually calls for it.

4. Head-Table Configuration

Under this configuration, the spindle head moves along one rotational axis while the table turns along another rotary table. It strikes a mix between flexibility and rotational accuracy.

5. Head-Head Configuration

This arrangement is perfect for machining big parts with complicated angles since both rotational axes lie in the spindle head.

Advantages of 5-Axis CNC Machining

1. Increased Accuracy and Precision

By removing the need to repeatedly reposition the part, five-axis machining guarantees tight tolerances and lessens human error. For high-precision sectors like manufacturing of medical devices and aerospace technologies, this makes it perfect.

2. Reduced Setup Time

5-axis CNC machines greatly save the number of setups needed since the tool can access desired parts from several angles in a single configuration, so accelerating production cycles.

3. Ability to Machine Complex Geometries

With 5-axis machining, complex forms, undercuts, and deep cavities difficult or impossible with 3-axis machining can be readily accomplished.

4. Improved Surface Finish

5-axis machining lowers the need for secondary finishing operations since the tool can approach the workpiece from several angles, without cutting surface and so improving general surface quality.

5. Cost Efficiency in High-Volume Production

Though the initial outlay in a 5-axis machine is high, long-term cost savings result from decreased labor, tool wear, and machining time.

Applications of 5-Axis CNC Machining

Where accuracy and complexity are absolutely vital, five-axis machining is extensively applied in many different sectors.

1. Aerospace Industry

High-precision components with intricate geometries—such as turbine blades, engine parts, and structural components—that fit the aerospace industry call for 5-axis CNC machining guarantees these parts satisfy exacting quality requirements.

2. Automotive Industry

For prototyping, custom parts, and high-performance engine components needing exact tolerances, car makers use 5-axis machining.

3. Medical Industry

Dental components, prosthesis, and surgical implants all call for great accuracy. Customized and complex medical devices fit to patients’ needs are made possible by five-axis CNC machining.

4. Energy Sector

Using 5-axis machining for intricate turbine components, which demand great accuracy and durability, power generating sectors—including nuclear and renewable energy—use this technique as well.

5. Die and Mold Manufacturing

Making high-quality molds and dies calls for complex details achieve complex geometries that 5-axis CNC machines can quickly generate two rotary axes.

Challenges of 5-Axis CNC Machining

5-axis CNC machining offers some difficulties even if it has many advantages:

1. High Initial Cost

Small manufacturers should consider 5-axis CNC machines as a major investment since they are far more costly than 3-axis machines.

2. Complex Programming

5-axis machining uses simultaneous multi-directional movement three linear axes, thus programming calls for sophisticated software and qualified operators spindle speed.

3. Higher Maintenance Requirements

5-axis machines require regular maintenance to guarantee best performance given their more moving components and sophisticated mechanisms cutting tool remains tangential.

4. Tool Interference

The extra degrees of movement require machining raise the possibility of tool collisions fourth and fifth axes, thus careful design and simulation are even more important before machining computer numerical control.

How to Choose the Right 5-Axis CNC Machine

Think through the following while choosing a 5-axis CNC machine tool here:

- Type of Parts Being Made: Select the appropriate arrangement depending on size and degree of part complexity.

- Machine rigidity and accuracy make sure the machine can manage small tolerances.

- Software and Programming Capabilities: Perfect operation of advanced CAM depends on advanced CAM software.

- Cost and ROI: Compare the machine’s price to possible output increases.

- Maximizing efficiency depends on skilled programmers and machinists using operator expertise.

Conclusion

5-axis reference By allowing the manufacturing of extremely sophisticated, exact, and efficient parts, CNC machining has transformed modern industry. Although it comes with more expenses and complicated programming, its benefits must exceed its negatives, thus it is essential in sectors including aerospace, automotive, and medical manufacturing.

5-axis CNC machining capabilities will become even more available as technology develops, opening the path for more machining industry innovation and efficiency.