Meta Description: Detailed overview of 4130 steel vs 4140 steel, along with other steel alloys, discussing the chemical composition, mechanical properties, uses, economic comparison, and selection factor when dealing with the aerospace industry, cars and manufacturing businesses.

The difference between 4130 and 4140 steel grades in the alloy steels process can have a substantial effect on the level of success of your manufacturing venture. They are in the same family of low alloy steels, chromium-molybdenum (Cr-Mo) steels, but there are significant differences between the two that enable them to be applicable to varying applications. This technical overview of the key differences, characteristics and uses of this two types of steel, which are commercially common in the steel industry and known for good corrosion resistance landing gear components, will assist you in making well informed choices of steel to use in your projects in the industry.

Understanding the Basics: What Makes 4130 and 4140 Steel Special

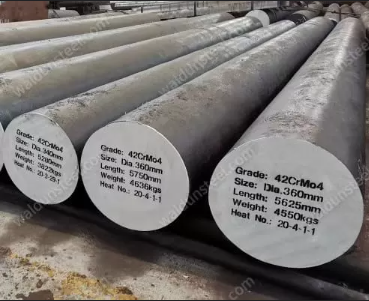

Both 4130 and 4140 steel are low-alloy steels which fall under the AISI (American Iron and Steel Institute) classification system of steel. Their numbering system is four-digit and gives important information regarding their composition; the original two-digit(41) shows that they are chromium-molybdenum steels, and the remaining two are the approximate percentage of carbon concentration by hundredths of a percent chromium molybdenum alloy steel.

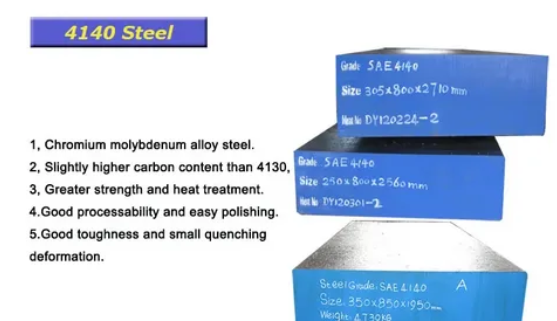

Steel 4140 is richer in carbon and manganese concentrations compared to 4130 with manganese at about 0.30 % in 4130 and greater 4140. Such a basic variation in composition also contributes to great differences in their mechanical characteristics and use, particularly in high strength components suspension components.

They are both very strong to weight ratio, good hardenability and tougher than plain carbon steels, making them competitors to high strength spring steels local surface deformation. Nevertheless, their certain peculiarities precondition its utilization in various industries, including aerospace devices or auto parts, due to their exceptional durability .

Chemical Composition Breakdown: The Foundation of Performance

Their chemical make-up is what provides support to these steels as regards their performance. Knowledge of these differences is vital when it comes to selecting materials in a proper way.

In 4130 there is 0.28-0.33 % Carbon, 0.40-0.60% Manganese, and 4140 includes 0.75-1.00% Manganese, 0.38-0.43% Carbon. The quantity of chromium (0.80-1.10%) and molybdenum (0.15-0.25%) in both grades are very similar and this helps in producing hardenability and strength properties, aligning with specific heat treatment requirements .

Increased carbon directly correlates into harder and stronger options with regards to the 4140 steel whereas lower carbon content offers easier welding and bends to the 4130. The levels of silicon used in both grades are also considered to be comparable (0.15-0.35%), which leads to their strength, deoxidation capacity, and excellent ductility aluminum alloys.

The two grades are relatively low in phosphorus and sulfur (generally below 0.035 percent of each) in order to have good mechanical properties, and to avoid brittleness.

Mechanical Properties Comparison: Strength, Hardness, and Performance

These steels can be applied in various applications and under various conditions of operation as shown by their mechanical properties.

The 4140 steel is hard, tensile, and yield strength compared to the 4130 steel. This renders 4140 more favorable in uses that are more demanding in terms of strength and rockwell hardness, allowing it to achieve high hardness levels most aluminum alloys . When normalized, 4130 will normally offer tensile strength between 90,000 and 95,000 PSI whereas 4140 could be provided in strengths more than 100,000 PSI, which also contributes to its fatigue strength .

The yield strength of 4130 steel is usually 70,000-75,000 PSI but 4140 can have yield strengths of 85,000-90,000 PSI or greater based on heat treat. This high strength is what makes 4140 very useful in realizing high-stress applications through effective heat treatment processes connecting rods.

Hardness level also varies largely between the two grades as 4130 steel tend to attain hardness values as much as 20-25 HRC Rockwell C hardness in the normal hrc range, whereas when properly heat treated, 4140 can attain values of 25-30 HRC or more and can achieve high rockwell b hardness levels.

Heat Treatment Capabilities and Options

Both 4130 and 4140 steel react favorability to an array of heat treatment forms, yet their best options between them apply in accordance with their compositions and desired uses tempering temperature.

Both the forms are able to undergo typical methods of heat treatment with the respective effect and changes of hardness, ductility and strength on the surface. Both grades are frequently normalized in order to hone grain structure and to enhance machinability plastic deformation.

4130 steel 4130 steel is commonly utilized in the normal or normal and tempered condition; this allows good strength and toughness balance. It could undergo quenching and tempering in case of higher strength demand but this should be done without encouraging brittleness.

The increased level of carbon content of 4140 steel makes it more susceptible to hardening processes. and may be successfully through-hardened in sections to 2 inches and more in thickness, it is excellent for parts where hardness is demanded throughout the cross-section machinery components.

Stress relieving treatments are useful to both grades, especially after either machining or welding processes to alleviate internal stress to avoid distortion during service.

Weldability and Fabrication Characteristics

In most manufacturing processes, the weldability of these steels and their impact resistance is a major concern, especially when using gas metal arc welding determining not only the manufacturing process, but also quality of the final products.

The 4130 steel can be welded more easily than the AISI 4140 steel, and its wear resistance capabilities are pulled down compared to 4140, especially when using gas tungsten arc welding engineering metals. 4130 is more lenient in terms of its carbon content and therefore less prone to cracking during the welding process due to its unique properties, allowing less pre-heat and need of wife heat treatment.

When 4130 steel is to be welded the preheat temperatures should be around 200-400F depending on section thickness and the welding process. Critical applications should be stressed relieved after welding at a temperature of 1100-1200 o F.

The increased carbon content of 4/140 steel increases the ease of cracking during a weld. The process requires it to be preheated to 400-600 degree and it has to be cooled very slowly air cooling. There is almost certainty that post weld heat treatment will be needed so as to eliminate brittle areas in the heat affected zone.

The types of welding which can result in successful welding of both grades are such processes as GTAW (TIG), GMAW (MIG), and SMAW (shielded metal arc welding), and conventional methods also play a role but strict procedure and definition of a suitable filler metal are vital in producing good joints.

Machinability and Manufacturing Considerations

Surface finish, tool life and production efficiency in manufacturing of these steels are influenced by the machinability of these steels.

As compared to 4140, 4130 steel is usually more machinable with lower carbon content and hardness. It cut good surface finishes and has the capability of making reasonable cutting speeds when using traditional tooling.

Increased hardness of 4140 steel may cause difficulties when conducting machining activities. It might need reduced cutting speeds, increased tool changing and special tools to get the best performance, while materials like 4130 can be readily machined elastic deformation. But its high strength attributes in most cases make it worthy of the extra machining factors.

Those two grades can be efficiently machined with conventional machine tools and tooling. Good results can be realized with either by use of proper cutting fluids, proper speeds and feeds, and sharp tooling that can withstand high loads.

The 4130 steel is normally simpler to cold form because it is weaker and more ductile desired properties. Both grades can be Hot formed successfully at suitable temperatures.

Automotive Industry Applications

4130 and 4140 steel are widely used in the automotive industry to build different parts, one of the most important properties is strength in different parts of the automobile where weight cutting and reliability are involved, showcasing their versatile alloy nature.

4130 steel has been widely used in the manufacturing of automobiles in high-performance components such as roll cage, suspension, and chassis because the material is very strong and resistant metal machining. It is also weldable and it is suitable to fabricated components which need more of garnered geometries.

The 4140 steel is used in car parts where high strength is needed and wear resistance is of great importance, particularly in high stress components . With sufficiently high tensile strength and fatigue resistance, 4140 steel crankshafts are able to withstand a high level of stress and high-velocity rotations, increasing the engine performance and its life.

4140 steel is often used in drive shafts, axles and transmission parts because of its fatigue and strength. The rotating component properties are also favorable to the current material because of its capability to sustain properties even when loaded cyclically.

Both of the grades are applied in the production of racing car components and in this case, the strength, weight advantage and reliability combination is important in the competitive performances.

Aerospace Industry Applications

The aerospace industry requires materials with high strengths to weight ratios, its reliability, and ability to perform in extreme conditions.

The good balance of strength, toughness and weldability of 4130 steel makes it a popular material in other industries: Aerospace: Aircraft Fuselage Components: 4130 steel tubing finds use in lightweight but tough fuselage structures due to its good strength-to-weight ratio.

Both 4140 and 4130 steel are applicable in the aerospace engineering segments where are used in producing aircrafts components, including landing gear parts, wings of the aircrafts, parts of engines, and other structural components of aircrafts. A decision to use either of them is based on the definite requirements concerning the performance and manufacturing considerations.

4140 steel is commonly used in the aerospace industry, in landing gear parts of commercial aero planes, since it has to be high strength, fatigue-resistant, to support the plane during repeated loading with minimum risk of failure.

Superior properties of these chromium-molybdenum steels, versus plain carbon steels, apply to aircraft engine brackets, mounts, and other structural components.

Oil and Gas Industry Applications

The oil and gas sector poses special demands in the kind of materials that can be used in those environments which are hostile, suffocating with high pressures and corrosive turnovers.

4130 steel and 4140 steel are commonly applied in petroleum equipments and construction equipment, particularly as structural steel . The four common performance requirements of 4130 include 60K and 75K, whereas the limits of 4140 are broader. The performance grades are called minimum yield strength suitable in thousands of pounds per square inch.

Drilling equipment components such as drill collars, tool joints and downhole tools such as drilling bits, commonly use these steels to provide a mix of both strength and toughness. Impact resistance and fatigue cycle would play an important part in the drilling processes.

Oil and gas applications using pipeline components and pressure vessels that use the alloy steels also have the advantage of higher mechanical properties of the alloy steels than plain carbon varieties.

The two grades are applied in the production of several fittings, flanges, and other parts, where pressure and reliability are important safety measures.

Manufacturing and Industrial Machinery Applications

Industrial machinery- Applications are where the materials have to go through heavy load, wear, and constant use in harsh conditions.

Steel 4140 is applied in products where a high rate of strength, durability, and resistance to abrasion are required such as gears, axles and other components of machinery when subject to high stresses. It is strong and hard under load, which makes the material suitable in the power transmission component application.

The strength and ability to apply surface finish to components such as hydraulic cylinders, piston rods, and other fluid power components commonly use 4140 steel because of these qualities. The material is also heat treatable to the necessary wear resistance and retain core toughness.

4130 steel is used in fabrication of machine parts where formability and weldability is a factor. It is also good in the structural parts and structures due to its balanced properties, making it suitable for other high stress components .

The two grades are applied in the production of diverse tooling applications such as jigs and fixtures, to certain manufacturing equipments where a reliable performance is imperative.

Sports and Recreation Equipment Applications

The sports and recreation marketplace appreciates materials with strength, ability to be lightweight and dependability in applications where performance is essential.

4130 steel is used in the production of bicycle frames, motorcycle frames as well as sports equipment and other structural elements. It is found to be suitable material to use as it has fantastic strength-weight ratio and weldability in fabricated frame construction.

frames matching the quality of racing and other performance types of bicycles often use the 4130 steel tubing. This is an enormous advantage in the ability of the material to be molded into compound shapes and retain the structural properties.

The 4130 steel provides the dual benefits of strength and toughness and weldability that are all used in such applications as motorcycle chassis components and frames. The material is capable of placing the dynamic loads and vibrations that we experience during the action of motorcycles.

A variety of sports equipment, together with exercise equipment, playground equipment, and sporting implement, employ these kinds of steel depending upon their reliability and performance attributes.

Cost Analysis and Economic Considerations

The cost effects of material selection are very relevant in the success of a project and competitiveness in the market.

The cost of 4130 steel is usually lower than 4140 steel, which can be attributed to its lesser amount of alloy and easy processing requirements, while still achieving the desired mechanical properties related to chemical composition . This provides an opportunity to save on price in large-volume applications, in which case 4130 can be a satisfactory choice when its properties satisfy the maximum stress requirements of the application.

The greater price of 4140 steel is sometimes attributed to the fact that it is mechanically more capable and functions well in tough applications. The price premium can be counteracted by longer life of components, lesser maintenance and performance.

The economic part of the survey should also take into consideration the cost of processing. 4130 can facilitate the lower cost of fabrication due to its better weldability whereas the cost of manufacturing with 4140 could be higher due to difficulties in machining.

When a decision to select material is being made, one must look at the total cost of ownership which is factoring in the material cost, the processing costs and the life of the service one would get.

Selection Criteria and Decision-Making Guidelines

To select the proper materials good consideration should be made to the application requirements, operating conditions, manufacturing restraints.

The 4140 steel is normally chosen when high strength and hardness are the major requirements. The 4140 has a superior application to the high stress, wear stress, and fatigue loading appliances.

Steel 4130 is frequently applied where high weldability and formability are demanded and places of such demands are aerospace and automotive industries. Where the fabrication needs require a great deal of welding (or forming) the properties of 4130 offer a major advantage.

During material selection, environmental conditions should be put into consideration. The two grades are associated with almost the same corrosion resistance though circumstances on the ground may demand further coating or treatment.

Decision regarding the selection of materials can be affected by manufacturing volume and complexity. It is possible that high-volume will work better with 4130 since it is cheaper and more easily machinable, and 4140 will be worth the price to those running low-volume but high-performance applications.

Future Trends and Developments

The evolution of the steel industry has gone hand in hand with the growth in technology and market dynamics and this has affected the evolution and use of these alloy steels.

Both grades of steel 4130 and 4140 are being enhanced by high technology in heat treatment and processing methods, increasing the performance capability of these steels. Control atmosphere heat treating and precision cooling are also facilitating more constant properties and better performance.

Additive manufacturing technologies allow exploring new opportunities with these steel grades but, at least in most applications, conventional manufacturing technique will be used.

The current nature of advances in the steel manufacturing process is being steered by environmental considerations whereby the aim is to consume less energy and impact on the environment but not compromise the materials performance.

Quality control and testing tools are still being developed and allow characterization of material properties and more sure performance prediction in services more effectively.

Conclusion

The decision made between the 4130 and 4140 steel is based on the fulfillment of the requirements in terms of performance and cost-effectively manufacturing the product, especially for critical components . 4140 steel will be better to use when high stresses are involved, and the product has to perform at the highest level. Nevertheless 4130 steel is great in welding and in shaping and still has good strength properties making it first choice in fabricated ructions and in those applications where the manufacturing process is key to the choice of metal. The two grades have significant roles to play in contemporary manufacturing which covers the aerospace, automotive, oil and gas, and various industries, as well as industrial machinery markets.