In contemporary manufacturing and engineering, threads are basic elements used as the main support of myriads of mechanical systems and industrial products. Whether it is the tiniest electronic devices or huge machinery on an industrial level, it is threads that make up the life lines that keep our world of technology in one piece. Learning the types of threads and their uses, including screw thread terminology, would be important to engineers, manufacturers, and logistics experts, who enter into contact with threaded products regularly.

Understanding Thread Fundamentals

Threads are equal-pitch spiral grooves produced on the surface of cylinder or cone. These helical elements translate rotational energy into the linear one so that they ensure safe mechanical connections between thread types and elements. The helical direction of the thread (the helix) is a manner of winding around the cylindrical bolt or pipe unceasingly, like on a wave. This basic principle of fundamental design makes the threads to grant strength, removability, ease of installation, and cost-effectiveness in various applications.

Thread Classification Systems

Thread classification systems sort the large number of thread types into manageable groups by their geometric characteristics and the applications. The concentration is first into straight thread (parallel) threads and tapered threads. Straight threads are uniform in diameter along the entire length whereas tapered threads taper with a gradual reduction in diameter towards the end of the threads. This categorization enables both engineer and technicians to recognize suitable types of threads to be used in certain applications to facilitate compatibility between mating elements.

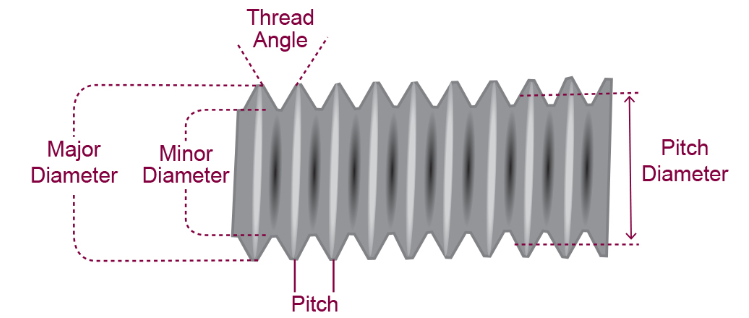

Major Diameter Specifications

The major diameter refers to the largest diameter of a thread and this is in fact a decisive measurement parameter to identify a thread and its compatibility. In the case of external threads, the major diameter includes the height of raised helix of the thread (the distance between two opposite crests). When it is an internal thread the major diameter is the separation between two opposite roots. Such specification directly affects the strength properties of the thread and determines the correct stringent requirements to the manufacturing of threaded elements.

Minor Diameter Characteristics

Minor diameter (or inner diameter) is the smallest diameter of a thread and has a strong effect on the load bearing strength of a thread. In an external thread, the minor diameter is explained to be that distance in between two opposing roots and in an internal thread the minor diameter is the distance in-between two opposing crests. Minor diameter specification is critical in calculating the engagement length of a thread and provision of sufficient depth of material to sustain the integrity of coarse threads during working stresses.

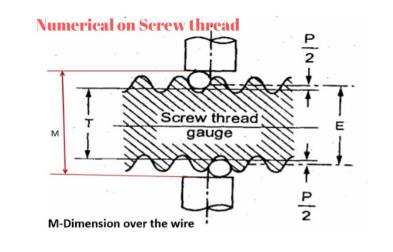

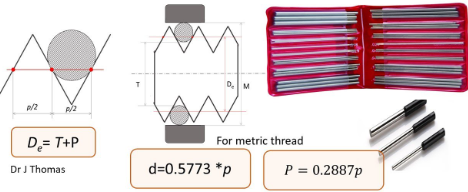

Pitch Diameter and Effective Measurements

An effective diameter (such as pitch diameter), a virtual coaxial cylinder, comes through the thread-surface length somewhere in the middle between the major and minor diameters. This fundamental value defines how the screw thread advances axially, working parameters and interconnectivity of the thread with its counterparts. The pitch diameter forms intercept points which are at the meeting of opposite flanks of threads grooves and each intercept is half of the nominal pitch. A thread pitch gauge helps in accurately measuring the diameter and size of the thread during inspection and quality controlled processes of threads.

Thread Pitch and Spacing

Thread pitch is the distance between same points on neighbouring threads; measured along parallel to the axis of the thread. This is a basic parameter and essentially it ascertains the mechanical advancement of the thread and the varying multiplication that will be accomplished by the input of rotational power. Various applications will have varied pitch requirements to adapt the performance parameters to suit the requirements like holding power, speed of assembly, its resistance to vibration loosening and so forth. Pitch relationships allow proper selection of mating components and thus maximum performance of the mechanical parts.

Lead Calculations and Applications

Lead is the axial distance travelled by a screw thread part through one full turn, which is closely related to thread pitch . In single-start threads, lead is the same as pitch whereas in multi-start the lead is an integer multiple of the pitch. The lead values of double-start threads are two times the pitch, and of the triple-start threads are three times the pitch. This maintenance has an influence on the mechanical advantage and speed of threaded assembly so that lead calculations are mandatory in cases where particular motion characteristics are needed.

Thread Start Configurations

Thread starts denote how many helical threads happen to be independent and go around the length of a threaded part. Single-start have only one thread on them with multiple threads, on waiting lines that are parallel in multi-start designs to enhance the mechanical efficiency. The lead depends directly on the number of thread starts having a direct effect on the operational characteristics of threaded assemblies. Multi-start threads have greater linear motion per revolution but can lose a certain amount of holding power when compared to single-start versions.

Helix Angle Considerations

Helix angle Angle between the helical trajectory of the thread and a line normal to the rotation axis. Increased helix angles lead to lower and loss of friction resulting in a better mechanical efficiency to power transmission applications. That geometric parameter has an impact on the self-locking property of the threaded assemblies and impacts the assembly and disassembly required torque. Helix angle relationships aid in optimizing the thread selection in regards to specific performance needs.

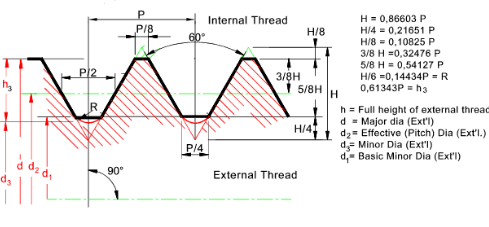

Thread Angle Measurements

Thread angle determined the angle between adjoining thread flanks and has great influence on the load sharing feature of the thread. Depending on the requirements, different thread standards have different thread angles optimised to those requirements, including bolt threads . The 60 degrees angle as found in metric and unified threads offers great load distribution and manufacturing ability and the other angles such as 55 degrees as in British standards, or 29 degrees as in the Acme threads explains specific performance that applies to a definite situation.

Right-Hand Thread Systems

The right-hand threading direction is a standard, where the clockwise thread tightens in an observant threaded end. These strands obey the right-hand rule, hence moving outward as they are rotated in a clockwise direction, and inward with a counterclockwise turn. Most industrial applications are done through right-hand single threaded screw, including national fine thread, because it is easy to use and it can interface with most of the tooling and manufacturing procedures. This makes them largely used thus they interchange parts and are less complex in inventory.

Left-Hand Thread Applications

Left-hand threads turning in the opposite direction (counterclockwise) would loosen both Left-hand threads are used in special situations in which right-hand threads may loosen during operation. The threads get applied in rotating machinery where the direction of rotation would cause conventional threads, like grinder wheel arbor and some automotive uses, to become loose. Left-hand threads are less frequent than those of the right-hand; nonetheless, they are needed in certain mechanical systems where reverse threading features are necessary.

Tapered Thread Designs

Tapered threads have closures that become smaller at their length and produce sealing that is metal to metal due to their weddings action or regulated thread distortion. They are particularly useful in pressure-containing uses including pipe fittings and brass valves , in which the taper causes ever-tighter engagement when mated. National Pipe thread ( NPT ) and British Standard Pipe Taper ( BSPT ) are some commonly used examples of a tapered thread standard that is used widely in plumbing as well as pneumatic and hydraulic systems where leak proof connections are required.

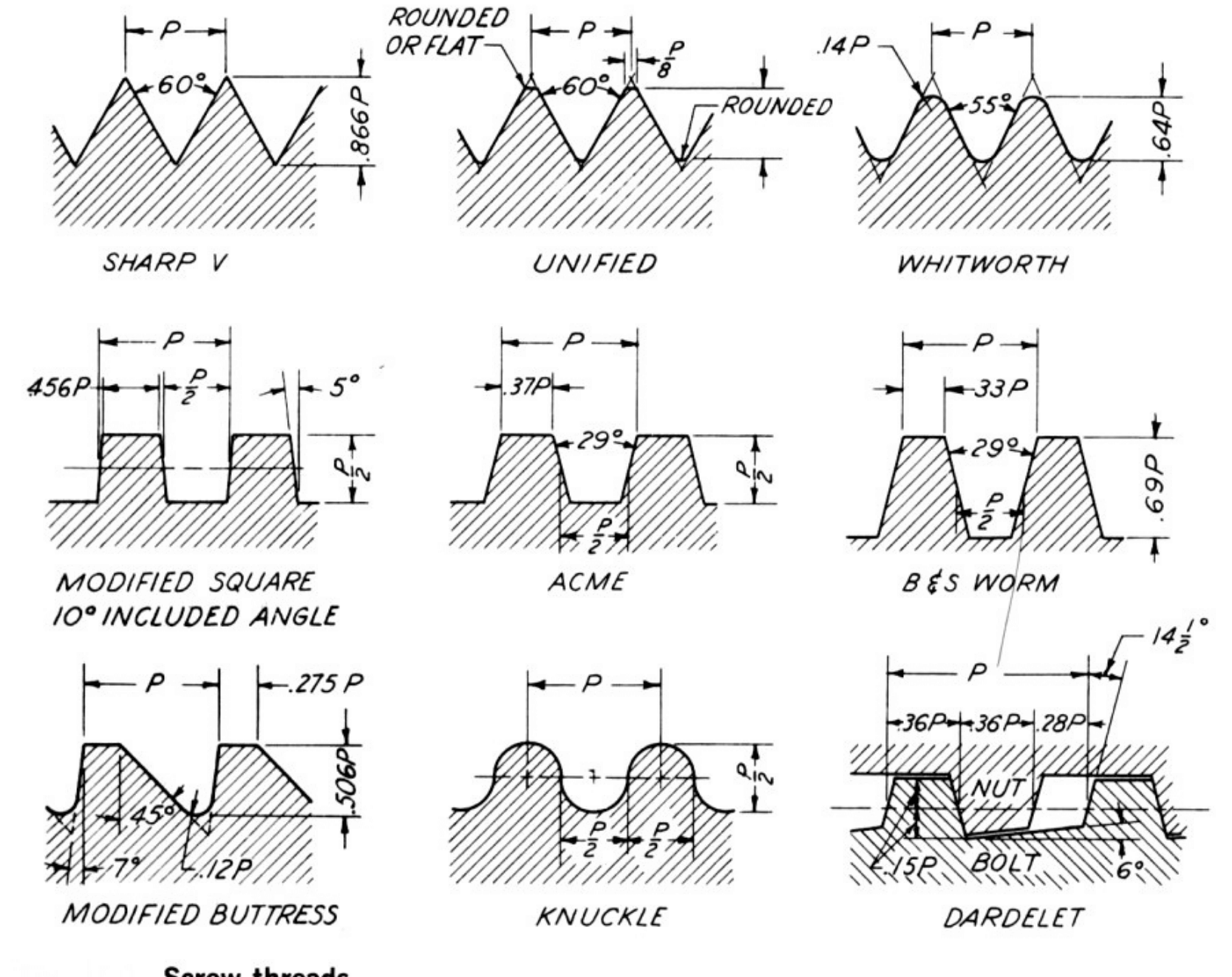

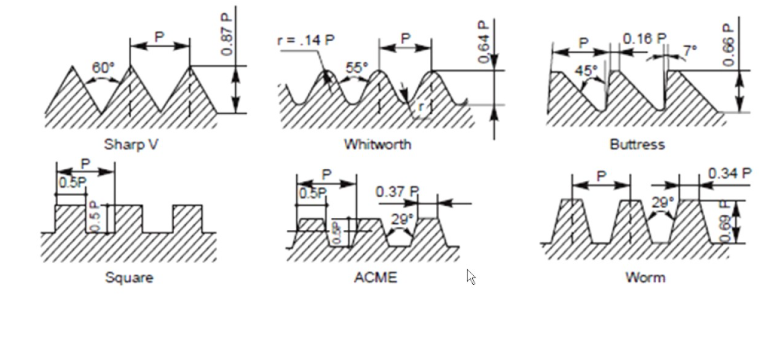

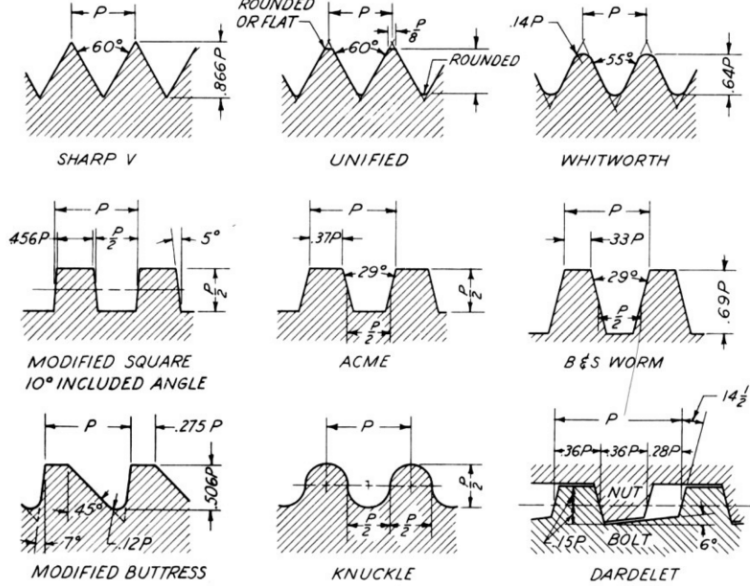

V-Shape Thread Configurations

The most common thread profile is V-shaped with triangular cross-section under it, this type has the strength to weight ratio and ease in manufacture. These threads can be machined in many different forms such as taps, dies, screw cutting lathes and milling machine thus they are very useful in a wide range of production environments. V- profile gives load effectively through the thread flanks and offers the well established characteristics of engagement adaptable to general purposes fastening use in a variety of industries.

Metric Thread Standards

Metric threads are international standardized to millimeter specification of pitch and diameter. The included angles of these threads are 60degrees with crest being flat and the roots being rounded which ensures both load distribution and efficient manufacturing. Metric The metric designations are prefixed with the letter M and consist of the major diameter and pitch, e.g. M20 x 2.5 would have a 20mm diameter and 2.5mm pitch. This uniformity makes it easier to exchange parts across the world and also makes it easier to manage such internationally based operations.

British Standard Thread Varieties

British Standard wires are of various categories namely Whitworth (BSW), Fine (BSF), Association (BA), and Pipe (BSP) threads. BSW threads also have 55- degree angles with rounded crests and roots to use in general purposes. The threads of BSF are the same 55-degree angle but provide finer pitch due to applications that need more grip when vibrating. BA threads are used to serve the sensitive electrical and mechanical equipment whereas BSP threads are used to serve the pipe fitting applications with special taper properties.

American National Thread Systems

American National threads American National threads (also known as Seller threads) have flat crests and roots and 60included angles. These threads, including unified screw thread, are recognized by American standards institute and can be used in vehicles, aircrafts and general industry field. They include coarse (UNC), fine (UNF), and extra fine (UNEF) pitch series; the Unified Thread Standard (UTS) contains threads that have diverse strength and vibration resistance. This compatibility takes place through standardization of American manufacturing and maintenance.

Square Thread Profiles

Square threads have rectangular cross-sections which have the highest efficiency in power transmission applications because of the lower friction loss. These threads work well in linear motion systems like lead screws, jack screws, valve stems where linear and smooth operation and mechanical advantage are of main concern. Square threads are more costly to produce than V-shaped threads even though they have cost-saving benefits and specific machineries need to be used in the manufacturing and repair processes.

Acme Thread Characteristics

Acme threads are a concession between the efficiencies of the square thread and the strength of the V-thread, having trapezoidal shapes with included angles of 29 degrees. The design forms an easier to manufacture thread than squares with only a fair efficiency level as a power transmission thread. The acme threads make the split nuts very easy to disengage and copy making them use the moment to bypass the backlash problem of the square thread systems. These features render Acme threads common in machine tools feed mechanism and adjustable mechanism.

Knuckle Thread Applications

Knuckle threads are rounded in a way that they can move when a service is rough and durability before effortless production is of concern. They are non-machined (can be cast or rolled) and thus economical to use in bottle caps, as electrical insulators and even to couple railways. Its rounded profile does not dent as easily and is also harder to contaminate, but on the other hand, does not hold loads as well as other thread designs.

Buttress Thread Designs

Buttress threads employ square thread efficiency but with V-thread strength by the asymmetric profile with one perpendicular side and the other at some angle. The design has optimized in one direction to carry load but reasonably efficient in power transfer, making buttress threads particularly effective for specific applications . Buttress threads are especially effective where the loading direction is almost unidirectional e.g. in hydraulic cylinders and heavy-duty jack screws. The asymmetric design has to be guided with proper direction during installation to come up with the best performance.

Worm Thread Specifications

The worm threads are similar to the Acme threads in the included angle of 29 but are deeper to fit applications using special gear. When worm wheels are used with them, these threads have the capability to transmit power in 90 degree form, so a high ratio of gear reduction can occur in a small package. Worm thread systems have a high mechanical advantage and are smooth running so can be used in applications where a precise position is required such as motion control (where strong loads are required with a low backlash).

Single vs. Multi-Start Threading

Single-start threads have a single helical path running around the threaded piece that gives the greatest holding strength and vibration resistance on loosening. Multi-start threads include having multiple helical lines running parallel and thus their linear advance per revolution is higher at a time when there is a need to carry out the assembly or adjustment in a very short period of time. Whether to use a single or multi-start will be dependent on the needs of the desired application, which is determined by the need to have holding power or using coarse threads f high operation speed.

Thread Identification Tools and Methods

The correct identification of threads must be done with special equipment such as calipers to measure diameter, and pitch gauges to measure spacing of the thread. In the case of male threads, calipers ensure accurate measurement of the outside diameter, and in the case of female threads ensures an accurate inside diameter measurement. Pitch gauges use gauge teeth to measure thread spacing using a correlation between thread profiles and gauge teeth to correctly identify thread standards and particular specification. These tools facilitate the identification effort and the right choice of the components to use in maintenance and replacement tasks.

NPT and NPTF Thread Systems

National pipe threads (NPT) and national pipe thread fuel (NPTF) are the American standards tapered pipe threads, which employ 3/4- inch taper per foot. NPT threads must be sealed with thread sealer or tape to make a leak-free connection but unified screw thread can produce a metal-to-metal seal by a design controlled interference fit. They have come to predominate North American plumbing, pneumatic and hydraulic applications with pitch and diameter combinations established as standard depending on nominal size.

BSP Thread Standards

British Standard Pipe (BSP) is used as parallel (BSPP) and tapered (BSPT) to suit various sealing needs. Sealing of BSPP threads is by the use of O-rings or gaskets and BSPT threads are sealed by engagement of tapers. BSP threads have a 55-degree included angle, and thread widely in Europe and Commonwealth nations to house and hose work. The BSP specifications are important in the international equipment compatibility and the same in operations of equipment maintenance.

Metric Tapered and Parallel Systems

There are both parallel and tapered types of metric threading so that various applications needs can be served. Metric parallel threads use independent sealing elements (i.e. O-rings or gaskets), whereas in metric tapered threads, the seal is accomplished in a controlled interfere fit. All these systems are internationally standardized using measurements in millimeters to allow parts to be used interchangeably and also the logistics of companies whose operations are internationalized to be easy.

Thread Selection Criteria

To choose the right kind of thread, several factors must be considered such as the load requirements, environmental condition, the frequency in assembling, and compatibility between the thread and other available systems. The weight-bearing uses can be calling of fine-pitch threads to account of their greater strength, as opposed to some speedy multiplication application where coarse-pitch threads might be preferred. Environmental effects e.g. vibration same diameter, temperature cycling and corrosive effects affect the choice of type of threads and may necessitate special materials or coating to allow them to perform adequately external thread screw.

Conclusion

It is vital to familiarize oneself with the various forms of the threads in current manufacturing and engineering so that tasks could be accomplished effectively and produce the best output. There are various types of thread, including a simple V-shaped thread used with general fastening needs to highly specialized Acme thread used in power transmission where each type has advantages in different applications iso metric thread. Selection of proper thread involves adequate considerations of the loads, environmental factors, assembly and adaptability with the existing systems. The geometric dimensions such as the major diameter, minor diameter, pitch and thread angle are all combined to define the performance rotational characteristics and application to a variety of threads british standard fine thread.