Meta Description: Learn all about types of automotive fasteners and find the round up of the automotive fasteners and various automotive parts , bolts, screws, clips, nuts and specialty fasteners. Study their uses, materials and the criteria of selection so as to have the best functioning and leading vehicles.

The modern car counts on the use of thousands of fasteners that connect the parts and make them safe and secure. Automotive fasteners are used in construction, assembly and maintenance of vehicles and their components such as the engine, inside fittings and other parts of the vehicle carbon steel. Knowledge on different automotive fasteners, including common fasteners, is important to both mechanics, engineers and automotive enthusiasts engaged in the handling of vehicle components on regular occasions cap nuts.

Understanding Automotive Fasteners Fundamentals

The automotive industry has more than 64,000 kinds of definite fasteners, and manufacturing automotive fasteners requires careful quality control. , so each of them corresponds to particular functions and performance. These essential components are the mainstay of building vehicles, so that no part should fly away because of something as mechanical stress and vibration, as well as the temperature changes mechanical fastener.

Metal Automotive Fasteners: The Industry Standard

Automotive fasteners are metal and take several shapes such as bolts, springs, nuts, and screws. They are long-lasting, re-usable and can be used to join and hold heavy parts of the automotive, suspension and engine components, taking into account their mechanical properties . The metal fasteners are usually made of iron or aluminum alloy and most of them are coated by zinc for rust protection to increase their anti-corrosive and strength properties.

Automotive Bolts: Heavy-Duty Connection Solutions

Bolts, including carriage bolts, are considered to be one of the most widespread automotive fasteners. These fasteners are externally threaded and thus do in collaboration with nuts to bring to birth a strong and robust connection that can resist a high amount of stress and load. Hex head bolts and hub bolts re well-liked especially found in vehicle industry as they are easy to fix and take out with ordinary instruments.

Automotive Screws: Precision Fastening Components

Automotive screws come in different types i.e. self tapping screws, machine screws and sheet metal screws. They also exist in variety of shapes of heads; such as Phillips, flat, countersunk head screw and hex head types. The screws are a perfect fit in certain automobiles as they cut their own threads in plastic components where they are set. in the materials where they are set as compared to bolts that are used with unique tools.

Self-Tapping Screws in Automotive Applications

Self-tapping screws are necessary in the process of fixing the types of automotive parts to the sheet metal. and plastic parts spread out into the car. These threaded rods do not require pre-drilling holes and produce solid unions in the materials which may not be able to support the conventional bolts and nuts.

Machine Screws for Precision Assembly

Machine screws are one of the types of automotive fasteners used to achieve accurate fits in automobile applications and are applied on threaded holes or nuts. Such fasteners are often found in electrical parts, dashboard systems and other places that need precise placement and positive attachment.

Automotive Nuts: Essential Threaded Partners

Nuts are used in collusion with bolts in order to make a complete fastening system. Depending on their purpose, many types of nuts, including knurled nuts, all-purpose hex nuts and even the special captive nut that stays with the parts in the event of disassembly, are used in automobiles.

Captive Nuts and Specialized Threading Solutions

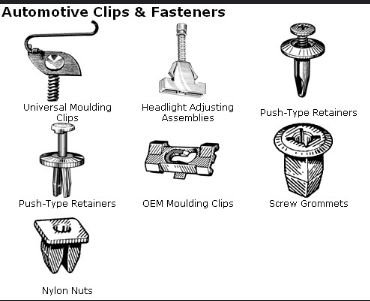

Specialty fasteners are produced to fulfill the needs of various manufacturers regarding specific automotive applications- this is including captive nuts, rivet nuts, panel clips, U-nuts, J-nuts and push-in plastic fasteners. These parts aid assembly procedures and secure adequate connections in difficult buildings to install.

Automotive Washers: Load Distribution Components

In cars, as in other objects, washers are opted so as to spread the strain on the joint over a greater area. This layout will avoid harms to electric vehicles components, potentially reducing repair costs, and keep fastener loads in control all over the connection.

Plastic Automotive Fasteners: Lightweight Solutions

Plastic fasteners are, however, the best when it comes to holding interior parts such as the trim pieces, panels and structural parts that are not critical to the car. The benefits of these fasteners, when choosing the right fastener, are as follows.: they are corrosion-resistant and lightweight in their construction and are affordable to use.

Automotive Clips: Quick-Release Fastening Systems

Clips are the easy to use solutions to fasten objects that need frequent accessibility or removal. Quick assembly and disassembly with easy-to-install push-in clips, panel clips, and retaining clips are available, and secure connections are ensured when using the clips in operation of the vehicles.

Rivet Nuts: Permanent Threading Solutions

Unlike threaded fasteners, rivet nuts or blind nuts, also called threaded inserts, are permanently fixed; in thin media where only one of the sides can be accessed. These rivets are especially applied in car body panel and structural parts.

Spring Fasteners: Dynamic Connection Systems

A great variety of springs, nuts, clips, screws, and bolts embedded on a car body is employed by auto part manufacturers. The spring fasteners provide clearance to movement and vibrations but still hold a secure connection and are necessary in suspension systems and dynamic assembly.

Self-Clinching Fasteners: Sheet Metal Solutions

Self-clinching fasteners provide permanent inserts in sheet metal parts and do not need access to the back side of the material. Installation of these fasteners, including split rivets, is through pressure and they become component parts in the structure.

Push-In Fasteners: Tool-Free Installation

They can be designed as push-in fasteners that can be easily used without tools and are recommended in interior trim pieces as well as body panels and any other parts where a lot of access would be essential. Such fasteners are normally designed with the aim of incorporating expandingctl; advances that make them stay in place.

Torque Specifications and Fastener Performance

Torque is the value of the force that is employed when tightening the fastener and correct application of torque is very essential to automotive fastener performance. Every type of fastener, including how many fasteners are needed hex flange bolts, has certain torque specification which provides maximum clamping force to hold without damaging the parts.

Material Selection for Automotive Fasteners

Most frequent car materials are iron or aluminium alloy in automotive projects. It is an extremely strong and reusable product in the auto industry and usually most bolts have zinc coating to protect them against rust and enhance strength solid rivets. The type of material that is to be used is determined based on strength, environmental factors and cost.

Corrosion Resistance and Surface Treatments

Automotive fasteners are coated against rust by chemical cleaning (like zinc plating, galvanizing and coating applications) which prolongs the life of automotive fasteners loosen automotive fasteners. These treatments are also quite essential in the manufacturing industry for metal automotive fasteners when the fasteners are under severe environmental conditions.

Specialty Automotive Fasteners for Specific Applications

Other than mainstream fasteners, the automotive industry also uses many special parts including specialised parts designed to fit certain applications common automotive fasteners. These are U-nuts to attach suspension components panel fastening, J-nuts of difficult installations and custom fasteners that have been created on specific vehicles or specific systems flange nuts.

Installation Considerations and Best Practices

The appropriate installation of the fasteners involves other factors such as thread engagement, surface preparation and the environmental conditions. The greatest results will be achieved by following the manufacturer specifications and industry best practices to guarantee the best performance and lifetime of fasteners riveting fasteners.

Quality Standards and Testing Requirements

These automotive fasteners should be of quality and high standards and their long-term tests should be exhilarated to produce safety and dependability. These criteria involve properties of materials, dimension accuracy, and the performance under different operating circumstances.

Selection Criteria for Automotive Fasteners

To select the proper fastener, one has to consider a number of factors such as the needed load, environment conditions, installation limitations, and the maintenance of the fastener materials. An appropriate selection would guarantee the best performance and affordability during the service life of the vehicle auto manufacturers.

Conclusion

Anyone who designs, manufactures, maintains or repairs automobiles in the automotive part manufacturing industry will need an appreciation of the different styles of automotive fasteners. Whether it is a heavy-duty bolt holding an engine part or a lightweight clip that holds trim, all of the types of fasteners improve the overall vehicle performance, safety and reliability. Appropriate acquisition, fixation as well as maintenance of automotive nuts and bolts guarantees maximum vehicle performance and life.