Meta Description: Learn the major differences between thermosetting plastics, thermo set and thermoplastics materials, including their physical properties . Get to know their properties, functionality, benefits, and drawbacks in order to make informed decisions in selecting material to use in carrying out your manufacturing services.

Introduction to Thermoplastic and Thermoset Materials

In the manufacturing and materials science field, it is imperative to know the basic distinction between thermoplastic polymers and thermosetting materials to the engineers, designers, and business practitioners in the product development industry. Such two materials, thermoplastic and thermosetting, have unique properties where their application depends on the product and purpose such as the consumer products and the industrial products.

The thermosets generally begin as liquid at room-temperature but upon being heated, or a chemical added, they permanently bond together, unlike thermoplastic and thermosetting plastic, into chemical combinations during the curing stage. Thermoplastics in contrast are rigid at room temperature, but release to become flexible and moldable when heated thereby being able to be reformed many times without permanent chemical changes.

Decision-making between thermoset and thermoplastic materials has a great influence on the manufacturing industry, performance, cost as well as environmental sustainability of the products. This all-inclusive book will take you through all the details of these materials so that you can make well-informed decisions concerning your particular applications.

What Are Thermoplastic Materials?

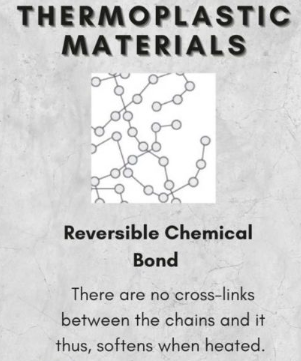

Thermoplastics are a type of polymer which has reversible physical characteristics; under the effect of heat, while thermosets are known for their heat resistant properties . Thermoplastics are solid at room temperature; however even at high temperatures, they start to soften and ultimately melt into a hot liquid at temperature much greater than the glass transition temperature. This special nature enables thermoplastics, including their flame resistance, to be brought to the softening point and re-melted and re-formed several times without appreciably appreciating their critical qualities.

The thermoplastics are molecularly structured using relatively weak intermolecular forces in long polymer chains. These forces become weak in presence of heat enabling the material to flow and assume new shapes, which is crucial for achieving good electrical insulation properties . This is because with cooling the intermolecular forces get reinforced again causing the material to gain shape in the new form, contributing to its corrosion resistance .

Some of the common thermoplastics are polyethylene (PE), polypropylene (PP), polycarbonate (PC), polyvinyl chloride (PVC), polystyrene (PS), nylon, and polyethylene terephthalate (PET) . All these materials contain special features which qualify them to be used in some special applications such as packaging materials, automotive parts, laboratory equipment, and piping systems.

Understanding Thermoset Materials

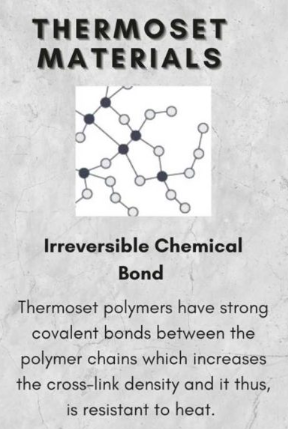

Thermosetting polymers, otherwise referred to as thermoset materials, have a different process of manufacturing. The curing of these materials forms permanent chemical bonds and crosslinking that fixes the molecules in positioning and alters the nature of the material making it impossible to run and turn into a liquid.

Thermoset curing The curing of thermosets entails the production of a three-dimensional network of covalent bonds within polymer chains. This reaction cannot be reversed (this process is also described as irreversible), and once a thermoset has been cured, it cannot be melted or deformed to be shaped again. Thermosets have crosslinked structures that offer high dimensional stability, chemical resistance and thermal characteristics than most of thermoplastics.

Epoxy resins, polyurethane, phenolic resins, silicone, unsaturated polyester melts resins are the popular thermoset materials. They find their wide application in the processes that require high strength, high resistance to chemicals, and thermal stability, especially under extreme heat.

Key Differences in Manufacturing Processes

Thermoplastic and thermoset manufacturing are quite different because both materials have different behavior at the molecular level. The manufacture of thermoplastics is usually undertaken via injection moulding, extrusion, blow molding and thermoforming techniques. These technologies are founded on the capability to warm the material up to molten condition, work it and afterward cool it so as to harden.

Thermoset plastics can commonly be manufactured through reaction injection molding (RIM) or resin transfer molding (RTM). These involve adding reactive in components and letting them cure in the mold and get the final shape and at the same time give it the crosslinked structure.

Tooling method also varies between two types of materials, particularly when considering the differences in their molecular chains . Thermoplastic tooling should be able to resist high temperatures and pressure involved in molding process whereas thermoset tooling should be able to resist the chemical reaction taking place during curing, which can include techniques such as compression molding . This variation in manufacturing complexity tends to affect cost of production and lead times, highlighting the importance of exploring different material options .

Physical and Chemical Properties Comparison

Physical and chemical characteristics of thermoset and thermoplastic materials differ a lot because of structural differences in their molecules. Thermosets have high-temperature heat resistance, outstanding electrical insulation characteristics, good resistance to corrosion, and can withstand high melting points, as well as strong dimensional stability. They are also crosslinked to give high strength weight ratios, while thermoplastics tend to be more flexible.

Different advantages, however, are presented by thermoplastics. They are not normally affected by the weaknesses of poor impact resistance and flexibility as well as low temperature feasibility processing. Thermoplastics have the tendency to maintain their size and they provide good elasticity and strength, thus can be used in places that need tough objects which are also flexible.

One of the greatest disparities of such materials, which is a key difference between thermoplastic, is the heat deflection temperature. Thermosets are usually capable of sustaining shape and characteristics at notably higher temperatures than thermoplastics, which soften and lose structural integrity when heated beyond their glass transition point.

Advantages of Thermoplastic Materials

There are many benefits of thermoplastic material which make it appealing to be used in many ways. Advantages of thermoplastics are: they stick well to metals, have quality of aesthetic finish, can be recycled with minimal effect on the properties of the material, and can withstand chemicals and detergents.

A characteristic feature that gives thermoplastics the highest level of service in the contemporary world, where we give a lot of emphasis to environmental conservation issues is the fact that they can be recycled. Thermoplastics can be re-melted and re-forged numerous times, which makes them a source of sustainable manufacturing activities, especially when considering how materials vary and support less waste production.

Thermoplastics are also space-saving especially using different molding processes which enable makers of these products to come up with rigid shapes and complicated details. The several grades and formulations makes engineers to have access to materials of their needs that are found in specific properties related to material properties .

Advantages of Thermoset Materials

The use of thermoset material comes with its own benefits and reasons why it cannot be avoided when it comes to particular applications. The better structural integrity of thermoset polymers includes irregular wall thicknesses, great endurance to heat and high temperatures, qualities of electrical insulation, or strength-to-weight ratio, all of which highlight specific thermoset properties .

Thermosets are especially useful where dimensional stability is required so that specified tolerances can be maintained over some period of time under changing environmental conditions. The setup and tooling cost of thermosets is lower than thermoplastics in most applications, which makes it cost advantageous in some production conditions where materials must withstand high temperatures .

Thermosets are also chemically resistant and do not damage easily in areas that have harsh chemicals such as solvents, acids or any other aggressive chemicals. This property coupled with the fact that they are thermally very stable makes thermosets to be the preferred material in many industrial applications.

Disadvantages and Limitations

Although they are all beneficial, the two types of material, including chemical processing equipment, still possess limitations that should be put into consideration before making a choice of material. Thermosets are irreproducible and cannot be remolded and even after using them, they cannot be recycled and hence part of the problem with waste handling and end-of-life product planning, despite being chemical resistant .

Thermoplastics are also not without limit. They cannot be applied in every application because they soften upon heating, and are usually costly as compared to the thermosetting polymers. Thermoplastic temperature limitations are especially an issue in high temperature operations where dimensional stability is eminent.

Brittle placing of certain thermosets could also become a drawback when an impact resistance or flexibility is necessary. Moreover, the irreversible condition of thermoset curing process implies that defects or any alteration of design requirement cannot be conveniently fixed once the material has undergone processing at certain temperature, which highlights the difference between thermoplastic materials.

Industrial Applications and Use Cases

Thermoplastics and thermoset are used in many industries with each industry utilizing capabilities of these materials. Conductive thermosets can be found in many markets such as adhesives and sealants, aerospace, defense, electrical, automotive, energy and building and construction.

Other thermoset applications are chemical processing pipes and fittings, electrical housings, automotive components, and agricultural equipment. Thermosets have excellent chemical resistance and thermal stability, and are therefore suited to such taxing applications.

There are significant applications of thermoplastics in many sectors to produce products such as milk bottles, plastic bags, and piping, building and construction, electronics, medical, biomedical, food and drinks, chemical, automotive and plumbing. They are versatile and processable, which means that they are applicable both to such high-volume consumer product and to such specialized industrial part.

Environmental Impact and Sustainability

Environmental effect of thermoplastic and thermoset materials has gained importance in the choice of materials. After parts have been originally molded thermoplastic materials are easily remelted so that the existing parts can be ground into granules to be used to form new parts or remelted and molded again reinforcing materials.

Nevertheless, the thermoset products are not recycled or can be re-used as they have cross-linked bonds and would be tricky, or outright impossible, to recycle in large numbers. This has necessitated more research to be done on the bio-based thermosets and other means in which end-of-life solutions can occur, including techniques like reaction injection moulding .

Sustainability goes further than recyclability and covers the energy requirement in processing, raw material selection and general lifecycle effect. These factors are growing increasingly in the minds of manufacturers in terms of the material they pick on their products.

Cost Considerations and Economic Factors

Cost analysis is a very essential part of the material selection which refers to the raw material cost, processing cost, tooling needs and the lifecycle cost, particularly in plastic injection molding . The majority of thermoplastics are usually cheaper than the thermosets and the distinction is in tooling requirements, materials, and labor to formulate the resins during the injection molding process molecular weight .

Thermoplastic processing may have initial tooling costs which are higher as the molds are hot and more sophisticated processing gear is required. But such first investments tend to be countered by the capacities of producing parts fast and in great quantities through the extrusion process low melting points .

Additional elements like catalysts, fillers and additives may be needed in thermoset materials and this can hike the cost of material. Nevertheless, the cost savings are achievable due to the possible reduced tooling costs and make complex geometry one-shot-moulding possible in some applications.

Future Trends and Innovations

With the advances in polymer chemistry with regard to thermoplastic and thermoset material, sustainability requirements and processing technologies, the future of thermoplastic and thermoset materials are taking form. Bio-based polymers, recyclable thermosets, and high-performance thermoplastics developments are opening the gate to an increasing variety of opportunities in both material groups.

Additive manufacturing or 3D printing is opening up new horizons in thermoplastic and thermoset formulations, not only being able to produce very intricate geometries, and even custom parts. A higher level of composite materials is also coming up which embrace the best of both materials liquid form.

The next development in the technology of polymers would be the integration of self-healing materials formed by self-healing polymers, multifunctional materials formed by the integration of multiple material capabilities into a single-material composite plastic materials, and smart materials formed in integration of self-acknowledgement of chemically changing circumstances desired shape.

Conclusion

Selection of thermoplastic or thermosetting plastics is an intricate matter of balancing many aspects such as the requirements of an application, processing factors, price restrictions, and the considerations of environment impact, especially when analyzing the thermoset vs thermoplastic debate. Thermoplastics are better in recyclability, flexibility in design and efficiency in processing hence the best choice in consumers products and consumer products where design change is frequently desirable. The high performance of thermosets are characterized by high thermal stability, good resistance to chemicals and dimensionally stable to offer high performance in harsh environments.