Find out the key differences between overmolding and insert molding processes, specifically the insert molding vs overmolding . Find out what would be the most efficient manufacturing approach to your project by going to our in-depth explanation of the costs, application, and advantages.

Two injection molding processes remain the leaders when complex and multi-material parts are to be manufactured: insert molding and overmolding. The two methods are effective in allowing manufacturers to make complex plastic parts that incorporate a mixture of materials, although they are used to serve different functions and have separate benefits. It is important that engineers, the design and manufacture of the products have a basic understanding of the differences of these processes, such as the single bonded component, that will enable them to design the best strategies in their production.

What is Insert Molding?

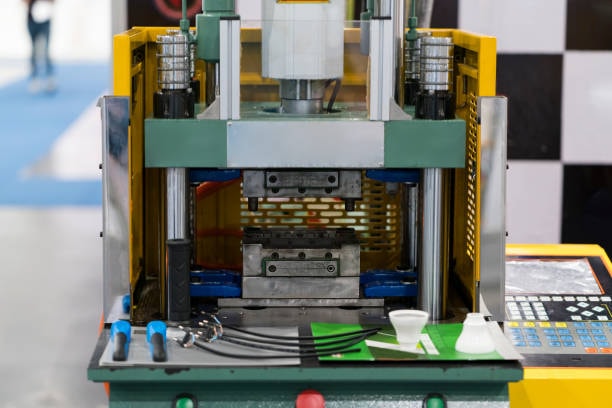

Insert molding is a type of injection molding used to produce products with pre-made pieces or inserts, usually metal inserts, into a pre-heated molten plastic mold cavity and then injecting plastic around it. Insert molding is a process, which involves pre-fitting of an insert, often metal into the tool into which the injected plastic flows about. By enclosed the insert in plastic the result is a unit piece of molded plastic which is usually stronger than that produced by secondary assembly.

The operation commences by placing the insert parts in the mold applying special fixtures or a robotic arm systems. When correctly oriented, molten thermoplastic is then injected into the mold cavity and surrounds the insert establishing a bond between the two materials on a permanent basis. The outcome can be described as a single component made of metal components that only possesses strength and functionality but the widened attributes of plastic in terms of versatility and cost efficient status.

Some typical types of inserts used in the process are threaded fasteners, threaded inserts pins, bushings, electrical contacts, metal tool shanks and electrical components generally. Insert molding process establishes mechanical and often also chemical bond between the materials, depending on the used particular materials and part design.

Understanding Overmolding Technology

Two-shot molding can also be referred to as; overmolding, multi-shot molding, and two or multiple material injection, or double injection molding, which involves advanced techniques. and it is a two step process, which entails injecting one or more different materials sequentially to produce a single and integrated part. This is in contrast with the typical molding process where one finished piece is produced in a single spending; for overmolding, a minimum of two or more components injection processes are required with a different material to create overmolded parts . The called method can also be referred to as: 2K overmolding or the so called two-shot molding, or even multiple material molding.

An overmold process normally kicks off by producing an inflexible foundation in the initial injection procedure. This plastic substrate is the basis of the structure of the last part. When the substrate has cooled and solidified, another material (usually soft and/or flexible, and sometimes with different properties) can be injected onto (or around), or into certain selected regions of the substrate, after the first material has been established . The materials can be same or not and either combine to form a mechanical bond or a chemical bond. compared to inserts molding whereby, a mechanical bond is usually provided. It is also normal to have an overmolded part created through a two-shot injection molding process.

Key Process Differences Between Insert Molding and Overmolding

The core role in the difference of these two processes is in the method of executing the process, as well as, a material integration approach. Insert molding tends to be a one shot process, and Overmolding is a two shot process. With Insert Molding and also Overmolding, molds are critical, especially during the application of the second layer of materi . Elements of mold design, such as design of mold cavity, pins, and mating tools, direct the plastic through the manufacturing process.

During insert molding, the full plastic injection is completed in just one cycle and the insert which has been placed inside assumes a permanent station in the plastic matrix. Inserting should be done with utmost precision once before the actual process of injection starts because once it begins, the process cannot be adjusted at all during the injection of plastic, particularly in a complex two shot mold .

On the other hand, overmolding entails several injection operations that are unique in their parameters, material, and aim at a time. The initial shooting forms the substrate and every other shot forms extra layers of materials or parts to achieve a lighter weight in the overall structure . Such a multiple stage system enables more complex parts and a higher level of tooling and process control is required.

Cost Analysis: Insert Molding vs Overmolding

Manufacturing decisions should also involve knowing the economic costs of every process and potential cost savings so that an informed manufacturing decision is made. Nevertheless, overmolding is more costly compared to insert molding because this is a procedure that entails two stages, contributing significantly to assembly costs . This especially concerns prototype or small quantities manufacture since the overmolding process demands to produce two tools one of them (substrate) and another (overmold).

Insert molding usually provides lower startup tooling used as insert molding does not need any additional tooling or injection time. The main cost factors on which it should concentrate are related to the mold design and fabrication, threaded metal inserts, and of course the plastic material. Nevertheless, when custom insertion is needed instead of the off-shelf parts in a custom design , the sum could get much greater; this is because of the extra manufacturing procedures necessary to create the inserts.

The sizes of upfront investments in overmolding are often more complicated because of tooling complexity. It could also require special two-shot molding machines or several single-shot machines raising both capital and operational expenses, especially when dealing with electronic components . Also, exact material compatibility and procedure have to be considered, which increases the cost.

In large production scales, both processes are capable of considerable savings with fewer assembly work and enhanced efficiency in production. Nonetheless, the break-even value changes based on complexity of the parts, such as the need for vibration damping the cost of material and the volume of parts that are needed to be produced.

Material Selection and Compatibility

One of the most important elements in the effective insert molding and overmolding processes is the choice of material to be used, making this a popular manufacturing process . Not only the performance of the final product is influenced by its selection of materials, such as softer plastic but also the manufacturability and of the process itself.

During insert molding, the factor of consideration is majorly about the compatibility between the remainder material, which will be plastic, and the component as the insert. The thermal expansion properties of the two materials should be well aligned, as any concentration of stresses may result in failure of the part. The most used insert materials are stainless steel, brass and aluminum, and the insert plastic materials vary depending on the performance of the thermoplastics which could be commodity thermoplastics or engineering plastics, including applications in dash panels.

In overmolding, it needs even further special attention to the material selection because now there are two types of plastic materials, very different in structure, and these two materials must be similar enough so that they can gel together and have a strong bond between them, but retain their original characteristics. A common substrate material is a rigid thermoplastic like ABS, polycarbonate or nylon and a common overmold material is a less rigid, more flexible material like thermoplastic elastomer (TPE) or thermoplastic polyurethane (TPU).

Overmolding requires compatible materials in order to form strong bonds between those materials. Chemical bonds can exist between some material combinations and because of this, they are joined via the interdiffusion of the molecules, particularly when utilizing a second mold for added strength.

Design Considerations for Insert Molding

Insert molding is a process that should be handled with caution considering a number of design elements that influence the quality of the part and molding efficiency. The insert molded part positions and orientation in the mold must be accurately governed, potentially enhanced by cnc machining, to allow good flow of the plastic within the mold and to be totally engulfed.

The thickness of the wall towards the insert is also important to have the stress concentration and, also to have a good flow of material. Lack of adequate also thickness may cause weak points or porosity and excess thickness may produce sinks or slower cycle time. The best industry standards advise keeping the wall thickness uniform and draft angles wide enough to allow proper ejection of parts.

This is because the geometry of the insert itself has to be molding friendly. Such features as undercuts, sharp corners, or intricate shapes are able to hinder the flow of plastic or even form the stress concentration. Several inserts are knurled or have some other mechanical texture so as to enhance the adhesiveness to the plastic material.

In particular, venting considerations become of importance to insert molding since the insert may cause an air trap that results into incomplete filling or surficial defects. Good venting design allows air to move out of the way because it is being driven into the mold cavity by the plastic.

Overmolding Design Best Practices

Overmolding design involves depending on the subtracted and the overmold materials, but also on the behavior along the interface. The substrate design should also do justice to the plastic mold and overmold material in that it should withstand the process up to its desired structural properties.

Overmold and substrate The interface design plays an essential role in ensuring tight adhesion between substrates and overmold materials. Undercuts, grooves or textured surfaces in the perimeter of the mechanical interlocking apply are capable of considerably adding bond strength. The shape of those features should be well thought out in order to have the adequate material flow and sufficient mechanical retention.

When overmolding of a part is performed problems arise regarding the positioning of gates and to design the flow path because one would need to fill around or over an original existing substrate. Overmold material should flow freely without forming of weld lines or air trap; this would affect part quality and aesthetics.

Thermal consideration can especially become relevant in overmolding because over heating of the substrate should occur at the right temperature without degrading the already molded matter. Successful overmolding processing windows in general tend to be narrower than with successful single-material molding processes.

Production Speed and Efficiency Comparison

Insert molding and overmolding may differ in terms of cycle time, which has a big impact on efficiency and overall cost of manufacturing. The cycle time of insert molding is usually faster as a result of being a one-shot process, however, insert inserts and treatment may require a long time hence decreasing this advantage.

To increase efficiency in high-volume insert molding work, automated insert placement systems may be used, however; they demand further capital investment, and are more complex. Insert placements are more flexible and time-consuming and thus more applicable in low-volume applications or complicated insert geometry.

The cycle time usually has to be longer because there is going to be repeated injection and also because there are going to be very tight timing requirements between shots. Nonetheless the secondary assembly processes that are eliminated can be used to counter the extended cycle times of the molding process especially when in applications where complex multi-material assembly is needed.

The production efficiency is also influence by quality control considerations. Insert molding systems generally need to have insert locations and orientations verified, whereas overmolding systems need material bonding and interface to be checked. Inline quality monitoring system is beneficial to both processes; to track key issues that may be misinterpreted to other parts.

Industry Applications and Use Cases

Insert molding has the widespread application, particularly in other industries where there is the need to combine metal parts with the plastic boxes or structures. Automotive uses are seen as dashboard assembly, door handle and other under-hood assembly, where the metal insert would offer strength and versatility and where the plastic would offer cost effective manufacturing and production flexibility.

The electronics industry will use insert molding almost exclusively in the production of connectors, switches, interface connectors, card edge connectors, and other products which need metal contacts or structural details. It allows production of hermetically sealed-based assemblies that isolate delicate electronic parts to the environment.

Insert molding has been used in the manufacture of medical devices in the medical industry : Surgery instruments, diagnostic medical devices, implantable devices where metal properties and the plastic compatibility are crucial. The process facilitates its performance with high guaranteed reliability and also adherence to the high standards of regulations.

The applications of overmolding dwell on the products that need multiple material properties in one part, including various molded parts . The tradeoff of hard structural parts and soft comfortable surfaces designs are applied to consumer products, including rubber handles, tooth brushes, hand tools, and the bodies of electronic devices.

Overmolding is common in auto interiors to make parts have hard structural pieces with soft touch surfaces. This allows forming complicated shapes that would be hard or impossible to form by assembling different parts.

Quality Control and Testing Methods

Insert molding and over molding both need individual quality control measures to maintain constant part quality and performance. The quality assurance of insert molding is based on the accuracy of insert placements, having the plastics successfully fill the mold, the bond strength between the material, and the choice of manufacturing techniques.

The forms of non-destructive testing to be applied in the insert molding process are visual testing, dimensional testing and functional testing of the assembled part. Destructive tests can comprise destruction by pull-out to check bond strength and a cross-sectional examination to check the plastic-to saucer interface.

In overmolding quality control is more complicated because of the various materials and interfaces in the production. Testing on bond strength of substrate and overmold materials is paramount in part reliability. Peel tests, tensile tests, and environmental stress testing are some of the adhesion testing methods, which are implemented to test the long-term performance.

Both processes need to have their material property verified, such as stating the material composition, mechanical property, and thermal property. More sophisticated tests, such as dynamic mechanical analysis (DMA), and differential scanning calorimetry (DSC), can however give in depth material characterization information.

Future Trends and Technological Advances

Advances in insert molding and overmold technology grow and increase their uses. The sophisticated materials progression process is making it possible to create combinations of qualities, including soft seals, and functionality factors, which could not be previously established.

Both processes are becoming more efficient and consistent through automation and the usage of robotics. Increasingly sophisticated, low-cost automated insert placement systems based on vision guidance and force feedback are now available to medium-volume uses.

The real-time monitoring and control of the molding processes were possible through the Industry 4.0 technologies, which allow improving quality consistency and minimizing wastes. Through data analytics and sensors, variations in a process could be noted and can be used to optimize parameters of production and determine how to predict the necessity of maintenance.

There is a movement toward bio-based and recyclable material as a consideration of sustainability in both insert molding and overmolding. Capacity to turn out long-lasting, multi-material components with no neglect of environmental responsibility is gaining prominence among manufacturers.

Conclusion

Insert molding and overmolding selection is based on individual application requirements, production quantity, cost analysis and performance requirement. Insert molding has the advantage of being very easy, economical and of short cycle; it is suitable in cases that need integration of metal and plastic with simple geometry, often utilizing an injection molding machine . Overmolding is more versatile in design and combinations of properties and materials, and is thus appropriate in more complex multi-material applications than using two-material injection molding, required at higher costs and longer cycle times.

Knowledge on the technicalities behind both processes, design consideration features, and application requirements helps the manufacturer to make informed decisions, which will optimize product performance as well as regulate the cost of production. Even more capabilities and applications with these technologies are ahead in the future through their further development.