Learn how to master the injection mold drafts angles in a 2024 ultimate guide. Study how to calculate, material factors and ideal practices in achieving a perfect ejection of the part in addition to manufacturing cost reduction.

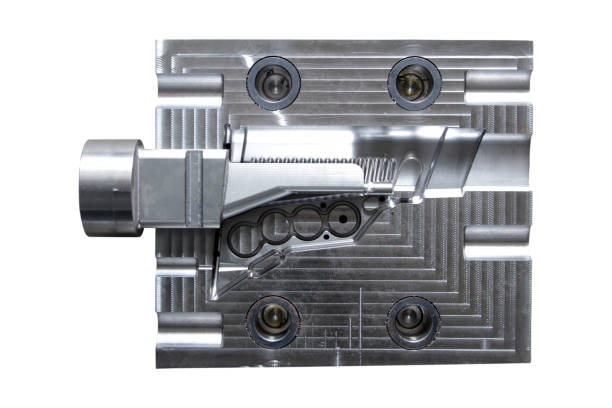

Injection molding is one of the most common procedures in the injection molding process that are used to manufacture injection molded parts. and the draft angles are very important in the process of designing molds. Draft angles signify the small slope that is put on vertical walls on molded pieces, often using a single draft angle which makes a removal of the piece easier in both the cavity and the mold hole without destroying the part or the mold in it.

What is Draft Angle in Injection Molding?

A draft angle is a geometric aspect which implies giving the vertical surfaces of an injection molded element a little slope. This taper in degrees to vertical axis ensures that during the mold release actions and ejection of the part form the mold, the part releases and slips smoothly, contributing to successful part production . Improper drafting of the angles may lead to the part adhering to the mold wall leading to surface blemishes and high eject needs as well as damages, which may affect both the mold and the part.

It is clear that underpinning the draft angles is the shrinkage properties of injection molding materials and thermoplastic materials, particularly at various mold depths . Once an amount of molten plastic has been poured into the mold cavity and has cooled and solidified, it shrinks somewhat binding it more firmly to the walls of the mold. Dry draft angles rectify this contraction and they also allow the appropriate clearance in ejection of parts, potentially requiring an additional degree of angle .

Understanding the Physics Behind Draft Angles

Quite a number of physical phenomena underlie the science of draft angles that runs through the course of injection moulding. Plastic material when placed in a mold cavity is heated and injected filling the mold cavity, then cooling off, which is essential for a high quality production process . It is because during this cooling process the material experiences dimensional changes as a result of the thermal contraction process which may result in the part fitting into the walls of the mold depths tightly.

Resistance is originated by the friction between the cooling plastic and solid cylindrical mold surface which must be defeated in order to complete the ejection. This friction may cause deformation of parts or scratches on the surface or even total failure of parts if one does not properly incorporate draft angles. This friction is well minimized by the draft angle in the correct draft direction because it generates a wedge-like shape that establishes ease of release.

Standard Draft Angle Requirements

In typical practice, the draft angles utilized by the designers on injection molded parts are 1.5 to 2 degree draft as the mold depth does not exceed 2 inches by general rule of thumb a one degree draft at one inch of cavity depth. But these standards depend a lot on the properties of materials, injection molding cost, features of parts, and manufacturing capabilities, which should be considered when design draft angles .

Design can be done with 0.5 of degree of draft, or even as low as 0.25 degrees that is better than none. The minimum acceptable draft angle varies with a number of factors such as material choice, complexity of parts, and metal sliding capabilities, typically not less than half a degree, as even this is better than no draft .

In the greater majority of applications, including the cooling time, the guidelines below are standard:

- Elementary geometries: minimum 0.5 to 1 degree

- Complex geometries: minimum 1-2 degrees

- Deep cavities: 1 to 2 degrees per inch of depth

- Surfaces: more draft on the basis of the texture depth

Material-Specific Draft Angle Considerations

The rates of shrinkage and release rates of the various thermoplastic materials differ, and this directly affects the draft angle that is needed, particularly concerning wall depth . Sweeter materials, such as PLA, might need a draft angle of perhaps 1-2 deg round, whereas harder materials, such as ABS, might respond to a bigger angle (2-5 degrees) depending on where thermoplastic material occurs .

The draft angles can be smaller, i.e., 1-2deg on softer materials as compared to stiffer materials where generally a 3deg angle is necessary or more, in order to enable ease of mold release without compromising the part. Such dispersion happens due to the difference in the material coefficient of friction and shrinkage tendency, especially when designing for deeper or larger parts .

The crystalline-based polymers such as nylon and polyethylene normally have larger draft angle since they shrink at higher rates whereas amorphous- type polymers such as polystyrene and ABS can perform with smaller angles. The melting flow property and the recessed surface features and glass transition temperature of the material also determine the best angle of the draft.

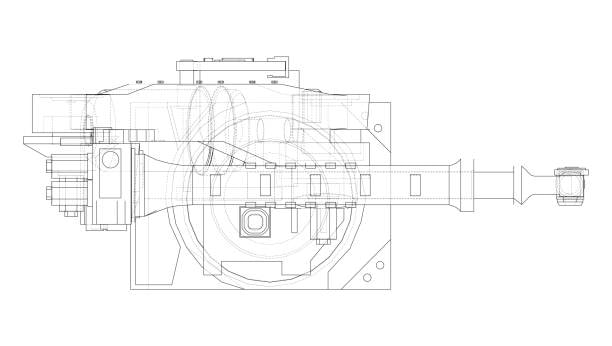

Calculating Draft Angles for Your Parts

One of the guide lines in the injection mold design is the cavity and core draft of between one and two degrees of cavity draft to each 25 mm (1″) or cavity depth. But it has to be correctly calculated to separate properly using a core cavity approach, taking into account numerous factors that are beyond measurements of depth.

Calculation formula The depth-to-angle ratio is the basic calculation equation, but needs to be varied to suit properties of materials, finish requirements and geometry complexity. Overall, it is suggested to add at least 1 degree of draft per inch (2.54 cm) of mold cavity depths, especially when utilizing cnc machining .

In more practical application, engineers can resort to simulation program to calculate the ideal draft angle with reconsideration of shrinkage rates, cooling preference, and characteristics of ejection forces. This method of computing gives more accurate results compared to use of simple rule of thumb calculations, particularly when dealing with a zero degree draft angle .

Impact of Wall Thickness on Draft Requirements

The wall width is essential towards regulating special draft angles. The molding process requires thicker walls to keep the heat longer resulting to more shrinkage and more friction with the molds. On the other hand, thin walls cool faster and perhaps they do not need as much draft angle to complete a successful ejection, a point best evaluated by injection molding specialists .

The degree of correspondence between wall thickness and draft angle is not linear however; other characteristics like material properties along with geometry has an effect on optimal angle. In general, components that have a consistent wall thickness will have a nearly uniform angle of draft and components that require different wall thickness may need local draft angle corrections.

The military issue can also be a sink mark or warpage on thick sections of a part not designed with enough draft angles. Such flaws may affect not only aesthetic but also the functional quality of the final piece, especially if it is just one component .

Surface Finish and Texture Effects

Draft angle specifications also depend largely on surface finish and textures. The more texture one wants, the more the angle of draft one needs, particularly considering the surface depth . An excellent guideline concerning design: 1.5 degrees of the draft per 0.001in of texture depth.

Polished, smooth surfaces do not need substantial draft angles where as textured surfaces should have a higher angle to cover the bigger surface area and extra friction. Other more widespread textures are leather grain, wood grain, or geometric patterns, which require different draft angles depending on depth and direction according to the grains.

Method of application of texture also influences draft requirement. Different surface characteristics are made by chemical etching, EDM texture and laser texture respectively, and vary in the best decision of the draft angle when one needs to incorporate draft .

Draft Angle Guidelines for Ribs and Bosses

In rib structures normally the draft angle is kept in the range of 0.25 to 1degree, though ensure that the top dimension does not go below 0.8mm. Ribs and bosses are rather problematic to injection mold: they are protruding, and may induce undercuts draft angle injection molding.

There is a wide range of draft angle to be considered in ribs so as to avoid sticking and facilitate ejection injection molding project. Draft angle of ribs The draft angle of ribs is usually used on the inside and outside faces of a rib, and the angle may be a smaller than the main part walls, because of the shallowness of the feature.

Bosses are elevated cylindrical protrusions and the internal and external surfaces do need draft angles. The drafts in boss and un-boss inner surfaces of one metal mold component may be required to be higher than in the exterior surfaces since there is more friction in ejection select few soft materials.

Common Draft Angle Mistakes to Avoid

There are several errors that occur commonly in draft angle design, one is the insufficient angle applied to deep cavities. The oversight may result in the part sticking, surface defects and high manufacturing costs. The other common mistake is the inability to apply the draft consistently where there are different sections within the part.

The angles required to make the internal features like holes, slots and recesses draft are also not taken into consideration by the designers sometimes. Such features have the potential of causing serious ejection problems when not drafted right especially in deep or complicated geometries.

It can also be a problem to fail to note the machining parting line when specifying draft angles. Parting line separates part into some sections of the molds, and on each side of the line, draft angles should be provided accordingly.

Optimizing Draft Angles for Cost Reduction

Using the right draft angle can save the manufacturing cost (better cycle time, lesser tool wear and lesser scrap). Components exhibiting proper draft angle eject faster, cutting on the cycle time and making production efficiency efficient.

An inadequate draft angle may result in amplified ejection forces that may lead to premature wear of ejector pins as well other mold parts. This abrasion multiplies the costs of maintenance, in addition to the compilation of downtime in the case of repairing the mold.

The draft angles and associated part quality is a special consideration in terms of high volume production runs, in which the features may have a huge cost benefit even with minor cycle time/scrap decreases.

Advanced Draft Angle Techniques

In order to deal with complex geometries, complicated draft angle methods might be needed. Variable drafting is a process of using various angles in separate parts of the same object and making the perfect use of each dent.

Step draft: step draft creates draft angles of numerous angles on the same surface that can be used in components that are needed in different shallow depths. The method enables the best application of draft and critical dimensions in certain regions.

In some instances reverse draft (angle sloping inward instead of outward) may be used due to functional requirements, but must be analyzed carefully with regard to ejection mechanisms..

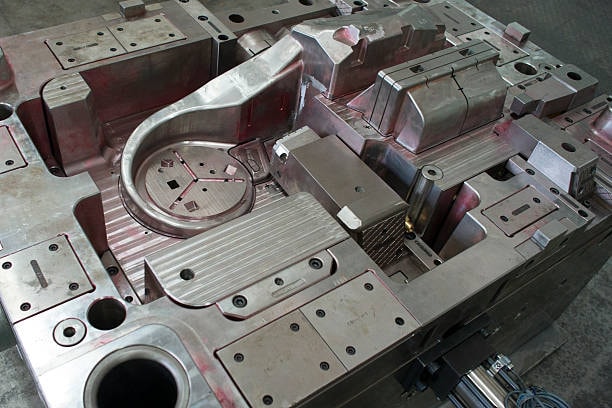

Mold Design Considerations

There is one more factor that greatly affects the draft angle requirement, and it is the design of the mold. The application of draft angles depends on the side-action molds, lifter mechanisms and the complicated parting lines. Interaction between various mold faces can also be taken into consideration in the determination of best draft angles.

Draft angle requirements are also influenced by design of the ejection system. The kind, size as well as positioning of ejector pins will determine the degree of draft angle required to make a part release successful. Well designed ejection systems may mitigate the loss of draft angle in key locations in some cases.

Quality Control and Draft Angle Verification

Quality assurance in the manufacturing process entails measurement and checking of president angles in drafts in order to ensure quality of the parts. The draft angles can be measured using the various techniques and instruments such as crude mechanical gauge to more complicated optical gauges to check draft.

Routine checking of draft angles will enable the detection of any problem in good time avoiding the occurrence of expensive problems. The variation in draft angles as a production routine can reveal the signs of tool wear, thermal defects, or other problems that should be addressed during the process, especially in light of complex part ejection requirements .

Industry-Specific Draft Angle Applications

The different industries possess different demands in terms of draft angles in the light of their performance requirements. It can commonly take small draft angles on automotive parts that must be able to fit and finish precisely, whereas consumer goods may be able to have larger draft angles to better work in production.

The components of the medical devices also usually require a lot of considerations concerning the draft angles, as far as the high requirements of the regulatory standards and the efficiency of the dimensions are concerned. Housings in electronics frequently require a trade off between draft angles and the demands of Electromagnetic Interference shields.

Future Trends in Draft Angle Design

Sophisticated simulation software is simplifying the task of optimizing draft angles when this is required on an application-specific basis. Machine learning to forecast the best drafting angles basing on material characteristics, part characteristics, and the manufacturing conditions is a developing machine learning algorithm.

New additive manufacturing helps creating mold inserts for injection molding metal , allowing variable draft angle and complex structures that were hard to impossible to produce in the past.

Troubleshooting Draft Angle Problems

The typical issues in the draft angles in the common drawing issues are part sticking, surface-related issues, and dimensional differences. To determine the cause and effect of these problems with integral components, the part design, the metallurgical properties of the material, and the manufacturing process must be analyzed in a systematic way.

The draft angles problems can present solutions in the form of change in design, material change, or change in process. There are other instances, when complex issues with the draft angle may require several ways to be addressed completely.

Best Practices for Draft Angle Implementation

Implementation of different draft angles is a success when put in consideration during the design stage early. The necessity to cover draft angles at the early stages of designing helps to avoid the need of redesigns of the construction in the further development.

Trade relations between design engineers, mold makers and manufacturing personnel have to include communication concerning the best angle of draft. Each of the stakeholders is having their own perspective and needs which are to be considered in equilibrium in the final design.

Conclusion

The draft angles are the core element of an effective injection molding procedure which affects the quality of parts directly, efficiency of production processes and the cost. An awareness of the principles involved in selecting the draft angles and a proper application of the same can make a great deal of difference in terms of moldability of plastic component and diminish the potential difficulties of manufacturing.

Draft angle design is the pivotal point that requires one to consider various aspects such as material properties, part geometrics, surface finish requirements and manufacturing limitations. With defined guidelines in mind, yet looking at the requirements of the application in question during the design process , designers can find the best angle drafts to work with not only in terms of functionality but also manufacturability as well.