Meta Description: Find out the major distinctions between FDM and SLA 3D printers, particularly in the context of fused deposition modeling vs stereolithography . Compare prices, materials, quality, and applications and find an ideal 3D printing process to use in the manufacturing of your products.

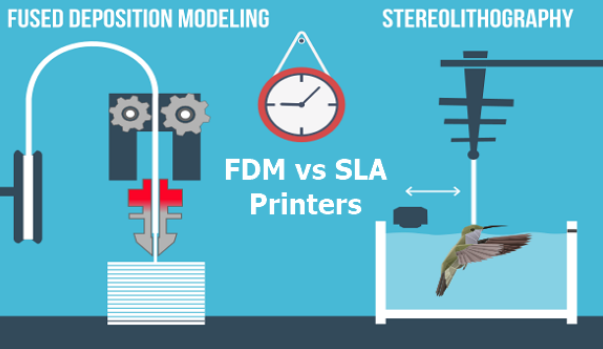

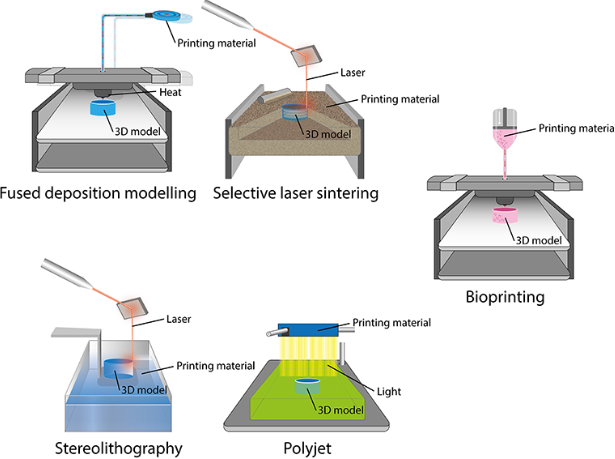

Additive manufacturing and prototyping have transformed the manufacturing industry and Fused Deposition Modeling (FDM), often referred to as fused filament fabrication, and Stereolithography (SLA) have been the most popular types of 3D printing that manufacturers are embracing in order to facilitate the production process. Both of them appeared in the 1980s, but use very different methods to make 3D objects, each having different advantages in different uses and needs.

The differentiation between these technologies is vital information to the business, engineers, and the manufacturers who are aiming at streamlining their production processes. Do you want to develop prototypes, generate parts at the end-use, or explore a rapid manufacturing application solution? Deciding whether to use FDM or SLA may have a profound effect on the destinies of your project, its schedule, and costs.

Understanding Fused Deposition Modeling (FDM) Technology

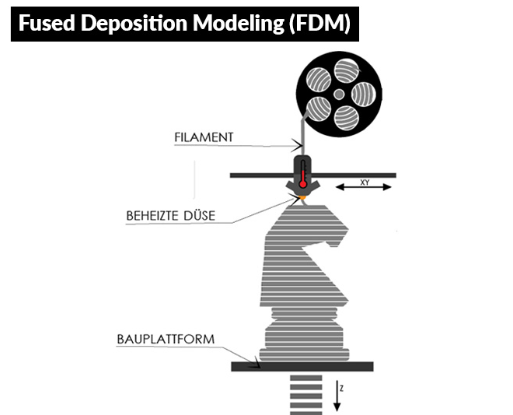

The Fused Deposition Modeling, invented by Scott Crump and commercialized by Stratasys, works on a rather a simple principle of a complex hot glue gun, unlike liquid resin used in SLA laser beam. Thermoplastic filament will be fed into a hot extruder (temperature ranges between 180-400 C (depending on the material)). This molten plastic is then placed with accuracy on a nozzle onto a build platform and forms thin sheets that harden and cool quickly.

Layer by layer, I go in an extruder which moves in the X and Y directions to form each horizontal cross-section of part. After one layer has been completed the build platform descends by one layer, and this is repeated until the whole object is built. The complex geometries that can be achieved with this vertical construction direction along the Z-axis are a big advantage, especially when considering layer thickness; however, overhanging details usually insist on support structures that can be detached.

FDM uses the same type of thermoplastic materials, including various filament materials, as molding ABS, PLA, PETG, or TPU offering an extraordinary material compatibility once compared to the traditional manufacturing methods. The easiness of accessing and its reliability has caused the technology to be the most popular way of 3D printing in the world specifically in education, small companies and in prototyping.

Understanding Stereolithography (SLA) Technology

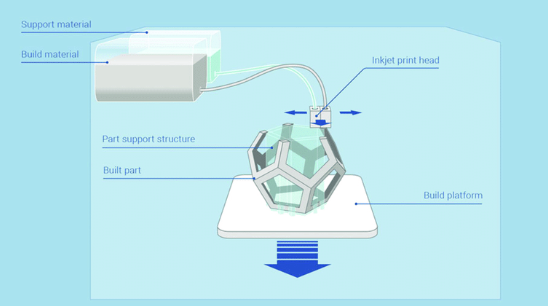

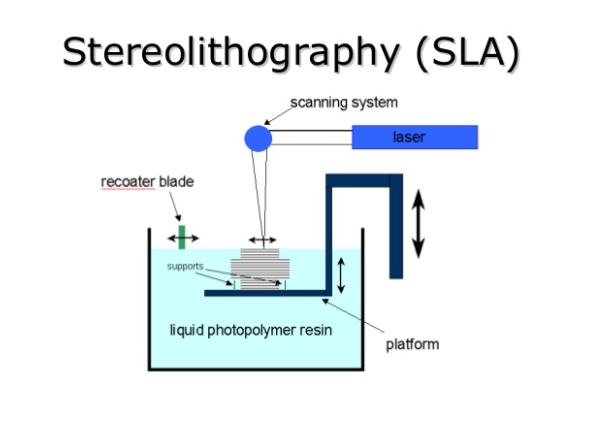

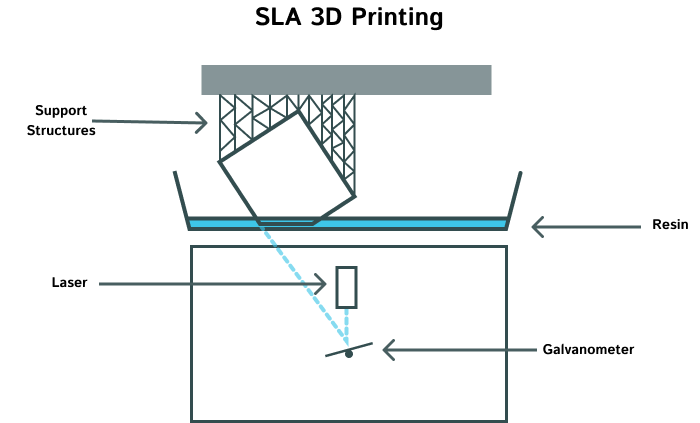

One of the first 3D printings is stereolithography that uses the process of photopolymerization to produce very detailed pieces using liquid resin. It starts by a vat of liquid photosensitive resin usually with photoinitiators which respond to certain wavelengths of light fdm machines. To cure the resin a high-precision laser or DLP (Digital Light Processing) projector is used to selectively expose the UV light in predetermined areas.

The build platform will be at the level slightly below the resin surface and with every layer being cured, the platform will be lowered to permit the next layer formation. UV laser system is very accurate and steered using galvanometer mirrors so High resolution detail is possible and products with features down to 0.0025 inches (0.0635mm) in diameter can be realized. Such accuracy also qualifies SLA to be used in areas that demand a complex shape and surface finishing.

The current systems of SLA use multiple strategies such as top-down laser scanning and bottom-up projection. Another type of the light propagation, the bottom up, has seen an increased use because light is propagating through a translucent vat bottom, allowing large parts to be printed without diminishing the resolution of the entire build volume.

Material Comparison: Thermoplastics vs Photopolymers

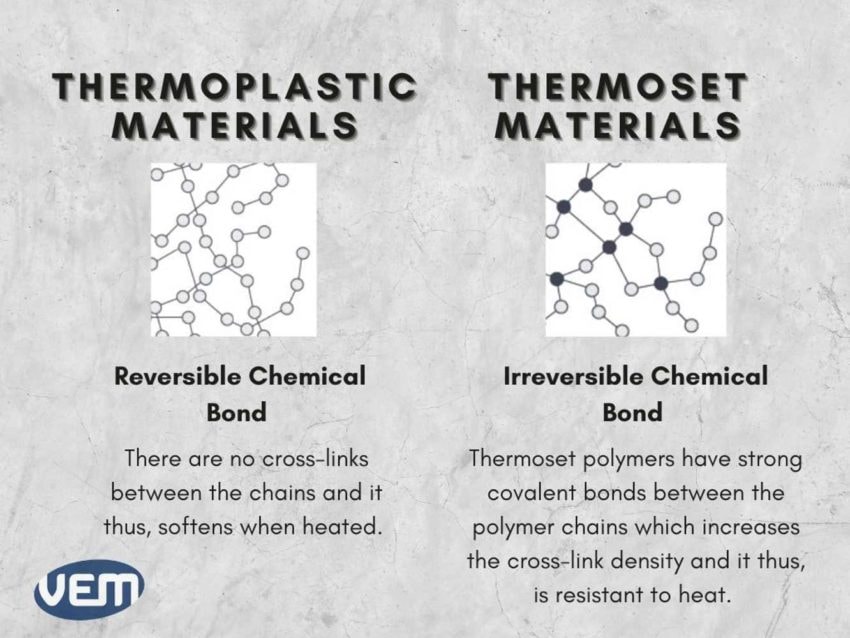

The basic distinction between raw materials of FDM and SLA have great repercussions on respective applications and performance parameters of the two methods. FDM uses thermoplastic filaments that melt and can be then molten and cooled numerous times without the loss of vital characteristics. Commercial FDM plastics comprise Polylactic Acid (PLA) in general-purpose printing, Acrylonitrile Butadiene Styrene (ABS) in durable applications and specialty material filaments such as carbon fiber reinforced composites in high strength applications.

SLA resins are considerably more expensive than FDM materials, which come in form of PLA or PETG, and the cost of filaments can generally vary between 20 and 50 dollars per kilogram, so FDM is notably cost-efficient in the case of less demanding, larger products and large run omission. This also includes the material variety in engineering grade thermoplastics such as PEEK, PEI and more filled composite materials characterized by certain defined properties such as chemical or temperature resistance or improved mechanical properties.

In SLA, thermoset photopolymer resins are used in which the chemical quality is irreversible and during curing process. Although this reduces material flexibility in comparison to FDM, currently existent industrial SLA resins are very diverse, with such types as general-purpose resins used to create prototypes, tough resins used in functional demos, flexible resins with rubber-like properties, and dedicated resins such as dental, jewelry, and industrial resins. The prices of SLA resin begin at about $50 per kilogram and it goes significantly higher depending upon the type and quality of the resin.

There are special material qualities available, not possible with thermoplastics, due to the chemical nature of photopolymers, including transparent resins used in optical applications, biocompatible materials used in medical equipment and castable resins used in investment casting techniques.

Print Quality and Resolution Differences

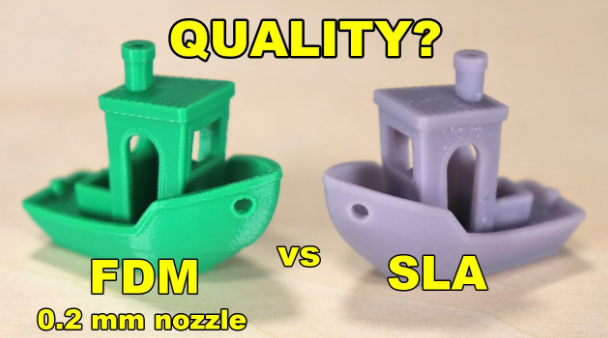

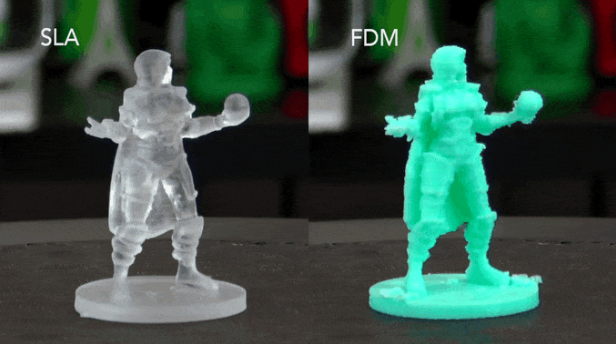

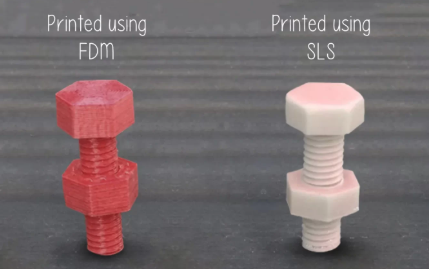

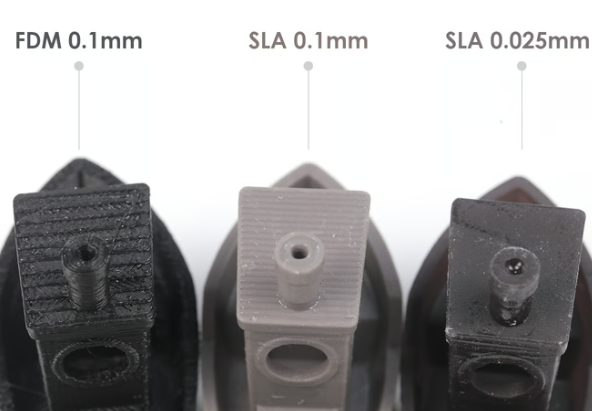

One of the most crucial separations between the FDM and the SLA technologies is the print quality, especially in producing intricate details . SLA is always associated with precise surface finish, dimensional accuracy, quantity, and reliability, because of layer-by-layer photo polymerization mode. Solvent-based Layer heights reach a fine line of 0.01mm (0.0004 inches) allowing near invisible layer lines and extremely smooth surfaces which often do not need much post-processing.

The accuracy of SLA is on the fact that not a layer of material is deposited via the moving nozzle but cured. This and many factors that may influence the quality of print in FDM like fluctuation in nozzle temperatures, filament quality, mechanical vibrations are removed during this. This produces parts of superior dimensional geometry and the capability of capturing fine detail as well as text, logos, and complex geometry.

Print quality of FDM is highly affected by layer height, nozzle diameter, speed of printing and the properties of the material used to print. Although some of the most recent FDM printers have an ability to do lower than 0.1mm layer height, the physics of material deposition makes layer lines and overall machine look of any curved surface look like steps, a characteristic of FDM. But the recent development of FDM technology such as on-the-fly layer heights and motion control systems have greatly improved how well things print surface detail.

Compared to FDM SLA parts are also weaker. This is because photopolymer mechanical characteristics are inferior to those of the thermoplastics used in FDM, but higher surface quality and smooth surface finish often causes SLA to be the choice of visual prototypes and, especially fine-detail, parts chemical bonds.

Cost Analysis: Equipment and Operational Expenses

Initial cost of 3D printing machines both with FDM and SLA types is considerably different. Of entry-level FDM printers, the minimum price is $200-500, and stocks the professional grade systems start with an amount of 2,000 to 50,000 and so on. Prices for desktop SLA printers start at approximately $1, 500-3, 000 and continue with industry machines ranging between $10, 000 to half a million relying on development volume and features.

Operational expenses do not only cover the cost of original acquisition of equipment but also the costs of consumables, maintenance and facility needs. In general, FDM systems are less complicated, and they need filament swap and nozzle cleaning at times. Most FDM printers are open-material, which allows buyers to access many suppliers of filament to spur competitive pricing and innovation of materials.

SLA systems also use more consumable materials such as resin tanks, release films and cleaning solvents resulting to increased costs of operation. SLA printing process needs additional devices. The recommended items are protective gloves to use to handle the resin with, solvents to wash away excess resin and seen to avoid the fumes, and masks/ventilators to avoid them. The wash stations and the UV curing chambers to be used as post-processing equipment are also needed and are represented as another investment to reach the optimal work of the SLA.

The cost of labor is not the same between technologies either, the SLA parts need a lot of manual labor in term of cleaning, removing the support, and curing parts which would take much more time when compared to the FDM parts, which would not need much post-processing to be used as functional prototypes.

Throughput and speed considerations Speed The speed, measured in both directions, remains a repeated concern of several of the same software applications that were used to achieve the throughput. Speed is measured on the road in both directions to ensure that it is unidirectional only. Speed may be subjective to the character of several software applications as well as subjective to the amount of traffic on the road. Speed in both directions is repeated because there could be a variation in speed at one point and the other. Throughput The throughput uses the same software applications as those used in speed with the difference being that the software applications used in

Speed and Throughput Considerations

The speed of printing using SLA is highly influenced by the height of the layer used as well as the cross-sectional level of individual layers rather than the overall volume comparing fdm. This trait in turn makes SLA especially effective at printing many small pieces at once, since they can be positioned on the build platform without causing too much of a time drain. Nevertheless, tall features having small cross-sections can take longer to print on SLA because of the layer-to-layer nature.

Progression in technology in the modern age enhances the speed functionality in both of these technologies. The use of faster motion control and bigger nozzles on high-speed FDM systems and the newer acryloxypentaethylene-based SLA processes (like Carbon DLS (Digital Light Synthesis)) have made improvements by allowing faster deposition rates, and these newer processes readily support continuous printing patterns that substantially accelerate print times on some applications.

The throughput is greatly influenced by the time that must be taken during post processing and FDM models often do not have much time put in post processing time whereas SLA involves many steps, such as cleaning and curing processes, including managing support structures fdm printing .

Mechanical Properties and Durability

The difference in 3D printing mechanical properties between FDM and SLA is quite significant since these processes differ fundamentally in terms of materials and manufacturing process sla materials. FDM parts are anisotropic, that is, the strength properties of a part will vary depending on the particular orientation of the force applied relative to the layers. Parts in general are strongest at forces acting parallel to the layer lines or weakest when the forces are trying to create a separation between layers material properties.

ABS, PLA, PETG, or TPU thermoplastic materials involved in the molding process made available to moisture-wise versatile and enhanced mechanical properties material, freely at FDM. Most FDM materials can attain mechanic properties as near or equal to injection-molded components, especially when printed with the best orientations and settings material layer.

The SLA parts tend to be more isotropic as a result of the chemical cross-linked that take place in the process of the photopolymerization selective laser sintering. Nevertheless, they normally have reduced resistance to impact, particularly when exposed to UV radiation or higher temperatures, and may turn brittle with time. Cured photopolymers are in a thermoset state, and so cannot be remelted, or reformed, which reduces recyclability compared to thermoplastic FDM materials fdm filaments.

FDM has the better performance in long-term applications or functional purposes where printed parts are essential, as it is known that SLA has better performance than FDM in applications where high dimensional precision and surface quality is required though not extended mechanical capabilities same material.

Post-Processing Requirements

Post processing demands demonstrate to be a serious work process factor in the selection of the FDM and SLA procedures modern fdm printers. The parts made by FDM normally need little post-processing to make it functional with support removal the most important. The support can generally be manually eliminated after being printed on by hand or even low grade tools, complex shapes might want additional consideration to remove without damaging the part.

FDM Pro D uses sanding, vapor finishing or chemical work to smooth parts, depending on the desired finishing effect. The granular layer marks which are an effect of FDM can be reduced by means of post processing, but this increases both the time and effort into the whole process.

The processing of SLA has various obligatory procedures that make a big difference in workflow and requirements in a facility. Isopropyl alcohol or other cleaning agents should be used to conduct thorough cleaning of parts using isopropyl alcohol or special cleaning solutions, to eliminate uncured resin. The cleaning involves ventilation and the use of personal protective gear because uncured photopolymers could be harmful.

SLA parts are cleaned and finally cured with UV lights to obtain their desired mechanical characteristics. All of this is carried out in special UV curing environments that can take 15-60 minutes depending on part geometry and type of resin being cured. Removal of supports on SLA parts should be considered closely because there is a chance of the surface marks but supports are usually smaller and more refined compared to FDM analogs.

Application-Specific Use Cases

Selection of either FDM or SLA will usually be determined by the needs of a particular application and targeted performance. FDM is the most suitable where object prototyping, functional parts, end-use models, jigs and fixtures and low-cost rapid prototyping are needed. FDM is ideal suited to the requirements of such industries as automotive parts, consumer goods, tooling as well as educational products because of the variety of materials and mechanical qualities.

Compared to SLA printers, FDM 3D printers have large build volumes, and they are competent to undertake some limited-run additive manufacturing applications, which qualify them to produce larger functionality parts and assemblies. Some of the industries that commonly use FDM, besides as a method of prototyping, include aerospace, auto and industrial manufacturing.

The SLA has its strength in producing applications that require high precision, details, and the finish is smooth. The perfect use case of SLA is in manufacturing of jewelry, dental applications, fine scale modelling and precision tooling. This feature of the technology producing complex geometry and internal channels means it is useful in microfluidics, optical components and in architectural scale models that contain detail.

Industry Applications and Market Trends

Additive manufacturing market is constantly developing, with FDM and SLA technology used in a wider variety of applications in different industries. FDM assets are so superior that it leads consumer and educational markets with its affordability and the versatility of the materials that can be used; however, it also holds considerable shares in industries that demanded rigid and functional component parts.

Recent developments in the FDM technology have involved creation of high performance materials, which include PEEK and PEI used in aerospace products, continuous fiber reinforcement which is used in making structural part and large format which is used in architectural and auto industries. Public nature of most FDM systems has led to quick advancement and development of materials.

The SLA technology has been making progress and developments of specific formulations of resins by targeting potential industries including dental, jewelry, and automobile. Improvements in the high-speed SLA systems and increased build volumes are broadening the technology capability to production use that has been largely in the domain of the conventional manufacturing technique.

Both technologies are utilizing artificial intelligence and machine learning to increase the quality of print, mitigate failure, and the automated process optimization of parameters. All of these developments are making FDM and SLA more user-friendly to non experts and more reliable and highly performant too..

Making the Right Choice for Your Needs

The choice of FDM vs. SLA should be taken very carefully depending on the project needs, the budgetary conditions, and in the long-term goals. FDM would be the best of options in an application that would show cost efficiency, the use of variety of materials, mechanical based performance as well as ease of use. Organizations that have greater needs of larger parts, functional prototyping or production parts that are used are more likely to find the FDM more convenient to them.

SLA is chosen as the method of choice when workmanship like precision, smooth surface finish, and fine detail are of greater consideration than price and mechanical performance. The increased cost of operation is often offset by better outcomes and the lower need of manual finishing in applications that include jewelry, dental, miniature and precise tooling.

Most organizations have gained the advantage of making use of the two technologies in a complementary manner, using both FDM and SLA in different roles, with FDM in its utilization in functional testing and strong parts and SLA in its use in presentation models and fine work. The hybird technology combines the best parts of the two techniques and reduces to the bottom, the weakness of each technology.

Suitable expert availability, facility needs, and workflow integration should be taken into consideration in the decision too. The easier working nature and reduced post-processing requirements of FDM means that it is a better choice when dealing with organizations where you do not have dedicated technical personnel, but that the need to have proper ventilation, the ability to handle chemicals and multi-stage post-processing of SLA would mean that a training program would be necessary and that facility adjustment may be required.

Future Developments and Innovations

Both FDM and SLA technologies are swiftly developing, and some breakthroughs in materials, hardware, and software capabilities are likely to be observed in the future. The development of the FDM is based on the use of higher temperature materials, multi-material printing as well as better surface quality achieved by the enhancement of the motion control and the methods of material deposition.

SLA innovation focuses on an improved printing speed, increased build volume and new resin types focusing on industry and custom application. Advances in continuous printing techniques and use of AI to optimize manufacturing processes will further resolve most of the existing shortcoings and widen possibilities of applications.

The combination of additive manufacturing and conventional production technologies is on-going to generate hybrids in manufacturing that utilize the capabilities of various technologies. These trends indicate that in the future the FDM-SLA decision might not be as black-and-white, since integrated manufacturing systems will use both several additive and subtractive processes.

Innovation is also environmentally motivated, and both technologies are paying more attention to recyclable materials, energy efficiency as well as manufacturing sustainability. Such developments are bound to have effects relating to future elimination of technology choice since sustainability is becoming very important in the manufacturing choice.

Conclusion

No matter which 3D printing technology is used, whether FDM or SLA, the final selection is based on project-specific conditions, with a cost-benefit analysis being the crucial point. FDM is cost effective and has outstanding value in functional applications, even though some models may produce visible layer lines, with the availability of engineering grade materials and available build volumes with sensitivity to cost of use relative to both prototyping and manufacturing. It is highly user friendly and does not require many post-processing making it an ideal choice in organizations that are interested in having accessible additive manufacturing capabilities.

SLA is well suited to applications that require accuracy, fine detail and high surface finish to an extent that it is necessary to the jewelry, dental and precision manufacturing industry. Although demanding increased operation expenses and more complicated post-processing, SLA produces quality that is unsurpassed when such values as visual aspect, dimensional precision, and the effectiveness of the print bed are of paramount importance.