Computer numerical control (CNC) machining depends critically on G-code programming. Lathes, mills, and 3D printers are among automated machine tools run under this language. This programming language offers exact instructions defining how a machine should shape, cut, drill, or move materials. Engineers, machinists, and hobbyists operating these CNC programming machines must grasp G-code.

Understanding the Basics of G-Code

Control of CNC machines is accomplished using the standardized numerical control (NC) programming language G-code, sometimes known as RS-274. It comprises of a set of directions guiding the movement, speed, and activities of machine tools. Every command is written in a line of code usually beginning with the letter “G” then specifying a particular function with a number.

Key Elements of G-Code

- G-code commands specify activities like movement (G01 for linear motion, G02 for circular motion), drilling (G81), and positioning (G90 for absolute positioning, G91 for relative positioning).

- Usually operating in a coordinate system—typically X, Y, and Z for three-dimensional movement—CNC machines run on axes.

- Feed rate and speed define the tool’s rotational and moving speed (e.g., F100 for feed rate, S2000 for spindle speed).

- G-code lets one swap between several tools using commands T01 (Tool 1) and M06 (Tool Change).

- A well-organized G-code program consists in headers, setup instructions, execution steps, and an ending sequence.

- Machine-Specific Codes: Certain G-code commands may differ depending on manufacturer and type of machine, hence they call for customizing.

Different Types of G-Codes

Grouped according to its purpose, G-codes regulate CNC machines. The following are the primary varieties of G-codes:

1. Positioning Commands

These directives regulate the movement of the machine tool:

- G00: Quick positioning (rapid movement devoid of cutting)

- G01: Controlled straight-line movement – linear interpolation

- G02: Circular interpolation in clockwise direction

- G03 – Interpolation in counterclockwise circles

- G90: Absolute orientation based on a given origin coordinates

2. Speed Commands

These commands regulates spindle speed and feed rate:

- G08; G09; Change speed (increment or decrease)

- G93 through G95 – Choose linear feed units

- G96: Maintain continuous surface speed

- G97: Maintain continuous spindle speed.

3. Machining Operation Commands

These directives manage particular machining operations:

- G 81: Simple drilling

- G82: Dwelling drills

- G83: Deep hole excavating

- G84: Drawing on

4. Offset Commands

These codes change tool offsets:

- Tool offset values: G40 through G44

- G53 – G59 – Work coordinate offsets

5. Miscellaneous Commands

These instructions govern auxiliary tasks:

- G04: Dwell (a defined period pause)

- G61: Explicit stop mode

- G80 – G89 – Methodologies for process descriptions

How to Read G-Code Commands

Practice helps one to find reading G-code easier. Use these instructions:

- Identify the command letter.

- Codes “G” and “M” regulate machine running.

- G00, for instance, moves the machine quickly. G81 launches a drilling cycle.

- Identify the coordinate letters.

- X, Y, Z define points in space.

- X10, for instance, advances the tool to X = 10.

- Identify angular positioning letters.

- Rotation angles define A, B, C.

- An A30 turns the tool by thirty degrees.

- Identify speed-related letters.

- F regulates feed rate, S spindle speed.

- F200, for instance, establishes a 200 unit per minute feed rate.

- Add comments for clarity.

- Add remarks with semicolons (;).

- G01 X10 F100; go to X=10 at 100 speed.

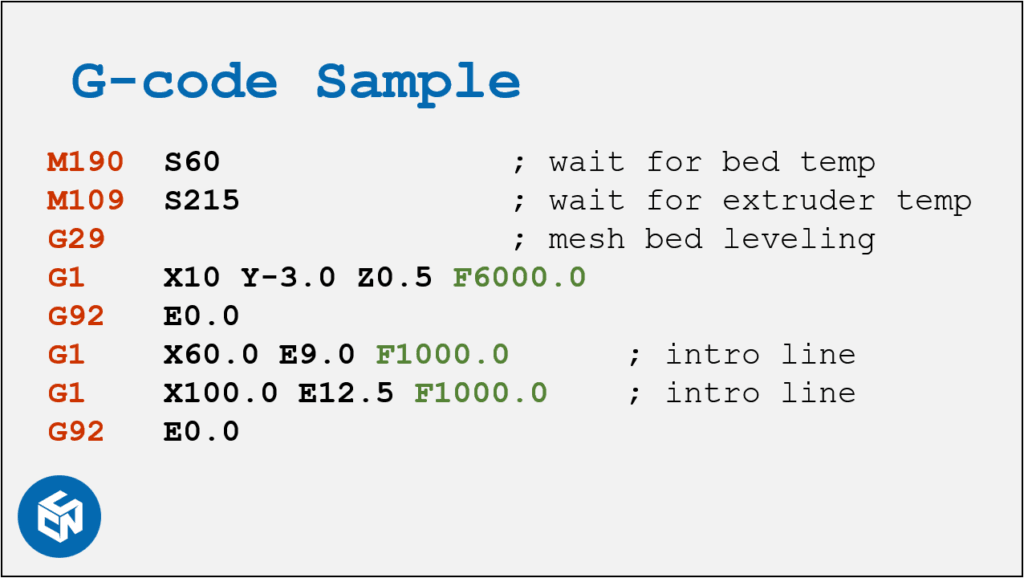

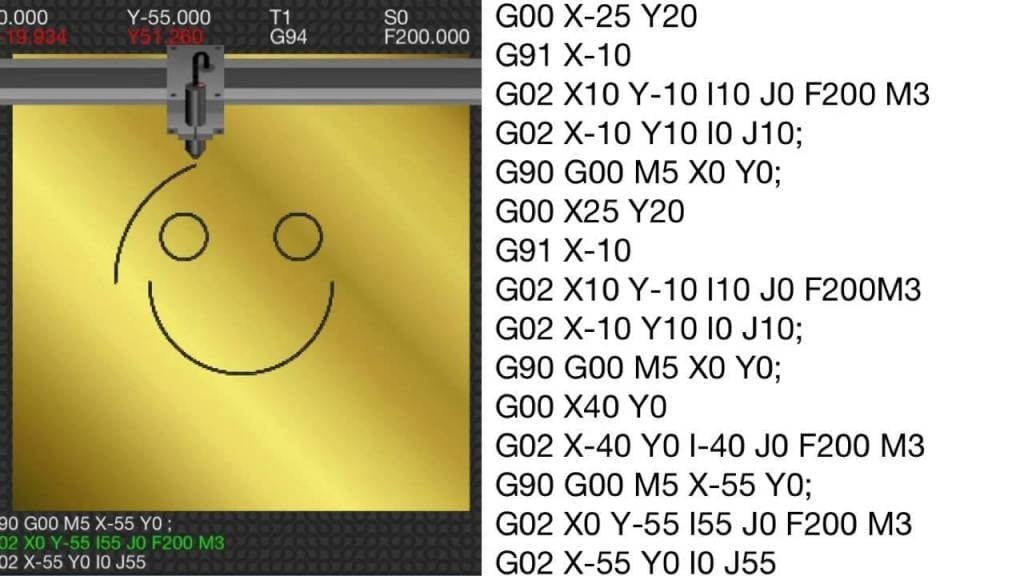

Example G-Code Program

Below is a simple CNC mill program to cut a 20mm x 20mm square:

G21 ; Use millimeters

G90 ; Absolute positioning

G00 Z5 ; Move tool 5mm above workpiece

G00 X0 Y0 ; Move tool to origin

G01 Z-1 F100 ; Lower tool 1mm

G01 X20 F200 ; Move to X=20

G01 Y20 ; Move to Y=20

G01 X0 ; Move to X=0

G01 Y0 ; Move to Y=0

G00 Z5 ; Raise tool

M0 ; Stop program

Each CNC machine may use line number or slightly different codes, but the structure remains the same.

Machines That Use G-Code

In CNC machining and 3D printing, G-code is extensively applied. Various machines apply G-code for different purposes:

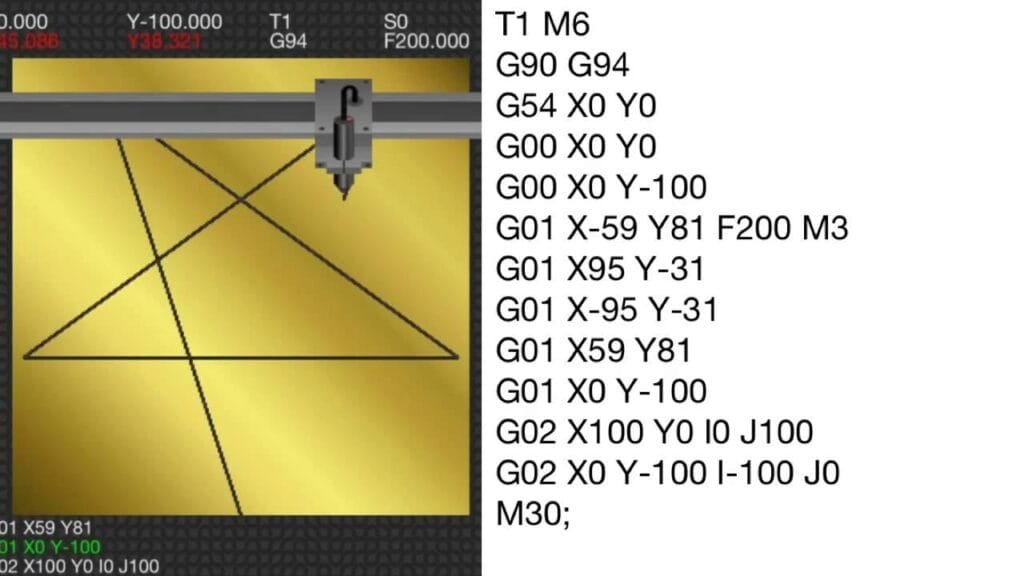

1. CNC Milling Machine

- Shapes materials using revolving cutting tools.

- Typically used in metal, plastic, and wood milling.

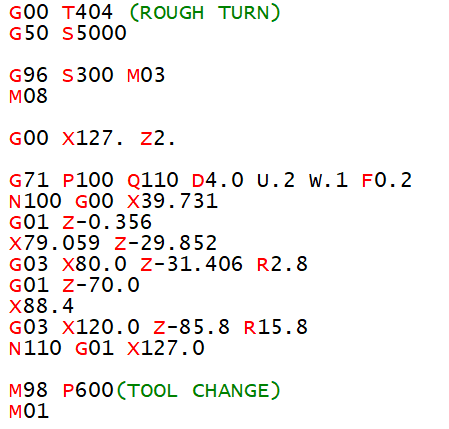

2. CNC Turning Machine

- While a cutting tool removes material, rotates the workpiece.

- Applied for conical and cylindrical pieces.

3. CNC Grinding Machine

- Finish fine surfaces with abrasive wheels.

- Usually a side operation following milling or turning.

4. CNC Drilling Machine

- opens holes with a revolving drill bit.

- For screws, assembly, or decoration.

5. CNC Routing Machine

- Mostly used for wood, plastic, and soft metals, this milling machine functions similarly to others.

- permits careful engraving and carving.

6. CNC Laser Cutting Machine

- chops items using a high-power laser.

- Not fit for plastics since they create dangerous fumes.

7. CNC Water Jet Cutting Machine

- cuts materials using high pressure water.

- Can precisely cut large objects.

Controlling these machines and enabling manufacture accurate and efficient depend on G-code programming.

Common G-Code Commands

Movement Commands

- G00, Rapid Positioning, moves the tool fast to a designated spot without cutting.

- G01 (Linear Interpolation) drives the tool straight ahead at a given feed rate.

- Move the tool in a circular motion either counterclockwise (G03) or in a clockwise (G02)..

Tool Control Commands

- M06, Tool Change: Turns the tool to the one indicated.

- M03, or Spindle On, Clockwise: Starts the spindle clockwise.

- M05, or spindle stop, pauses the spindle.

- Coolant on/off M08/M09 controls coolant flow for temperature control.

Drilling and Cutting Commands

- G81, or Simple Drilling Cycle, tells the machine to drill a hole at designated position.

- G83, the Peck Drilling Cycle, uses little increments to effectively remove chips.

- Based on a fixed origin, G90—Absolute Positioning—moves the tool to an exact coordinate.

- G91, relative positioning, moves the tool in line with its present position.

- G95, Feed Rate per Revolution, regulates the feed rate in respect to spindle speed for exact cutting.

How G-Code Works

G-code functions by instructing CNC machines via a computer or controller. Usually composed as a text file (.nc or.gcode), the program loads into the software of the CNC machine. After that, the machine reads the commands and carries out the intended operations, including 3D item printing or metal piece cutting.

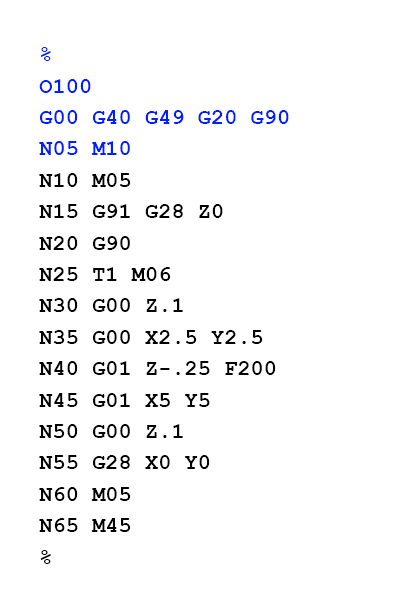

Example of a Simple G-Code Program

G21 ; Set units to millimeters

G90 ; Absolute positioning

M06 T1 ; Select tool 1

G00 X10 Y10 Z0 ; Move to position (10,10,0) rapidly

G01 Z-5 F100 ; Lower tool to -5mm depth at feed rate of 100

G01 X50 Y10 F200 ; Cut straight line to (50,10) at feed rate of 200

G00 Z10 ; Lift tool to 10mm

M30 ; End program

The Importance of G-Code in CNC Machining

Because G-code offers exact, repeatable, automated control over production operations, it is the backbone of the CNC machining process. Some main benefits are:

- Extreme accuracy in G-code instructions guides CNC machines toward high precision.

- Automation raises efficiency by doing away with the requirement for human operation.

- Customizing allows users to alter code to generate intricate forms and designs.

- Consistency guarantees homogeneous dimensions and quality of manufacture for parts.

- Continuous running of machines reduces manufacturing times and increases output by means of speed and productivity.

- Automating production lowers the possibility of human mistake and mishaps.

Applications of G-Code Programming

G-code finds extensive application in many different fields, including:

- Production of metal and plastic components for industrial, aeronautical, and automotive uses.

- In additive manufacturing, 3D printing involves layer-by–layer control.

- Using G-code, CNC routers cut and shape wooden components.

- Medical devices include exact surgical tools and implants.

- Prototyping is fast generating and testing fresh ideas for products.

- Making jewelry requires highly precise creation of complex designs.

Challenges and Limitations of G-Code

G-code has certain difficulties even if it is really useful.

- Complexity: Manual G-code writing can be error-prone and time-consuming.

- Many CNC users create G-code automatically using CAD/CAM software, hence there is a software dependence.

- Different CNC machines may have special G-code dialects that call for modifications.

- Mistakes in G-code can cause defective machining, which calls for thorough testing.

- Certain materials may call for specific G-code changes in order to guarantee appropriate cutting and finishing.

Who Needs to Know G-Code?

For CNC machine operators, G-code is absolutely indispensable. Although CAM systems may create G-code on demand, knowledge of it helps operators to optimize programs. Operators can fix machining problems and customize the code cad or cam software.

Learning G-code helps engineers, architects, hobbyists as well. Widely applied in 3D printing, it is thereby important in many different sectors computer aided manufacturing.

Best G-Code Editors

A number of applications enable G-code editing. Among the better free choices are:

- NC Viewer lets one see and edit G-code.

- Simple text editor with syntactic highlighting available from Notepad++.

- Popular for 3D printing G-code is cura.

- G-code QnDirty offers fast tweaks and improvements.

More sophisticated capabilities including simulation and optimization tools are provided by paid G-code editors m00 program stop.

Safety Considerations in G-Code Programming

Writing G-code calls for great attention to safety automatic tool changer. Bad directions can lead to tool breakage or crashes. To guard against problems:

- Find out the working limits of the machine.

- Add tools length compensations and axis offsets.

- Run a simulation on a machine first then run the code.

Difference Between G-Code and M-Code

Different facets of CNC machines are under control via G-code and M-code:

- G-code regulates speed, feed rates, tool location, and movement cnc machine programming.

- Handles auxiliary tasks including coolant flow, program start/stop, gear selection, and tool changes under M-code.

Why Is It Important to Know G-Code?

1. Understanding CNC Machines

CNC machines are operated upon by G-code, the language. Understanding G-code can allow you to grasp machine operation tool length offset.

2. Better Communication

Understanding G-code helps conversations whether you deal with machinists, programmers, or operators. When they reference CAM programs or machining problems, you won’t struggle cnc software.

3. Troubleshooting Issues

Examining the G-code will assist find flaws in a CNC machine when it breaks down. Knowing the end of program code enables you to examine and resolve unexpected machine behavior.

4. Improving Efficiency

Understanding CNC machine operation lets you design parts for simpler machining. Less operations, setups, and complicated geometries translate into reduced costs and faster output computer aided design.

List of G-Code Commands

Below are common G-code commands for CNC lathe and milling operations.

Fanuc G-Code List for CNC Lathe

| G-Code | Function |

| G00 | Rapid traverse |

| G01 | Linear interpolation |

| G02 | Circular interpolation (Clockwise) |

| G03 | Circular interpolation (Counterclockwise) |

| G04 | Dwell (Pause) |

| G09 | Exact stop |

| G10 | Programmable data input |

| G20 | Input in inches |

| G21 | Input in millimeters |

| G22 | Enable stroke check |

| G23 | Disable stroke check |

| G27 | Check reference position return |

| G28 | Return to reference position |

| G32 | Thread cutting |

| G40 | Cancel tool nose radius compensation |

| G41 | Tool nose radius compensation (Left) |

| G42 | Tool nose radius compensation (Right) |

| G70 | Finish machining cycle |

| G71 | Turning cycle |

| G72 | Facing cycle |

| G73 | Pattern repeating cycle |

| G74 | Peck drilling cycle |

| G75 | Grooving cycle |

| G76 | Threading cycle |

| G92 | Set coordinate system / Max spindle speed |

| G94 | Feed per minute |

| G95 | Feed per revolution |

| G96 | Constant surface speed |

| G97 | Cancel constant surface speed |

Fanuc G-Code List for CNC Milling

| G-Code | Function |

| G00 | Rapid traverse |

| G01 | Linear interpolation |

| G02 | Circular interpolation (Clockwise) |

| G03 | Circular interpolation (Counterclockwise) |

| G04 | Dwell (Pause) |

| G17 | Select XY plane |

| G18 | Select ZX plane |

| G19 | Select YZ plane |

| G28 | Return to reference position |

| G30 | Return to 2nd, 3rd, or 4th reference position |

| G40 | Cancel cutter compensation |

| G41 | Cutter compensation (Left) |

| G42 | Cutter compensation (Right) |

| G43 | Tool length compensation (+ Direction) |

| G44 | Tool length compensation (- Direction) |

| G49 | Cancel tool length compensation |

| G53 | Select machine coordinate system |

| G54 | Select work coordinate system 1 |

| G55 | Select work coordinate system 2 |

| G56 | Select work coordinate system 3 |

| G57 | Select work coordinate system 4 |

| G58 | Select work coordinate system 5 |

| G59 | Select work coordinate system 6 |

| G68 | Coordinate rotation |

| G69 | Cancel coordinate rotation |

| G73 | Peck drilling cycle |

| G74 | Left-spiral cutting |

| G76 | Fine boring cycle |

| G80 | Cancel canned cycle |

| G81 | Drilling / Spot boring cycle |

| G82 | Drilling / Counter boring cycle |

| G83 | Peck drilling cycle |

| G84 | Tapping cycle |

| G85 | Boring cycle |

| G86 | Boring cycle |

| G87 | Back boring cycle |

| G88 | Boring cycle |

| G89 | Boring cycle |

| G90 | Absolute positioning |

| G91 | Incremental positioning |

| G92 | Set work coordinate system / Max spindle speed clamp |

| G98 | Return to initial point in canned cycle |

| G99 | Return to R point in canned cycle |

These G-codes control CNC machines, guiding their movement, speed, and machining operations m code programming.

Future of G-Code Programming

G-code programming develops together with technology to:

- AI-driven CAD/CAM tools are simplifying the generation and optimization of G-code.

- 5-Axis machining expands CNC machine capability outside conventional 3-axis motions.

- Smart factories mix CNC machines with real-time monitoring and adaptive controls in IoT and automation machine instructions.

- Combining additive and subtractive techniques in hybrid manufacturing produces more effectively.

Conclusion

Anyone handling CNC machines, 3D printers, or automated machining systems must be able to write G-code. It guarantees exact control over manufacturing operations, therefore enhancing accuracy and efficiency. Although understanding G-code has its difficulties, machinists, engineers, and manufacturers will find much advantage in optimizing output manual tool change. G-code will always change as technology develops, hence it is becoming more and more important for contemporary design and construction.