Meta Description: Learn the main distinction amid low alloy steel and stainless steel, especially in their performance under high temperatures . Contrast materials, uses, prices, and capabilities to select the appropriate material to purchase in your work.

In the sector of metallurgy and production, the correct choice of steel grade is one of the important steps towards the success of a project. There exist two major groups that tend to confuse the engineers and manufacturers which are low alloy steel and stainless steel, along with their common alloying elements . It is imperative to understand their basic differences, corrosion properties areas of usage, and performance capacities when making good material selection decisions which subsequently changes functionality and costs.

Understanding Low Alloy Steel Fundamentals

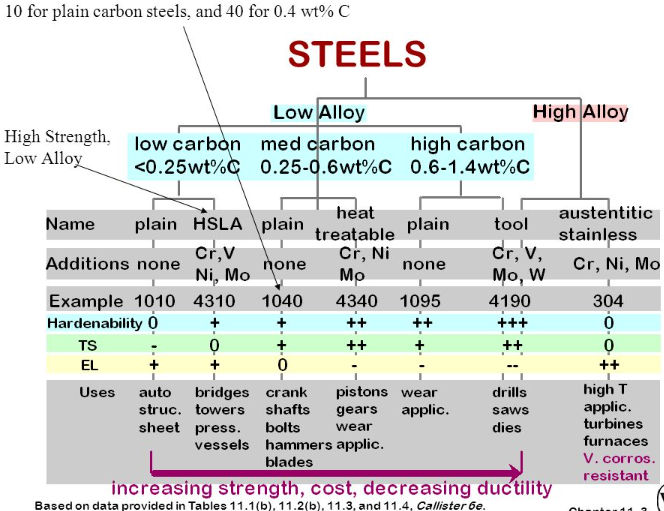

Low alloy steel, which can be compared to carbon steel’s mechanical properties, is simply a steel that has the alloying elements making up at the most 5 percent total mass of the steel. Such steel is also a major advancement in regard to plain carbon steel, and cost-effective at the same time. Mechanical properties, strength, toughness, and hardenability are improved through the judicious combination of many alloying elements, which qualifies the low alloy steels to be utilized in great applications within several industries.

The basic formulation normally consists of mainly iron, the carbon levels between 0.05 and 0.25 percent, and well chosen alloying agents chromium, nickel, molybdenum, vanadium and manganese. All the components bring in certain properties to the end product and this enables the manufacturers to customize the properties according to particular applications.

Stainless Steel: The Corrosion-Resistant Alternative

Stainless steel is a form of steel in which at least 10.5 percent by weight of chromium is added. This is a minimum amount of chromium in the alloy because it is the surface of the oxide that is deposited on the surface, where the quality of corrosion resistance is outstanding. The chromium forms a passive oxide layer that prevents the steel underneath it to rust and stain, as a result stainless steel can be used in conditions that comprise of a place where corrosive resistance is vital.

Other elements added to stainless steel formulations, besides chromium, tend to be nickel, molybdenum, titanium and others, depending on the desired performance characteristic (the steel needs greater strength, the steel needs to exhibit superior mechanical properties, be more ductile and resistive to certain lines of attack in a given environment). Exact composition, including stainless steel composition, differs substantially across different grades depending on the applications and performance expected of the grades.

Chemical Composition Differences

The basic difference with these materials is that of their chemical composition. Moderate amount of alloying elements are found in low alloy steel, and the combined volume of chromium will be less than 2 percent and volume of nickel usually non-existent. Typical alloying ingredients are manganese (0.5-2%), silicon (0.2-0.5%), and traces of molybdenum, vanadium or tungsten.

Stainless steel in turn needs a large amount of chromium and usually large amounts of nickel. The most widespread type, the austenitic stainless steels, has those quantities of chromium (17-25 %) and nickel (8-20 %). Such a radical variation in composition actually falls directly into extremely disparate attributes and performance characteristics.

Mechanical Properties Comparison

Most of the time, stainless steel is inferior to low alloy steel in terms of strength, toughness and hardness. Low alloy steel is especially influential in construction projects that require heavy loads bearing qualities, as well as in manufacturing automotive components because of its strength-to-weight ratio.

Ordinary low alloy steels obtain tensile strengths of 550 1,400 MPa, depending on grade and heat treatment. The strength in yield usually is 350-1,200 MPa and fatigue resistance and impact toughness are very good. Such attributes render low alloy steel applicable to instances of dynamic loading as well as stress cycling.

Though in general stainless steel does not supply as high absolute values of strength, its mechanical properties are sufficient in most cases. The typical tensile strengths of the standard austenitic stainless steels lie in the range of 515-750 MPa and their yield strengths also lie in the range of 200-350 MPa. But special grades of stainless steel grades are capable of attaining far higher degrees of strength on particular alloying and heating.

Corrosion Resistance Performance

The stainless steel is superior in resistance to corrosion compared to low alloy steel due to high levels of chromium that also form a passive oxide film. This excellent corrosion resistance, which includes extreme corrosion resistance, stainless steel means that stainless steel is favored in uses that involve direct contact, or exposure to, moisture and chemicals or other corrosive situations.

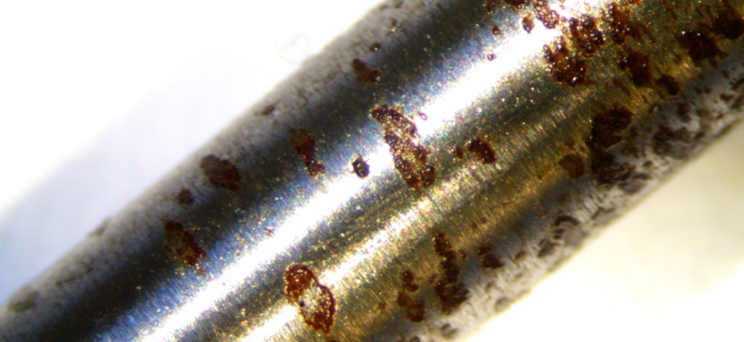

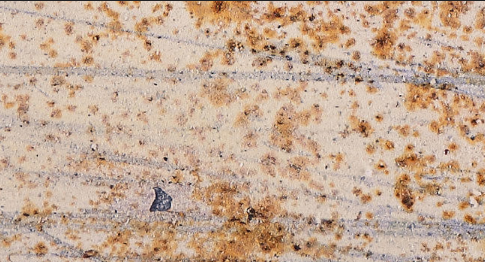

Low alloy steels although better than plain carbon steels in terms of resistance to corrosion are still prone to rust and corrosion in most environments, leading to reduced corrosion resistance . The small quantity of the chromium will offer a partial protection but is not enough in aggressive conditions for adequate corrosion resistance properties . Advisable preventive treatments may include coatings, galvanizing or periodic treatment.

The level of stainless steel corrosion resistance differs with grades. Austenitic alloys such as 304 and 316 are associated with good general corrosion resistance, whereas corrosion resistance to pitting and chloride stress corrosion cracking is improved in e.g. duplex stainless steels.

Heat Treatment and Workability

Low alloy steels have very good heat treatment responses and the manufactures are able to get a broad spectrum of mechanical properties by subjecting the alloys to a vigilantly marked out heating and recuperation. The rate of strength and hardness may be enhanced highly upon quenching and tempering and its rate of ductility and machinability undergo enhancing by the annealing procedure.

One of the most important strengths of low alloy steel is the ability to customize the properties with different heat treatment and this makes them special. By our judicious choice of alloying elements as well as in heat treatment conditions, manufacturers can maximize strength, toughness, and resistance to wear.

The heat treatment of stainless steel is more complicated because such a metal has certain requirements concerning microstructure. Austenitic grades normally need solution annealing to give the best of corrosion behavior and mechanical qualities. Certain grades of steel, not all but mostly martensitic grades and some precipitation-hardening grades can be strengthened by certain heat treatments that consist of controlled heating and controlled cooling.

Manufacturing and Machinability

The high versatility is possible since alloy steels are more machinable. Low alloy steel has an advantage of superior machinability in comparison to stainless steel even though it has a higher cutting speed, tool life and quality of surface finish. This advantage has been translated to cheap manufacturing and better productivity in the machining processes.

Most low alloy steels have moderate levels of hardness which makes them suitable to undergo traditional machining techniques such as turning, milling, drilling and grinding. It cuts clean with well-chosen cutting tools and parameters to fabricate superior dimensional accuracy and surface quality.

Machining stainless steel is where cutting parameters have to be more seriously considered along with choice of tool and coolant. Work hardening tendency especially with austenitic grades requires the use of positive rake angles and constant cutting to avoid work hardening. Nevertheless, owing to recent innovations before the modern techniques of machining and specialized tooling, medical equipment stainless steel machining has become very efficient.

Cost Analysis and Economic Considerations

It is an economical one. Low alloy steel should be much cheaper in terms of material as well as processing costs as compared to stainless steel, especially when considering alloy steel vs . Theoretically it can be manufactured at lower expenses due to the lower alloying level and use of simplified heat treatment which makes it appealing to the cost-restricted application areas.

Cost of materials in the low alloy steel tends to be between 30-50 percent cheaper than similar grades of stainless steel. More savings can be made by less machining time, tool wear, easier heat treating procedures. The low alloy steel is also suitable in high-volume production owing to such considerations.

The increased cost of stainless steel with an elevated initial cost can be compensated with its longer operational service, less maintenance, and better functioning under hostile atmosphere. The ultimate cost of finding may also recommend stainless steel when the resistance to corrosion is essential and there are high maintenance expenses.

Industrial Applications of Low Alloy Steel

Low alloy steel, similar to high carbon steel, is largely used in the automotive sector to manufacture important components like the axles, crankshafts, connecting rods and transmission parts. Its outstanding strength-to-weight ratio and fatigue resistance is the most suitable in dynamic applications where there is repetitive loading.

Low alloy steel finds uses in construction and infrastructure, such as structural components, bridges, heavy equipment, etc. The high mechanical strengths enable them to be designed lighter but still have the same structural strength and safety provisions. Industrial equipment, earth moving equipment and mining equipment often utilise low alloy steel because it is harder wearing.

Applications in the oil and gas industry are to drilling equipment, pressure vessels and pipeline components when high strength and moderate corrosion resistance are needed. Low alloy steel can be used in pressure-containing uses because of its capability to obtain certain levels of strength by use of heat treatment.

Stainless Steel Application Areas

Stainless steel is used in most functions for which corrosion resistance is a primary requirement. The food and beverage industry has been relying on stainless steel as the equipment used in the processing of food processing equipment , in storage tanks and packaging machines. Its non-reactive surface and ease of cleaning properties makes it very necessary in the maintenance of the standards of hygiene, especially in sheet metal fabrication .

Medical and pharmaceuticals apply stainless steel to surgical and processing equipment as well as implants. The specific grades of stainless steel are biocompatible and thus resistant to sterilization, which makes them applicable in direct contact with human tissue and body fluids both alloy steel.

Chemical industries such as chemical processing and chemical reprocessing industries rely on stainless steel to fabricate reactor materials, heat exchangers and stainless steel piping to transport corrosive chemicals heat resistance. The inability of many acids, bases and/or organic compounds to penetrate stainless steel makes this form of steel invaluable in such challenging settings.

Welding and Fabrication Considerations

Welding of low alloy steel demands special care in respect of preheating, interpass temperature, post-weld heat treatment so as to avoid cracking and develop desirable properties. Welding procedures and the choice of the filler metal is based on the carbon equivalent and hardenability that the particular grade has formed steel alloy.

Low alloy steels joinings could retain or even better after proper welding technique. Depending on thickness, or highly restrained joints, post-weld heat treatment may be required to eliminate residual stresses and maximize mechanical properties stainless steel comparison.

Welding of stainless steel is a challenging process which is connected to preservation of the resistance to corrosion and avoiding sensitization. Controls in controlling the level of heat input, the choice of a shielding gas, and filling metals are essential in order to have satisfactory outcome comparing alloy steel. Distortion and residual stress tendencies necessitate improvement in the plans of fixture design and care in sequence of welding replace stainless steel.

Environmental Impact and Sustainability

Low alloy steel and carbon steel display high recyclability, making them to contribute towards the concept of sustainable manufacturing processes alloy steels compared. The recycling of steel needs lesser energy and raw materials than those needed to process steel at the very first stage. The steel recycling system is entrenched all over the world and it is one of the most recycled products other alloying elements stainless steel performs.

The less alloy content in the low alloy steel also makes processing or recycling marginally easier since it is less important to separate the different alloying elements. The simpler composition of the low alloy steel means that overall requirements in energy to recycle the low alloy steel are lower than is required in stainless steel.

The recycling of stainless steel is more complicated because certain ratios of alloying elements must be preserved especially chromium and nickel. This is because the cost of these ferritic stainless steel alloying elements is very high thus making stainless steel scraps desirable to recycling activities conclusion alloy steel.

Selection Criteria for Material Choice

Low alloy steel or stainless steel selection must be made after a thorough analysis of the necessities of application, surrounding conditions as well as economics. Such critical requirements as strength, corrosion resistance, temperature ability, high hardness as well as wear resistance will have to take priority.

The conditions that the environment presents such as moisture, exposure to chemicals, extremes in temperatures and atmospheric conditions affect material selection a lot. External use in the marine environment or during chemical processing applications will usually prefer stainless steel whereas low alloy steel could be used as a structural material within buildings.

Economical factors include preliminary material cost, production cost, maintenance cost, and lifetime of the expectation service. Life cycle cost analysis usually indicates that additional cost of initial investment in stainless steel may be recompensed by long service life and low costs on maintenance.

Future Trends and Developments

The research work in both stainless steel and high alloy steel is still going and developing them with widest possibilities. Automobile and energy applications are using advanced grades of low alloy steels that are more tough and resistant to corrosion. Fine tuning of properties is made possible through microalloying methods and at the same time, cost-effective.

The stainless steel in development is concerned with better performance grades with better corrosion resistance, including martensitic stainless steel, and higher strength grades with specific application needs of new products. Lean duplex stainless steels and advanced grades of high strength help to increase the area of usage and control the costs of the materials.

Additive technologies are providing the breakthrough in both types of materials, with complex geometries and now tailorable properties being achievable where it was once not possible due to traditional manufacturing practices.

Conclusion

Whether to use low alloy steel or stainless steel is just a matter of weighing the amount of performance requirements to be achieved, the environment conditions, and financial limitations. Low alloy steel perform well in the cases when high strength, good machinability and economical efficiency are important, especially when corrosion resistance is not of primary concern. It has an excellent mechanical property and heat treatment response thus making it useful in structural and mechanical applications.

The required costs of the stainless steel are more compared to the initial costs and complex processing processes, but still stainless steel will be the best option to be used in such situations where corrosion resistance is the priority. Stainless steel is also used in food processing, medical and chemical applications because of the unsurpassed protection afforded by the self-passivating chromium oxide layer in harsh environments.