Meta Description: A detailed comparison of 3D printing vs injection molding into the manufacturing process. Find out prices, advantages, usages, and the best way through which your production can be enhanced in 2025.

Such decisions on manufacturing determine the success or failure of a product in the current competitive market. Three major technologies in the manufacturing sector, which include 3D printing and injection molding perform differently in various production cases and thus are unique to the other cnc machining. Knowledge of what differentiates them, what they cost, and how they would be used is the key to companies that want to streamline their manufacturing and improve supply chain performance.

Understanding 3D Printing Technology injection molding machine

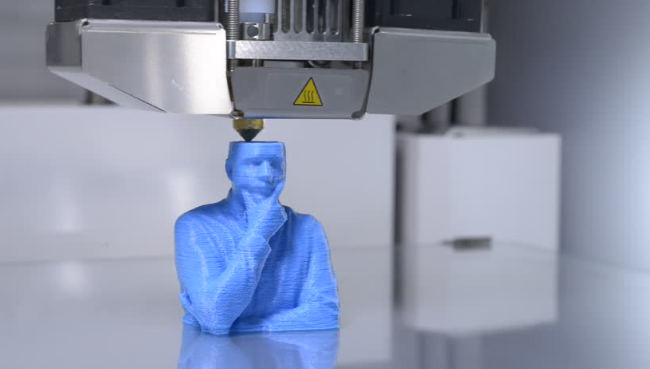

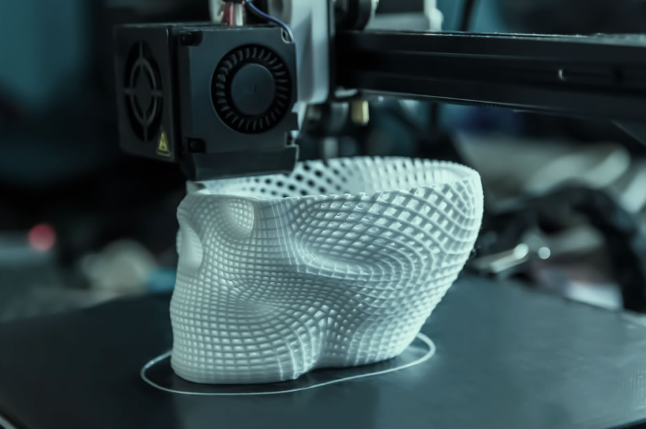

Additive manufacturing (also called 3D printing) is a process of making objects by adding layers of material used on a computer-aided design, especially for complex geometries . The process of this additive printing involves adding material to create an object thus it is essentially the opposite to traditional subtractive processes of manufacturing.

The technology has developed a lot since its introduction and now performs several forms of printing such as Fused Deposition Modeling (FDM), Stereolithography (SLA) and Material Jetting. All these techniques involve employing various materials and techniques but the principle behind them all is the layer-by-layer build-up selective laser sintering.

Contemporary 3D printers have the ability to operate with various material such as plastics, metals, ceramics, and even biological materials. Running the precision systems have a possible layer height of 16-50 microns, which can result into fine and accurate parts production.

Understanding Injection Molding Technology

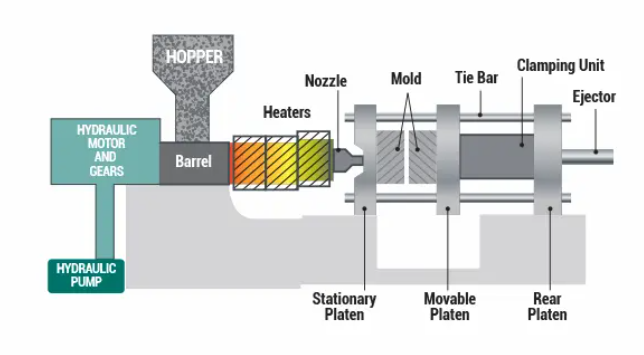

The injection molding is a method of forming the parts using the pressure injection of the melted material into die

mold size. It requires heating thermoplastic substances until molten and then the molten thermoplastic material is forced into the neatly machined molds using high pressure.

Mass production using this technology is decades old and is mostly used in automotive, consumer goods and the packaging companies artificial heart valves. In standard injection molding process, large up-front expenditure is necessary in tooling since it costs between 10,000 to 100,000 dollars to make the mold viable option.

The process can be used to perform very well when it comes to manufacturing equally equivalent parts with close tolerances and high intensity. When the mould is manufactured and the conditions of the process are set up, injection molding can be used to create thousands or millions of exactly the same part with amazing consistency and quality.

Cost Analysis: Initial Investment vs Production Volume

The cost models of 3D printing and injection molding differ tremendously depending on the volume and complexity of the product being manufactured. The cost of entry in 3D printing is minimal example, whereby desktop 3D printers and materials consumption cost are lower in cost than injection molding machines.

With low-volume manufacturing (less than 100 parts), 3D printing has more economics when possible, especially for custom items frequent changes . There are no tooling costs, so that when the digital file is available, production can immediately be started. The price of materials used to conduct 3D printing stands at around 90-170 dollars in a kilogram, varying according to technology and material type two halves.

At volume levels, injection molding is less costly because of high rate of production after achieving tooling. Large scale production of thousands or even millions of components may be produced in a typical run sharing the cost of the initial tooling among the numerous parts.

The break-even in most parts ranges between 500-1000 parts, depending upon material and complexity of the parts. Above this limit the cost per part advantage of injection molding increases.

Speed and Lead Time Considerations

Speed of production is also substantially different among these technologies based on the volume and project phase. 3D printing has great turnaround times of 1-2 weeks hence a perfect use-case in rapid prototyping and changeable designs, but it can struggle with tight tolerances simple parts .

To prepare the production of parts, long turnaround times are needed in the case of injection molding (5-7 weeks of complex part). But after the production starts, injection molding is capable of producing parts in hundreds or thousands of parts in an hour.

3D printing has a very short set up time it can often be as simple as it take to prepare and have the printer ready to print. This is why it makes it great in emergency prototypes or small runs where getting a product in the market fast is significant.

Both set up and part production times have to be taken into account in production planning. The 3D printing has an advantage of ensuring an abridged project initiation project, but an injection molding is better when it comes to throughput of bulky products.

Design Flexibility and Complexity

3D printing is ideal to print of complex or intricate designs with elaborate infrastructures, since through it the parts are formed layer by layer. Internal geometries, undercuts, and complicated assemblies, which would not have been possible using the traditional processes, are enabled by the additive characteristic.

3D printing has the advantage of design freedom which allows quick iterations and experimentations, particularly in the creation of dental products . The design is allowed to be changed even during production thereby saving both time and materials on a batch of worked parts which might have a defect.

There are design limitations in injection molding because of the required mould removal, especially when using metal molds . The parts have to accommodate draft angles, require no undercuts, and hardly need wall thickness to be very uneven. But these restrictions can usually result in designs that are optimal towards manufacture or assembly.

Complex gThe intricate geometries of injection molding necessitate multi cavity molds or secondary processes, making tooling more expensive and complicated. Injection molding is most capable of simple, well designed parts.

Material Properties and Performance

A significant change in performance characteristics of the final product can arise due to selection of material. Posts injection molded components incorporate only one layer of poured component, which prevents fissures or any other weak points. It produces isotropic characteristics i.e. strength that is the same in all directions.

Layers of 3D printed parts tend to be anisotropic in their behaviours. The most pronounced direction is usually along the plane of the layer and inter-layer bonding could be less pronounced. This demands due consideration of directions of loads in design.

Both technologies are still growing in the range of materials. Basically all thermoplastics can be used in injection molding and current 3D printing technologies offer printing in engineering plastics, metals, ceramics and composite materials.

The requirements after the processing vary greatly. Injection molded-parts usually do not need finishes or other cleaning processes whereas 3D printed parts might need support removal or smoothing processes to meet the application needs.

Quality Control and Repeatability

One of the advantages of injection molding is reliability in producing similar parts in high volume, and good tolerances. Most parts of a production run are produced in a controlled environment and regulated parameter process settings that cause minimal variation in parts.

Injection molding quality control is concerned with maintenance of mold, stability of material and observation of process parameters. When in place, the procedure can operate with minimum input and at the same time quality standards are kept.

Quality in 3D printing is subject to as many factors as are present in end user printing activity, the printer supervision, the material quality, climate, put up work processes. It may be necessary to spot check each printed piece, especially where safety is a factor.

But what 3D printing does have is the capability to print one part at a time, so an individual could customise a particular part, or a design could be changed, and that would not affect the rest of the manufacturing line.

Volume Production Capabilities

A significant number of mold inserts can be used simultaneously during injection molding and, therefore, injection molding is more economical when producing many objects. Multi-cavity molds can run part-counts of dozens in a single cycle, and in the seconds.

The number of molds and availability of machines is considered the main limitation to production capacity of injection molding. Under adequate planning, throughput rates in continuous productions runs can be very high.

Printer accessibility and the duration of printing are the restrictions to the printing of 3D production. Although printer farms can scale up the capacity, the layer-by-layer process is intrinsically slow when compared to injection molding when it comes to volume production.

Advances in 3D printing technology e.g. higher printing rates, and multi-material printing, are further increasing the feasible production volume segments of additive manufacturing.

Surface Finish and Post-Processing

Regardless of the level of deposition detail, the layers are additively constructed and that is why the finish of 3D printed parts is rough. Critical surfaces may need post-processing, by sanding, chemical smoothing, or machining.

The injection molded parts often produce the excellent surface finish at the mold face, which is influenced by temperature . The surface finish is a dependent factor to the finish of the mold surface and may be highly polishable or textured with many surfaces depending on the requirement.

Injection molding Injection molded parts typically require only post-processing (running and gate removal) during post-processing, followed by little additional finishing. This helps to make the process as a whole efficient and cost-effective.

The high-end 3D printing facilities such as SLA and Material Jetting have the ability of producing very smooth 3D printing surface, though post-processing would be required in order to do so.

Environmental Impact and Sustainability

The process of injection molding implies pouring the material into the mold, and the number of materials used is precisely the amount needed to complete the design, and thus, the supply of materials is minimal. It is environmentally preferable since it is self-efficient in terms of volume production.

The printing process consumes material optimised to the part design and geometry, so 3D printing can create wastes of support structures and failed prints. The on-demand printing capacity saves on waste of inventory and transport.

As a way of pushing towards more sustainable technologies, the two share similarities in recyclable materials, low energy demand, and efficiency of the processes. The options of the two need to take into account the entire environmental impact of the lifecycle.

The 3D printing can enable the production locally and decrease the transportation-related emissions, whereas the efficiency of injection molding can be more useful for the design of the products with long lifecycle and in large quantities.

Industry Applications and Use Cases

The small batch production, which include prototyping, complicated designs with a hole in the middle, and design modifications during production fit into 3D printing. Industries such as Aerospace, medical appliances, automobile prototyping are intensive users of 3D printing.

Injection molding is well adapted in large batch producing since you are able to make several identical items at once, robust solid designs through the use of a singular seamless shape, and flat endings to moving objects on different objects.

An illustration of such complementary use of the two types of technologies is the medical industry. On the one hand, through 3D printing, customisable prosthetics and surgical guides can be made, whereas injection molding can be used to manufacture standardised medical devices and components.

Consumer electronics, cars, and packaging industries base their volume production on injection molding and low-volume specialized part production on 3D printing.

Future Trends and Technology Integration

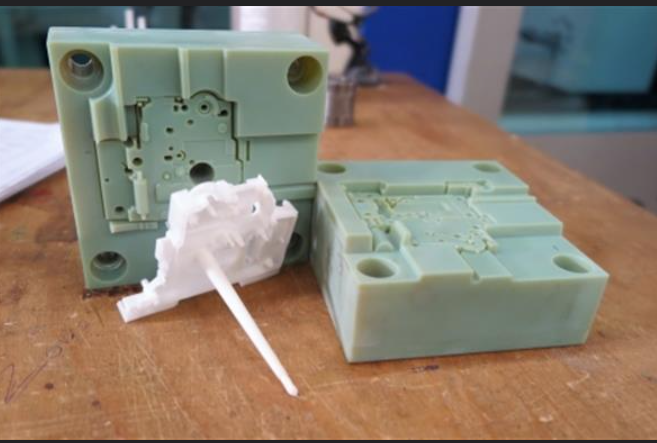

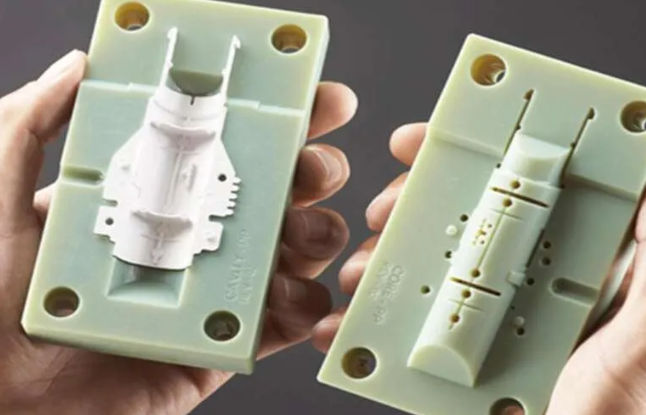

It is seen in the manufacturing industry where these technologies are no longer seen as a competing technology but as a complementary one. 3D printed injection molds have now become possible that fill the gap between prototype and production injection molding project.

Hybrid manufacturing methods mix the design tolerance of 3D printing with the efficiency of injection moulding, enhancing the cost effectiveness of production mold halves. With the level of integrations, production strategies can be optimized according to volumetric demands and different points of product lifecycle relatively small plastic parts.

Increased sophistication of materials and faster printing speeds are still widening the range of viable applications of 3D printing, and injection molding is taking advantage of more advanced mold technology and the capacity to automate the process cost effective.

Both technologies are being more and more incorporated into digital manufacturing platforms, where the manufacturer can choose the most appropriate process in the light of the current set of requirements and the cost-efficiency.

Conclusion

The decision between 3D printing and injection molding will depend on various conditions such as the quantity of products to be produced, the complexity of the design, the time constraint, and the budget. 3D printing will be used where quick prototyping, manufacturing of a small quantity, as well as complicated shapes are involved, whereas injection molding is used when a large quantity of a design is to be made and the speed is combined with low costs. The combination of both technologies is becoming a strategic point in modern production lines where manufacturers can use them in a complementary course to make their lines more efficient and efficient in their supply chains.